JINHCN05 RevE 22/07/14

If the appliance has been unused for a long period,

such as during the spring and summer months, a

competent person should check the chimney for

potential obstructions before lighting the stove i.e.

get the chimney swept before the start of the

heating season.

AS NECESSARY

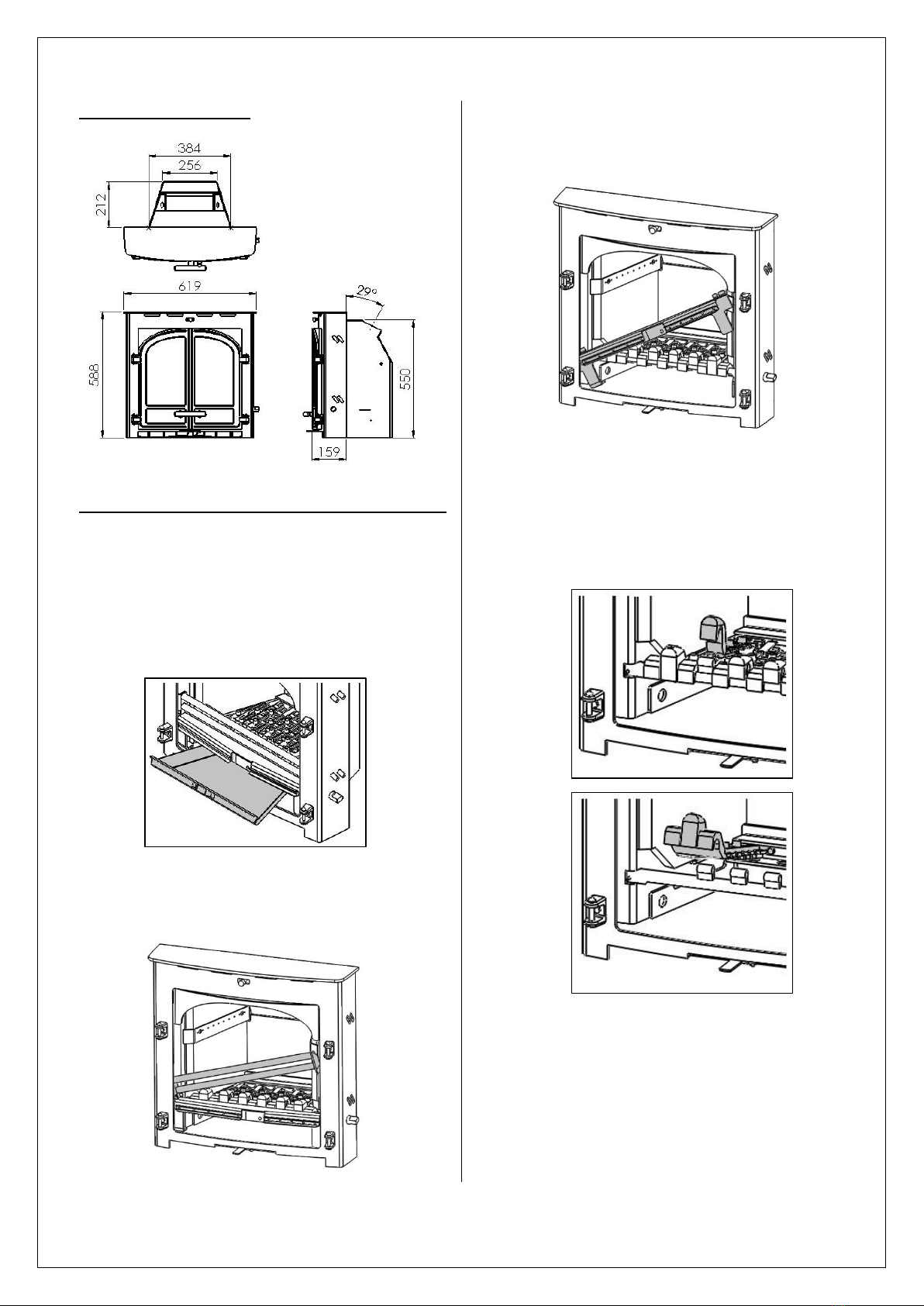

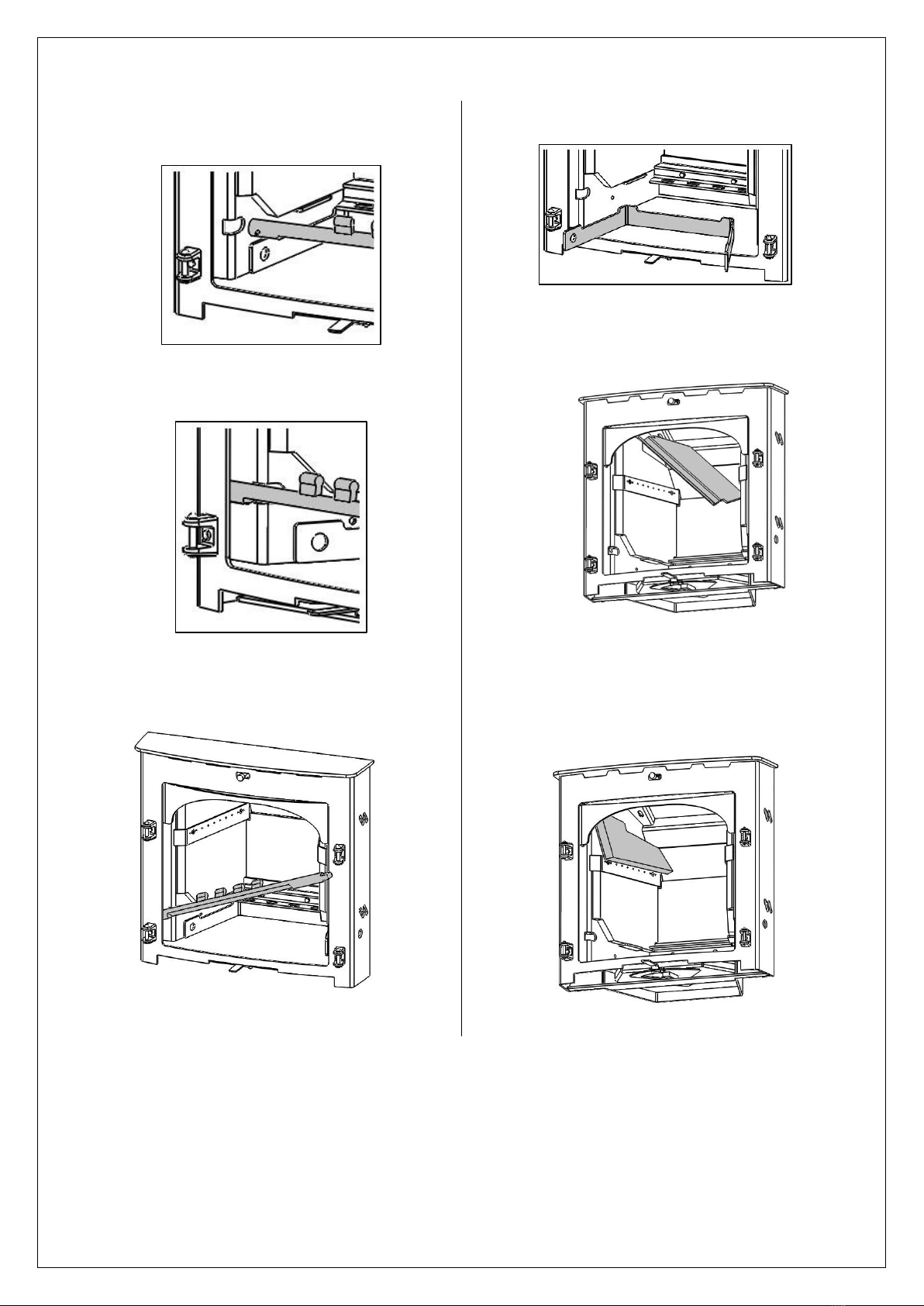

Baffle-This should be removed and cleaned at

least once a month to prevent any build up of soot

or fly ash that could lead to blocked flueways and

dangerous fume emission.

If the baffle is removed the chimney/flueway can

be swept through the appliance.

Stove body –the stove is finished with a heat

resistant paint and this can be cleaned with a soft

brush. Do not clean the stove whilst it is hot; wait

until it has cooled down. The finish can be

renovated with proprietary stove paint.

Glass Panel(s) - Clean the glass panel when cool

with proprietary glass cleaner.

Highly abrasive substances should be avoided as

these can scratch the glass and make subsequent

cleaning more difficult.

Wet logs on heated glass, a badly aimed poker or

heavy slamming of the door could crack the glass

panel.

The glass will not fracture from heat.

Firebricks -In normal use, these can last for many

years. It is possible however, to crack them if logs

are continually jammed against them or if they are

frequently struck with a poker.

Check periodically for seriously cracked bricks,

which can be replaced with new, available from

your dealer.

