CLAYTON MARK 5451 Series User manual

• HEAVY DUTY-BUILT FOR YEARS OF RELIABLE USE

• HIGH STRENGTH STAND PIPE PROVIDES PROTECTION AGAINST DAMAGE

• STAND PIPE HAS SUPERIOR CORROSION RESISTANCE

• STEEL, ZINC PLATED ROD FOR LONG LIFE

• HEAVY DUTY DUAL BYPASS BOTTOM VALVE ALLOWS BETTER FLOW WITH LESS

RISK OF BLOCKAGE FROM DEBRIS

• COMPONENTS CAN BE REPLACED FROM ABOVE GROUND WITHOUT DIGGING

• LOCKING EYE HOLES ALLOW HYDRANT TO BE PADLOCKED WHEN NOT IN USE.

• INLET 3/4” NPT, OUTLET 3/4” GARDEN HOSE THREAD.

ITEM QTY DESCRIPTION MAT'L OF CONSTRUCTION

1 1 HEAD CAST IRON

2 1 HANDLE CAST IRON

3 * 1 CONNECTOR BRASS

4 * 2 LINK STEEL-ZINC PLATED

5 * 1 FULCRUM BOLT STEEL-ZINC PLATED

6 * 1 FULCRUM NUT STEEL-ZINC PLATED

7 * 1 SQUARE HEAD SET SCREW STEEL-ZINC PLATED

8 * 1 PACKING NUT BRASS

9 * 1 PACKING GRAPHITE

10 1 HOSE ADAPTER 3/4" BRASS

11 1 BOTTOM VALVE BRASS

12 1 CLEVIS ROD/ROD ASSEMBLY STAINLESS STEEL/STEEL-ZINC PLATED

13 1 PIPE STEEL, GALVANIZED

14 * 1 PLUNGER BUNA-N/BRASS

* ITEMS ARE INCLUDED IN YRK1 REPAIR KIT.

5451 SERIES

FROST-PROOF YARD HYDRANT

HOW A FROST-PROOF HYDRANT WORKS

CLOSED

The hydrant is closed and no water is in the

riser pipe or head. Water is stopped by the

plunger (valve) below the frost line.

Protected like this, no freezing can occur.

CLOSED - DRAINING

Closing the handle pushes the plunger

down to seal off the water and uncover

the drain hole. This allows the water in

the head and riser pipe to drain back

down into the gravel drain bed. The

hydrant is now empty and cannot freeze.

OPEN - WATER FLOWING

Water is made available by raising the handle.

This will lift the plunger allowing water to flow and

the plunger to seal off the drain hole.

®

LEAVE THIS SHEET WITH END USER.

NOTE: WATER FLOW CANNOT BE THROTTLED.

Hydrant handle must be positioned in the FULL

open position for proper water flow and drainback

seal. This hydrant will not operate properly in a

PARTIALLY open position.

5451 HYDRANT INSTALLATION

5451 HYDRANT ADJUSTMENT PROCEDURE

1. Turn water supply OFF.

2. Open hydrant to relieve pressure.

3. Loosen set screw. (Item 1)

4. Push stainless steel rod down as far as it will go by hand to be sure the plunger is touching the seat.

5. Open handle (Item 2) approximately 30° from closed position.

6. Tighten set screw snugly.

7. Turn water supply ON.

8. Operate hydrant and make sure the hydrant is shutting off properly and flowing properly.

9. If hydrant still does not shut off, repeat steps 1 through 8.

10. Flow water through hydrant and then close completely to check for proper drainage by:

a) listening for water draining down pipe or

b) putting your hand over the hose connection to feel for a vacuum.

If hydrant does not drain, see step 11.

11. To clear drain hole blockage, close off hydrant spout by using hose cap or by attaching and kinking

a hose. Open and close hydrant to allow water pressure to clear blockage. For anti-pollution models, make sure that the small hole in the vent

valve is not blocked or plugged. Repeat step 10 to verify proper drainage. If hydrant still does not drain, repeat steps 1 through 10 to fully

uncover drain hole.

CAUTION: Do not try to make the shutoff adjustment in one attempt or you may overadjust and cause damage to the plunger and rods.

