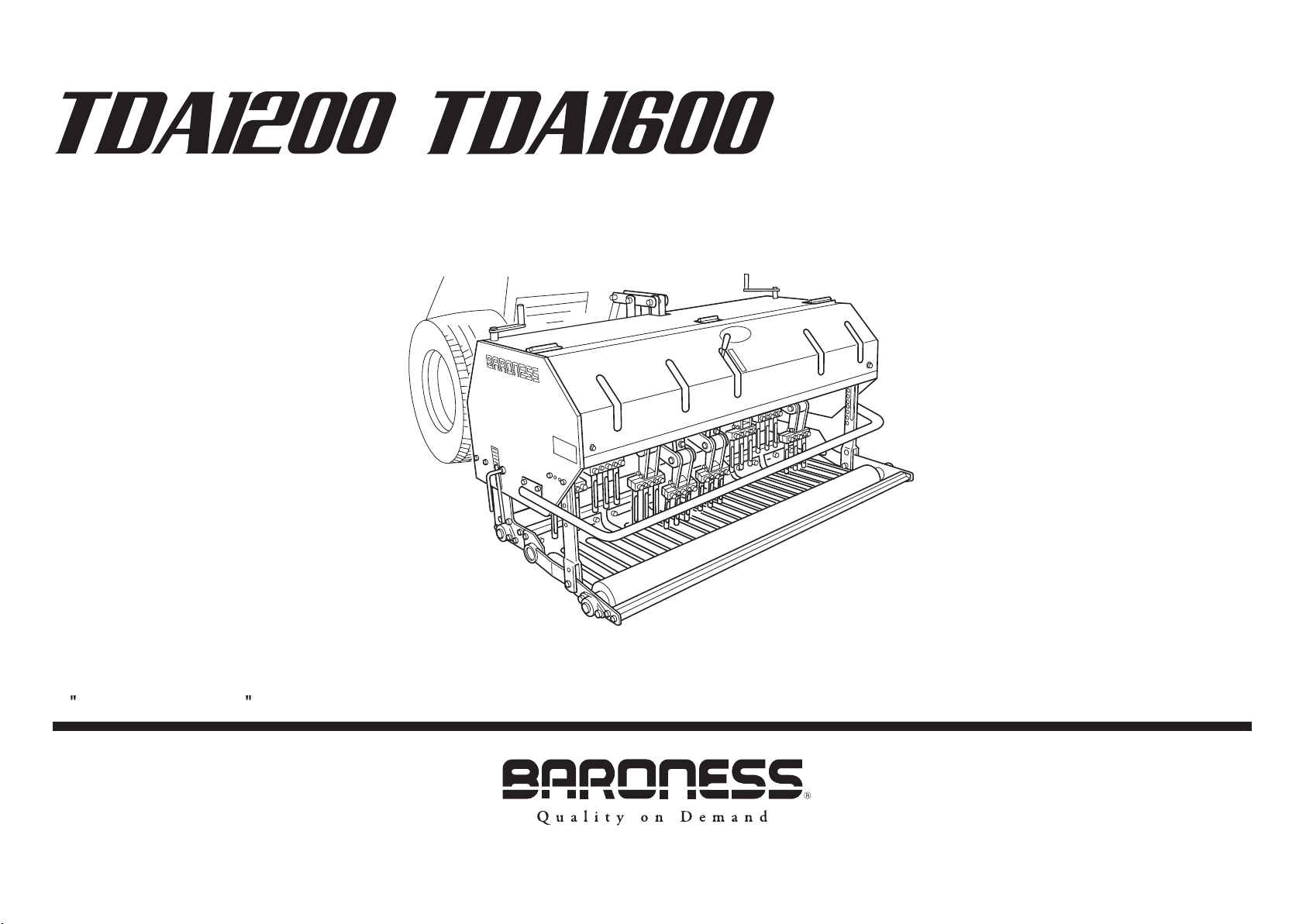

Baroness TDA1200 Operation manual

・

Serial No. TDA1200: 21038-・ TDA1600: 21026- Original lnstructions Ver. 2.1

Read this manual and the owner's manual for the engine before using the machine.Required reading

Tractor Mounted AeratorTractor Mounted Aerator

Owner's Operating Manual

Greeting.................................................................................................................................. 3

Introduction............................................................................................................................. 3

Warning Symbols............................................................................................................... 3

Precautionary Statement ................................................................................................... 4

Purpose.............................................................................................................................. 4

Safety ..................................................................................................................................... 4

Safe Operating Practices ................................................................................................... 5

Training.......................................................................................................................... 5

Preparation.................................................................................................................... 5

Operation....................................................................................................................... 5

Maintenance and Storage ............................................................................................. 6

Towing ........................................................................................................................... 6

Disposal.................................................................................................................................. 6

Recycle and Waste Disposal ............................................................................................. 6

About Recycle ............................................................................................................... 6

About The Waste Disposal ............................................................................................ 6

Product Overview ................................................................................................................... 7

