CleanCraft SSM 281 User manual

Scrubbing vacuum cleaning machine

SSM 281

Operating Instructions

SSM 281

SSM 281

2 SSM 281 | Version 1.02

Imprint

Product identification

Machine type Item number

SSM 281 7252128

Manufacturer

St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.cleancraft.de

Indications regarding the operating instructions

Original instruction

Edition: 23.02.2021

Version: 1.02

Language: English

Author: RL

Indications regarding the copyright

Copyright © 2021 St rmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions is the sole

property of the company St rmer Maschinen GmbH.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not expli-

citly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Content

1 Introduction..................................................................3

1.1 Copyright ............................................................ 3

1.2 Costumer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety............................................................................3

2.1 Symbol explanation ............................................ 3

2.2 Obligations of the operating company ................ 4

2.3 Qualification of the staff ...................................... 5

2.4 Personal protective equipment ........................... 5

2.5 General safety instructions ................................. 5

2.6 Safety markings on the machine ........................ 6

2.7 Battery safety notes............................................ 6

2.8 Safety data sheets.............................................. 7

3 Intended Use ................................................................7

3.1 Misuse ................................................................ 7

3.2 Residual risks ..................................................... 7

4 Technical Data .............................................................8

4.1 Table................................................................... 8

4.2 Type plate........................................................... 8

Transport, Packaging, Storage...................................8

5.1 Transport ............................................................ 8

5.2 Packaging........................................................... 8

5.3 Storage ............................................................... 8

6 Description ...................................................................9

6.1 Scope of delivery .............................................. 10

6.2 Optional Accessoires........................................ 10

7 Before Commissioning .............................................10

7.1 Unpacking the machine .................................... 10

7.2 Assembling the machine................................... 10

7.3 Parking position of machine.............................. 11

7.4 Adjusting angle of the handle ........................... 11

7.5 Mounting the brush........................................... 12

7.6 Dirty water / Detergent tank.............................. 12

7.7 Adjusting the drive ............................................ 13

7.8 Battery charge indication (1, Fig. 3).................. 14

7.9 Care by cleaning............................................... 14

8 Operating....................................................................14

8.1 Description of the function keys........................ 14

8.2 Working with the machine................................. 14

8.3 Finishing work................................................... 15

9 Maintenance and Service/Repair..............................16

9.1 Cleaning the float.............................................. 16

9.2 Cleaning the water/cleaning agent tank filter.... 16

9.3 Cleaning the suction filter ................................. 16

9.4 Cleaning the suction hoses............................... 16

9.5 Cleaning the diverter valve ............................... 17

9.6 Cleaning the squeegee ledges ......................... 18

9.7 Adjusting the squeegee ledge .......................... 18

9.8 Replacing the suction lips................................. 18

9.9 Replace brush................................................... 19

10 Malfunctions, Possible Causes and Measures .....20

10.1 Troubleshooting.............................................. 20

11 Disposal, Recycling of old Equipment ..................22

11.1 Decommissioning ........................................... 22

11.2 Disposal of electrical equipment..................... 22

12 Spare Parts...............................................................22

12.1 Ordering spare parts....................................... 22

12.2 Spare parts drawings...................................... 23

13 Electrical circuit diagram ........................................34

14 EC - Declaration of Conformity ..............................3

Introduction

SSM 281 | Version 1.02 3

1 Introduction

You have made a good choice by purchasing the

CLEANCRAFT Scrubbing vacuum cleaning machine.

Read the operating manual thoroughly before com-

missioning the machine.

It gives you information about the proper commission-

ing, intended use and safe and efficient operation and

maintenance of your Scrubbing vacuum cleaning ma-

chine.

The operating manual is part of the Scrubbing vacuum

cleaning machine package. Always keep this operating

manual in the location where your Scrubbing vacuum

cleaning machine is being operated. All local accident

prevention regulations and general safety instructions for

the operating range of your Scrubbing vacuum cleaning

machine must also be complied with.

Illustrations in this operating manual serve the general

understanding and may deviate from the actual design.

1.1 Copyright

The contents of these instructions are copyright. They

may be used in conjunction with the operation of the

Scrubbing vacuum cleaning machine. Any application

beyond those described is not permitted without the writ-

ten approval of St rmer Maschinen GmbH. For the pro-

tection of our products, we shall register trademark, pa-

tent and design rights, as this is possible in individual

cases. We strongly oppose any infringement of our intel-

lectual property.

1.2 Costumer service

If you have questions about your machine or technical in-

formation, please contact your dealer. There you will be

happy to help with expert advice and information.

Germany:

St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair-Service:

Fax: 0049 (0) 951 96555-111

Email: [email protected]

Internet: www.cleancraft.de

Spare parts orders:

Fax: 0049 (0) 951 96555-119

Email: ersatz[email protected]

We are always interested in valuable experience and

knowledge gained from using the application-which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised while taking applicable standards and

rules, the state-of-the-art technology and our longterm

knowledge and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- Unauthorised modifications

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the ex-

planations and presentations described here in case of

special models, when using additional ordering options

or due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-ti-

ons of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This section provides an overview of all important safety

packages for the protection of operating personnel as

well as for safe and fault-free operation. Other task-ba-

sed safety notes are included in the paragraphs of the in-

dividual phases of life.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are introduced by

signal words which express the concern of the risk.

ANGER!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injury if not avoided.

4 SSM 281 | Version 1.02

Safety

Tips and recommenations

To reduce the risk of personal injury and property da-

mage and to avoid dangerous situations, the safety inst-

ructions in this manual must be observed.

2.2 Obligations of the operating company

The operating company is the person who operates the

Scrubbing vacuum cleaning machine for business or

commercial reasons by herself, or leaves it to a third

party for use or application, and who bears the legal pro-

duct responsibility for the protection of the user, the staff

or for third parties.

Obligations of the operator:

If the machine is used in the commercial sector, the ope-

rator of the machine is subject to the legal obligations for

occupational safety.

For this reason, the safety instructions in this operating

manual as well as the safety, accident prevention and

environmental protection regulations applicable to the

area of application of the machine must be observed.

The following applies in particular:

- The operating company must be informed about

the applying industrial safety regulations and fur-

ther analyse hazards resulting from the special

working conditions at the place of use of the Scrub-

bing vacuum cleaning machine. She must imple-

ment these in form of operating manuals for the

operation of the Scrubbing vacuum cleaning ma-

chine.

- During the entire lifetime the Scrubbing vacuum

cleaning machine, the operating company must

verify whether the operating manuals prepared by

her correspond to the current status of the regulati-

ons, and must adapt these if necessary.

- The operating company must unambiguously regu-

late and determine the responsibilities for installa-

tion, operation, troubleshooting, maintenance and

cleaning.

- The operating company must ensure that all per-

sons who work with the Scrubbing vacuum clea-

ning machine, have read and understood this ma-

nual. Furthermore she must instruct the staff in re-

gular intervals and inform them about the hazards.

Furthermore the operating company is responsible to

keep the Scrubbing vacuum cleaning machine always in

a technically flawless state. Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices checked

regularly for their good working order and their in-

tegrity.

WARNING!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to death or severe injury if not avoided.

CAUTION!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to slight or minor injury if not avoided.

ATTENTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

NOTE!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to material or environmental damage if not avoi-

ded.

Tips and recommendations

This symbol highlights useful tips and recommendati-

ons as well as information for efficient and trouble-

free operation.

Safety

SSM 281 | Version 1.02 5

2.3 Qualification of the staff

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

Operator

The operator is instructed by the operating company ab-

out the assigned tasks and possible risks in case of im-

proper behaviour. Any tasks which need to be performed

beyond the operation in the standard mode must only be

performed by the operator if it is indicated in these inst-

ructions and if the operating company expressively com-

missioned the operator.

Electrically qualified person

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-

edge of the relevant standards and regulations, in a po-

sition to carry out work on the electrical systems and to

independently recognize and avoid possible dangers.

Qualified personnel

Due to their professional training, knowledge and expe-

rience as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.4 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while wor-

king. The staff member has to wear personal protective

equipment while performing different tasks on and with

the machine which are indicated in the individual para-

graphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

2. General safety instructions

The following must be observed:

- Use the guards and fasten them securely. Never

work without guards and keep them in working or-

der.

