Clarus 6000 Series User manual

© Copyright 2019. All rights reserved.

SECTION: C4.00.121

CL0162

0319

Supersedes

0515

6000 Series Automatic Multizone Valve

OWNER'S MANUAL

Congratulations on the purchase of the Clarus Environmental

6000 Series Automatic Multizone Valve. High quality workmanship and

easy maintenance design has been incorporated into this line of onsite

wastewater products. This Clarus Environmental product will provide

yearsoftrouble-freeservicewheninstalledaccordingtothemanufacturers

recommendations.

This manual incorporates the installation, operation, maintenance,

and service instructions into one document to aid the owner of a Clarus

Environmental onsite wastewater product. Please read and review this

manual before installing the product. The instructions contained herein,

when followed correctly, will not only ensure a long and problem-free life

for the system, but will also save time and money during installation. Should

further assistance be necessary please call 1-800-928-7867.

Owner’s Information

Part Number: ______________ Date Code: _________

Job Name: ___________________________________

Dealer: ______________________________________

Date of Purchase:______________________________

Contractor: __________________________________

Date of Installation:

______________________________

System Readings During Operation:

Voltage __________ Amps _________

Safety Instructions............................................................................. 1

Limited Warranty ................................................................................ 2

Major Components.............................................................................. 2

Cam Replacement Instructions............................................................ 2

Valve Installation Instructions ............................................................ 2

Technical Specications ..................................................................... 3

Parts List............................................................................................ 3

Troubleshooting and Service Checklist ............................................... 4

Table of Contents Safety Instructions

CAUTION

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR MAJOR

PROPERTY DAMAGE, READ AND FOLLOW ALL SAFETY

INSTRUCTIONS IN MANUAL AND ON VALVE.

THISMANUALISINTENDEDTOASSISTINTHEINSTALLATION AND

OPERATION OF THIS UNIT AND MUST BE KEPT WITH THE VALVE.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the valve or in the manual,

look for one of the following signal words and be alert

to the potential for personal injury or property damage.

Warns of hazards that WILL cause serious personal

injury, death or major property damage.

WarnsofhazardsthatCANcauseserious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or

property damage.

Indicates special instructions which are very

important and must be followed.

THOROUGHLYREVIEWALLINSTRUCTIONSANDWARNINGS PRIOR

TO PERFORMING ANY WORK ON THIS VALVE.

MAINTAIN ALL SAFETY DECALS.

®

MAIL TO: P.O. BOX 16347 • Louisville, KY 40256-0347

SHIP TO: 3649 Cane Run Road • Louisville, KY 40211-1961

(502) 778-2731 • 1 (800) 928-PUMP • FAX (502) 774-3624

Visit our web site:

clarusenvironmental.com

Product information presented

here reects conditions at time

of publication. Consult factory

regarding discrepancies or

inconsistencies.

Register your

Clarus Environmental Product

on our website:

http://reg.clarusenvironmental.com/

2

© Copyright 2019. All rights reserved.

Limited Warranty

Manufacturer warrants, to the purchaser and subsequent owner during the

warranty period, every new product to be free from defects in material and

workmanship under normal use and service, when properly used and maintained,

for a period of one year from date of purchase by the end user, or 18 months

from date of original manufacture of the product, whichever comes rst. Parts

that fail within the warranty period, one year from date of purchase by the

end user, or 18 months from the date of original manufacture of the product,

whichever comes rst, that inspections determine to be defective in material or

workmanship, will be repaired, replaced or remanufactured at manufacturer's

option, provided however, that by so doing we will not be obligated to replace an

entire assembly, the entire mechanism or the complete unit. No allowance will

be made for shipping charges, damages, labor or other charges that may occur

due to product failure, repair or replacement.

This warranty does not apply to and there shall be no warranty for any material

or product that has been disassembled without prior approval of manufacturer,

subjectedtomisuse,misapplication,neglect,alteration,accidentor act ofGod;that

has not been installed, operated or maintained in accordance with manufacturer's

installation instructions; that has been exposed to outside substances including

but not limited to the following: sand, gravel, cement, mud, tar, hydrocarbons,

hydrocarbonderivatives (oil, gasoline, solvents, etc.), orotherabrasiveor corrosive

substances, wash towels or feminine sanitary products, etc. in all applications

other than in raw efuent pumping applications. The warranty set out in the

paragraph above is in lieu of all other warranties expressed or implied; and we

do not authorize any representative or other person to assume for us any other

liability in connection with our products.

Contact manufacturer at, 3649 Cane Run Road, Louisville, Kentucky 40211,

Attention: Customer Service Department to obtain any needed repair or

replacement of part(s) or additional information pertaining to our warranty.

MANUFACTURER EXPRESSLY DISCLAIMS LIABILITY FOR SPECIAL,

CONSEQUENTIALOR INCIDENTALDAMAGESORBREACHOFEXPRESSED

OR IMPLIED WARRANTY; AND ANY IMPLIED WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE AND OF MERCHANTABILITY SHALL BE

LIMITED TO THE DURATION OF THE EXPRESSED WARRANTY.