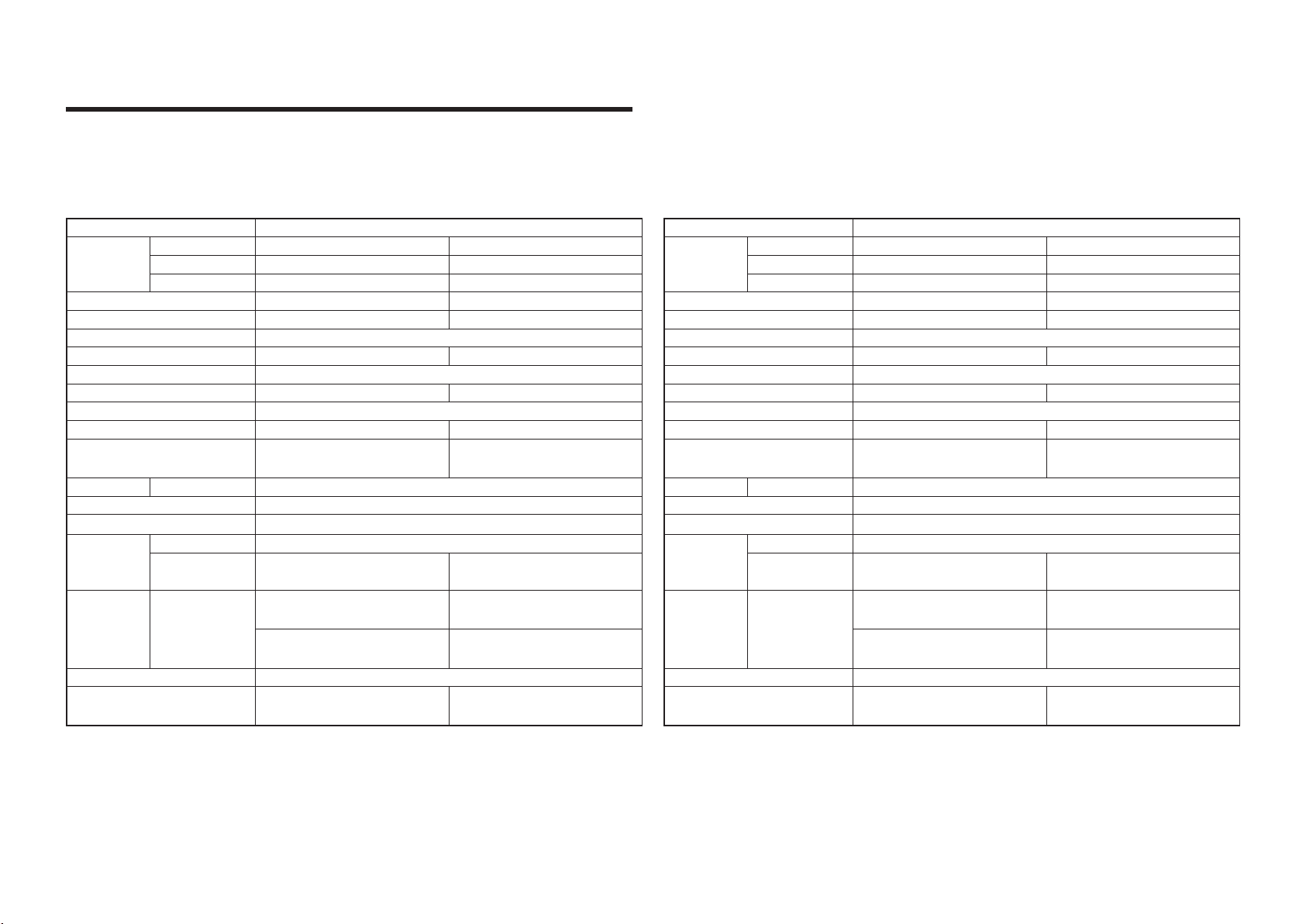

1. Specications................................................................................................................. 7

1-1. Specications ......................................................................................................... 7

TDA1200 .............................................................................................................. 7

TDA1600 .............................................................................................................. 7

1-2. Types of Tines ........................................................................................................ 8

1-3. Relationship between Operation Speed and Pitch................................................. 9

TDA1200 .............................................................................................................. 9

TDA1600 .............................................................................................................. 9

2.

Names of Each Section................................................................................................ 10

3.

Regulation Decals .........................................................................................................11

3-1. Positions of Regulation Decals .............................................................................11

3-2. Description of Regulation Decals ..........................................................................11

Serial Number Plate ............................................................................................11

Specication Decal..............................................................................................11

UKCA Mark......................................................................................................... 12

Year of Manufacture Decal ................................................................................. 12

4. Safety Signs and Instruction Signs .............................................................................. 13

4-1. About Safety Signs and Instruction Signs ............................................................ 13

4-2. Positions and Description of Safety Decals and Instruction Decals..................... 13

Handling Instructions............................................................................................................ 14

5. Tractor.......................................................................................................................... 14

5-1. Tractor Standards................................................................................................. 14

5-2. Preparation on The Tractor .................................................................................. 14

6. Adjustment before Attachment ..................................................................................... 14

6-1. Precautions about Attachment ............................................................................. 14

6-2. Method of Attaching The Machine........................................................................ 14

6-3. Method of Attaching Universal Joint..................................................................... 15

6-4. Method of Cutting Universal Joint ........................................................................ 17

7.

Inspections ................................................................................................................... 18

7-1. Precautions before Inspection.............................................................................. 18

7-2. Inspection of Covers ............................................................................................ 18

7-3. Inspection of Rollers............................................................................................. 18

7-4. Inspection of Tines ............................................................................................... 18

7-5. Inspection of Lawn Pressing Plate ....................................................................... 18

7-6. Inspection of Gear Oil .......................................................................................... 19

7-7. Supply of Gear Oil................................................................................................ 19

7-8. Inspection of Universal Joint ................................................................................ 19

7-9. Inspection of Oil Leakage..................................................................................... 19

8. Tightening Torques....................................................................................................... 20

8-1. Standard Tightening Torques ............................................................................... 20

8-2. Tightening Torque by Model ................................................................................. 21

TDA1200 ............................................................................................................ 21

TDA1600 ............................................................................................................ 22

9. Adjustment before Operation ....................................................................................... 23

9-1. Precautions about Adjustment ............................................................................. 23

9-2. Adjustment of Tine Depth ..................................................................................... 23

10.

Operation Method ...................................................................................................... 24

10-1. Positions and Description of Operation Decals.................................................. 24

10-2. Change Lever..................................................................................................... 25

Contents

−1−

10-3. Up-Down Handle................................................................................................ 25

10-4. Rear Roller ......................................................................................................... 26

11.

Traveling..................................................................................................................... 26

11-1. Precautions before Traveling.............................................................................. 26

11-2. Traveling Operation ............................................................................................ 26

12. Operations ................................................................................................................. 27

12-1. Precautions before Operation ............................................................................ 27

12-2. Aeration Procedure ............................................................................................ 28

13. Transporting ............................................................................................................... 28

14. Long-Term Storage .................................................................................................... 28

Maintenance......................................................................................................................... 29

15. Maintenance Precautions .......................................................................................... 29

16. Maintenance Schedule .............................................................................................. 29

17. Greasing .................................................................................................................... 30

17-1. About Greasing .................................................................................................. 30

17-2. Greasing Points.................................................................................................. 30

18. Maintenance Work ..................................................................................................... 30

18-1. Cleaning of Aeration Section.............................................................................. 30

18-2. Change of Tines ................................................................................................. 30

18-3. Change of Gear Oil ............................................................................................ 31

18-4. Disassembly of Crank ........................................................................................ 31

Timing Chart....................................................................................................... 32

TDA1200 ............................................................................................................ 32

TDA1600 ............................................................................................................ 33

−2−

Greeting

Thank you for purchasing the Baroness product.

This manual describes the proper handling, adjustment, and inspection of your product.

We hope you will use the product safely, and take advantage of its best performance.

Introduction

Read this manual carefully to ensure that you thoroughly understand how to properly operate

and maintain the product, and to avoid causing injury to yourself or others.

The operator is responsible for operating the product properly and safely.

Maintenance should only be performed by a certified specialist.

If you have any questions concerning maintenance or genuine parts, please contact your

local Baroness dealer or Kyoeisha.

When making inquiries about the product, please specify the product's model designation

and serial number.

When loaning or transferring the product, please also provide this manual together with the

product.

Kyoeisha Co., Ltd.

Warning Symbols

This manual uses the following warning symbols for handling precautions that are important

for your safety.

Warning symbol

This symbol indicates the articles regarding “Danger,” “Warning,” or “Caution.”

Those articles describe important safety precautions and so read them carefully to

understand completely before operating the machine.

Failure to adequately follow these safety precautions may cause an accident.

This symbol indicates that serious injury or death will occur if the warning is ignored.

This symbol indicates that serious injury or death may occur if the warning is ignored.

This symbol indicates that injury or damage to property may occur if the warning is ignored.

This symbol indicates precautions on the mechanism of the machine.