- Always keep the machine an the work environment

clean. Always ensure that there is sufficient lighting.

- The scrubbing vacuum cleaning machine must not

be modified in its design and must not be used for

purposes other than those intended by the manu-

facturer.

- Never work under the influence of diseases that may

impair concentration, fatigue, drugs, alcohol or me-

dication.

- Keep children and persons unfamiliar with the scrub-

bing vacuum cleaning machine away from the work

area.

- Do not pull on the power cord to unplug it from the

wall socket. Protect the cord from heat, oil and sharp

edges.

- Immediately rectify any faults that affect safety.

- Make sure that the machine is operated in a suitable

power supply network.

- Protect the scrubbing vacuum cleaning machine

from moisture (risk of short circuit).

WARNING!

anger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the single-disc machine and expose

themselves and others to the danger of severe or let-

hal injuries.

- Have all works only performed by qualified per-

sons.

- Keep insufficiently qualified persons out of the wor-

king area.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed, fal-

ling parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

6 SSM 281 | Version 1.02

Safety

- Do not use the machine in explosive atmospheres.

- Do not vacuum flammable liquids or hazardous pow-

der.

- To avoid the formation of harmful gases, do not mix

cleaning agents of different types.

- Do not bump against shelves or scaffolding where

there is a risk of objects falling.

- Do not use acidic or alkaline solutions that may da-

mage the machine and/or endanger people.

- Before each use, make sure that no parts of the

scrubbing vacuum cleaning machine are damaged.

Damaged parts must be replaced immediately to

prevent hazards.

- Do not overload the scrubbing vacuum cleaning ma-

chine! You will work better and safer in the specified

performance range.

- Use only original spare parts and accessories to

avoid possible hazards and risks of accidents.

- Always keep the ventilation slots of the machine

clean. Always remove dirt with the main switch tur-

ned off. Never operate the machine if the air flow is

blocked.

2.6 Safety markings on the scrubbing vacuum

cleaning machine

Safety labels and instructions are attached to the scrub-

bing vacuum cleaning machine (Fig. 1) that must be ob-

served and followed.

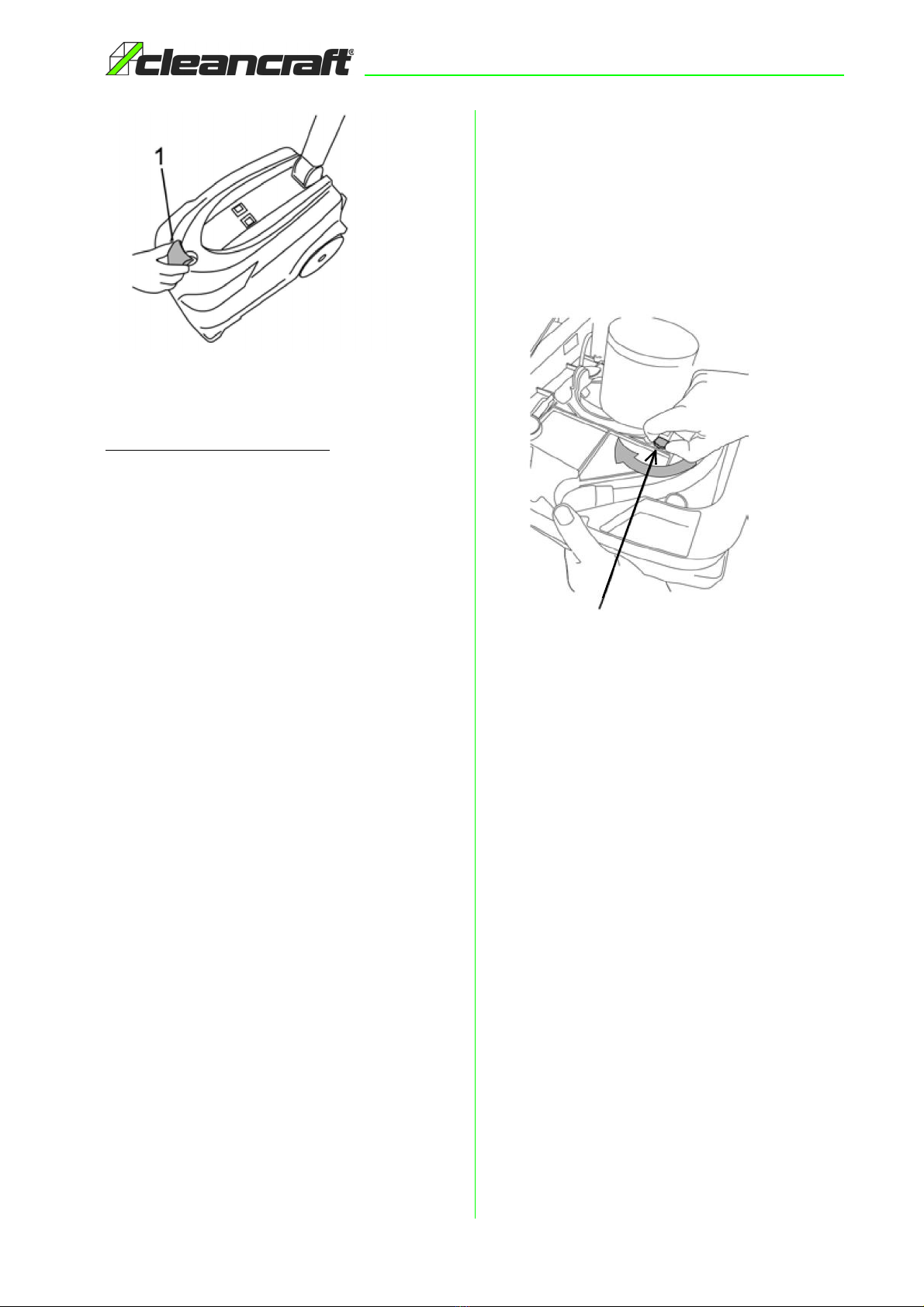

Fig. 1: Safety markings

2.7 Battery safety notes

- Take care when handling battery acid.

- Always keep the battery clean and dry to avoid leakage

currents on the surface.

- Protect the battery from contaminants such as metal

dust.

- Do not place tools on the battery. There is a risk of short

circuit and explosion.

- Only use the supplied charger to charge the battery.

- If the mains cable is damaged, do not use the charger.

To replace the cable, contact the Customer Service

Centre.

- Make sure that the battery charger sockets are properly

earthed and protected by a thermal magnetic switch.

ATTENTION!

Make sure that the brushes do not rotate when the

machine is at a standstill so that the floor is not

damaged!

Avoid any contact with moving parts of the machine

(brushes and drive).

Keep hair, loose clothing, fingers and all other body

parts away from slots and moving parts.

Set the speed according to the grip of the floor.

Do not use the machine on floors with a slope of

more than 2%.

ATTENTION!

This machine should be stored taking into account its

weight, i.e. on a stable, safe, level surface and only

in storage places without moisture.

ATTENTION!

Do not use or store the unit outdoors or in a humid

environment.

Storage temperature: -25° C ~ +55° C.

Operating temperature: 0° C and +40° C at relative

humidity of 30% to 95%.

ATTENTION!

Never leave the machine unattended. Always unplug

the machine from the mains when not in use and

keep it out of the reach of children or unauthorised

persons.

ATTENTION!

In case of liquid or foam leakage, switch off the

machine immediately.

ATTENTION!

The unit is not suitable for environments protected

against electrostatic discharge.

Intended Use

SSM 281 | Version 1.02 7

2.8 Safety data sheets

Safety data sheets for hazardous goods can be obtained

from your specialist dealer or by calling +49 (0)951 /

96555-0.

Specialist dealers can find safety data sheets in the

download area of the partner portal.

3 Intended Use

The scrubbing vacuum cleaning machine is suitable for

sweeping, washing and drying flat, horizontal, smooth or

moderately rough, evenly textured and obstacle-free

floors in private and industrial premises.

The machine may only be used for cleaning in indoor

areas or at least covered areas. The scrubbing vacuum

cleaning machine must not be operated in explosive en-

vironments.

Intended use also includes compliance with all the infor-

mation in these instructions.

