Cleanburn Sonderskoven Inset User manual

V05.11

Sønderskoven Inset

Multi-Fuel Inset Stove

Installation and Operating Instructions

General Guidance

It is important that your stove is correctly installed as

Cleanburn Stoves cannot accept responsibility for any

fault arising through incorrect use or installation.

These instructions cover the basic principles to

ensure satisfactory installation of the stove, although

detail may need slight modification to suit particular

local site conditions.

The installation must comply with current Building

Regulations, national and European standards, Local

Authority byelaws and other specifications or

regulations as they affect the installation of the stove.

The Building Regulations requirements may also be

met by adopting the relevant recommendations in

the current issues of British Standards BS 8303 and BS

EN 15287-1.

COMPETENT PERSONS SCHEME

Cleanburn Stoves recommend that this stove is

installed by a member of an accredited competent

persons scheme e.g. HETAS.

If the installer is not a member of a competent

persons scheme, it is a legal requirement to notify

your local building control body in advance of any

work starting.

HEALTH AND SAFETY PRECAUTIONS

Special care must be taken when installing the stove

such that the requirements of the Health and Safety

at Work Act are met.

HANDLING

Adequate facilities must be available for loading,

unloading and site handling.

FIRE CEMENT

Some types of fire cement are caustic and should not

be allowed to come into contact with the skin. In case

of contact, wash immediately with plenty of water.

ASBESTOS

This stove contains no asbestos. If there is a

possibility of disturbing any asbestos in the course of

installation then please seek specialist guidance and

use appropriate protective equipment.

METAL PARTS

When installing or servicing this stove, care should be

taken to avoid the possibility of personal injury.

MODIFICATION

No unauthorized modification of this appliance

should be carried out.

Safety

WARNING –This appliance will be hot when in

operation and due care should be taken. The supplied

gloves may be used to open the door and operate the

air controls.

AEROSOLS

Do not use an aerosol spray on or near the stove

when it is alight.

FIREGUARDS

Always use a fireguard in the presence of children,

the elderly or the infirm. The fireguard should be

manufactured in accordance with BS8423 –

Fireguards for use with solid fuel appliances.

DO NOT OVER-FIRE

It is possible to fire the stove beyond its design

capacity. This could damage the stove so watch for

signs of over-firing. If any part of the stove starts to

glow red, the stove is in an over-fire situation and the

controls should be adjusted accordingly. Never leave

the stove unattended for long periods without first

adjusting the controls to a safe setting. Careful air

supply control should be exercised at all times.

FUME EMISSION

Properly installed and operated, this appliance will

not emit fumes. Occasional fumes from de-ashing

and refueling may occur. Persistent fume emission

must not be tolerated.

This appliance should not be operated with the

doors open

If fume emission does persist then the following

action should be taken immediately;

Open Doors and windows to ventilate room.

Let the fire out, or eject and safely dispose of fuel

from the appliance.

Check for flue/chimney blockage and clean if

required.

Do not attempt to relight the fire until the cause

has been identified and corrected.

If necessary seek professional advice.

ADVERSE WEATHER

In a small number of installations, occasional local

weather conditions (e.g. wind from a particular

direction) may cause downdraught in the flue and the

stove to emit fumes. In these circumstances the stove

should not be used. A professional flue installer will

be able to advise on solutions to this problem (e.g.

anti-downdraught cowl).

DO NOT FIT AN EXTRACTOR FAN IN THE SAME

ROOM AS THIS APPLIANCE.

IN THE EVENT OF A CHIMNEY FIRE -

Raise the alarm

Call the Fire Brigade

Close appliance air controls

Move furniture, ornaments etc away

Place a fireguard in front of stove

Check the chimney breast for signs of excessive

heat.

If the wall is becoming excessively hot, move

furniture away. Ensure the Fire Brigade can gain

access to your roof space in order to check for fire

spread.

Installation

APPLIANCE DIMENSIONS

FLUE OUTLET POSITION

The flue outlet angle is 30°. The effective centre

dimension is shown below.

AIR SUPPLY

The room or space containing this appliance should

have purpose provided ventilation (where necessary)

in accordance with Building Regulations.

