Claymarc A-lign Fencing User manual

A-lign Fencing

12 easy steps

Classic. Elegant. Simple.

All components are manufactured

from clear exterior treated finger-

jointed radiata pine and are machine

primed and undercoated with a two-

coat oil based coating system.

After assembly finish the paint

system with a minimum of two

premium exterior acrylic top coats

with LRV 45+. Alternatively paint

each component form separately

before the fence is erected. This

eliminates cutting in if two or more

finished colours are used. (See

claymark.co.nz for further detail on

painting)

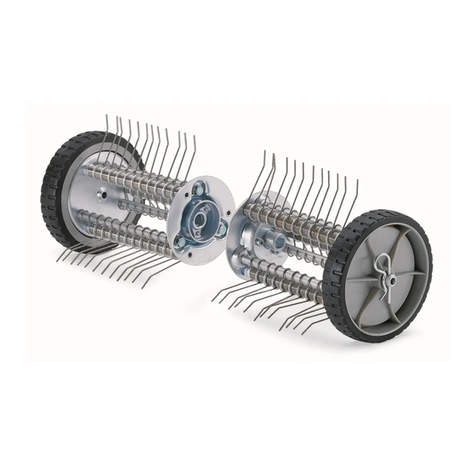

Components (overview)

Bottom Rail

Bottom Rail Infill Bead

or

200mm or 150mm Scribers

112mm or 132mm Posts Metal Angle Bracket

Top Rail

154mm or 179mm Post Cap

200mm Profiled Fence Boards

150mm Profiled Fence Boards

200mm or 150mm

Centre Scriber

Notes:

All fence components available in

5.4m lengths on request.

All cut ends should be primed

and sealed.

36x18mm H3 treated scribers in

1560mm lengths for 200mm profiled

fence boards or 1570mm lengths for

150mm profiled fence boards.

112x112mm or 132x132mm

H4 treated laminated posts in

2.7m lengths.

40x40x40x3mm galvanized

metal angle bracket.

88x42mm H4 treated grooved

bottom rail in 2.7m lengths.

18x6mm H4 treated infill locator

bead in 2.7m lengths.

42x36mm centre scribers in 1560mm lengths

for 200mm profiled fence boards or 1570mm

lengths for 150mm profiled fence boards.

Ex. 150mm wide (110mm cover) H3 treated

profiled fence boards in 2.7m lengths.

Ex. 200mm wide (155mm cover) H3 treated

profiled fence boards in 2.7m lengths.

154x154mm or 179x179mm bevelled post cap

for 112mm or 132mm post.

88x42 H4 treated grooved

top rail in 2.7m lengths.

Other components:

A. 10 gauge 40mm stainless raised head screws

(allow 50 per fence segment)

B. 8 gauge 75mm counter sink screws

(allow 10 per fence segment)

C. Timber adhesive

D. Premium exterior acrylic paint and brush

E. Square, measuring tape and pencil

F. 20mm panel pins

G. Metal angle brackets (two per fence segment)

H. Stringline

I. Woodfiller and trowel

J. Jenkin end seal primer (used for all cut ends)

K. Sandpaper and block

Tools:

L. Post hole borer (300mm diameter) Optional

M. Handsaw or circular saw

N. Drill

O. Drill bits (3&4mm diameter), screwdriver bit

P. Digging equipment

Q. Hammer or Nail gun

R. Spirit level or laser level

S. Easy set concrete

T. A cold beer to appreciate your new fence

Along with the components

shown in the diagram above

you will need the following:

What you will need

K

G

H

I

A

B

C

L

M

N

O

P

Q

R

S

T

J

F

D

E

Plan: the fencing project on

graph paper before proceeding.

Check that the fence lines are

correctly positioned in relation to

the boundary and/or survey pegs.

Ensure the fence and fence height

conform to local council bylaws and

subdivision covenants.

Before digging post holes:

Locate underground services such

as power, gas, telephone, water and

drainage to ensure a safe separation

distance from excavated holes.