For this reason adjust in multiple small increments.

Liverpool, New York

www.americangranby.com

1. Dig hole for hydrant approximately 2 feet in diameter and 1 foot deeper than the bury depth.

2. FLUSH PIPING BEFORE CONNECTING THE HYDRANT to clear any gravel or other debris that may have

collected in the piping during its installation and assembly. If not flushed out of the piping, this debris

may jam the hydrant mechanism or clog the flow ports.

3. Make the piping connection* but do not bury the hydrant yet. Operate the hydrant to be sure it is oper-

ating properly and the piping connections are not leaking. Open and close the hydrant and check for

flow and drainage. If leakage continues from the drain port see "adjustment procedure" below.

4. Fill the hole around and below the hydrant with medium size gravel. This will provide a drain field for

the hydrant. Without a drain field, the hydrant will not empty itself and it will freeze in cold weather.

This will cause damage to the hydrant and result in loss of water and possible flooding damage.

* CAUTION: USE WRENCH ON VALVE BODY & FITTING ONLY. Do NOT use wrench on stand pipe.

HYDRANT INSTALLATION TIPS

• Never leave hose attached to hydrant after use. This will prevent the hydrant from draining properly

and will allow the hydrant to freeze.

• If the hydrant is to be installed inside a barn or other structure, or if it is installed in asphalt or concrete

such as a driveway, connect a 1/8" drain pipe or tube to the drain port and dig a remote drain field out-

side the structure for the drain pipe to empty into. Without this remote piping and drain field, the water

from the hydrant drainage will percolate up to the surface around or near the hydrant and will damage

the flooring or cause muddy areas in stalls or walkways.

• Water pressure to the hydrant should be regulated to not more than 80 psi. The higher pressures will

accelerate wear and may cause leakage that will saturate the ground and drain field and prevent the

hydrant from draining. If the hydrant is not allowed to drain, it can freeze and cause damage to itself

and cause flooding and loss of water. High pressure will also cause you to have to replace parts and

adjust the hydrant frequently. A normal operating pressure would be 20 to 40 psi.

• Saturated ground in the hydrant drain field can prevent the hydrant from draining and may result in

freezing. If the area where your hydrant is located is low laying or has a tendency to have standing

water, a larger drain field or pit may be required to provide the hydrant a place to drain into.

NOTE: Every 5451 Series hydrant is tested and adjusted at the factory for shutoff at 20 to 40 psi. Adjustment should NOT be necessary

upon normal installation. If installed hydrant does not stop water flow use adjustment procedure below.

American Granby Inc. warrants the products manufactured by us to be free from manufacturing defects for a period of ONE YEAR from

the date of shipment by AGI to the ORIGINAL PURCHASER ONLY. NOTE: The inability to keep water from shutting off is NOT consid-

ered a manufacturer’s defect. Water shut down is considered an adjustment issue or a worn part that needs replacement.

Replacement parts are available from an AGI distributor at end user’s cost.

CAUTION: If a hose is attached to nozzle of hydrant when hydrant is shut off, back siphoning can occur if end of hose is left in container of liq-

uid. The end of hose must be left open to the air so hydrant can drain back. Under no circumstances should CM hydrants drain back into

well or drinking water supply. AGI disclaims all liability of any kind and voids the CM hydrant warranty for installations of this product where it

can or could drain back into a drinking water supply.