Due consideration should be given to air

requirements for any other appliance in the same

room or space.

Any air opening must be kept clear from blockage or

obstruction.

APPLIANCE OPENING

FLUE CONNECTION -All inset installations must have a

‘Throat Forming Lintel’, if a ‘Builders Opening Lintel

is present then this will have to be modified for

these units to be fitted.

This stove must be fitted on a hearth or base with

adequate load-bearing capacity.

The opening into which this stove is fitted should be

constructed wholly from non-combustible materials.

The dimensions of the opening should be at least

those shown in the diagram.

This appliance will fit into a standard 16” fireplace

opening if the clay fireback is removed.

Any non-combustible walls within 50mm of this

appliance should be at least 200mm thick and

should extend at least 300mm above the top of the

appliance and at least 1.2 metres above the hearth.

Any walls more than 50mm from the appliance may

be reduced to a thickness of 75mm. Ensure the inter-

connecting flue pipe also has adequate clearances to

combustible materials.

The walls surrounding the stove will become hot and

should therefore be finished in a heat resistant

plaster.

Do not hang pictures, plasma screen televisions or

ornaments above the stove, as these could be

damaged and could potentially create a fire hazard.

Please check the suitability of any

fireplace/surround for closed solid fuel appliances

before installation. Cleanburn Stoves cannot be held

responsible for any fault arising through incorrect

use or installation. Fire surround back panels

suitable for solid fuel are usually in three sections

and slabbed. Many fire surrounds are suitable only

for use with gas and electric fires and therefore not

suitable for solid fuel.

HEARTH REQUIREMENTS

A constructional hearth with a minimum thickness of

125mm should be provided. This constructional

hearth should extend to at least 300mm in front of

the stove and 150mm at the sides.

The constructional hearth should be made of solid

non-combustible material and can include any solid

non-combustible floor. The boundary of the hearth

must be clearly marked. This can be done by adding a

super-imposed hearth on top of the constructional

hearth –e.g. a slate slab on top of a solid concrete

floor.

FLUE REQUIREMENTS

The flue serving this appliance must be dry,

free from cracks and obstructions and be in

accordance with the designations shown in

Table 1.

The diameter of the flue should not be less

than 150mm and not more than 200mm.

If these requirements are not met the chimney

should be lined by a suitable method.

If there is no existing chimney then either a

prefabricated block chimney in accordance

with Building Regulations Approved Document

J or a twin-walled insulated stainless steel flue

to BS EN 1856 can be used. These chimneys

must be fitted in accordance with the

manufacturer’s instructions and Building

Regulations.

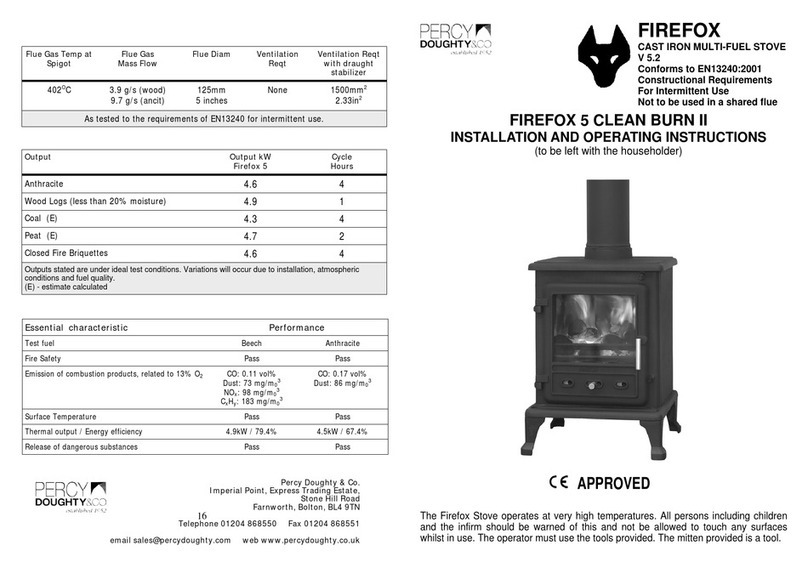

Flue Type

Minimum Designation

Masonry or flue block flue

with liner

T400 N2 D3 G

(BS EN 1443:2003)

Clay Flue Blocks

FB1 N2

(BS EN 1806:2006)

Clay/Ceramic Liners

B1 N2

(BS EN 1457:2009)

Concrete Liners

B2

(BS EN 1857:2003)

Factory Made Metal

Chimney

T400 N2 D3 G

(BS EN 1856-1:2003)

Table 1 –Minimum Flue Designations

The chimney/flue should have a vertical height

of at least 4.5 metres and should terminate in

accordance with Table 2.