Planning sketch and dimensions

1

Setout: Peg out, excavate and

concrete-in a post at either end of

the fence line. Ensure posts are

accurately positioned and plumb as

these determine the accuracy of

the fence line.

Intermediate Posts: Measure and

install intermediate posts up to the

maximum centre span of 2.7m.

Horizontal and vertical alignment

can be achieved by a laser or string

line and level or plumb bob. Posts

should be plumb and secure

before proceeding. Post should

be plumb and secure before

proceeding.

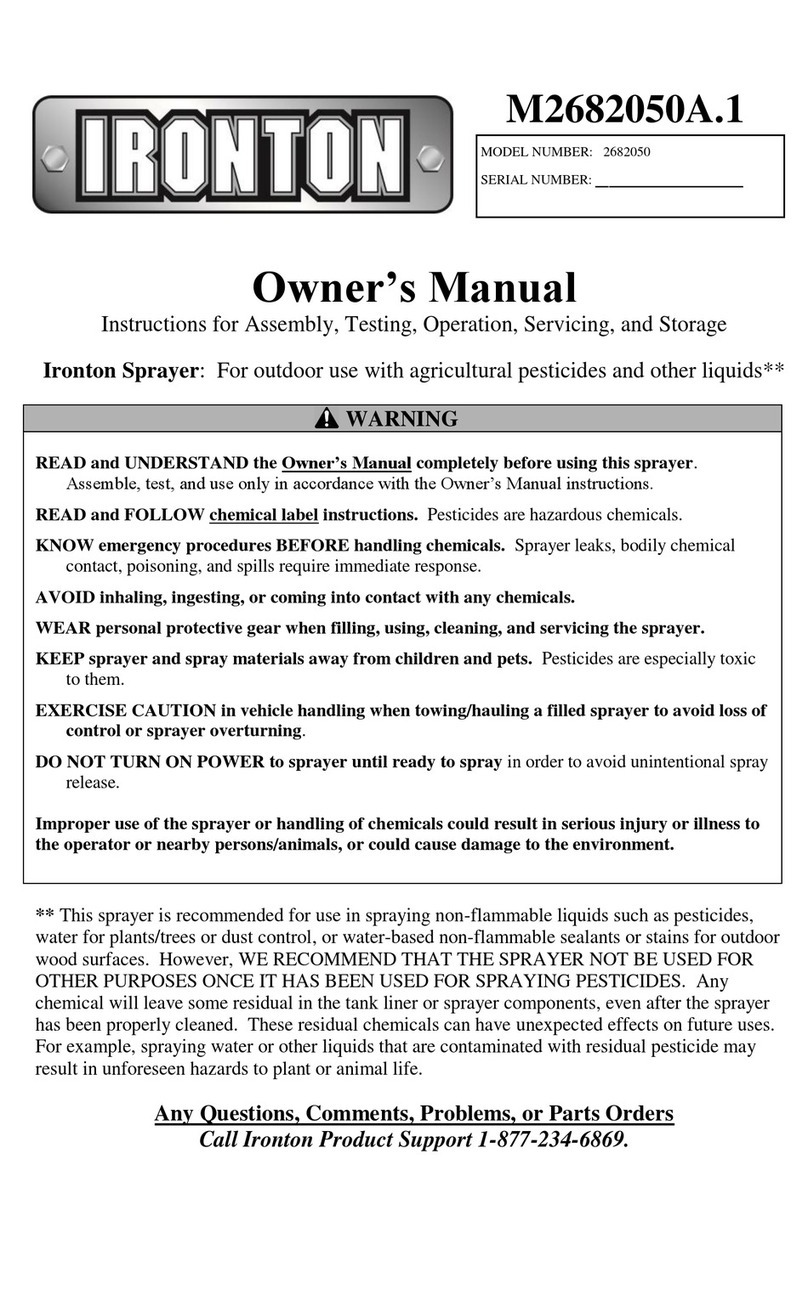

Installing the Posts

2

112x112mm or 132x132mm

H4 laminated posts

Note: For recommended post depths,

relating to area wind speed, refer to

‘foundation detail’ in the table below.