−3−

Precautionary Statement

The information described in this manual is subject to change for improvement without

prior notice.

When replacing parts, be sure to use genuine Baroness parts or parts designated by

Kyoeisha.

Note that the Baroness product warranty may not apply to defects caused by the use of

parts from other companies.

Prior to use, carefully read the following manuals to thoroughly understand the contents for

safe and correct operation.

● Baroness Owner's Operating Manual

● The Tractor’s Owner’s Manual

● Service Instructions for PTO Drive Shafts

Purpose

This product is intended for aerating golf courses.

Do not use this product in any way other than its intended purpose, and do not modify this

product.

Operating this product for other purposes and modifying it may be very dangerous and may

cause damage to the product.

Safety

Failure to adequately follow these safety precautions may cause an accident resulting in

injury or death.

This product is designed to ensure safe operation and has been tested and inspected

thoroughly before shipment from the factory.

The product is equipped with safety devices to prevent accidents.

However, whether the product demonstrates its original performance level depends on the

manner in which it is operated and handled, as well as the manner in which it is managed

on a daily basis.

Inappropriate use or management of the product may result in injury or death.

Observe the following safety instructions to ensure safe operation.

−4−

Safe Operating Practices

Training

1.Read this manual and other training material carefully.Be familiar with the controls, safety

signs, and the proper use of the equipment.

2.If the operator or mechanic can not read English it is the owner’s responsibility to explain

this material to them.

3.All operators and mechanics should seek and obtain professional and practical

instruction. The owner is responsible for training the users.

4.Never allow children or people unfamiliar with these instructions to use or service the

machine.

5.The owner/user can prevent and is responsible for accidents or injuries occurring to

themselves ,other people, or property.

6.Keep in mind that the owner, operator, and mechanic are responsible for accidents or

hazards occurring to other people or their property.

7.You can find additional safety information where needed throughout this manual.

Preparation

1.Evaluate the terrain to determine what accessories and attachments are needed to

properly and safely perform the job. Only use accessories and attachments approved by

the manufacturer.

2.Inspect the area where the equipment is to be used and remove all objects such as rocks,

toys and wire which can be thrown by the machine.

3.Keep children out of the operating area and under the watchful care of a responsible adult

other than the operator.

4.Check that shields are attached properly.

5.Before using, always visually inspect to see that the tines and tine mounts are not worn or

damaged.

When some tines are worn, replace all the installed tines at the same time to prevent

abnormal vibration.

6.Pay attention to all the tine mount holders, which operate simultaneously.

Operation

1.Only operate in good light, keeping away from holes and hidden hazards.

2.Never operate the machine with damaged guards, shields, or without safety protective

devices in place.

3.Stop the engine in the following conditions.

[1]Before making depth adjustment.

[2]Before clearing blockages.

[3]Before checking, cleaning or working on the machine.

[4]After striking a foreign object or if an abnormal vibration occurs.

Inspect the machine for damage and make repairs before restarting and operating the

equipment.

4.Keep hands and feet away from the rotating parts.

5.Never operate while people, especially children, or pets are nearby.

6.Stop the tines rotating before crossing surfaces other than grass.

7.Disengage drive to attachments when transporting or not in use.

8.Take care when loading or unloading the machine into a trailer or a truck. Load or unload

the machine in a flat and safe place. Before loading or unloading, set the parking brake

on the truck or trailer, stop the engine, and chock the wheels.

Fasten the machine to the truck with a rope or other suitable restraining device that has

sufficient strength.

−5−

Maintenance and Storage

1.Disengage drives on level ground, stop drive to the tine section, set parking brake, stop

engine. Wait for all movement to stop before adjusting, cleaning or repairing.

2.Never allow untrained personnel to service machine.

3.Appropriately manage and correctly use the tools necessary for servicing or adjusting the

machine.

4.Carefully release pressure from components with stored energy.

5.Use care when checking the tines.

[1]Wrap the tines or wear gloves, and use caution when servicing them.

[2]Only replace tines.

6.On multi-bladed machines, take care as rotating one blade can cause other blades to

rotate.

7.Keep hands and feet away from moving parts. If possible, do not make adjustments with

the engine running.

8.Keep all parts in good working condition and all hardware tightened. Replace all worn or

damaged decals.

9.Keep all nuts, bolts and screws tight to be sure the equipment is in safe working condition.

Towing

1.Follow the manufacturer’s recommendation for weight limits for towed equipment and

towing on slopes.

Disposal

Recycle and Waste Disposal

About Recycle

Recycling battery etc. is recommended for environmental conservation and economical use

of resources.

It may be required by local laws.

About The Waste Disposal

Make sure that waste generated when servicing or repairing the machine is disposed of in

accordance with local regulations.

(e.g. waste oil, antifreeze, rubber products, and wires etc.)

−6−

TDA1600

Model TDA1600

Dimensions

Total length 38.19 in 97 cm

Total width 70.47 in 179 cm

Total height 33.46 in 85 cm

Weight 1278.66 lb 580 kg

Gear oil capacity 1.0 U.S.gals 3.8 dm3(3.8 L)

Number of crank 8

Tine φ17 ・8.46 in φ17・215 mm

Number of tines 24 pcs (Various options available)

Aerating width 61.42 in 156 cm

Pitch (Traveling direction) Depending on the condition

Interval 2.56 / 3.94 in 6.5・10 cm

Working depth Max. 7.09 in

(Depending on the condition)

Max. 18 cm

(Depending on the condition)

Drive Aerating PTO driving

Speed of PTO rotation Max. 1,000 rpm

Working speed -

Applicable

tractor

Horsepower 17.6 kW (24.0 PS) or more

Max lifting

capacity 1,432.98 lbf or more 700 kgf or more

Universal

joint

Clutch setting

torque

Allowed max 4,602.52 lb-in Allowed max

520 N-m (5,302.44 kgf-cm)

Regular use 2478.28 lb-in Regular use

280 N-m (2,855.16 kgf-cm)

Connection Tractor ; 3-point link lifting type

Efficiency 0.77 acres/hour

(1.24 mph x Operating width)

3,120 m2/h

(2.0 km/h x Operating width)

Product Overview

1. Specifications

1-1. Specifications

TDA1200

Model TDA1200

Dimensions

Total length 38.19 in 97 cm

Total width 55.91 in 142 cm

Total height 33.46 in 85 cm

Weight 1157.41 lb 525 kg

Gear oil capacity 1.0 U.S.gals 3.8 dm3(3.8 L)

Number of crank 6

Tine φ17 ・8.46 in φ17・215 mm

Number of tines 18 pcs (Various options available)

Aerating width 46.06 in 117 cm

Pitch (Traveling direction) Depending on the condition

Interval 2.56/3.94 in 6.5・10 cm

Working depth Max. 9.84 in

(Depending on the condition)

Max. 25 cm

(Depending on the condition)

Drive Aerating PTO driving

Speed of PTO rotation Max. 400 rpm

Working speed -

Applicable

tractor

Horsepower 13.2 kW (18.0 PS) or more

Max lifting

capacity 1,432.98 lbf or more 650 kgf or more

Universal

joint

Clutch setting

torque

Allowed max 4,602.52 lb-in Allowed max

520 N-m (5,302.44 kgf-cm)

Regular use 2478.28 lb-in Regular use

280 N-m (2,855.16 kgf-cm)

Connection Tractor ; 3-point link lifting type

Efficiency 0.46 acres/hour

(0.99 mph x Operating width)

1,872 m2/h

(1.6 km/h x Operating width)

−7−

1-2. Types of Tines

There are two main types of tines: "pipe type" (which pulls out the lawn) and "spike type"

(which drills holes).

