Flat

Washer

and Retainer Springs (shown

full

size above)

found in

Bag

of

Parts. Insert Control

Arm

Pin

into

R.H.

Plate, place Flat Washer on Pin and secure

with

Retainer

Spring (Fig. 5).

11

.

If

necessary, loosen Set Screws

to

position

Lift

Bracket on

Lift

Lever Shaft

so

that

Bracket lines up

with

Lift

Bar.

Tighten

both

Set Screws securely.

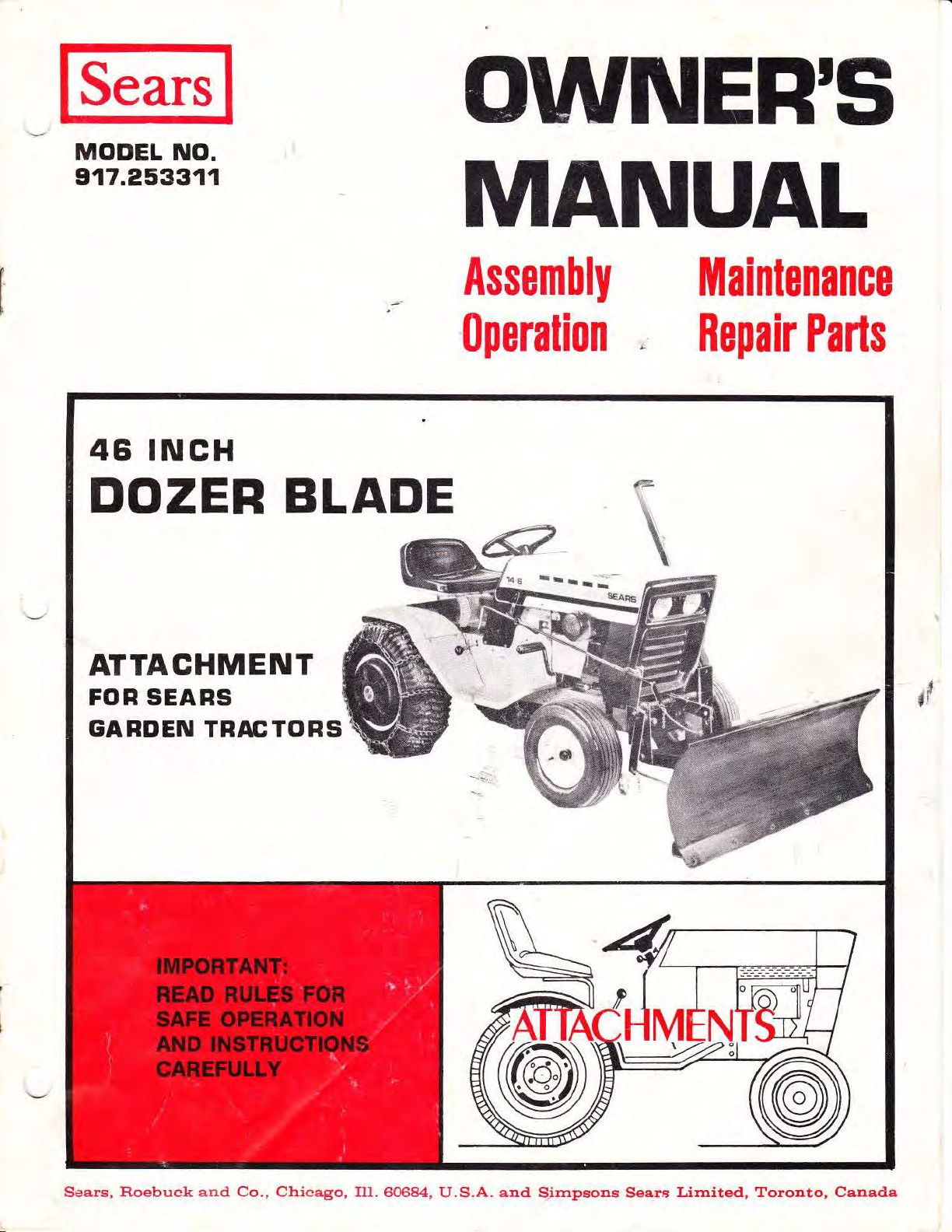

12.

Place

a 2 x 4

or

similar object flatwise beneath

each

end

of

Blade (Fig. 6).