Post depth

600 - 800mm

Post depth

700mm - 1m

1.8m

0.9m

1.2m

1.5m

300

300

Setout: Peg out, excavate and

concrete-in a post at either end of

the fence line. Ensure posts are

accurately positioned and plumb as

these determine the accuracy of

the fence line.

Intermediate Posts: Measure and

install intermediate posts up to the

maximum centre span of 2.7m.

Horizontal and vertical alignment

can be achieved by a laser or string

line and level or plumb bob. Posts

should be plumb and secure

before proceeding.

Post should be plumb and secure

before proceeding.

Installing the Posts

2

112x112mm or 132x132mm

H4 laminated posts

Note: For recommended post depths,

relating to area wind speed, refer to

‘foundation detail’ in the table below.

Post depth

600 - 800mm

Post depth

700mm - 1m

1.8m

0.9m

1.2m

1.5m

300

300

Post size

mm

Maximum

Post Centres Windzone

For Fence heights

0. 9-1 .2 m 1.5 m 1.8m

Embeded depth for fence posts

High 600mm 700mm -------

112 x 11 2 2.7m Extra high 700mm 800mm -------

Brisbane 800mm 800mm -------

High ------- ------- 700mm

112 x 11 2 1.8m Extra high ------- ------- 800mm

Brisbane ------- ------- 800mm

High ------- ------- 800mm

132x132 2.7m Extra high ------- ------- 900mm

Brisbane ------- ------- 1000mm

Post size

mm

Maximum

Post

Centres

Windzone

For Fence heights

0.9-1.2m 1.5m 1.8m

Embeded depth for fence posts

High 600mm 700mm -------

112 x112 2.7m Extra high 700mm 800mm -------

Brisbane 800mm 800mm -------

High ------- ------- 700mm

112 x112 1.8m Extra high ------- ------- 800mm

Brisbane ------- ------- 800mm

High ------- ------- 800mm

132x132 2.7m Extra high ------- ------- 900mm

Brisbane ------- ------- 1000mm

Trim the 88x42mm bottom rail

to the required length and fix

the metal angle bracket to the

underside of the rail with 10

gauge (40mm) screws.

Level and fix the bottom rail on

the centre line of the posts by

screw-fixing through the metal

angle bracket into the post.

Use a spirit or laser level to

ensure bottom rail is fixed level

between posts.