Some states do not allow limitations on the duration of an implied warranty, so

the above limitation may not apply to you. Some states do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

Major Components

1. Valve Top: A high strength metal die cast top which is secured to the valve body by eight stainless

steel screws.

2. Valve Body: A high strength metal die cast housing.

3. Inlet: Female 1 ½" NPT inlet for connection to water source.

4. Vacuum Breaker Port: Used to prevent back-siphon of water to course.

5. Valve Bottom: High strength ABS plastic bottom which is secured to a valve body with 6 stainless

steel screws.

6. Outlets - Allows for slip and glue connection to 1 ½" PVC pipe.

Cam Replacement Instructions

Replacement cams are available to increase or decrease the number of outlets to be used on the 6000 Series Automatic Multizone Valve. 6400 Series four outlet

valves have interchangeable cams for two, three or four zone operation. 6600 Series six outlet valves have interchangeable cams for ve or six zone operation.

To replace cam, rst remove valve top by removing eight valve top retaining screws. Remove two cam retaining screws which hold cam on the underside of the valve

top.

Insert replacement cam into valve top, ensuring that the wide notch on came is aligned with notch on valve top, and secure with two cam retaining screws.

Replace top, ensuring body seal is in place.

Valve Installation Instructions

Prior to installation of 6000 Series Automatic Multizone Valve, make sure that the system is designed using adequate pipe sizes and control valves to ensure maximum

performance of the valve.

For installation with large terrain elevations, or applications with high lift requirements such as overhead systems in greenhouses, the valve should be installed at the

highest point in the system, or check-valves should be installed near the valve in the elevated lines to prevent the back ow of water from the higher locations to the

lower zones.

When connecting the lines to the valve outlets, ensure that the correct cam is installed. See diagram for proper zone hookup of outlets.

Do NOT turn the valve upside down when gluing the lines into the open valve outlets. Glue may run down into the valve and interfere with valve operation. Allow glue

to dry for at least two hours before operating or testing the valve. For best results, use a multipurpose glue which is compatible with ABS plastic.

To seal off any unused outlets, install a piece of PVC pipe at least six inches in length to the outlet and cap the pipe. This will allow additional zones to be added eas-

ily at a later time. Make sure proper cam is installed for number of zones to be used.

3

© Copyright 2019. All rights reserved.

Pump Fed Application

For direct pump-fed installations, the 6000 Series Automatic Multizone Valve is directly connected to the discharge side of the pump and is cycled from one zone to

the next by turning the pump off and on. See the Active Zone Diagram below in Figure 1.

Technical Specifications

Valve Top and Body Construction: Die cast

Valve Bottom Construction: ABS High strength plastic

Flow Range: 15-100 GPM

Inlet: Threaded 1½" NPT

Outlets: Allows for 1½" PVC pipe slip and glue connection

6400 Series 4 Outlet Valve

Flow (GPM) 15 20 30 40 50 60 70 80 90 100

PSI Loss 2.0 2.5 3.0 3.5 4.0 5.0 6.0 7.5 9.0 10.0

Flow Characteristics:

6600 Series 6 Outlet Valve

Flow (GPM) 15 20 30 40 50 60 70 80 90 100

PSI Loss 2.0 3.0 3.5 4.0 5.0 6.0 7.5 9.0 10.0 11.0

Parts List

Parts List

REF NO. DESCRIPTION PART NO.

14 Outlet valve top 153295

6 Outlet valve top 153296

2 Valve body seal 150495

3Rubber ap disc 153268

4Stem with .032 spring 153269

Stem with .028 spring 153270

5Stem / disk assy. w/ .032 spring 019141

Stem / disk assy. w/ .028 spring 019142

64 Outlet valve bottom 153271

6 Outlet valve bottom 153272

7 Vacuum Breaker assy. 151258

8

Two zone, 4 outlet cam 019136

Three zone, 4 outlet cam 019137

Four zone, 4 outlet cam 019138

Five zone, 6 outlet cam 019139

Six zone, 6 outlet cam 019140

9Valve bottom screws (6) (10-24 x

3/4 Phil Pan SS 153273

10 Valve top screws (8) (10-24 x 5/8

Stlt.phst SS 153274

11 Cam retaining screws (2) (6 x 1/2

Phil Pan SS) 153275

12 Valve bottom S.S Pin (¼" dia.) 153073

Figure 1

4

© Copyright 2019. All rights reserved.

All Clarus Environmental products must be installed and maintained in accordance with all applicable codes.

Product information presented here reects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies.

Troubleshooting and Service Checklist

Problem Cause Solution

Valve does not change

or cycle to next zone

or outlet.

Debris or foreign objects prevent-

ing proper movement of stem and

disk assembly.

• Remove valve top and check for foreign

objects. Clean build-up from walls as

necessary.