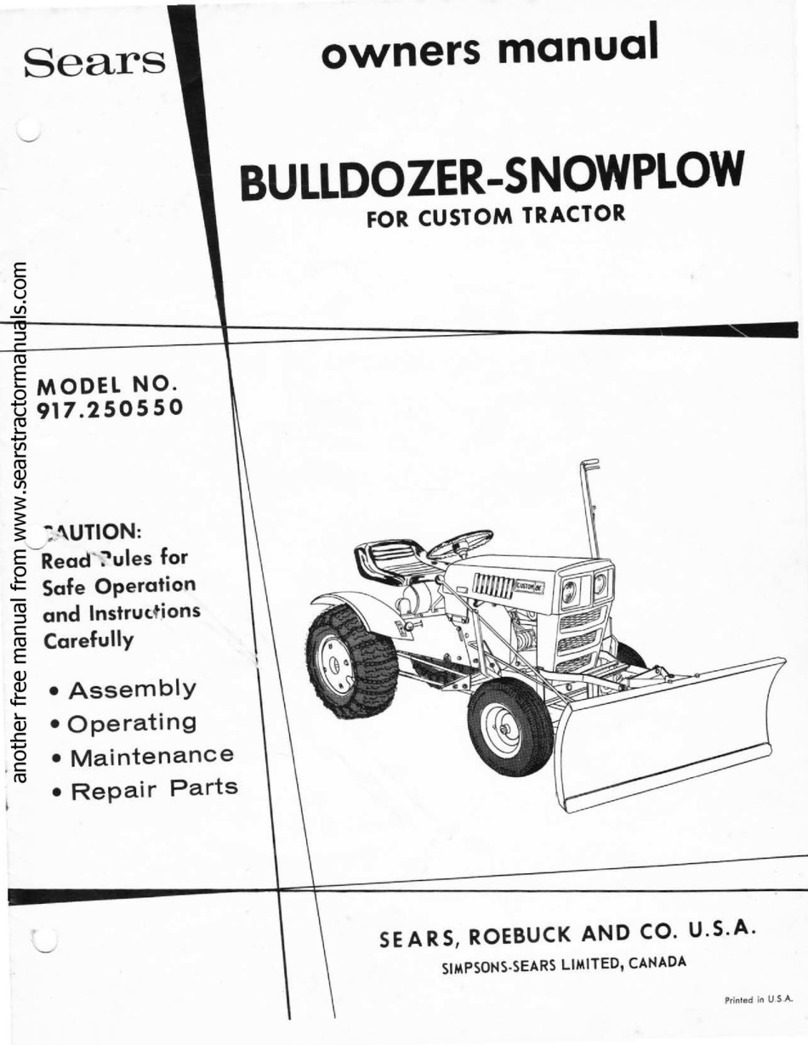

13. Insert Pivot

Pins

of

R.H. Plate

and

L.H. Bracket

into

Front

Mounting Bracket slots (Fig.

6-

Inset).

14. Turn

front

tractor

wheels

to

the right to assemble

Mount·

ing Rod

and

Retainer Spring (furnished

with

Front

Mount-

ing Bracket)

thru

holes in R.H. Plate, L.H. Bracket and

Front

Mounting Bracket. Secure

with

Retainer Springs

to

the inside (Fig.

6-

Inset).