Pipe type Spike type

Aeration effect Large effect Good

Permeability effect Large effect Good

Underground gas diffusion effect Large effect Good

Damage to turf surface Large Less than with pipe type

Damage to lawn Large Less than with pipe type

Lawn recovery Takes time Quick

Aeration period When lawn cultivation is

thriving

Whenever needed

Core disposal Necessary Unnecessary

(Cores not discharged)

Mowing after aeration Better to mow Better to mow

Effect on play after aeration Not immediately possible Instantly possible

(However, mowing after

tamping is required.)

Degradation of thatch by mixing with soil Promoted Limited

1.Pipe-type tines

Tip dimensions Outer

diameter

of mount

Total

length

Quantity

used

Tine

mount

Lawn

pressing

plate

Inner

diameter

Outer

diameter

φ10V tine 100 6 mm

(0.24 in)

9.5 mm

(0.37 in)

100 mm

(3.94 in)

72

96

Specialized Specialized

φ12V tine 120 8.2mm

(0.323 in)

9.5 mm

(0.37 in)

120 mm

(4.72 in)

72

96

Specialized Specialized

φ13V tine 225 7 mm

(0.43 in)

12 mm

(0.47 in)

225 mm

(8.46 in)

18

24 - -

φ16V tine 125 11 mm

(0.43 in)

16 mm

(0.63 in)

125 mm

(4.92 in)

36

48

Specialized

-

φ17V tine 215 10 mm

(0.39 in)

12 mm

(0.47 in)

215 mm

(8.46 in)

18

24 - -

φ17V tine 265 10 mm

(0.39 in)

12 mm

(0.47 in)

265 mm

(10.43 in)

18

24 - -

* In the column “Quantity used”, the upper figure indicates the quantity for TDA1200 and the

lower for TDA1600.

2.Spike-type tines

Tip dimensions Outer

diameter

of mount

Total

length

Quantity

used

Tine

mount

Lawn

pressing

plate

Inner

diameter

Outer

diameter

φ8 spike tine 8 mm

(0.31 in)

16 mm

(0.63 in)

120 mm

(4.72 in)

36

48

Specialized

-

φ10 solid tine 10 mm

(0.39 in)

9.5 mm

(0.37 in)

100 mm

(3.94 in)

72

96

Specialized Specialized

φ12.5 spike tine 12.5 mm

(0.49 in)

16 mm

(0.63 in)

120 mm

(4.72 in)

36

48

Specialized

-

* In the column “Quantity used”, the upper figure indicates the quantity for TDA1200 and the

lower for TDA1600.

−8−

1-3. Relationship between Operation Speed and Pitch

TDA1200

The engine rotation speed during tractor operation should be 1,600 - 2,000 rpm.

Max PTO rotation speed should be 400 rpm.

If the PTO rotation speed exceeds 400 rpm, the machine will be damaged.

Use the following table as reference.

Tractor's speed and the pitch vary depending on the tractor's specifications.

Tractor TDA1200

Auxiliary

speed change

Main

speed change Speed PTO rotation Crank rotation Pitch

1 1 0.52 km/h 1st speed

Slow speed 53 mm

High speed 42 mm

1 2 0.75 km/h 1st speed

Slow speed 75 mm

High speed 60 mm

1 3 1.06 km/h 1st speed

Slow speed 108 mm

High speed 86 mm

1 4 1.60 km/h 1st speed

Slow speed 163 mm

High speed 130 mm

* The above table shows the figures during the maximum engine rotation speed 1,800 rpm.

TDA1600

The engine rotation speed during tractor operation should be 1,800 -2,300 rpm.

Max PTO rotation speed should be 1,000 rpm.

If the PTO rotation speed exceeds 1,000 rpm, the machine will be damaged.

Use the following table as reference.

Tractor's speed and the pitch vary depending on the tractor's specifications.

Tractor TDA1600

Auxiliary

speed change

Main

speed change Speed PTO rotation Crank rotation Pitch

1 1 0.58 km/h

1st speed

Slow speed 53 mm

High speed 42 mm

2nd speed

Slow speed 37 mm

High speed 30 mm

1 2 0.83 km/h

1st speed

Slow speed 75 mm

High speed 60 mm

2nd speed

Slow speed 53 mm

High speed 42 mm

1 3 1.18 km/h

1st speed

Slow speed 108 mm

High speed 86 mm

2nd speed

Slow speed 75 mm

High speed 60 mm

3rd speed

Slow speed 50 mm

High speed 40 mm

1 4 1.78 km/h

1st speed

Slow speed 163 mm

High speed 130 mm

2nd speed

Slow speed 114 mm

High speed 91 mm

3rd speed

Slow speed 75 mm

High speed 60 mm

*The above table shows the figures during the maximum engine rotation speed 2,000 rpm.