Popular Lawn And Garden Equipment manuals by other brands

Black & Decker

Black & Decker 8288 owner's manual

Swisher

Swisher 3279 GRASS CATCHER ATTACHMENT manual

Stiga

Stiga Kitchen installation guide

RedMax

RedMax EXTREME EXZ2450S-PH Owner's/operator's manual

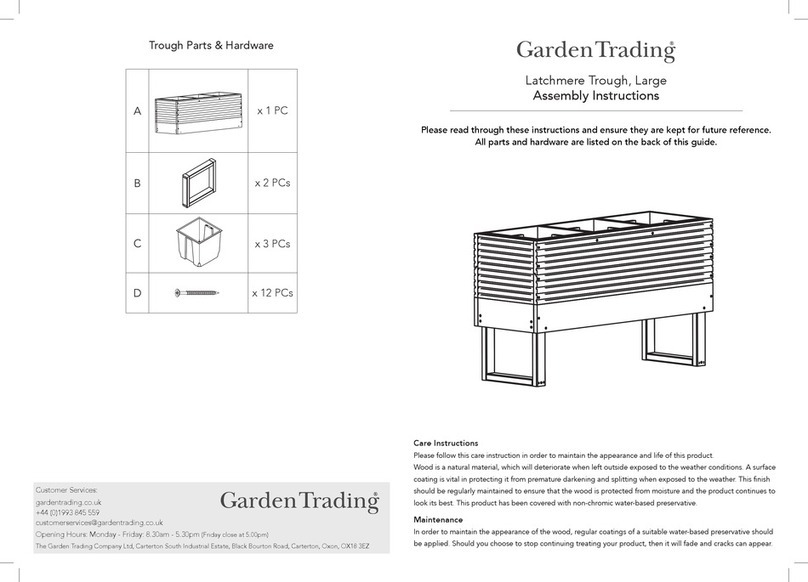

Garden Trading

Garden Trading Latchmere Trough Large Assembly instructions

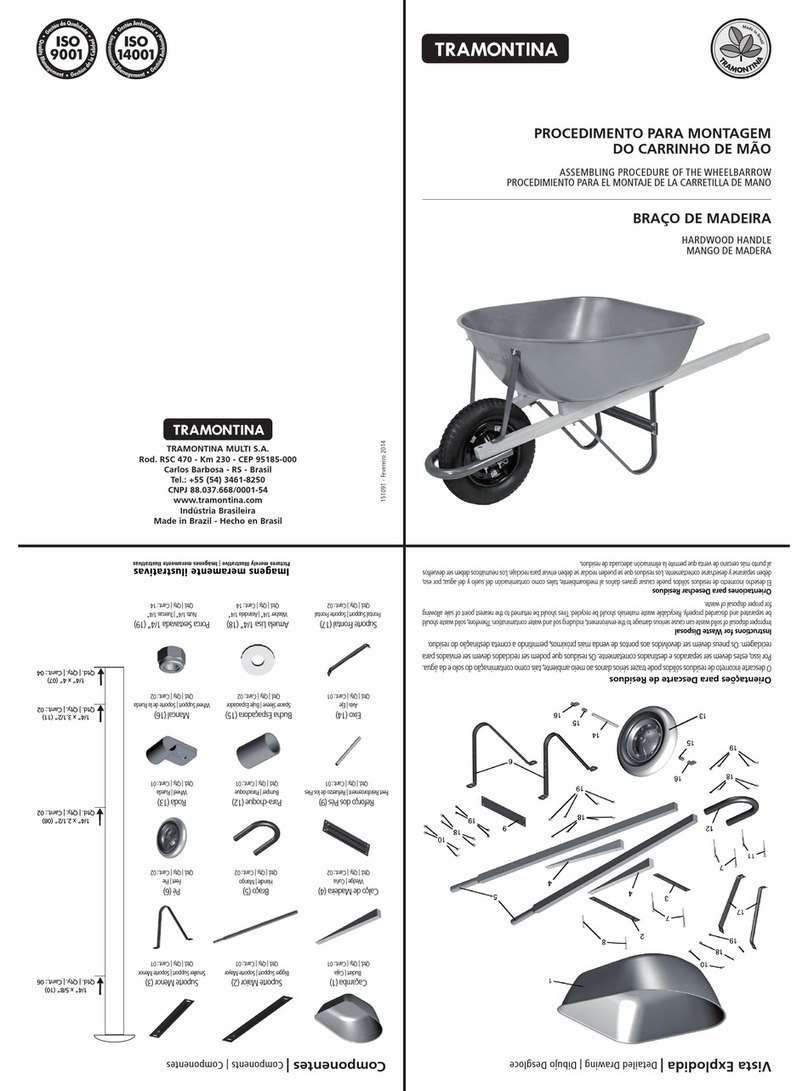

Tramontina

Tramontina 77717421 manual