15. Install Control Rod using:

@

~I

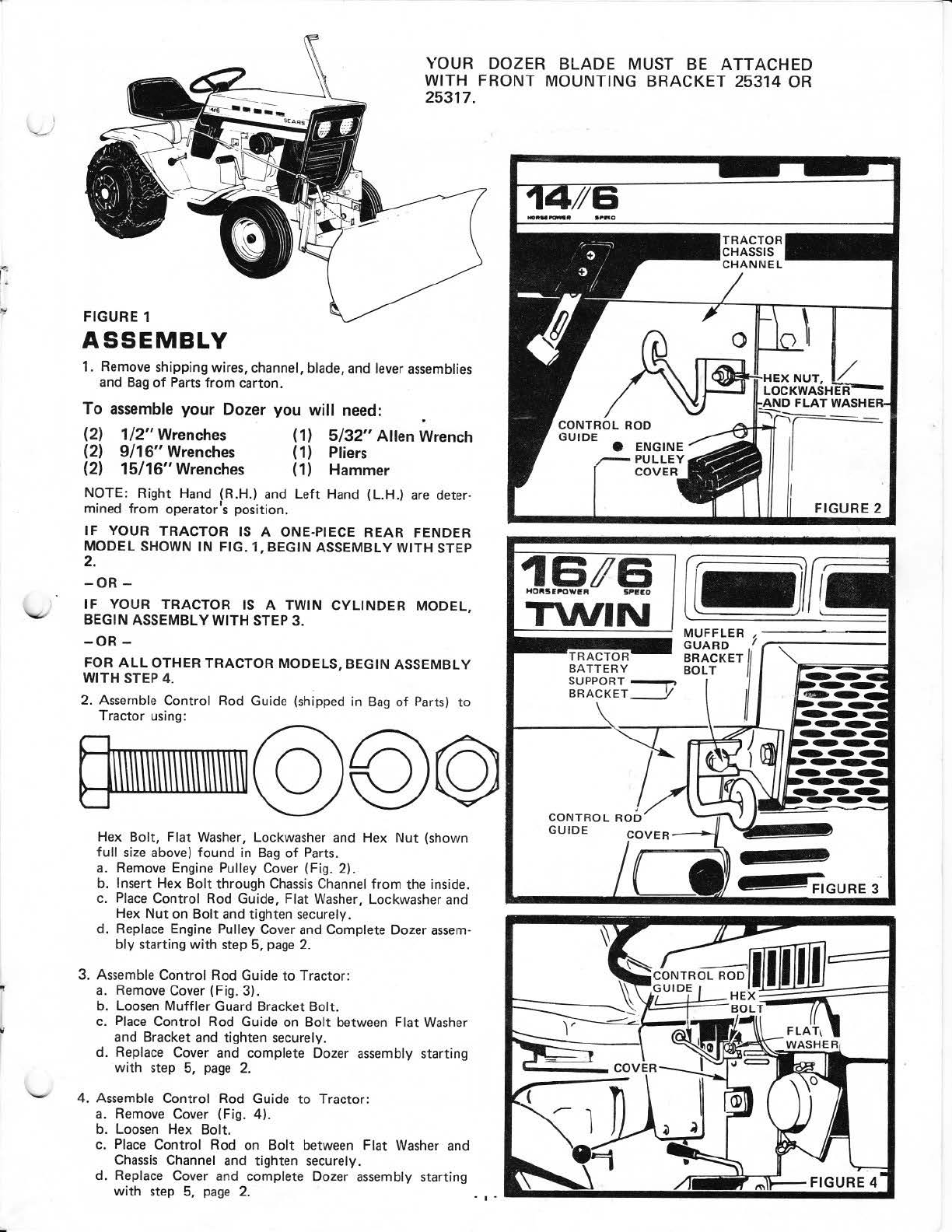

FIGURE 6

16. Remove 2 x 4's

from

beneath Blade.

17.

Adjust

Control Chain.

a.

With Control Rod handle in Blade Ang

le

"Set"

Pos

ition

(Fig. 6).

Cha

in must

be

long enough

to

allow

Return

Spring

to

pull Latch Pin

into

Blade Angle Adjustment

holes directly below (Fig. 6 - Inset).

b. Wi

th

Control Rod handle in Blade Angle

"Adjusting"

Position (Fig. 6). Chain must

be

short enough

to

pull

Latch Pin

from

Blade Angle Adjustment holes (F

ig

. 6 -

Inset).

18. Tighten Jam Nuts

sh

ipped on

Tr

ip Spring Bolts

until

a

sl

ight

spring tension is achieved

and

enough threads

are

ex-

posed

to

add:

Jam Nuts (shown

full

size

above) found in

Bag

of

Parts.

Tighten securely.