−9−

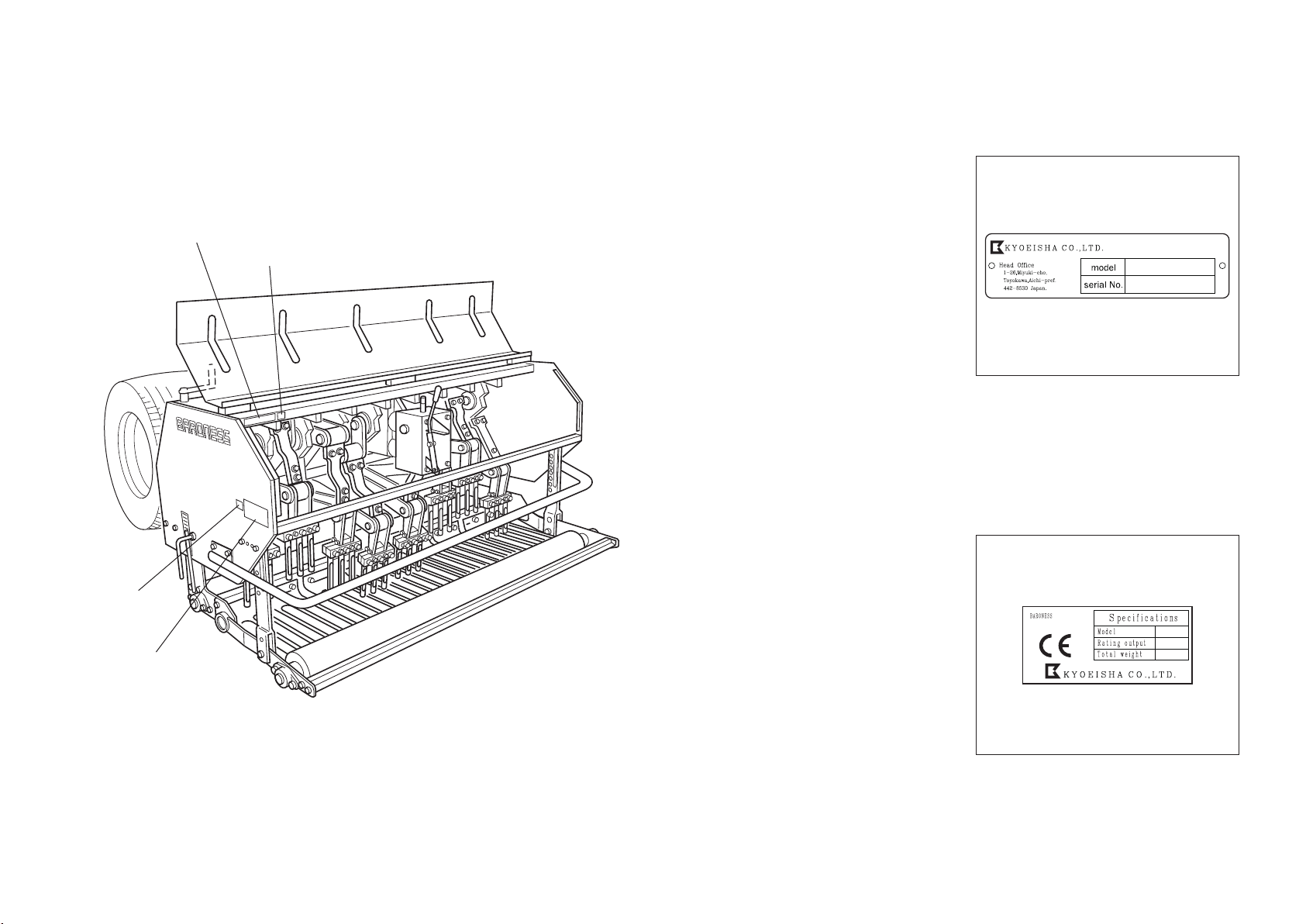

Front cover

Up-down handle

Scraper

Protection pipe

Rear roller

Tine mount

Tine

Lawn pressing plate

Roller hanger

Frame

Roller holding fixture

Rear cover

Change lever

Gear box

Front roller

Tine mount holder

2.Names of Each Section

−10−

3-2. Description of Regulation Decals

Serial Number Plate

The serial number plate indicates the model and serial number of the machine.

Specification Decal

(For Europe)

CE mark indicates that the machine sold in the EU nations complies with the EU

requirements.

The Specification decal indicates the CE marking, model , and weight, etc.

3.Regulation Decals

3-1. Positions of Regulation Decals

Serial number plate

Year of manufacture decal

Specification decal

UKCA mark

−11−

UKCA Mark

(For UK)

UKCA mark indicates that the machine sold in the UK complies with the UK requirements.

Year of Manufacture Decal

(For Europe)

The year of manufacture decal indicates the year when this machine was manufactured.

YEAR OF

MANUFACTURE

−12−

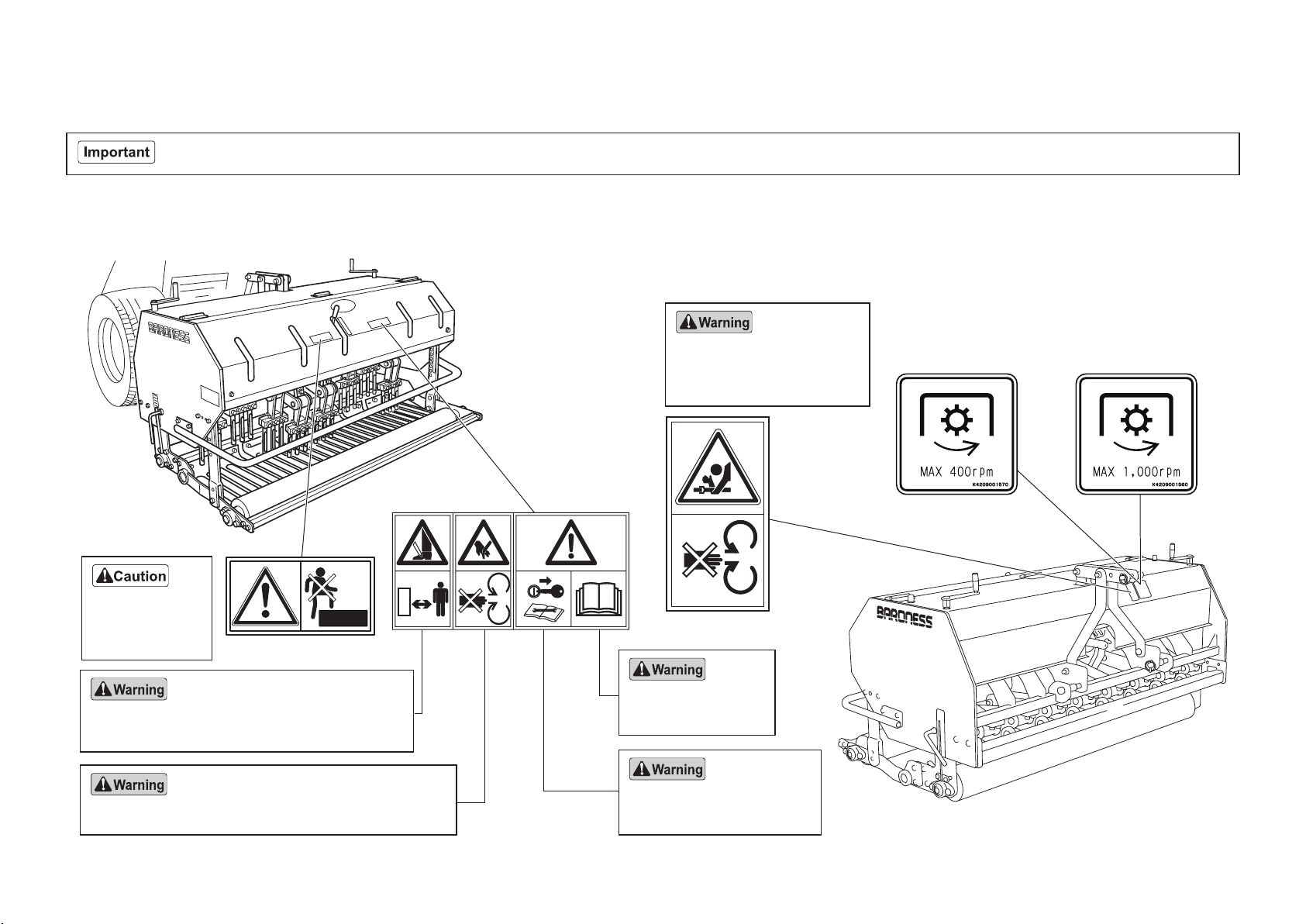

4. Safety Signs and Instruction Signs

4-1. About Safety Signs and Instruction Signs

Safety decals and instruction decals are attached to this product. Make sure that they are preserved in their entirety. If they are damaged, become dirty, or peel off, replace them with new ones.