If the chimney is believed to have previously

served an open fire installation, it is possible

that the higher flue gas temperature from the

stove may loosen deposits that were previously

firmly adhered, with the consequent risk of

flue blockage. It is therefore recommended

that the chimney is swept a second time within

a month of regular use after installation.

If you have any doubts about the suitability of

your chimney, consult your local

dealer/stockist.

Both the chimney and flue pipe must be

accessible for cleaning and if ANY part of the

chimney cannot be reached through the stove

(with baffle removed), a soot door must be

fitted in a suitable position.

FLUE DRAUGHT

If the draught exceeds the recommended

maximum, a draught stabiliser must be fitted

so that the rate of burning can be controlled

and to prevent over firing.

If the reading is less than the recommended

minimum then the performance of the

appliance will be compromised.

The flue draught should be checked under fire

at high output.

Minimum Draught –1.2mm Water Gauge

Maximum Draught –2.5mm Water Gauge

CLEARANCES TO COMBUSTIBLE MATERIALS

There should be no combustible materials for a

distance of 250mm either side of the stove or 325mm

above. No combustible furniture should be placed

any closer than 900mm from the front of the stove.

Terminal

Position

Clearances to Flue

Outlet

a

At or within 600mm of

the ridge

At least 600m above the ridge

b

Elsewhere on a roof

(whether pitched or

flat)

At least 2300mm horizontally

from the nearest point on the

weather surface and:

a) At least 1000mm above the

highest point of intersection of

the chimney and the weather

surface or

b) At least as high as the ridge

c

Below (on a pitched

roof) or within

2300mm horizontally

to an openable

rooflight, dormer

window or other

opening.

At least 1000mm above the top

of the opening.

d

Within 2300mm of an

adjoining or adjacent

building, whether or

not beyond the

boundary.

At least 600mm above any part

of the adjacent building within

2300mm

Table 2 –Flue Terminal Positions

REMOVING INTERNAL COMPONENTS

All internal components must be removed prior to

fitting the stove. This will make handling the stove

easier; allow access to fixings and the flue outlet; as

well as protect the internal components from

damage during the installation process.

1. Open the door(s) and remove the ash pan.

2. Remove the fuel retainers by turning them

towards you until the pins at the ends of them

align with the cut-outs in the fuel retainer

supports and sliding them out.

3. Remove the fuel retainer supports by lifting them

free from the slots in the catch bar and swinging

the bottom ends out of the stove.

4. Slide the side bricks out.

5. Remove the rear bricks.

6. Remove the lower rear brick support using the

finger hole provided to lift it from its slots.

7. Cut the cable ties and remove the baffle by rolling

it up over the baffle supports and out of the stove.

8. Remove the grate bars, starting with the high

bars.

9. Remove the firebox side plates.

10. Remove the catch bar/front plate.

11. Detach the cam bar linkage arm from the front

cam bar, rotate the cam bar and lift it out.

12. Lift out the rear cam bar along with the cam bar

linkage arm.

13. Lift out the primary air duct.

14. Lift out the primary air valve slider.

15. Undo the four M6 x 25mm screws and remove

the primary air valve and gasket.

16. Slide the primary air valve control arm all the

way to the left.

INSTALLATION INSTRUCTIONS

1. Using the diagram below, mark and drill a hole

using a 6mm drill bit to a depth of 70mm.

2. Slide the stove into position, ensuring that the

sealing rope is compressed against the fireplace

and fix using the supplied fixing screw (with

washer).