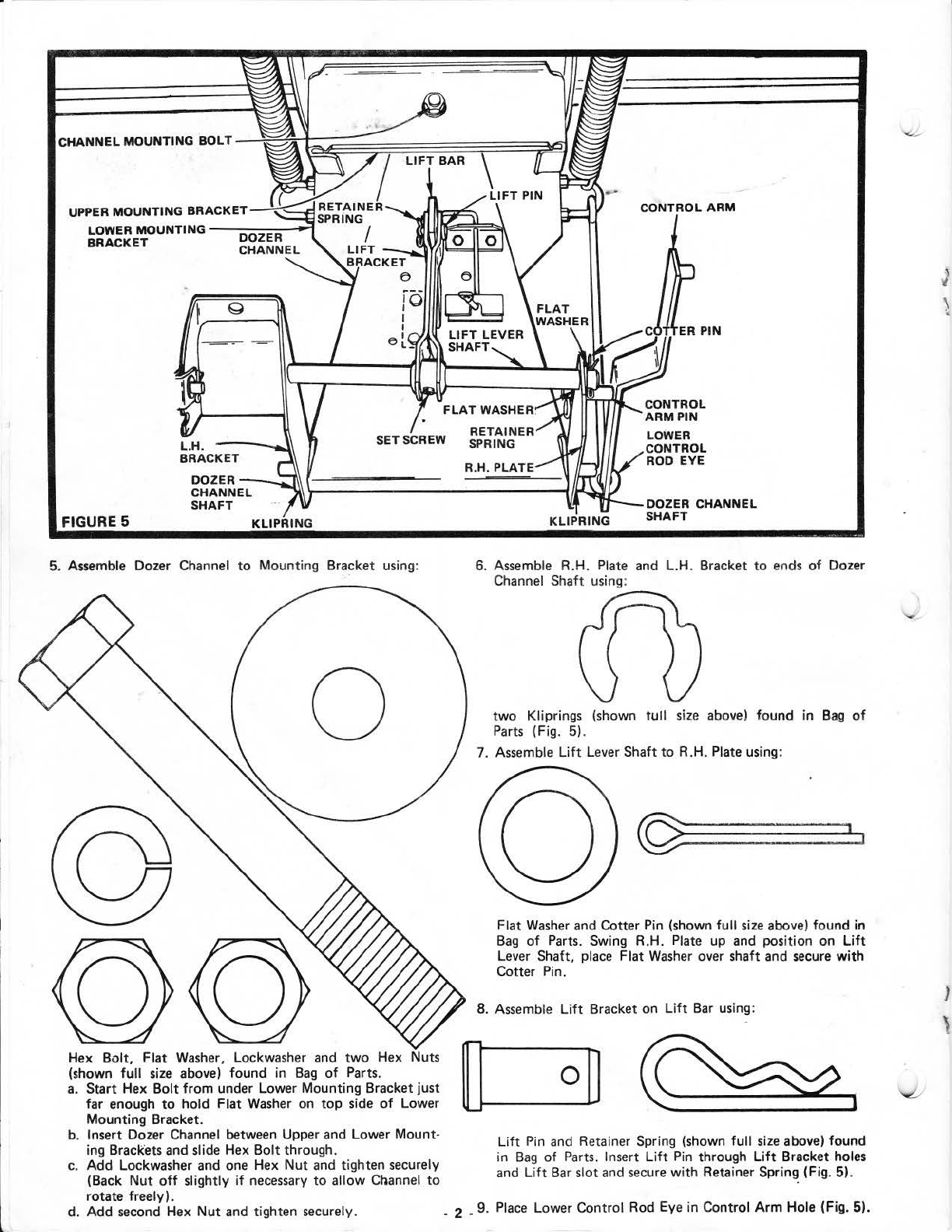

ADJUSTMENTS

1. Ll

FT

BLADE

Lift

Blade

from

ground before changing blade angle

or

trans·

porting.

a.

Squeeze

Lever Plunger (Fig. 6).

b. Move Lever

to

Lowest position on Lever Quadrant and

re

·

~

l

ease

Plunger

to

hold

this position.

c=::!J

2 . ANGLE BLADE

Flat Washer, Retainer Spring,

two

Hooks, Control Chain,

and Return Spring

found

in

Bag

of

Parts.

a.

Insert Control Rod

into

eye

of

Control Rod Guide

(Fig. 6).

b.

Place

Control Rod Pin

into

Control

Arm

Bushing, place

washer over Pin and

secure

with

Retainer Spring (Fig. 6

-Inset).

c.

Assemble

two

Hooks

into

Latch Lever and Control Rod

Strap (Fig. 6 - Inset).

d. Connect Control

Cha

in

to

hooks (Fig.

6-

Inset).

e. Assemble Return Spring

to

Latch Lever and Dozer

Channel (Fig, 6 - Inset). .