Part numbers for decals that need to be replaced are listed in the parts catalog. Order them from a Baroness dealer or Kyoeisha.

4-2. Positions and Description of Safety Decals and Instruction Decals

K4205002300

K4205001750

K4205001760

K4205001750

Handling precautions

Remove the ignition key

before maintenance work.

May cut your hand - Keep hands away from moving parts.

May cut your leg - Be sure that people around the

machine keep a safe distance away during operation.

Read the Owner's

Operating Manual.

K4205002300

Prohibition of riding decal

>TDA1200@

K4209001570

PTO MAX 400 rpm decal

It indicates PTO max

rotation speed.

>TDA1600@

K4209001560

PTO MAX 1000 rpm decal

It indicates PTO max

rotation speed.

K4205001760

PTO caution decal

May catch your arm -

Keep away from PTO moving

parts during the engine running.

Do not ride

the mechanical

equipment.

−13−

Handling Instructions

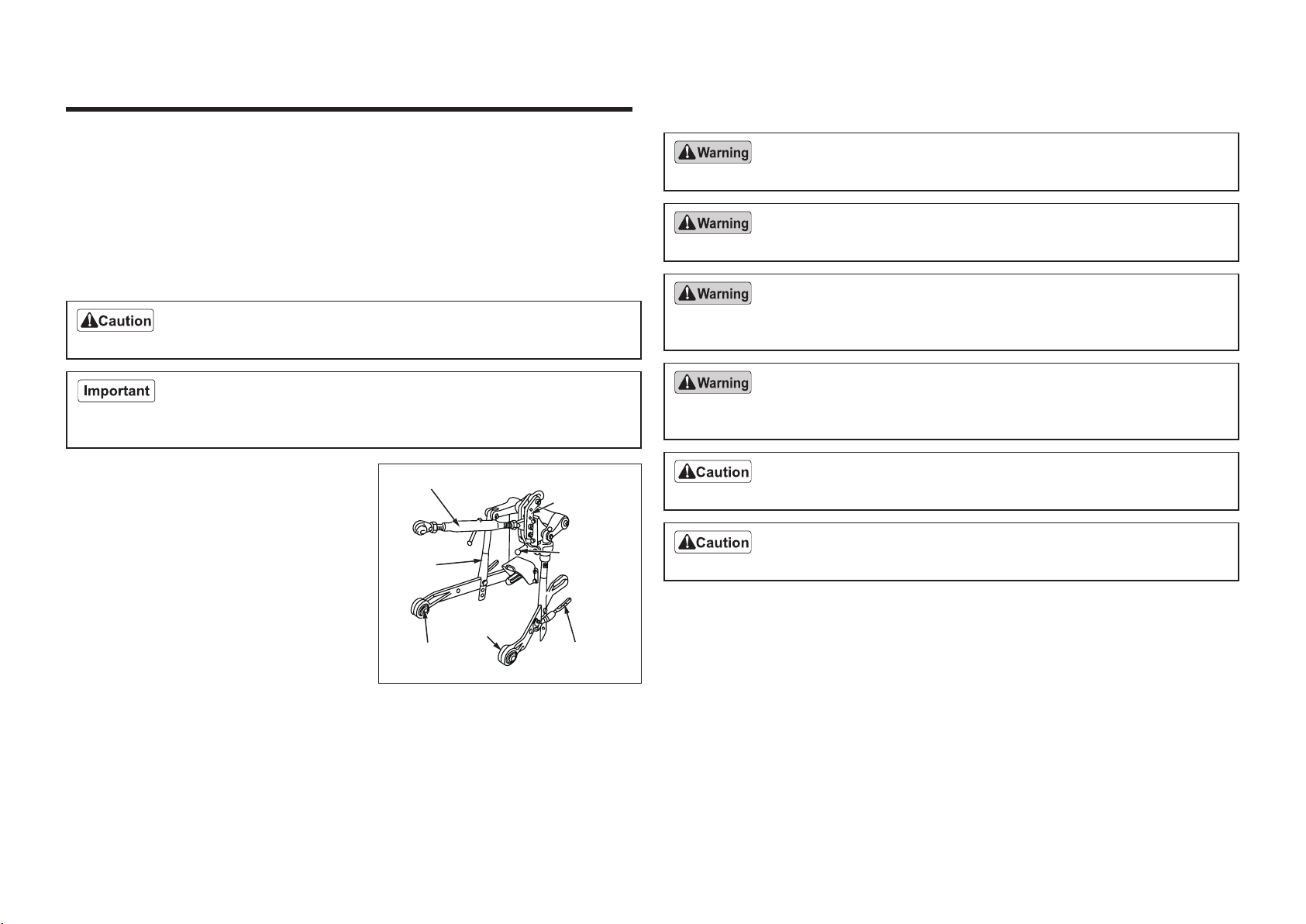

5. Tractor

5-1. Tractor Standards

This machine employs “standard three-point link” mounting system. In the “standard three-

point link”, attach the top and lower links of the tractor and the universal joint of this machine

by hand.

5-2. Preparation on The Tractor

Read the “three-point link standards” in the tractor’s owner’s manual carefully.

Only the tractors equipped with standard three-point link parts can be connected to this

machine.

1.If the tractor is equipped with specific three-

point link, remove the top link bracket for

specific three-point link and replace it with

standard three-point link parts.

Use the length-adjustable top link, the both

ends of which have a screw.

Attach the lift rod to the front hole of the

lower link.

2.If the moving distance when raising and

lowering the attached machine is insufficient, adjust it by changing the mounting holes on

the lift rod

● Use the upper hole to increase the moving distance when raising.

● Use the lower hole to increase the moving distance when lowering.

Top link Top link

bracket

Leveling

handle

Turn buckle

Right

lower link

Left lower link

Lift rod

6. Adjustment before Attachment

6-1. Precautions about Attachment

Make sure there is no one around the tractor and between this machine and the tractor.

Do not get under the machine. Do not put your foot under the machine.

Before attaching the machine, apply the parking brake of the tractor, set the PTO speed

change lever to the “Neutral” position and stop the engine.

When attaching the machine, install the tractor’s genuine balance weights to adjust

balance. Otherwise, the machine may lose balance and overturn.

Attach and detach the machine on a flat, stable place.

Two or more workers should attach and detach this machine since it is very heavy.

6-2. Method of Attaching The Machine

1.Place the machine on a flat, stable location.

2.Move the tractor backward to the machine and align the center position of the machine’s

linkage section.

3.Raise and lower the lower links with the tractor’s lift lever to align them with the link pin

position.

4.Apply the tractor’s parking brake and stop the engine.

5.Chock the tractor.

6.Attach the left lower link and lock the link pin.

7.Raise and lower the lower link with the leveling handle on the right lift link to align it with

the pin position.

−14−

8.Attach the right lower link and lock the link pin.