Any voids around the stove must be In-filled

with vermiculite concrete with a

recommended mix of six parts vermiculite to

one part Ordinary Portland Cement. This may

be carried out once the flue has been fitted

provided a suitable access hole for backfilling

is made in the chimney breast (see section on

connecting to a masonry chimney). Sufficient

water should be added so that when a handful

of the mixture is squeezed no more than one

or two drops of water are released.

FLUE CONNECTION

If connecting to a stainless steel liner, a liner clamp

(HHN07/ARRT/003) will need to be used.

The clamp should be connected to the liner by a

proprietary flexible liner to single wall flue adaptor

using the three fixing holes in the clamp socket and

those provided in the flue adaptor.

The clamp can be attached to the bottom of the

liner without the appliance fitted. Apply fire

cement to the inside of the stove’s flue collar. The

stove can then be set back in the recess and the

liner clamped onto the stove by passing the clamp

fixing bolts through the flue outlet and securing in

place using the clamping flange and nuts and

washers provided. Make sure all joints are sealed

with fire cement.

If connecting to an existing masonry chimney it is

recommended that a flue forming pipe (short length

of flue pipe) is used and the void between the flue

forming pipe and the chimney filled with vermiculite

concrete.

A suitable access hole will need to be made in the

chimney breast to allow the back filling to be carried

out and then filled and sealed once the installation is

complete.

Alternatively a connection can be made using a

register plate although it will be necessary to allow

access for fitting the flue pipe to the register plate,

infilling with vermiculite concrete and sealing all

joints.

RE-ASSEMBLING THE STOVE

Refit all the internal parts by following the ‘removing

internal components’ instructions in reverse order.

Ensure that the firebox side plates are refitted using

the following procedure.

Insert the side plate so that the front end of it locates

under the front plate/catch bar as shown.

Ensure that the back end of the side plate is outside

the rear grate support as shown.

Lower the side plate into position so that the top

surface of it is flush with that of the front plate/catch

bar as shown.

COMMISSIONING

Upon completion of the installation allow a suitable

period of time for any fire cement and mortar to dry

out. A small fire may then be lit and the installation

checked to ensure the smoke and fumes are drawn

up the flue and emitted safely to atmosphere. The

stove should not be run at full output for at least 24

hours.

Read the Operating Instructions before lighting the

stove for the first time.

Leave the instructions and operating tool(s) with the

customer and advise them on -

Correct use of the appliance

The recommended fuel

Action to be taken should smoke or fumes be

emitted from the stove or installation.

The use of a fireguard when the stove is used in

the presence of children or the infirm.

Operating Instructions

Read the ‘General Guidance’ Section at the start of

these instructions before operating your stove for

the first time.

Allow sufficient clearance between the stove and

pictures, plasma screen televisions or ornaments etc,

as these could be damaged and could potentially

create a fire hazard (For more information read the

‘Clearance Distances to Combustibles’ section of the

installation instructions).

WARNING –This appliance will be hot when in

operation and due care should be taken. The

supplied operating tool or gloves may be used to

open the door and operate the air controls.

AEROSOLS

Do not use an aerosol spray on or near the stove

when it is alight.

AIR CONTROLS

Installed and used correctly this stove will burn

cleanly and efficiently. Therefore, to avoid the

disappointment of poor performance, please

familiarize yourself with the controls and their

recommended settings before use.

PRIMARY AIR

The slider at the bottom of the stove controls the

primary air. This provides a conventional air draught

to the bed of the fire. The control is open when the

slider is fully to the right.

SECONDARY &TERTIARY AIR

Secondary air is controlled via the slider above the

door(s), it is this “Airwash” that keeps a clean and

uninterrupted view of the fire.

Tertiary air is fixed and enters the stove through the

holes at the back of the firebox. It aids in good

secondary combustion and reduces emissions into

the chimney and environment.

Warning! - This Appliance will be hot when in

operation and due care should be taken.

We advise that suitable gloves are used when

operating the Primary and Secondary air controls,

and when opening the door.

MULTIFUEL GRATE

Your Cleanburn Stove is fitted with a locomotive type

grate. So that de-ashing can be carried out cleanly

and easily, it is riddled from the outside of the stove

with the doors closed. The grate is designed to burn

both wood and solid fuels.