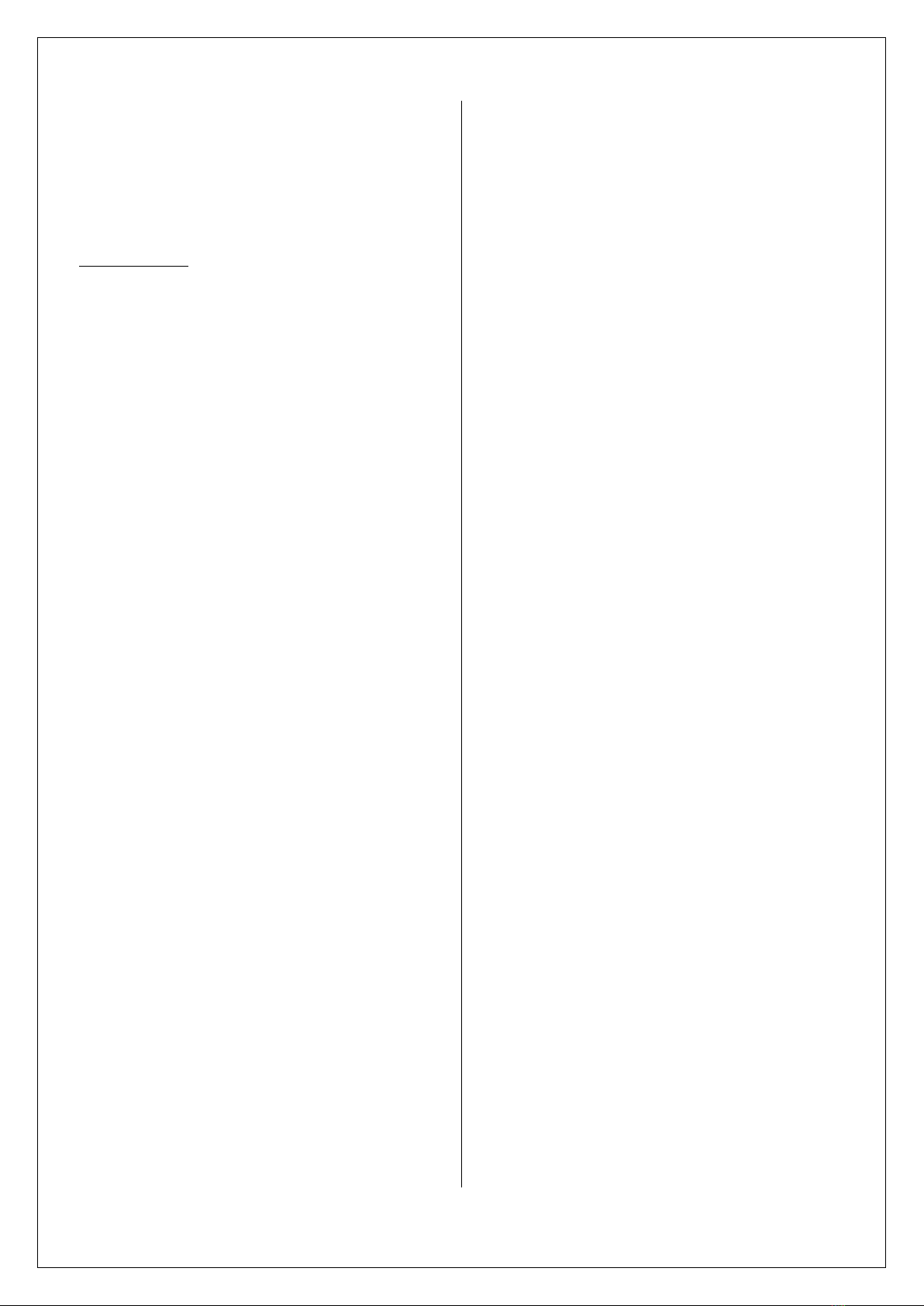

Door Catch -The door catch may require

adjustment to maintain the door seal. To adjust

the catch, follow the procedure below;

Loosen the M6 grub screw.

Rotate the catch shaft one complete turn to

achieve the correct door operation.

Tighten the grub screw.