9.Align the implement mounting hole in the top link (upper link) with the mounting holes of

the machine.

If the top link (upper link) is not aligned with the mounting pin hole, loosen the lock nuts

on the top link and adjust its length.

10.Attach the top link (upper link) , lock the link pin and tighten the lock nuts.

11.Start the tractor’s engine and raise the machine slightly with the lift lever.

When vibration is generated in the machine, the vibration will cause damages to the lawn,

tractor and the machine.

12.Adjust the top link (upper link) so that the machine can level off.

* Adjust it so that the machine vibrates only 10 - 20 mm on the right and left sides evenly.

Check the vibration on the right and left sides of the machine. If the vibration is large,

adjust so that the play is reduced.

Note :

For removing the machine, reverse the installation procedure.

Top link

(Upper link)

Lower link

Link pin

Protective cover

Drive shaft

Lower link

Link pin

6-3. Method of Attaching Universal Joint

Before attaching the universal joint, disengage the PTO clutch and stop the tractor’s

engine.

Do not mount the universal joint that is too long or too short.

A long universal joint prongs the tractor’s PTO shaft or the attached machine’s input shaft.

A short universal joint is in poor meshing engagement and will cause breakage.

The universal joint length depends on the type of tractor to be linked.

Do not raise the machine with only one side of tractor’s lower links attached.

Do not continue rotating the universal joint with the machine raised.

The universal joint or the machine may break.

1.Set the tractor PTO speed change lever to the "Neutral" position.

2.Raise or lower the machine slowly to adjust its height so that the height of tractor's PTO

shaft and that of machine's input shaft are on the same level.

3.Close the hydraulic stop valve completely.

Note:

For the location of the hydraulic stop valve, refer to the tractor operator's manual.

4.Apply the tractor parking brake and stop the engine.

5.Hang the chain of universal joint on the top link (lift link).

−15−

Be sure to attach the universal joint clutch part to the implement side.

6.Pull the set cover and simultaneously push

the universal joint onto PTO shaft until the

locking device engages.

*Make sure that the knock pin and set cover

have returned to their original positions.

7.Press the knock pin and simultaneously

push the universal joint onto PTO shaft until

the pin engages.

*Attach it with the tractor's PTO speed

change lever in neutral.

8.Attach the universal joint to the machine and then attach it to the tractor.

Insert it until the knock pin locks.

*Make sure that the knock pin and set cover have returned to their original positions.

Knock pin

Set cover

Do not forcibly insert the universal joint with a hammer etc.

It may cause the joint breakage.

9.Shorten the joint to the highest possible

extent and attach it if the clearance

between the joint tip and the tractor's PTO

shaft is approximately 10 mm.

*Make sure that the lock pin head projects

more than 10 mm.

*Make sure that the lock pin is precisely in

meshing engagement with the shaft groove.

If there is not that clearance, cut off the

excessive portion of universal joint.

10.Attach the chain for stopping protective cover rotation on the lower link hook.

11.Make sure that the machine is not equipped with tines.

12.Start the engine of the tractor.

13.Make sure that there is no abnormal noise in the universal joint and the machine when

rotating PTO shaft with the machine lowered (or with the front roller in contact with the

ground).

PP

−16−

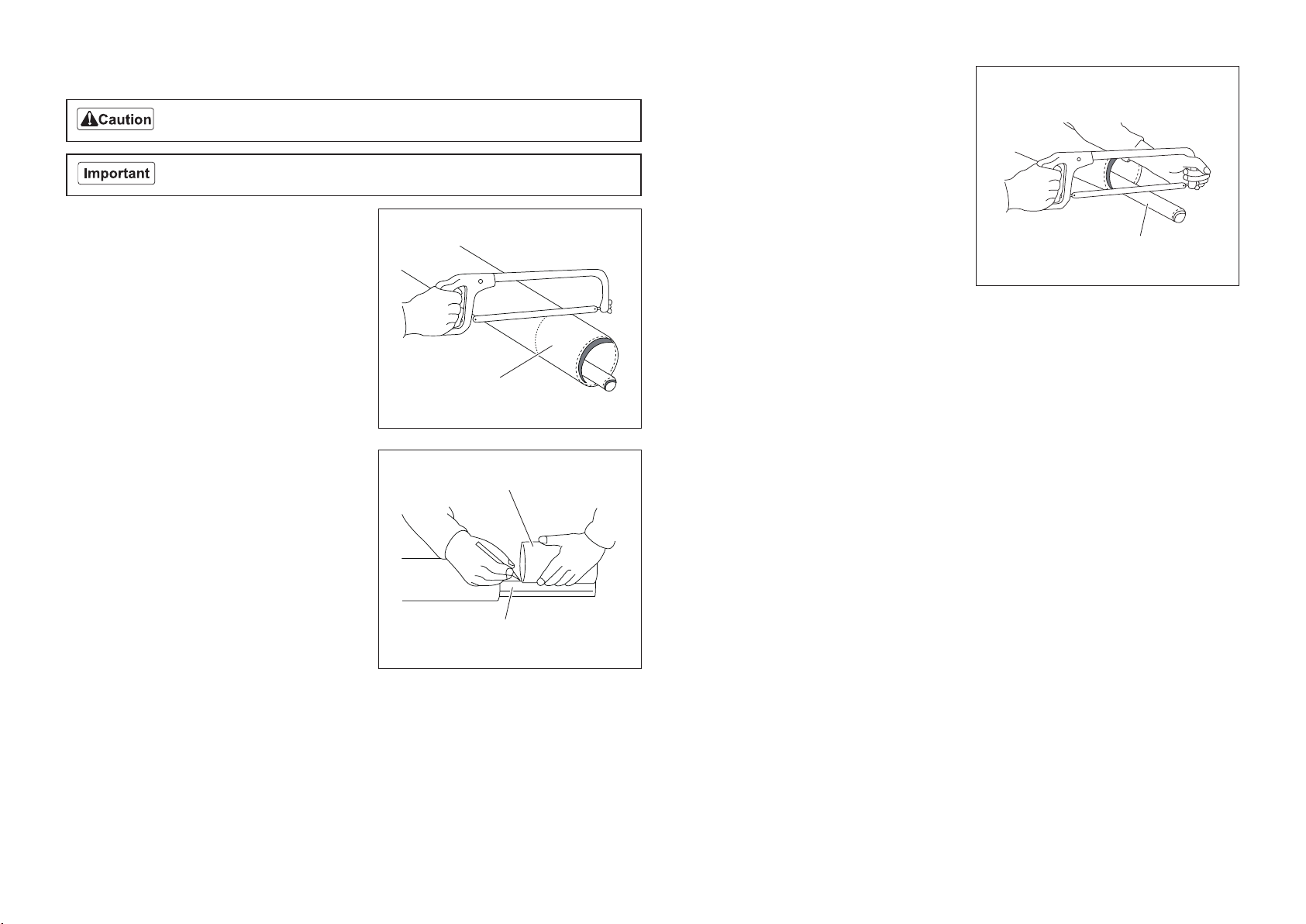

6-4. Method of Cutting Universal Joint

Work with great caution when using a high speed cutter.