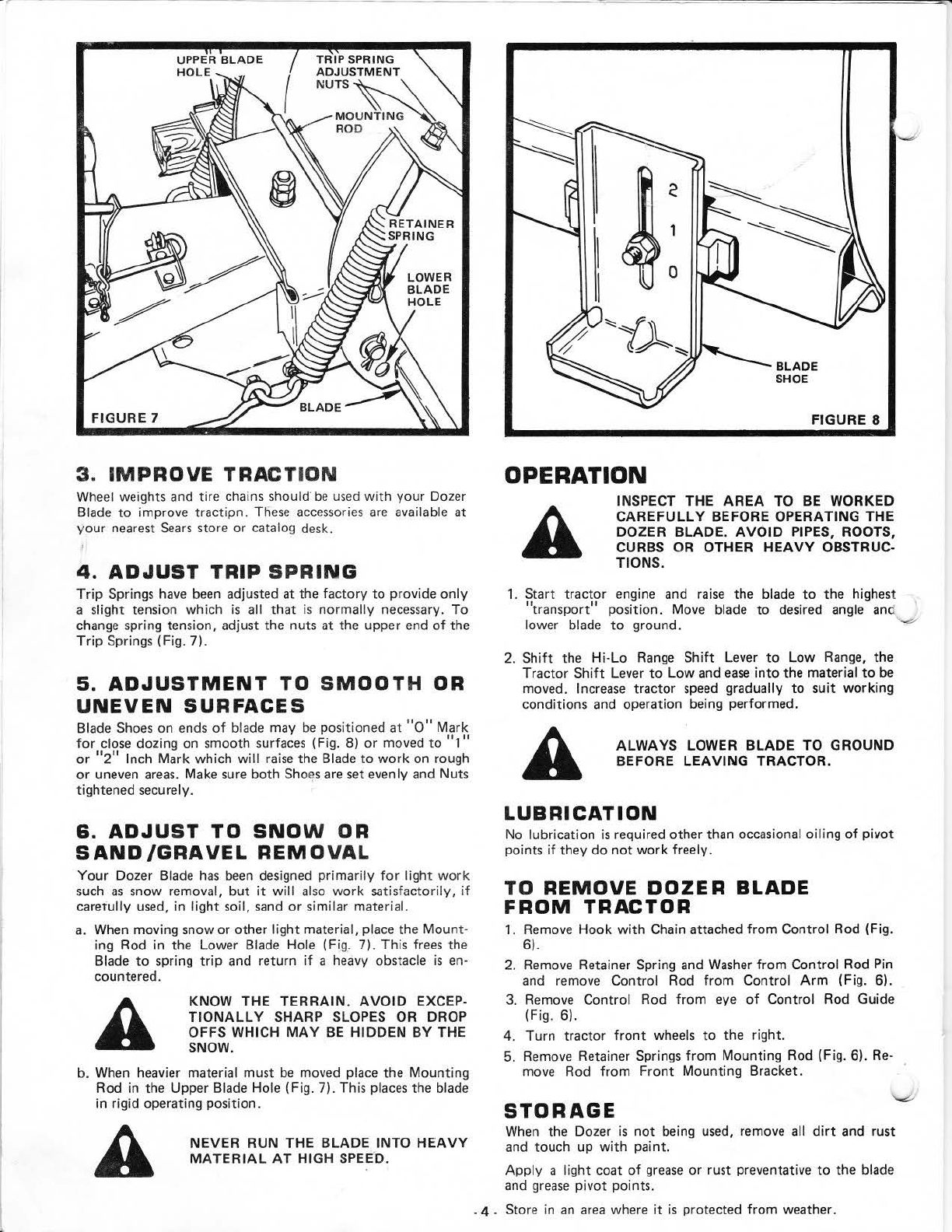

3.

There

are

five blade

pos

itions; straight ahead, and

two

distinct

angles

to

the right

or

left.

ALWAYS

LIFT

BLADE

FROM

GROUND TO CHANGE

ANGLE

PREVENTING

STRAIN

ON

ANGLE

CONTROL

LINKAGE.

a.

Turn Control Rod

to

Blade Angle

"Adjusting"

Position

(Fig. 6). .

b.

Push

or

Pull Rod

to

desired

an9tle.

c.

Turn Control Rod

to

Blade Angle

Set"

Position. Make sure

Latch Pin catches in one

of

the five Blade Angle

Adjustin~

Holes (Fig.

6-

Inset).

another free manual from www.searstractormanuals.com