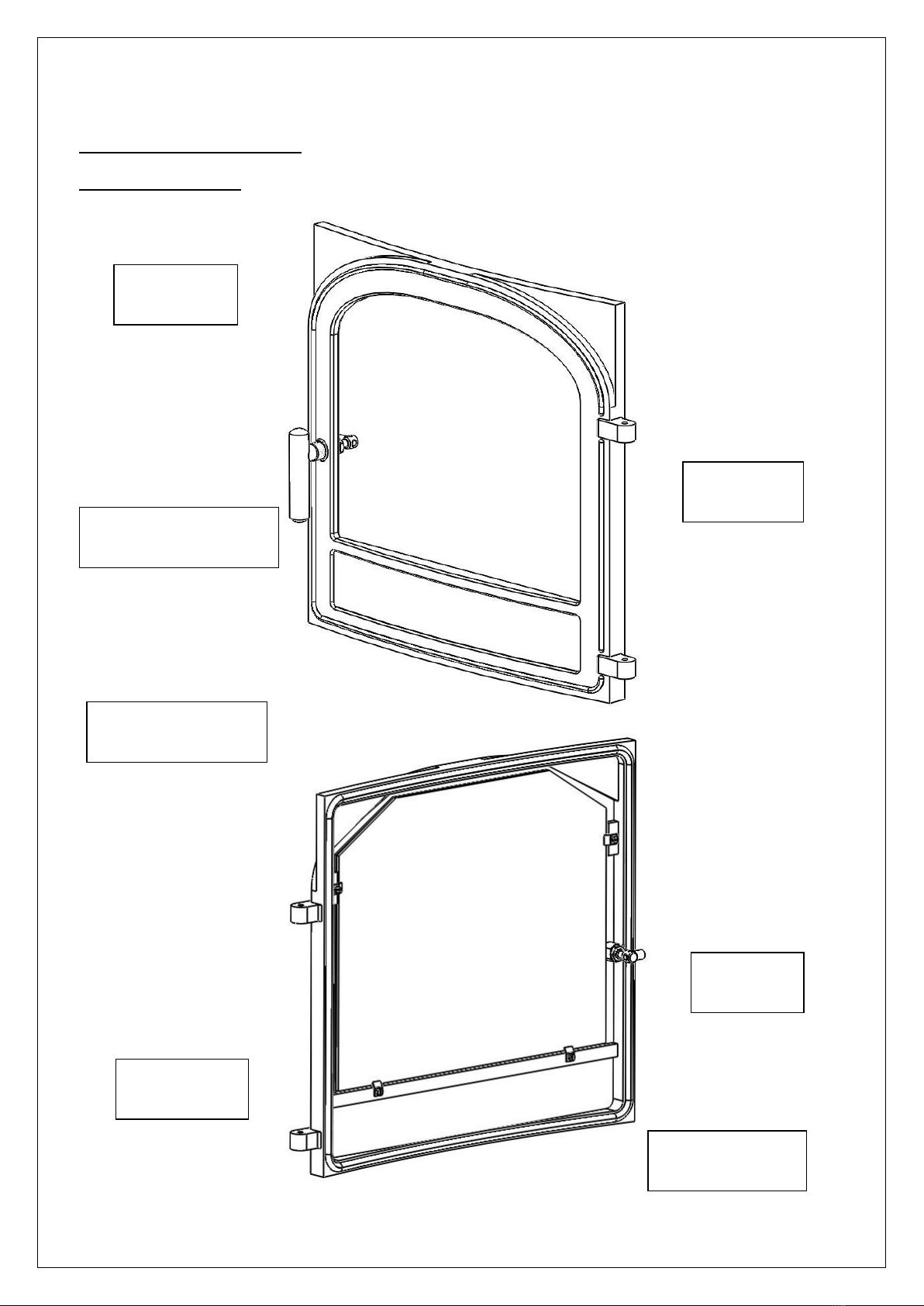

Rope - Check the rope around the door. If rope is

becoming detached, use Cleanburn Stoves rope

glue to reattach it. If the rope is in a poor

condition, a replacement rope kit may be ordered

from the Cleanburn Stoves spares range.

Chimney & Flueways - It is important that the

chimney, flueways and any connecting flue pipe

are swept regularly. This means at least once a

year for smokeless fuels and at least twice a year

for wood and other fuels.

The baffle will need to be removed from its

supports in order to sweep the chimney (see

‘Removing internal components’ instructions).

Only wire-centred sweeps’ brushes fitted with a

guide wheel should be used.

If it is not possible to sweep all parts of the

chimney through the appliance, ensure there is

adequate access to cleaning doors.

Seasonal use - If the appliance has been unused

for a long period of time, such as during the spring

and summer months, the chimney should be

checked for potential obstructions by a competent

person before lighting the stove.