St rmer Maschinen GmbH accepts no liability for design

and technical modifications to the scrubbing vacuum

cleaning machine.

Claims of any kind for damage due to improper use are

excluded.

3.1 Misuse

3.2 Residual risks

There are residual risks, which are listed below, even if

all safety instructions are observed and the machine is

used according to the instructions:

- Risk of injury to upper limbs (e.g. hands, fingers).

- Risk of short-circuit between the battery terminals du-

ring charging.

- Skin irritation when using cleaning agents.

- Never clean floors with a height gradient greater than

that indicated on the machine.

- Do not use at altitudes above 2000m.

ATTENTION!

Any modification of the appliance is prohibited. Modi-

fication may result in fire and injury, including death,

to the user, in addition to invalidating the warranty.

The manufacturer accepts no liability for damage

caused to property or persons as a result of failure to

comply with these instructions or in the event of

misuse of the appliance.

WARNING!

anger in case of misuse!

Misuse of the scrubbing vacuum cleaning machine

can lead to dangerous situations.

- Only operate the scrubbing vacuum cleaning ma-

chine in the power range specified in the technical

data.

- Never bypass or override the safety devices.

- Only operate the scrubbing vacuum cleaning ma-

chine when it is in perfect working order.

ATTENTION!

- The machine is not suitable for vacuuming hazar-

dous dust or other hazardous materials. Never va-

cuum incandescent, flammable, explosive or toxic

substances. The maximum permissible tempera-

ture for use is 40°C / 104°F.

- Do not vacuum aggressive cleaning agents, as

these could damage the appliance.

- Do not vacuum any materials that could damage

the filter elements (e.g. glass splinters, metal, etc.).

8 SSM 281 | Version 1.02

Technical ata

4 Technical Data

4.1 Table

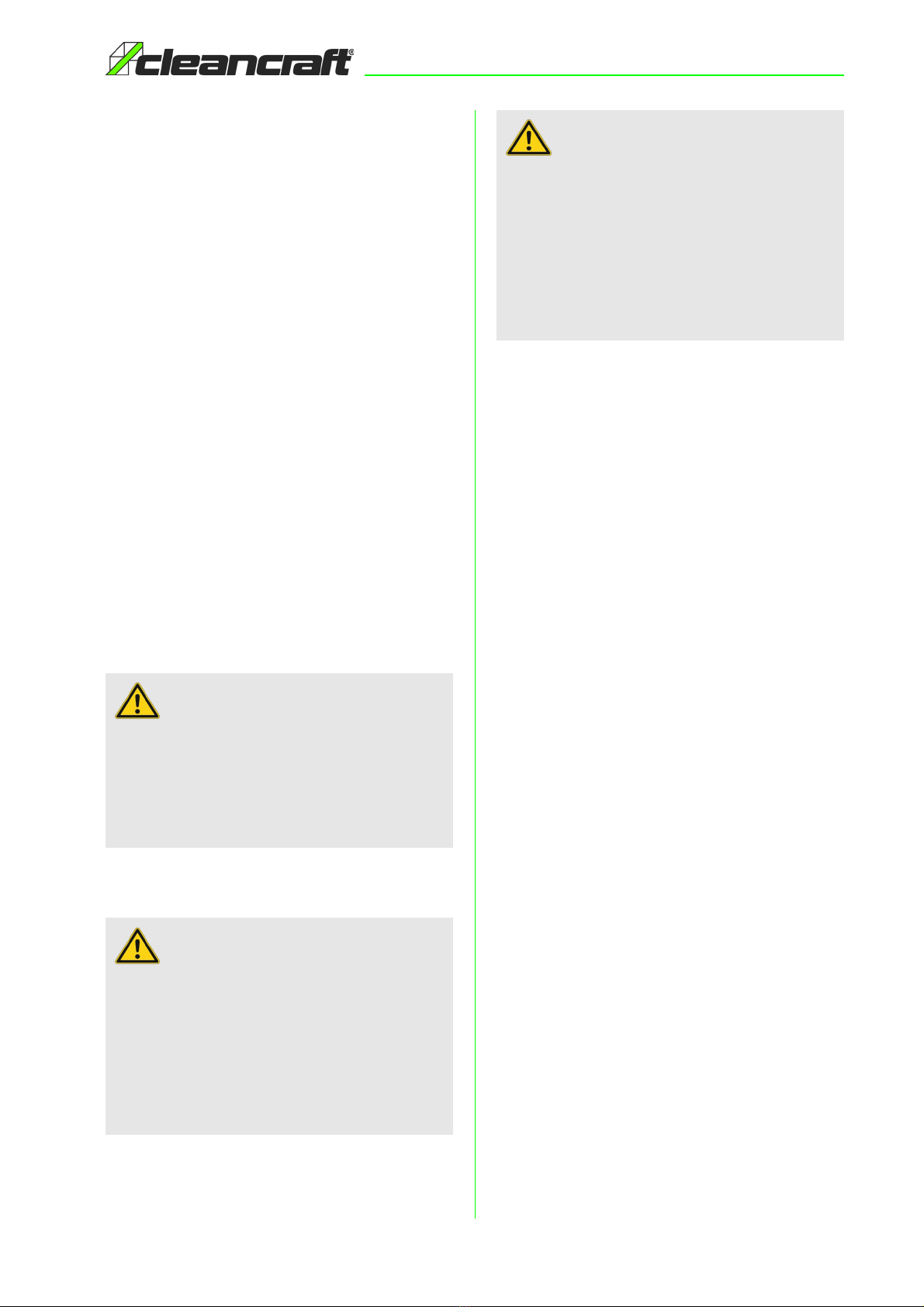

4.2 Type plate

Fig. 2: Type plate

Transport, Packaging, Storage

.1 Transport

Check the scrubbing vacuum cleaning machine for visible

transport damage after delivery. If you discover any da-

mage to the scrubbing vacuum cleaning machine, report

it immediately to the transport company or the dealer.

.2 Packaging

All packaging materials and packaging aids of the scrub-

bing vacuum cleaning machine are recyclable and must

always be recycled.

Shred cardboard packaging components and take them

to the waste paper collection.

The films are made of polyethylene (PE) and the padding

parts of polystyrene (PS). These materials should be ta-

ken to a collection point for recyclable materials or to

your local waste disposal company.

.3 Storage

Store the scrubbing vacuum cleaning machine in a dry,

clean and frost-free environment.

Model SSM 281

Length x Width/Depth x Height 758 x 376 x 392 mm

Net weight approx. 19,8 kg

Supply voltage 36 V

Cleaning surface 900 m

2

Working capacity 900 m²/h

Power supply Lithium-battery

(36V 5,5Ah)

Battery life max. 50 min

Battery recharge time 2 h

Power brushes motor 100 W

Vacuum power 160 W

Total output 220 W

Type of protection IPX3

Working width with central

brush

280 mm

Brush diameter 280 mm

Speed brushes 169 min

-1

Contact pressure brushes 10 kg

Contact pressure 30 g/cm

2

Squeegee width 380 mm

Vacuum 60 mbar

Speed max. 3,5 km/h

Maximum ramp gradient 2 %

Sound pressure level 63 dB(A)

Vibration level 1 m/s²

Solution tank 5 l

Greywater tank 5 l

escription

SSM 281 | Version 1.02 9

6 Description

The scrubbing vacuum cleaning machine sprays a solu-

tion of water and detergent in the correct concentration

onto the floor and finally removes the dirt by scrubbing.

Through careful selection of detergent and brushes (or

abrasive discs) from the range of accessories, the ma-

chine can be used on a variety of floor types and dirt.

The scrubbing vacuum cleaning machine has a wet sy-

stem that dries the floor immediately after washing. The

drying effect is generated by the suction motor, which

creates a partial vacuum in the dirty water tank. Suction

cups mounted below the tank are designed to pick up the

dirty water film as the machine moves forward and back-

ward.