BURNING SOLID MINERAL FUELS

Place the operating tool over the riddling spigot and

push it up away from you. When left in that position,

air is directed under and up through the slots in the

firebed, giving the optimum conditions for burning

solid fuels.

It is important that the riddling tool is used to remove

the ash to ensure airflow through the firebed and

allow the fire to burn over the entire area of the

grate.

The ash pan should be emptied at least daily and ash

should never be allowed to build up over a period of

time as this will result in damage to the fire bars. The

flat end of the riddling tool can be used to carry the

ash pan.

BURNING WOOD

Pull the operating tool down and towards you. When

left in this position, air is restricted through the bed

of the fire providing a solid base to build up a bed of

ash. Surplus ash can be removed either by gentle

riddling or with a shovel.

It might prove beneficial when burning more reactive

fuels to leave the grate in a “neutral” position, thus

directing some under fire air and some over fire air to

the firebed.

LIGHTING

We recommend that you have two or three small

fires before you operate your stove to its maximum

heat output. This is to allow the paint to cure in

steadily and to give a long service life to the paint

finish. During this curing in process you may notice

an unpleasant smell. It is non-toxic, but for your

comfort we would suggest that during this period

you leave all doors and windows open.

To light the fire, load the firebox with starting fuel,

i.e. paper, dry sticks and/or firelighters. Fully open

both air controls (by sliding fully to the right) and

light the fire at the base.

Wood burning; Once the fire is established, close the

Primary Air Control (slide fully to the left) and add

more fuel as necessary. The secondary Air control can

now be used to regulate the burn rate of the stove.

When the stove is up to operating temperature the

operating tool or gloves should be used to operate

the air controls.

Smokeless fuel burning; Once the fire is established,

adjust the Secondary Air Control to a reduced setting

(slide to the left) and add more fuel as necessary. The

Primary Air control can now be used to regulate the

burn rate of the stove. When the stove is up to

operating temperature the operating tool or gloves

should be used to operate the air controls.

REDUCED COMBUSTION

In order to shut down the stove, reduce the primary

and secondary air by sliding both controls to the left.

If the controls are left in this position, the fire will be

starved of air and will die down.

If you want to revive the fire it is recommended that

the primary air control is opened first, and then the

secondary air control.

Warning!- The stove will remain hot for a

considerable time after the fire has been

extinguished.

RECOMMENDED FUELS

Cleanburn Stoves recommend that wood logs or

approved smokeless fuels are burnt in this appliance.

Burn only dry, well-seasoned wood, which should

have been cut, split and stacked for at least 12

months, with free air movement around the sides of

the stack to enable it to dry out.

Burning wet or unseasoned wood will create tar

deposits in the stove and chimney and will not

produce a satisfactory heat output.

Only authorised smokeless fuels may be used in

smoke control areas.

Warning! - Petroleum coke fuels or household waste

must not be burnt on this appliance.

This appliance should not be used as an incinerator.

No liquid fuels should be burnt on this appliance.

Should any difficulties arise over fuel quality or

suitability, consult your local approved coal merchant

or:

HETAS Ltd –Telephone 01242 673257 –

www.hetas.co.uk

Solid Fuel Association –Telephone 0800 600 000 –

www.solidfuel.co.uk

General Maintenance

Important! –In order to ensure continued

compliance with current Building Regulations and

Local Authority Byelaws, this appliance requires

regular maintenance of the following –

N.B. Refer to the ‘Removing Internal Components’

section of the installation instructions for details on

how to remove each component.

PERIODS OF PROLONGED NON-USE

If the stove is to be left unused for a prolonged

period, then it should be given a thorough clean to

remove ash and unburned fuel residues. To enable a

good flow of air through the appliance to reduce

condensation and subsequent damage, leave the air

controls fully open.

If the appliance has been unused for a long period,

such as during the spring and summer months, a

competent person should check the chimney for

potential obstructions before lighting the stove i.e.

get the chimney swept before the start of the

heating season.

AS NECESSARY

Baffle- This should be removed and cleaned at least

once a month to prevent any build up of soot or fly

ash that could lead to blocked flue ways and

dangerous fume emission.