• Check for freedom of movement of stem and

disk assembly up and down over the center

pin in bottom of valve. Scale deposits may

build up on the pin and hold stem and disk

assembly down. Clean pin and again check for

freedom of movement.

Disk may have expanded and is

rubbing against inside walls of

body.

• Replace disk and clean build-up from walls of

valve as necessary.

Restriction of flow causing pres-

sure in valve to build up, prevent-

ing valve from cycling.

• Be sure that all operating outlets are not

capped and that the flow to operating zones is

not restricted in any manner.

• The backflow of water from uphill lines may

be preventing the valve from cycling properly.

If the valve cannot be placed close to the high

point of the system, a check valve should be

installed near the valve in the outlet line that

runs uphill from the valve.

Water comes out of all

the valve outlets.

Stem and disk assembly not seat-

ing properly on valve outlet.

• Check for sufficient water flow. A minimum of

15 GPM is required to properly seat the disk.

• Remove the valve top and clean the inside

walls as necessary to ensure that nothing is

interfering with the up and down movement of

the stem and disk assembly inside the valve.

• Make sure that the operating outlets are no

capped and that the flow to the operating

zones is not restricted in any manner.

• Replace disk if necessary.

Valve skips outlets or

zones.

This will case the valve to cycle

quickly several times, skipping one

or more zones.

• The stem and disk assembly is being advanced

past the desired outlet.

• Ensure that the correct cam for the desired

number of zones is installed and that the out-

let lines are installed to the correct outlet ports

of the valve.

3649 Cane Run Rd. • Louisville, KY 40211-1961 • (502) 778-2731 • FAX: (502) 774-3624

clarusenvironmental.com

Trusted. Tested. Tough.®

This manual suits for next models

2

Popular Control Unit manuals by other brands

Texas Instruments

Texas Instruments TPA6120A2RGY EVM user guide

Conbraco Industries

Conbraco Industries APOLLOPRESS Installation, operation, maintenance guide

MikroTik

MikroTik GPEN21 manual

Ewert Energy Systems

Ewert Energy Systems Orion Jr. 2 BMS Wiring & installation manual

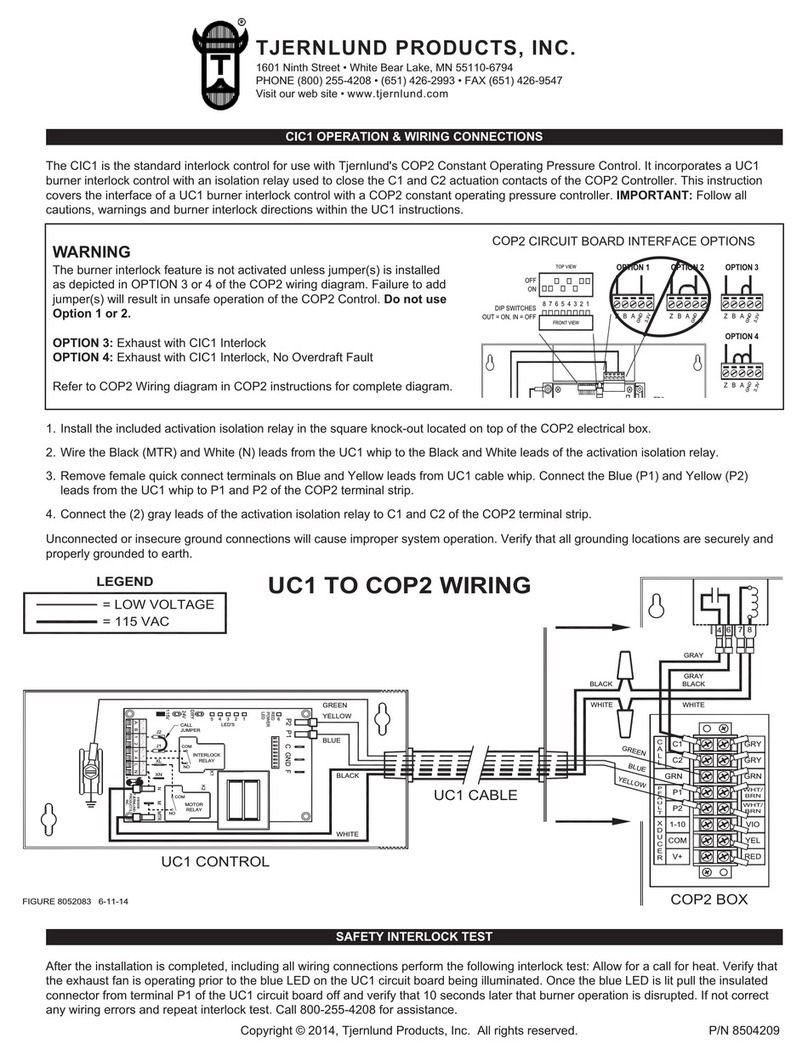

TJERNLUND

TJERNLUND CIC1 Operation manual

Delabie

Delabie TEMPOMATIC 4 quick start guide