Control Panel

Fig. 3: Control panel

1 Battery indicator

2 Detergent flow ON/OFF / control

3 Brush control button

4 Suction control button

5 Operating mode "ECO"

6 Brush control lever

Front view and rear view of the machine

Fig. 4: Front view of the machine

Fig. 5: Rear view of the machine

1 Driving lever

2 Brake lever

3 Lift/lower suction lip lever

4 Front squeegee

2

3 4

5

16

1

2

3

7

8

46

5

10

11

1

2

12

3

9

10 SSM 281 | Version 1.02

Before Commissioning

5 Brush

6 Rear squeegee

7 Sliding cover

8 Housing cover

9 Air filter

10 Battery compartment

11 Sliding cover

12 Main switch

6.1 Scope of delivery

- 1 x SSM 281

- 1 x Battery 36V 5,5Ah Li-Ion (7260015)

- 1 x Charger with Euro plug (7260017)

- 1 x Disc brush PPL 0.4

6.2 Optional Accessoires

- Brush (

7260000

)

- Brush (

7260001

)

- Brush (

7260002

)

- Driving plate (

7260005

)

- Front suction lips latex (

7260010

)

- Rear suction lips latex (

7260011

)

- Set suction lips latex (

7260012

)

- PU suction lip set oil resistant (

7260013

)

- Suction lips set Linatex (

7260014

)

- Li-Ion battery 36V 5,5 Ah (scope of delivery) (

7260015

)

- Li-Ion battery 36V 8,2 Ah (optional) (

7260016

)

- Charger with plug (EU standard) (

7260017

)

- Cleaning pad black (

7212020

)

- Cleaning pad brown (

7212021

)

- Cleaning pad green (

7212022

)

- Cleaning pad red (

7212023

)

- Cleaning pad white (

7212024

)

7 Before Commissioning

7.1 Unpacking the machine

Step 1: Open the packaging of the machine. If neces-

sary, remove any attached plastic straps by

using shear or pliers.

Step 2: Remove (if necessary) any individual parts or do-

cuments lying in the carton.

Step 3: Carefully lift the scrubbing vacuum cleaning ma-

chine out of the box by the handle and place the

machine on the floor. Keep the packaging for

possible transport.

The scrubbing vacuum cleaning machine is delivered in

a folded state as follows (accessories may still need to

be assembled):

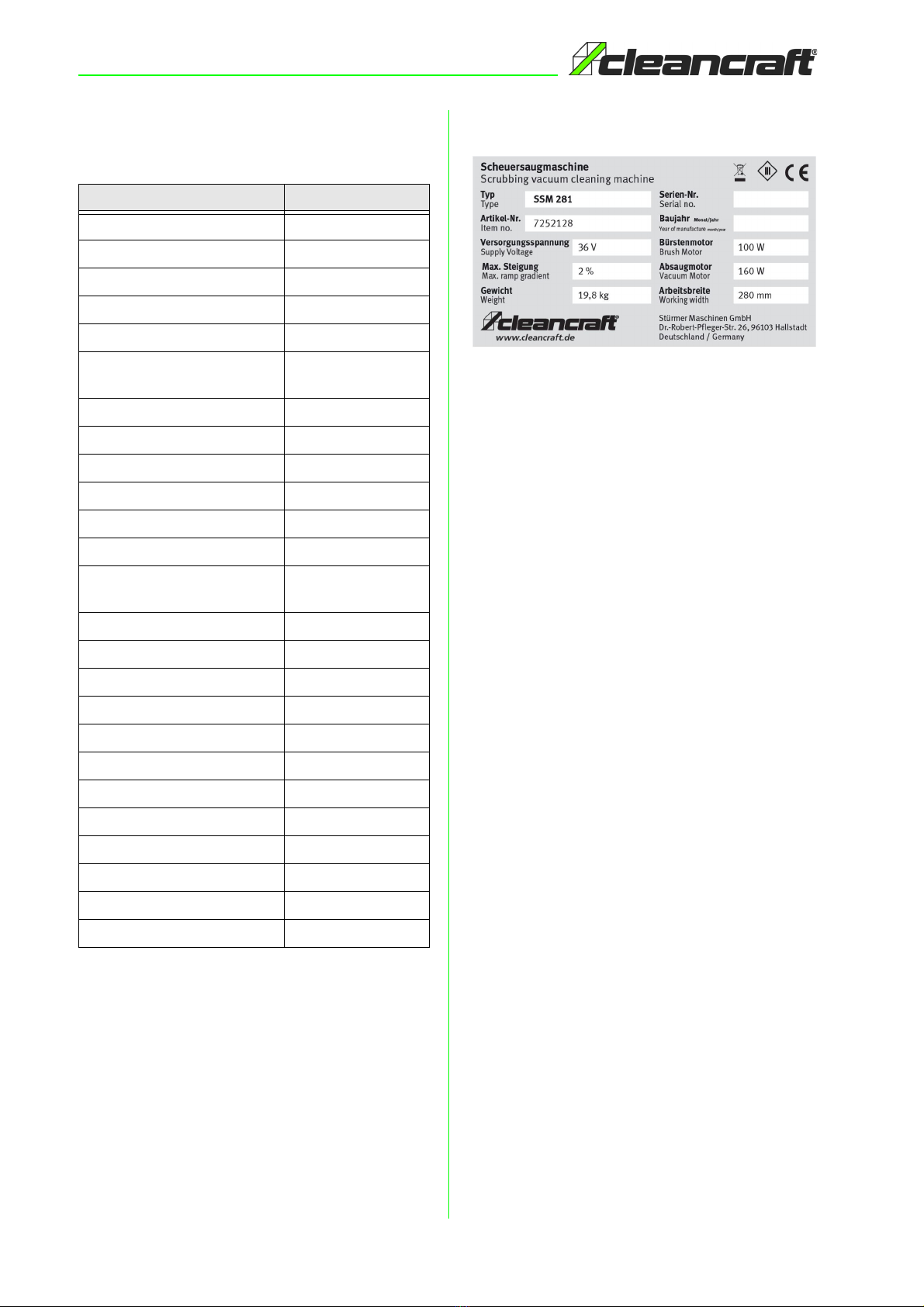

Fig. 6: Machine delivery state

7.2 Assembling the machine

Step 1: Fold the handle of the scrubbing vacuum clea-

ning machine upwards at a right angle so that the

handle is in the extended position.

The angle of handle is variable and can be adjusted as

desired:

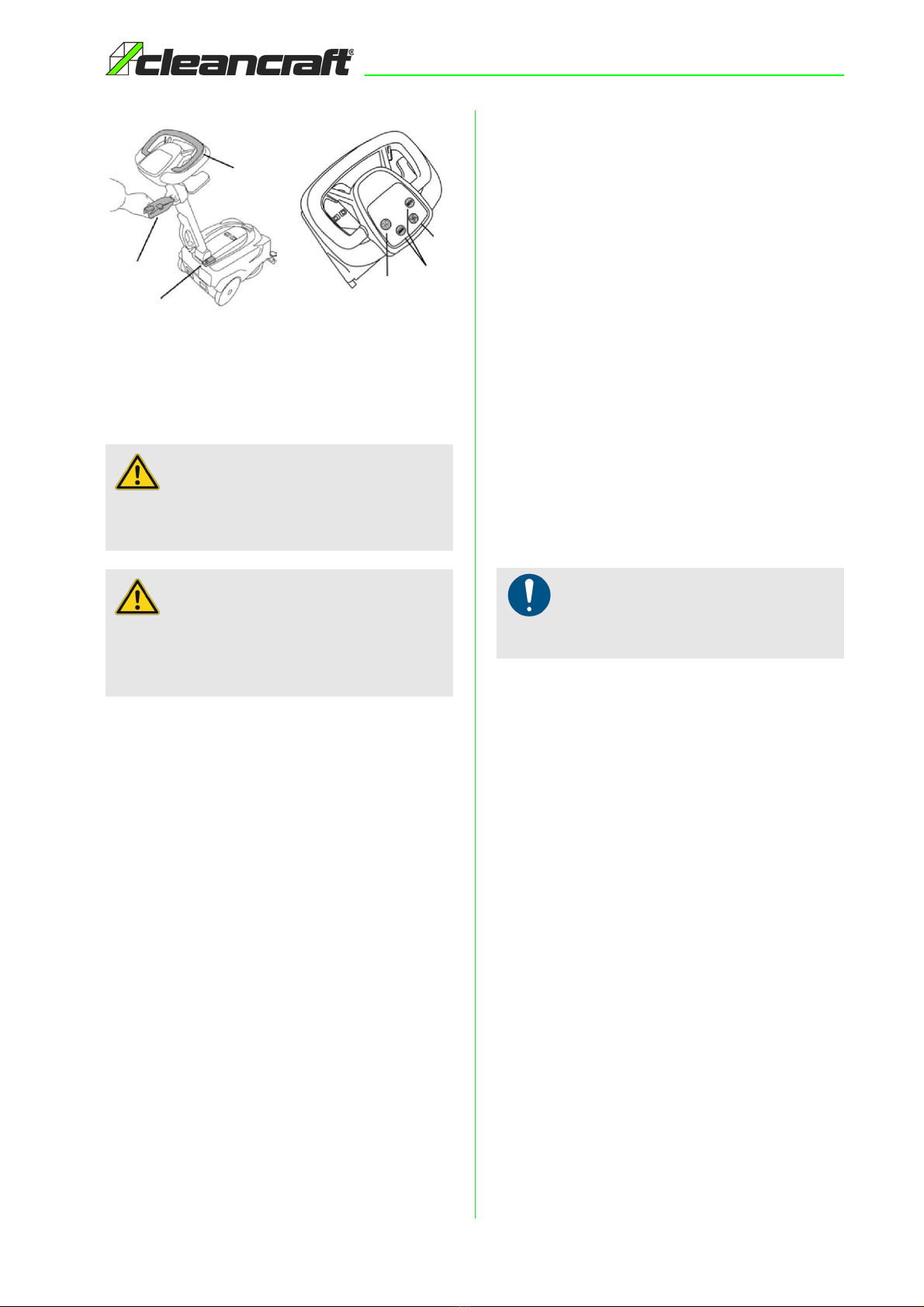

Fig. 7: Adjustable handle

Step 2: Remove the two tanks and place them on the

ground.

Step 3: Tilt the machine over and place it so that the

handle is on the floor.

Step 4: Cut the transport straps attached to the rear

squeegee.

Step 5: Install the front squeegee (left, Fig 8).

Step 6: Install the rear bumper (buffer) (right, Fig 8).

Before Commissioning

SSM 281 | Version 1.02 11

Fig. 8: Assembling

7.3 Parking position of machine

Step 1: Make sure that the main switch of the machine is

turned off. (1, Fig. 9).

Fig. 9: Operating position

Step 2: Make sure that the suction lips of the machine

are not activated. To raise the suction lips, ope-

rate the lever (2, Fig. 9).

Step 3: Fold the handle and put the machine in parking

position (Fig. 10).

Fig. 10: Parking position

Step 4: Wipe the brush and suction lips on the underside

of the machine dry with a cloth.

7.4 Adjusting angle of the handle

Pull the lever (Fig. 11) to set the desired angle of the

handle. Release the lever to lock the handle in the

selected position.

Fig. 11: Adjust angle of handle

ATTENTION!

If the product is delivered packed in a carton, ensure

that the product is raised with suitable lifting equip-

ment that complies with the applicable legal and

safety regulations.

ATTENTION!

The machine must always be parked upright (verti-

cally), in the parking position. Non-observance may

result in damage to the brush or deformation of the

squeegee bars due to the machine's own weight.

ATTENTION!

Empty the fresh and dirty water tank after each use

of the machine.

12 SSM 281 | Version 1.02

Before Commissioning

7. Mounting the brush

Inserting the brush

Step 1: Press the main switch (1, Fig 9) to switch ON the

machine.

Step 2: Press the brush button on control panel (3, Fig. 5).

Step 3: Place the brush (with bristle hairs down) on the

floor.

Step 4: Pull back the handle to lift the front part of the ma-

chine as shown in Fig. 12. Position the brush hood

directly above the brush and lower the machine

again (Fig. 12).

Fig. 12: Lift the front of the machine

Step 5: Carefully move the brush control lever back and

forward (6, Fig. 5) until the brush clicks into

place.

Removing the brush

Step 1: Pull back the handle to lift the front part of the

machine.

Step 2: Press and hold the brush button on the control

panel for 3 seconds (3, Fig. 5) to release the

brush locking mechanism.

7.6 Dirty water / Detergent tank

Removing the cover of the dirty water tank

Simultaneously press the two sliding latches (7 and 11,

Fig. 5) towards each other to remove the cover of the

dirty water tank.

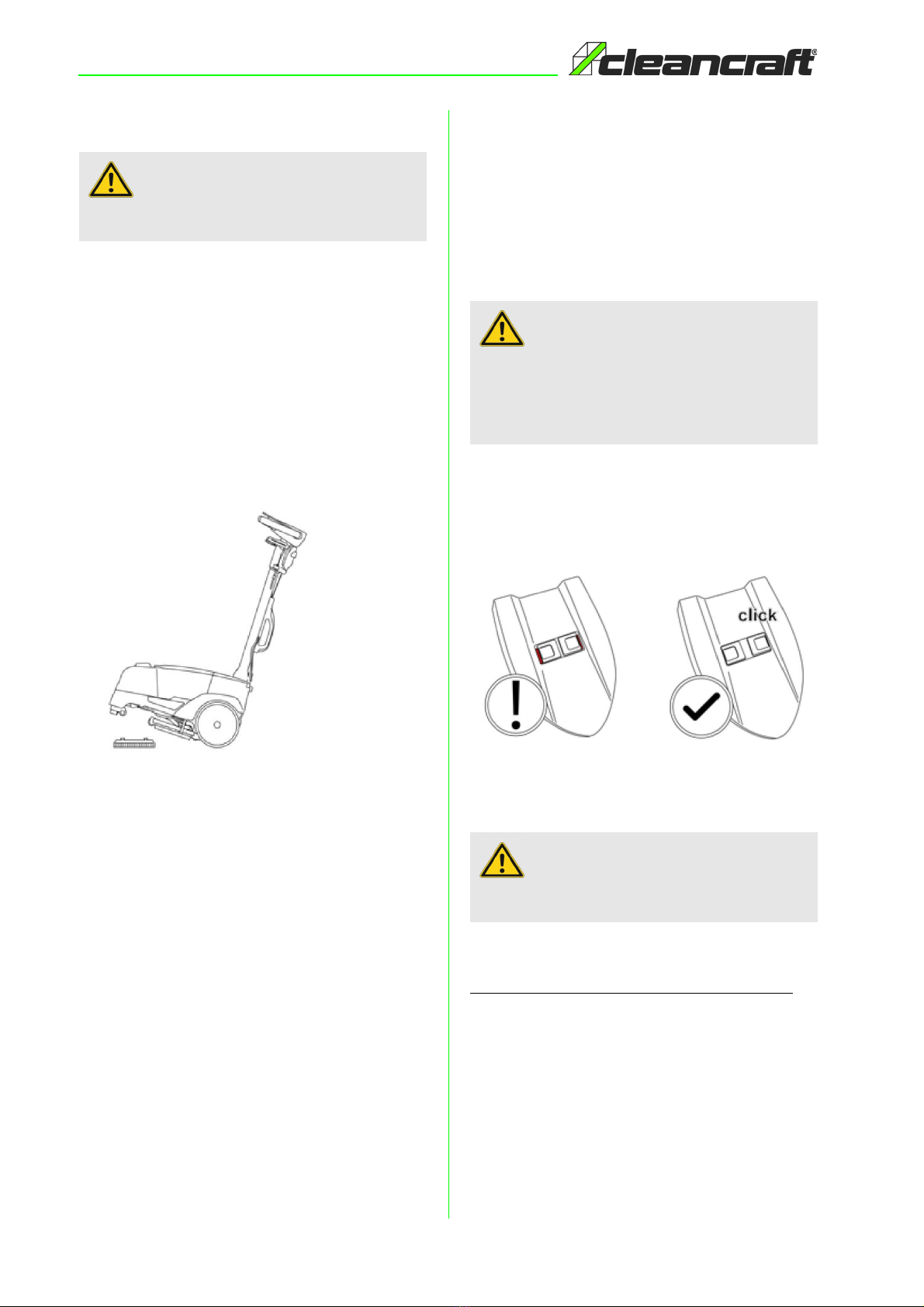

Mounting the dirty water tank

- Place the cover upon the tank

- Carefully press the cover down so that the release

springs outwards and thus the top of the dirty water

tank snaps into place (right, Fig. 13)

Fig. 13: Correct click-in of the cover

Filling the fresh water/cleaning agent tank

The tank can be filled in two different ways.