Fitting the Bottom Rail & Bracket

3

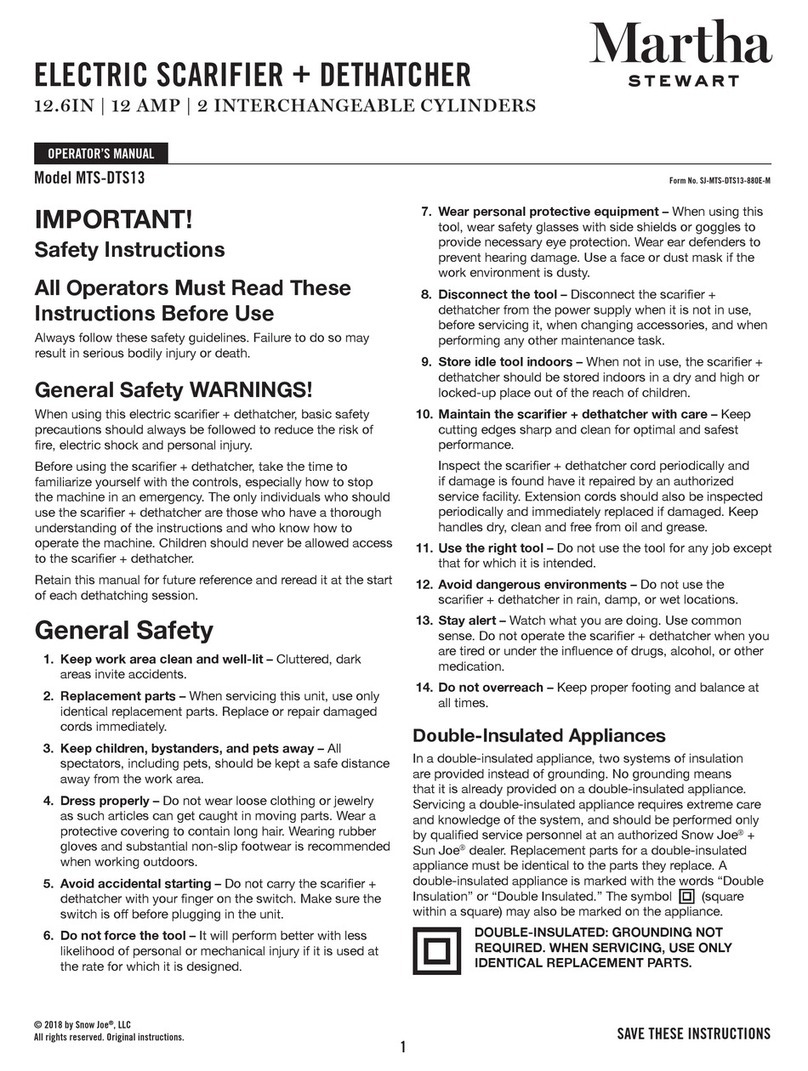

Where the ground is sloping,

maintain the alignment of the

profiled boards by creating

steps at each panel by one full

board cover width — (110mm)

for 150mm profiled fence

board and (155mm) for 200mm

profiled fence board (fence

board/s).

If the ground slope is severe

it may be necessary to install

a short stub post midway

between posts to split the

levels of the bottom rail.

Dealing with a sloping ground

Cover

width

4

Trim the bottom rail infill bead to

the length of the bottom rail. Fit the

bottom rail infill bead into the centre

groove of the bottom rail (tapered

side up). Avoid excessive bending of

the infill bead to avoid breakage.

Fitting the Bottom Rail Infill Bead

5

Trim the first fence board to fit.

Install only the first fence board

over the infill bead and bottom rail.

This step assists in setting the

scribers in the correct position.

Installing the first Profile Fence Board

6

Measure, trim and locate one set of

36x18mm scribers to the front side

of the fence. Fix scriber to the post

with 10 gauge (40mm) stainless

steel raised head screws at the

top and bottom, and as required

between.

Trim the top of the scribers

5mm below the last step

to allow the top rail recess

to engage and sit flat on the

scriber.

Setting the front Scribers

5mm

gap

7

Trim and stack three more fence

boards to the required height by

fitting into the 36x18mm scriber.

From the rear side, lightly pin

through the top of the fence

board to the scriber. Once set

nail/punch pins flush with the

profiled fence board.

Installing three more Profiled Fence Boards

8

Trim the 42x36mm centre scriber to

match 18mm side scribers already

installed. Install centre scriber on

front side after the fourth fence

board is in place.

Fix centre scriber into every second

rail with 10 gauge (40mm) stainless

steel raised head screws. Install the

remaining fence boards and lightly

pin through the centre of each

board.

Do not secure the centre

scriber to the bottom rail

until step 11.

Setting the front Centre Scribers

9

Trim and locate the rear set of

18mm side scribers to the reverse

side of the fence and secure to

the post as per step 7. Apply hand

pressure to the scriber so it seals

firmly against the fence boards.

Once all scribers are in place,

holding pins (from steps 8 & 9) can

either be removed or nailed off and

punched.

Setting the rear Scribers

10

Trim and install the 42x36mm

centre scriber on the rear side.

Screw fix into every second

fence board.

Fix centre scriber to bottom

rail using 8 gauge (75mm)

countersunk screws. Drill at 45˚

and screw fix centre scriber into

the bottom rail. Seal and fill any

remaining holes as required.

Setting the rear Centre Scribers

11

Trim the top rail and engage the

recess with the top

fence board.