If the baffle is removed the chimney/flue way can be

swept through the appliance.

Stove body –the stove is finished with a heat

resistant paint and this can be cleaned with a soft

brush. Do not clean the stove whilst it is hot; wait

until it has cooled down. The finish can be renovated

with proprietary stove paint.

Glass Panel(s) - Clean the glass panel when cool with

proprietary glass cleaner.

Highly abrasive substances should be avoided as

these can scratch the glass and make subsequent

cleaning more difficult.

Wet logs on heated glass, a badly aimed poker or

heavy slamming of the door could crack the glass

panel.

The glass will not fracture from heat.

Firebricks- In normal use, these can last for many

years. It is possible however, to crack them if logs are

continually jammed against them or if they are

frequently struck with a poker.

Check periodically for seriously cracked bricks, which

can be replaced with new, available from your dealer.

Door Catch- The door catch may require adjustment

to maintain the door seal. To adjust the catch, follow

the appropriate procedure below;

For Single-Door Stoves

Loosen the M8 nut.

Rotate the catch one complete turn to achieve

the correct door operation.

Tighten the M8 nut.

For Double-Door Stoves

Loosen the M6 grub screw.

Rotate the catch shaft one complete turn to

achieve the correct door operation.

Tighten the grub screw.

Rope- Check the rope around the door. If rope is

becoming detached, use Cleanburn Stoves rope glue

to reattach it. If the rope is in a poor condition, a

replacement rope kit may be ordered from the

Cleanburn Stoves spares range.

Chimney & Flue Ways- It is important that the

chimney, flue ways and any connecting flue pipe are

swept regularly. This means at least once a year for

smokeless fuels and at least twice a year for wood

and other fuels.

The baffle will need to be removed from its supports

in order to sweep the chimney (see ‘Removing

internal components’ instructions).

Only wire-centred sweeps’ brushes fitted with a

guide wheel should be used.

If it is not possible to sweep all parts of the chimney

through the appliance, ensure there is adequate

access to cleaning doors.

Seasonal use- If the appliance has been unused for a

long period of time, such as during the spring and

summer months, the chimney should be checked for

potential obstructions by a competent person before

lighting the stove.

Gaskets- all gaskets used on this appliance are

produced from a heat resistant material called

Manniglas. The glass gasket will have to be replaced

when a new piece of glass is fitted as the gaskets

become brittle after firing the stove. Over time you

may find that the gasket changes colour. This is due

to a reduction in the pigment used in the

manufacture of the product and no cause for

concern.

Trouble Shooting

FIRE WILL NOT BURN

Check that –

Chimneys and flue ways are clear.

A suitable fuel is being used.

There is an adequate air supply into the room.

An extractor fan is not fitted in the same room as

the stove.

Flue draught is above minimum level (see

installation instructions).

FIRE BLAZING OUT OF CONTROL

Check that –

The door is tightly closed.

The air controls are in the closed position.

A suitable fuel is being used.

The glass is not loose.

The door rope seal is in good condition.

Flue draught is below maximum level (see

installation instructions).

Spares Information

Single Door

Spares Information

Right-Hand Door

Spares Information

Left-Hand Door

Spares Information

Single Door Handle

Spares Information

Double Door Handle

Spares Information

Single Door Body Spares

Table of contents

Other Cleanburn Stove manuals

Popular Stove manuals by other brands

Regency

Regency Ultimate U39E Series Owners & installation manual

KYOWA

KYOWA KW-3503 instruction manual

Ferroli

Ferroli LIRA PLUS Installation, use and maintenance manual

Heatilator

Heatilator Eco Choice PS50-C owner's manual

THERMOROSSI

THERMOROSSI CIAO manual

Morso

Morso 3112 Instructions for installation and use

Lopi

Lopi Cypress GSR owner's manual

INIS Stoves

INIS Stoves InisBofin User and installation manual

Percy Doughty & Co

Percy Doughty & Co FIREFOX 5 CLEAN BURN II Installation and operating instructions

Ravelli

Ravelli HRV160 manual

Morsø

Morsø 6840 Instructions for installation and use

WARRIOR Stoves

WARRIOR Stoves WSDBAR user manual