Option 1: Fill the tank while it is fitted in the machine.

- Always turn off the main switch (1, Fig. 9) of the ma-

chine to fill the water tank.

- Remove the cap of the detergent tank (Fig.12)

ATTENTION!

During this procedure, make sure that there are no

objects or people located near the brushes.

ATTENTION!

Incorrect positioning of the cover on the dirty water

tank will cause the machine to malfunction when

drying the floor.

The cover is correctly snapped in when the red mar-

king (left, Fig. 13) on the latch is no longer visible.

ATTENTION!

The dirty water tank must always be emptied before

filling the clean water and cleaning agent tank.

Before Commissioning

SSM 281 | Version 1.02 13

Fig. 14: Remove tank cap

- Fill the tank with clean water

Option 2: Remove the tank for filling:

- Always switch off the main switch (1, Fig. 9) of the ma-

chine before filling the water tank.

- Open the housing cover (8, Fig. 5) by simultaneously

pressing the two sliding latches (7 and 11, Fig. 5) to-

wards each other.

- Now take out the dirty water tank from inside the ma-

chine and place it aside. Empty the tank if necessary

- Remove the clean water/cleaning agent tank from the

machine

- Remove cap and fill the tank with clean water

Emptying the dirty water tank

An automatic float-controlled shutdown device located

inside the dirty water cover prevents further flow of dirty

water when the tank is full.

As soon as the suction motor becomes louder during

operation and the floor no longer dries as expected, the

operator must stop the machine to empty the dirty water

tank as follows:

- Switch off the main switch (1, Fig. 9) of the machine.

- Open the housing cover (8, Fig. 5) by simultaneously

pressing the two sliding catches (7 and 11, Fig. 5) to-

wards each other

- Take out the dirty water tank inside the machine.

- Remove cap and empty tank

7.7 Adjusting the drive

The machine is equipped with a mechanical drive that

uses the friction that occurs between the brush and the

floor to generate a forward movement.

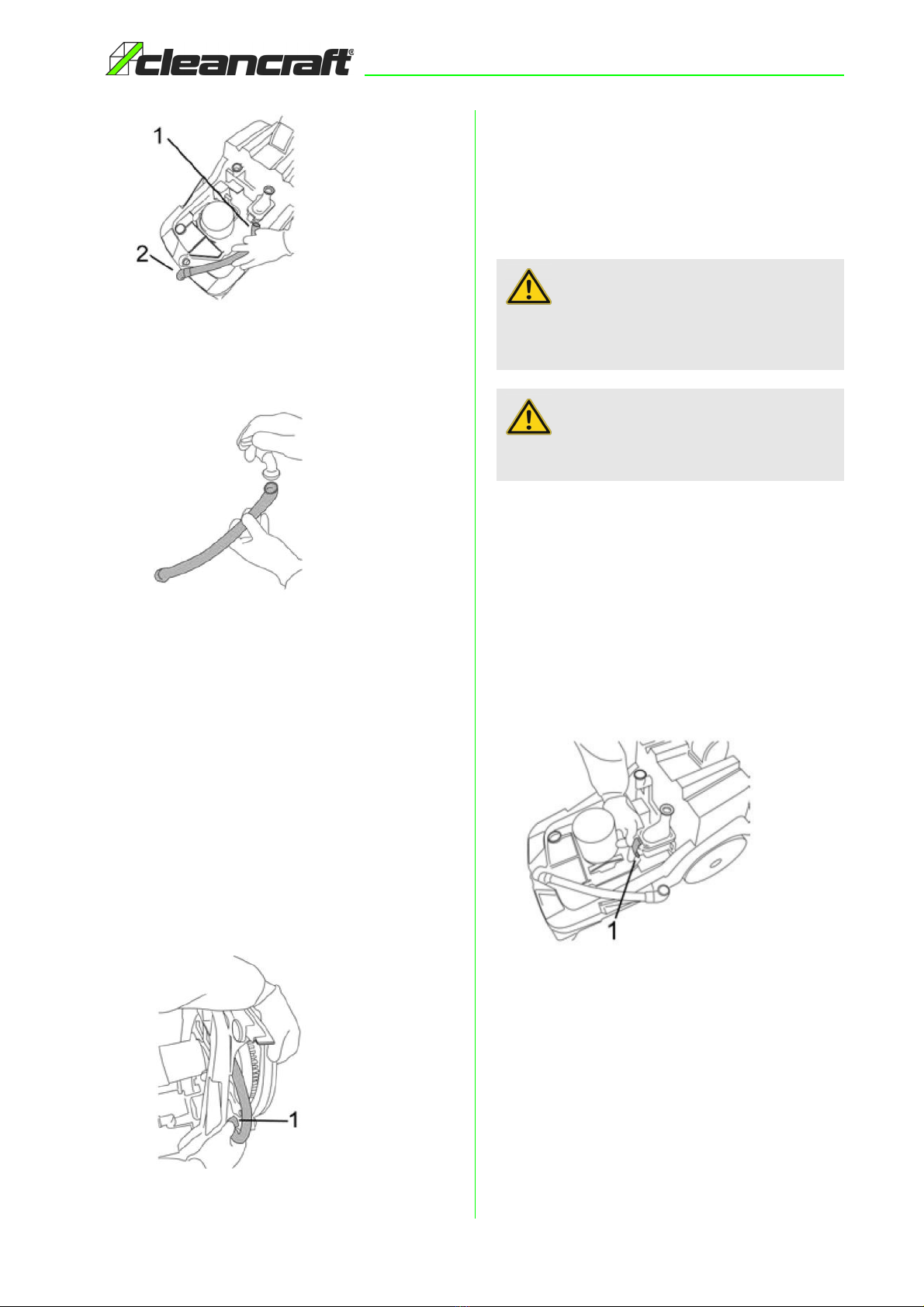

By turning the knob (Fig. 15), the driving power that the

machine develops can be adjusted.

Fig. 15: Rotary knob for setting the drive

There are two adjustment options:

- In the green setting range, the drive force is increased

and the machine tends to deviate from a straight line as

a result.

- In the yellow setting range, the drive force is reduced

and the machine moves in a straight line.

Do the following to make the adjustments:

- Switch off the machine at the main switch (12, Fig. 5).

- Remove the dirty water tank located inside the machine

and place it aside. Empty the tank if necessary

- Remove the clean water/cleaning agent tank out of the

machine

- Lift the brush/motor with one hand and turn the rotary

knob to the desired position with the other hand (Fig. 15).

14 SSM 281 | Version 1.02

Operating

7.8 Battery charge indication (1, Fig. 3)

The battery charge indication has 3 LEDS (red, yellow

and green) and lights up as follows according to the

charge level:

Battery level 100% --> Red, green and yellow LED lights up

Battery level 30% --> Red and yellow LED lights up

Battery level 10% --> Red LED lights up constantly

Battery level 5% --> Red LED flashes; battery fully discharged

After a few seconds, the brush and suction motor are

switched off when the battery is discharged.

7.9 Care by cleaning

The scrubbing vacuum cleaning machine must always

be kept in a clean condition.

8 Operating

8.1 Description of the function keys

- Pressing the brush control button (3, Fig. 3) automati-

cally also activates the suction and detergent flow func-

tions, which can then be controlled and set via the indi-

vidual buttons on the control panel.

- The suction control key (4, Fig. 3) starts the vacuum

motor (LED lights up). A vacuum is then generated,

which is necessary for drying the floor after scrubbing.

The motor only comes into operation when the brush

control lever (6, Fig. 3) has been released.

- The detergent flow button (2, Fig. 3) enables the flow of

the detergent solution (LED lights up). There are 3 le-

vels of detergent delivery available. The flow is activa-

ted only when the brush is operating.

- If the ECO button (5, Fig. 3) is activated (LED lights up),

the machine operates in the economy mode. In this

operating mode, the power of the brush and suction

motor is automatically reduced and the detergent flow

is preset to feed flow level "1".

8.2 Working with the machine

- Press the main switch to switch ON the machine (1,

Fig. 11).

- Press the brush control button or the ECO button (5,

Fig. 11). The brushes as well as the vacuum function

and flow of the cleaning solution get activated.