Drill & countersink 45˚ holes

for a clean finish. Screw fix

the top rail at 45˚ into the post

using a pair of 8 gauge (75mm)

countersunk screws at each

end. Fill hole, sand and seal for

a cleaner finish.

If required trim the post to the

desired height.

Apply adhesive to top of post,

then install post cap.

Installing the Top Rail and Post Caps

12

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

FCMP OUTDOOR

FCMP OUTDOOR RM4000 instructions

Texas

Texas Power Cart 120 user manual

Simplicity

Simplicity 4552 Illustrated parts list

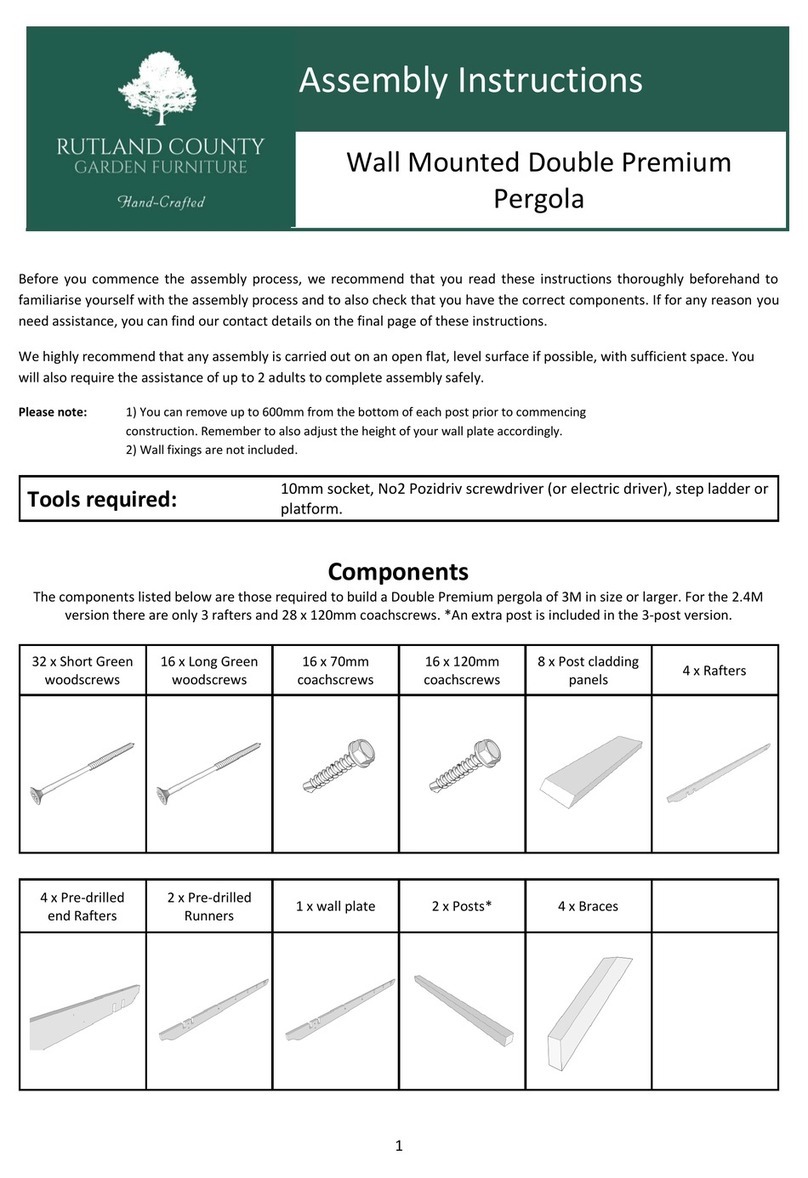

Rutland County Garden Furniture

Rutland County Garden Furniture Wall Mounted Double Premium Pergola Assembly instructions

Baroness

Baroness TDA1200 Owner's operating manual

Trac Vac

Trac Vac CV385-PRO Operating and assembly manual