The universal joint length depends on the type of tractor to be linked.

1.Hold the half shafts of universal joint next to

each other in the shortest working position

between the tractor and machine, and mark

them.

2.Cut the inner and outer guard tubes at the

marked positions.

3.Mark the shaft at the same length from its

tip as the removed guard tube.

Guard tube

Shaft

Guard tube

4.Cut the inner and outer shafts at the marked

position.

5.Round off all sharp edges, remove burrs and clean the shafts.

−17−

Shaft

−18−

7.Inspections

7-1. Precautions before Inspection

Read “Inspection before work” on the tractor’s owner’s operating manual carefully.

Be sure to stop the engine before inspection, service and adjustment with the tractor

linked.

7-2. Inspection of Covers

If you have removed a protective cover during inspection, be sure to securely install it in

its original position.

If a protective cover remains removed, foreign objects may fly off, possibly resulting in

injuries.

● Make sure that there is no wear or deterioration of protective covers.

● Make sure that there is no damage to protective covers.

● Make sure that there is no interference with moving parts due to deformation of protective

covers.

● Make sure that protective covers are installed in their appropriate positions.

7-3. Inspection of Rollers

Bearing wear due to frequent use or bearing damage caused by water infiltration may

prevent the roller from rotating smoothly.

Inspect the roller and, if necessary, replace parts such as oil seals and bearings.

1.Make sure that there is no abrasion nor adhesion of the roller.

2.Make sure that there is no wear of the roller shaft.

3.Make sure that there is no wear nor damage of the oil seal.

4.Make sure that there is no wear nor rust of the bearing.

5.Make sure that there is no play in the roller shaft.

7-4. Inspection of Tines

Wear gloves when touching tines to avoid cutting your hands.

Vibration from imbalance, dullness or poor discharge of cores may occur due to frequent use

or damage during transportation.

Inspect and, if necessary, replace.

1.Make sure that the tines are not bent.

2.Make sure that the tines are not chipped.

3.Check how much the tines are worn.

The operating depth cannot be maintained if tine wear is 10 mm (0.39 in) or more.

4.Make sure that the edges of tines are not too blunt, making cutting difficult.

5.Make sure that the mounting bolts for the tines are not loose.

6.Check how much the sliding plate of the tine mount section is worn.

7-5. Inspection of Lawn Pressing Plate

Damage may occur due to frequent use or during transportation.

Inspect and, if necessary, replace.

1.Make sure that there is no deformation of the lawn pressing plate.

2.Make sure that there are no cracks or damage to the lawn pressing plate.

3.Make sure that the mounting bolts for the lawn pressing plate are not loose.

−19−

7-6. Inspection of Gear Oil

The oil gauge is located on the side of the gear

box.

1.On a level surface, check that the oil level

reaches the middle of the oil gauge.

2.Check underneath the machine for oil

leakage.

7-7. Supply of Gear Oil

Do not mix different types of oil.

Use BONNOC TS680 (or equivalent) as oil.

1.If the oil level is low, follow the steps below to supply oil.

[1]Open the oil filler cap, and then supply oil through the oil filling port until the oil level

reaches the middle of the oil gauge.

[2]Tighten the oil filler cap securely.

2.On a level surface, check if the oil level is at

the middle of the oil gauge. If necessary,

supply oil.

3.Check underneath the machine for oil

leakage.

7-8. Inspection of Universal Joint

1.Inspect the chain for damage, abnormal wear and so on.

2.Inspect the cover for cracks, damage, abnormal wear and so on.

7-9. Inspection of Oil Leakage

After approximately 50 hours of operation, some joints may be loosened and oil and grease

may leak.

Be sure to retighten the parts.

Check the bottom of the machine for oil and grease leakage.

Chain Cover

Oil gauge

Oil filler cap

Oil gauge

Oil filler cap

Other manuals for TDA1200

1

This manual suits for next models

1

Table of contents

Other Baroness Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

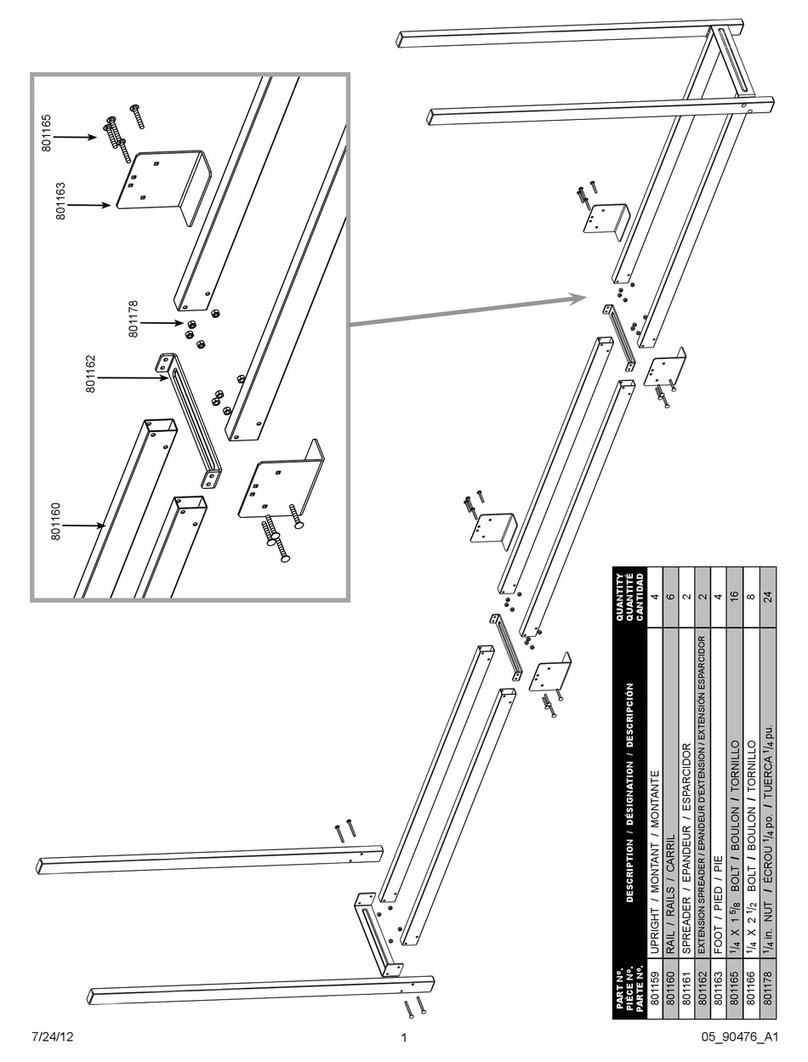

ShelterLogic

ShelterLogic 90476 manual

American Gardener

American Gardener GS36 instruction manual

Premier designs

Premier designs Wind Garden 25948 Assembly instructions

Diivoo

Diivoo WT-03 user manual

Broyhill

Broyhill A414034720 Assembly instructions

Erhardt Markisen

Erhardt Markisen KD Assembly instructions