- To lower the squeegee to the floor, operate the lever (2,

Fig. 11).

- Press the brush control lever (3, Fig. 11) to begin the

work.

Wear protective gloves

Wear suitable protective gloves for cleaning to protect

against injury.

ATTENTION!

Always clean all accessible parts of the machine

after use; empty the tanks and wipe the machine

parts dry with a cloth.

Maintenance and repairs must always be carried out

by qualified personnel; damaged parts must be

replaced only with original spare parts. Cleaning may

not be carried out by children.

ATTENTION!

Never use a high-pressure cleaner to clean the

machine. Water getting into the machine could

damage the electrical system or the motor of the

machine or cause a short circuit.

Do not use solvents or hydrocarbon-based products.

The casing and rubber parts could be damaged.

Avoid hot water and steam, the resulting heat could

permanently deform or damage the plastic parts.

NOTE!

The soil drying function can be operated not only in

the forward motion, but also in the reverse motion of

the machine. Pull the lever (2, Fig. 4) upwards to per-

form the soil drying function in the reverse direction.

Operating

SSM 281 | Version 1.02 15

Fig. 16: Working with the machine

- Check the thoroughness of the cleaning process during

operation. The flow rate of the cleaning agent can be re-

gulated by tapping the cleaning agent button (4, Fig. 11).

Stubborn soiling

For particularly stubbornly soiled floors, the scrubbing

and drying can be performed in two separate working

stages:

Pre-washing with brush/pad

- Operate lever (2, Fig. 11) to lift the squeegee ledge.

- Press the main switch to switch on the machine (1, Fig.

11).

- Press brush control button (5, Fig. 11)

- Deactivate the vacuum function by pressing the suction

control button (6, Fig. 11)

- Operate brush control lever (3, Fig. 11) to start the wor-

king process

Ensure that it is enough time for the cleaning agent to

take effekt when scrubbing particularly soiled areas. This

helps the detergent to exert its chemical effect to remove

the dirt. The brushes require a certain amount of time to

exert an effective mechanical effect.

rying

- Operate the lever (2, Fig. 11) again to lower the squee-

gee ledge.

- Activate the vacuuming function by pressing the suction

control button (6, Fig. 11) again and move the machine

over the pre-cleaned surface.

The process is similar to a thorough scrubbing process

of the floor. Subsequent routine maintenance work on

the floor is thus less time-consuming.

8.3 Finishing work

- Always switch off the machine via its main switch after

you have finished work.

- Empty the dirty water tank and rinse it out with clean

water

- Empty the water/cleaning agent tank as well.

- Place the machine in parking position.

ATTENTION!

Regularly check whether the detergent solution wets

the brush and make sure that the tank is sufficiently

filled.

ATTENTION!

The battery indication lights up red when the battery

is almost discharged. After a few seconds, the brush

and suction functions switch off automatically.

The battery must be recharged to resume work.

3

4

5

6

2

1

NOTE!

For notes on how to replace the brush, refer to chap-

ter "7.5 Mounting the brush".

16 SSM 281 | Version 1.02

Maintenance and Service/Repair

9 Maintenance and Service/Repair

If the scrubbing vacuum cleaning machine does not

function properly, contact a specialist dealer or our cus-

tomer service. The contact details can be found in chap-

ter 1.2 Customer service.

9.1 Cleaning the float

An automatic float-controlled shutdown system, located

at the cover of the dirty water tank, prevents further oper-

ation of the vacuum system when the tank is full. The

float can be cleaned as follows:

- Remove the cover of the dirty water tank

- Loosen the cap to check that the floats can freely move

(1, fig. 14)

- Clean the seals with a damp cloth (2, Fig. 17).

Fig. 17: Floats (pos. 1) and seals (pos. 2)

- Place the cover of the dirty water tank again on the ma-

chine.

9.2 Cleaning the water/cleaning agent tank filter

- Remove the dirty water tank and the cleaning agent

tank and place them on the floor (see chapter 7.6

"Dirty water/cleaning agent tank").

- Remove the filter and wash it with water (1, Fig. 18).

Fig. 18: Filter in the machine

9.3 Cleaning the suction filter

- Remove the dirty water tank and the cleaning agent

tank and place them on the floor (see chapter 7.6 "Dirty

water/cleaning agent tank").

- Take out the suction filter and wash it with water (2,

Fig. 18).

9.4 Cleaning the suction hoses

Clean the suction hose of the front squeegee

- Remove the dirty water tank and the cleaning agent

tank and place them on the floor (see chapter 7.6 "Dirty

water/cleaning agent tank").

- Pull off the hose from the diverter valve (1, Fig. 19) and

from the front suction foot (2, Fig. 19).

Protective gloves

Suitable protective gloves must be worn for cleaning

and maintenance to protect against injury.

ATTENTION!

Maintenance and repairs must always be carried out

by qualified personnel; any damaged parts must only

be replaced with original spare parts.

ATTENTION!

This work may only be carried out when the machi-

nes is switched off.

ATTENTION!

Before performing any repair work, take the battery

out of the machine to disconnect the power supply.

ATTENTION!

Never use aggressive cleaning agent solutions such

as ethyl alcohol to clean the seals.

Maintenance and Service/Repair

SSM 281 | Version 1.02 17

Fig. 19: Suction hose of the front squeegee

- Thoroughly rinse the hose with water by letting water

flow through the opening (Fig. 20).

Fig. 20: Cleaning the hose

- Reattach the hose after cleaning.

Clean the suction hose of the rear squeegee

- Remove the dirty water tank and the cleaning agent

tank and place them on the floor (see chapter 7.6 "Dirty

water/cleaning agent tank").

- Fold out the handle of the machine toward the top.

- Operate the lever (3, Fig. 5) to lower the suction lips.

- Tilt the machine backwards over the handle so that the

bottom side of the machine can be cleaned.

- Pull off the hose from the diverter valve and from the

rear squeegee ledge (Fig. 21).

Fig. 21: Suction hose of the rear squeegee

- Thoroughly rinse the hose with water by letting water

flow through the opening (Fig. 20).

- Reattach the hose after cleaning

9. Cleaning the diverter valve

- Remove the dirty water tank and the cleaning agent

tank and place them on the ground (see chapter 7.6

"Dirty water/cleaning agent tank").

- Detach the suction hose of the front squeegee from the

diverter valve.

- Detach the suction hose of the rear squeegee from the

diverter valve.

- Release the support lever (Fig. 22) and remove the

cover of the diverter valve.

Fig. 22: Release support lever

- The compartment of the valve can now be cleaned (Fig.

23). Remove any incrustations and rinse clean water.

Use a soft cloth to wipe off the seals.

ATTENTION!

Cleaning of the diverter valve should be performed in

an appropriate area for maintenance work, as the

floor could be wet and dirty.

ATTENTION!

Personal protective equipment must be worn during

all maintenance and cleaning work.

18 SSM 281 | Version 1.02

Maintenance and Service/Repair

Fig. 23: Clean valve compartment

9.6 Cleaning the squeegee ledges

- Remove the dirty water tank and the cleaning agent

tank and place them on the ground (see chapter 7.6

"Dirty water/cleaning agent tank").

- Unfold the handle of the machine upwards.

- Tilt the machine backwards over the handle so that the

floor side of the machine can be cleaned.

- Wipe the two suction bars (1, Fig. 24) with a damp

cloth.

- Clean the suction inlet connections of the two strips (2,

Fig. 24) also with a damp cloth.