Gaskets - all gaskets used on this appliance are

produced from a heat resistant material called

Manniglas. The glass gasket will have to be

replaced when a new piece of glass is fitted as the

gaskets become brittle after firing the stove. Over

time you may find that the gasket changes colour.

This is due to a reduction in the pigment used in

the manufacture of the product and no cause for

concern.

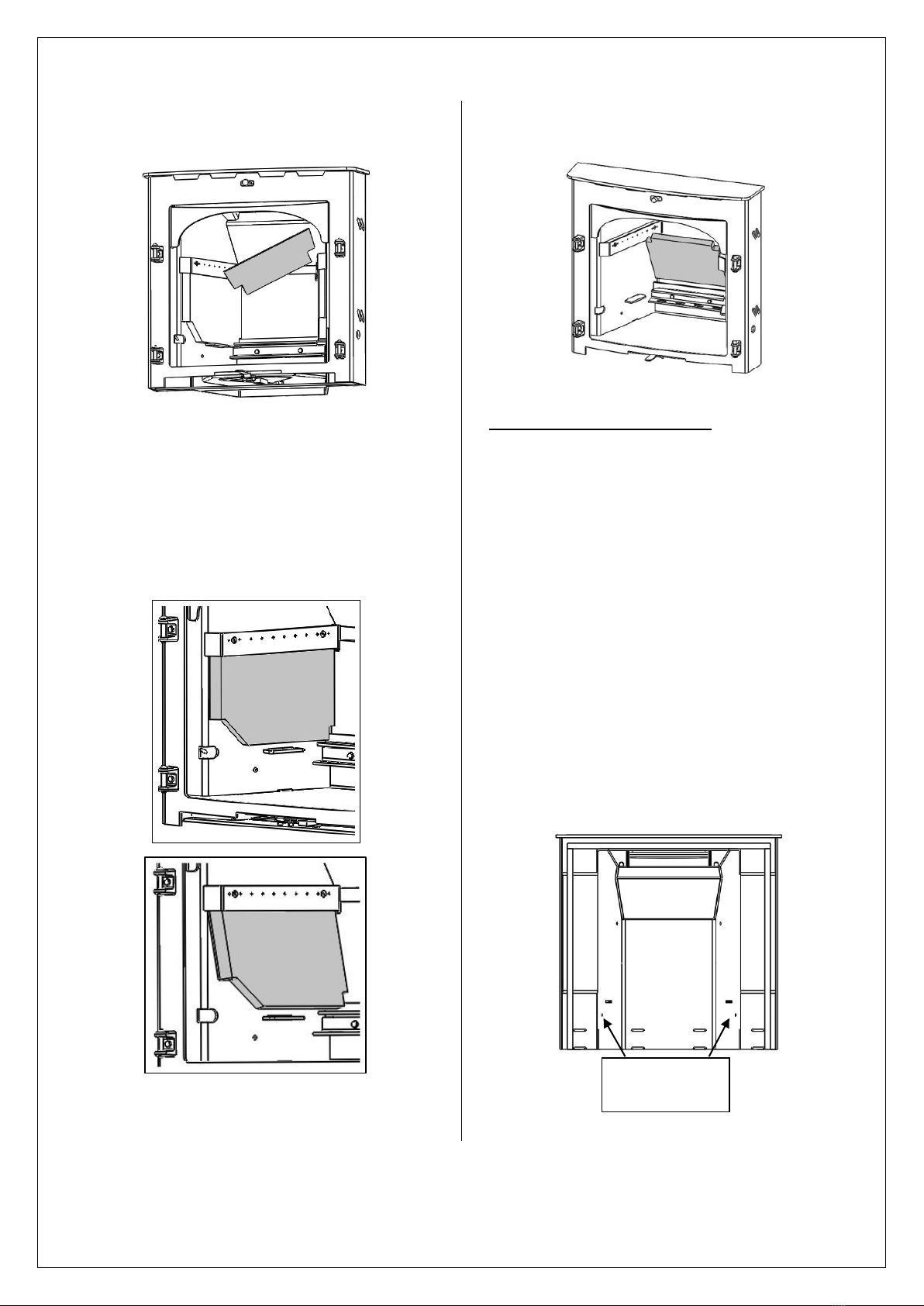

De-ashing –De-ashing should be carried out on a

regular basis to avoid a build up of ash and ensure

sufficient primary air flow. Empty the ashpan

regularly to prevent ash reaching the underside of

the great bars. At least every month remove the

ash barrier (see section ‘Removing Internal

Components’) and remove excess ash with a

vacuum cleaner.