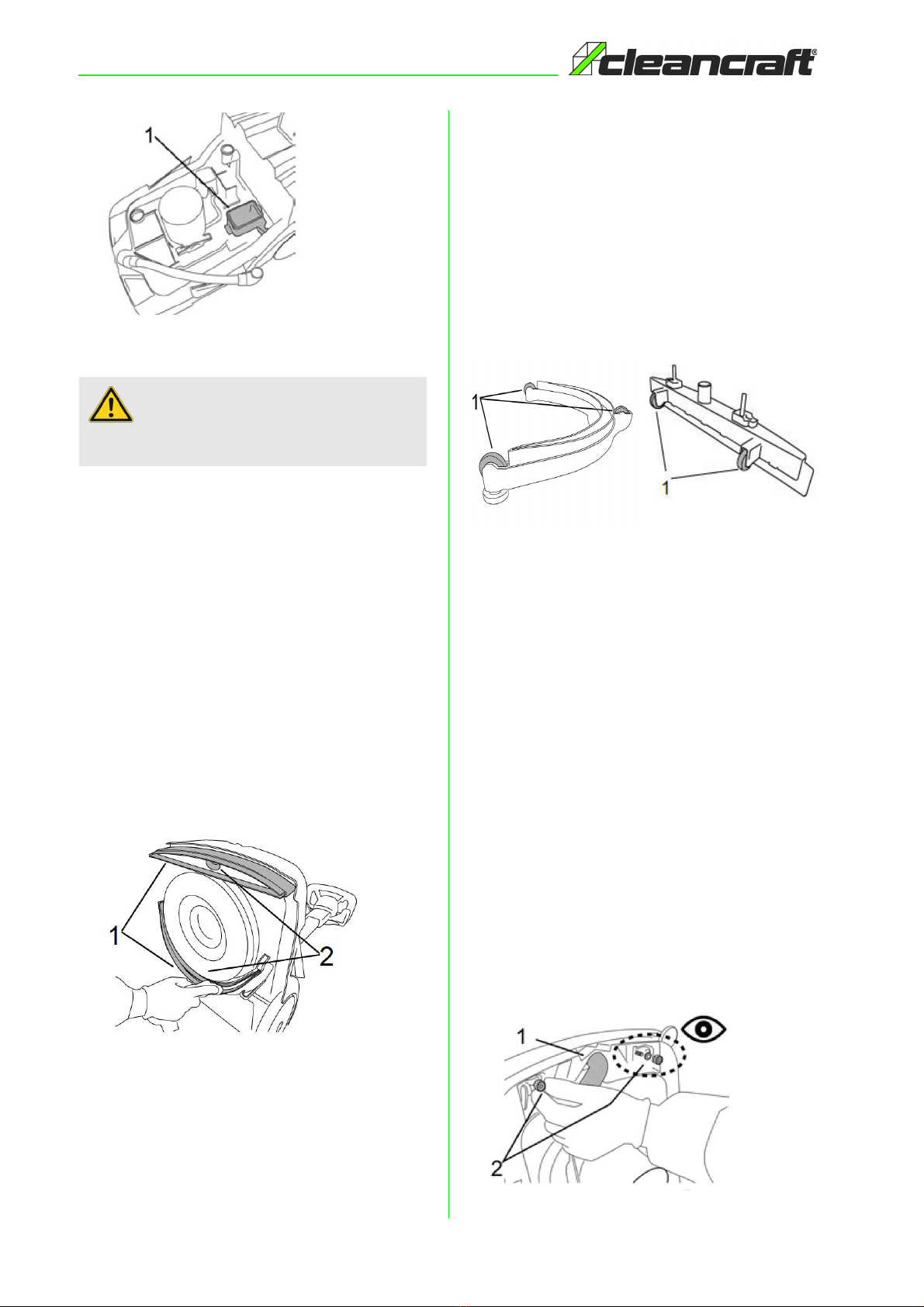

Fig. 24: Cleaning the squeegee ledges

9.7 Adjusting the squeegee ledge

The squeegee is factory-adjusted to achieve an optimum

drying effect on various floor surfaces.

In the event that the drying results do not comply with

your expectations, the squeegee can be re-adjusted:

- The rubber lips of the squeegee blade should be an-

gled 45° from the floor surface along its entire length.

- The height of the squeegee blade can be adjusted by

increasing or decreasing the height of the wheels (1,

Fig. 25)

Fig. 25: Adjusting the squeegee ledge

9.8 Replacing the suction lips

The suction lips pull off the water/cleaning agent film so

that the residual water can then be sucked in.

Due to the regular wiping motion and the contact with the

floor, the rubber lips show signs of abrasion (cracks/

rounded edges). The rubber lips must be replaced as fol-

lows:

- Remove the dirty water tank and the cleaning agent

tank and place them on the floor (see chapter 7.6 "Dirty

water/cleaning agent tank").

- Fold out the handle of the machine upwards.

- Tilt the machine backwards and support the handle on

the ground

Front suction ledge

- Detach the suction hose from the front squeegee (1,

Fig. 26)

- Unscrew the knobs (2, Fig. 26)

Fig. 26: Detach suction hose

ATTENTION!

Never use aggressive cleaning agent solutions such

as ethyl alcohol to clean the seals.

Maintenance and Service/Repair

SSM 281 | Version 1.02 19

- Detach the squeegee ledge from the machine (Fig. 27).

Fig. 27: Detach squeegee ledge

- Remove the rubber lip from the assembly (Fig. 28) and

reinsert it in the opposite way. The rubber lip so can be

used again.

Fig. 28: Remove rubber lip

- The rubber lip must be replaced when the wiping edges

are worn and can therefore no longer be reused.

- Then reassemble the parts in the machine in reverse

order.

Rear suction ledge

- Operate the lever (3, Fig. 5) to lower the suction lips.

- Detach the suction hose from the rear squeegee (1,

Fig. 26)

Fig. 29: Loosen the parts

- Screw off the knobs (2, Fig. 26).

- Remove the rear squeegee (Fig. 30)

Fig. 30: Remove squeegee ledges

- Pull out the rubber lip (Fig. 28) and reinsert it with the

wiping edge turned upside down. In this way, the rub-

ber lip can be reused once again.

- Then reassemble the parts back into the machine in re-

verse order

9.9 Replace brush

The brush has a number of red colored tufts which brist-

les are shorter than the rest (Fig. 31). When the black

bristle tufts are worn to the same length as the red brist-

les, the brush must be replaced.

Fig. 31: Replace brush

NOTE!

For notes on how to replace the brush, refer to the

chapter 'Mounting the brush'.

20 SSM 281 | Version 1.02

Malfunctions, Possible Causes and Measures

10 Malfunctions, Possible Causes and

Measures

10.1 Troubleshooting

General malfunctions

ATTENTION

If one of the following errors occurs, stop working

with the machine immediately. Before you start

troubleshooting, switch off the machine and dis-

connect the mains plug. Serious injury could result.

All repairs or replacement work may only be carried

out by qualified and trained personnel.

NOTE!

If you cannot solve the problems with your machine

yourself, please contact your nearest CLEANCRAFT

dealer.

Please write down the following information from the

machine or from the instruction manual beforehand,

so that they can help you with your problem in the

best possible way.

- Model of the machine

- Serial number of the machine

- Year of manufacture

- Exact error description

Malfunction Possible Cause Measure

Machine does not work - Low or empty battery

- Main switch is not activated

- Charge battery

- Activate main switch

Brush does not rotate - Brush control button is not activated

- Brush control lever is not activated

- Press the brush control button on

the control panel

- Operate brush control lever

Brush motor does not start easily - Machine is operating with a dry

brush on a rough surface

- Increase cleaning agent flow rate

Machine does not scrub evenly - Brush/pad worn out - Replace brush

Detergent solution does not reach

the brush

- Detergent tank empty

- Filter in tanks dirty

- Detergent hose clogged

- Fill tank

- Clean both filters

- Remove dirt inside the hose

Suction motor does not work - Suction button not pressed - Press the suction control button

Suction lips do not clean or vacuum

sucks weakly

- Rubber lips which touch the floor

are worn out

- Tank is full (fill level control triggers)

- Diverter valve dirty

- Blockage in suction hose or squee-

gee ledge

- Replace rubber lips

- Empty the dirt tank

- Clean the diverter valve

- Remove dirt

Battery does not reach the expected

operating time

- Battery charger does not work

- Battery defective

- Replace charger

- Insert new battery

This manual suits for next models

1

Table of contents

Popular Floor Machine manuals by other brands

SCANMASKIN

SCANMASKIN SCAN COMBIFLEX 450NS manual

Timberline

Timberline L Series Operator's manual

Tennant

Tennant EX-SC-1530 Operator's manual

Alto

Alto Clarke IMAGE 14 Operator's manual

Nilfisk-Advance

Nilfisk-Advance SelectGloss 21P 56010814 Operator's manual and parts list

Renown

Renown REN08026-VP Operator's manual