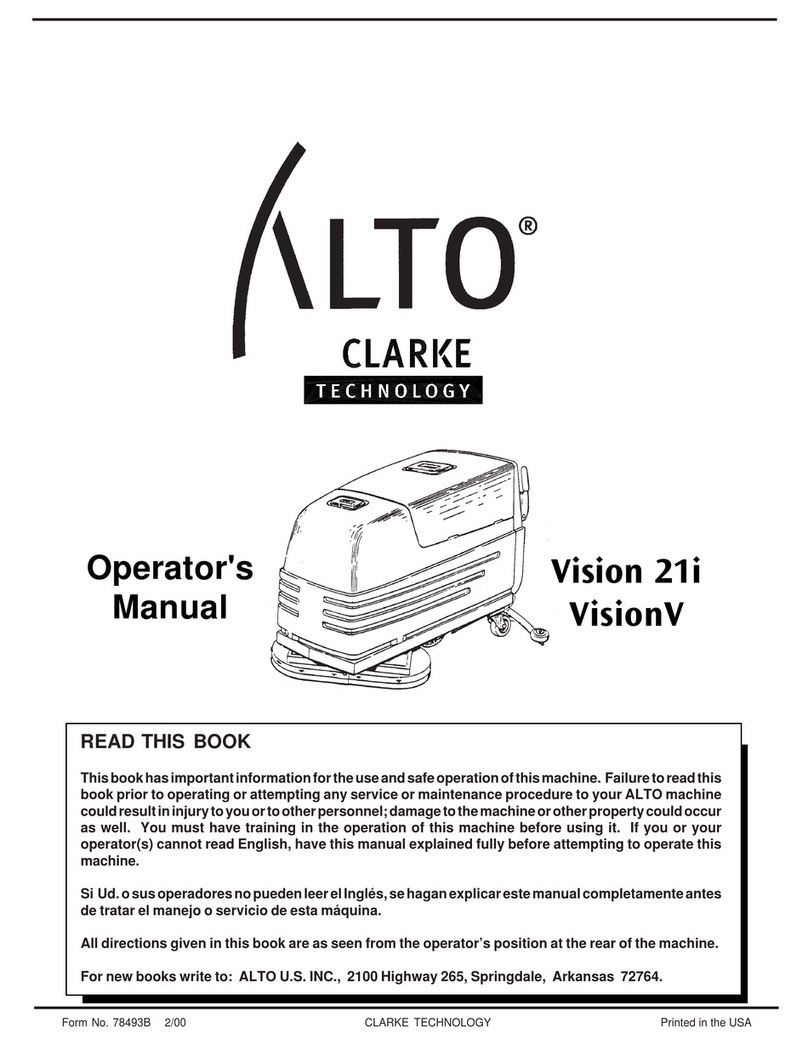

Clarke®Operator's Manual - Image 14 Page 7

HOW TO PREPARE THE MACHINE FOR OPERATION

THECONTROLS

The Vacuum/Accessory/Pump Switch

This switch is located on the handle. To turn the

vacuum motor on, place the switch in the middle

position. To turn pump, brush, and vacuum motor on,

place the switch in bottom position. (Figure 2, #1)

The Vacuum Hose Connector

The vacuum hose connector is on the right hand rear

of the machine. (Figure 2, #2)

The Solution Hose Connector

The solution hose connector is located on the bottom

center of the machine. This connection is used to

hook up optional auxiliary floor tools. (Figure 2, #3)

Recovery Tank Drain

Remove hose from rear of machine. Using the handle

lift the recovery tank free and and pour water into

drain.

Solution Tank Drain

Remove the hose from the rear of the machine. Place

over drain.

WARNING: This machine has moving parts.

To reduce the risk of injury,unplug

before servicing.

WARNING: To reduce the risk of fire, use only

commercially available floor clean-

ersandwaxes intended for machine

application.

WARNING: Do not use water that is hotter than

140°F.

WARNING: Operating a machine thatisnotcom-

pletely or fully assembled could re-

sult in injury or property damage.

Do not operate this machine unless

it is completely assembled. Inspect

themachinecarefully before operat-

ing.

This machine is intended for commercial use.

To preparethe machineforoperation,followthis

procedure:

1. Before moving the extractor onto the carpet, put

clean hot water into the solution tank. The solution

tank capacity is approximately four gallons.

2. Add two to ten ounces of "Clarkare®Extractor

concentrate"perevery onegallon of water, depend-

ingon carpetcondition.

3. If the extractor removes an excess amount of foam

from the carpet, add a defoamer such as Clarkare®

Defoamer Concentrate to the recovery tank. The

amountneeded willchange accordingtothe

amountof detergentalready inthe carpet.

CAUTION: Do not leave the extractor or

other cleaning machines or

tools on the carpet when not in

use. Cleaning solution in the

machines and tools can leak

onto the carpet and cause light

spots or stains.

NOTE: Toorder Clarkare®ExtractorConcentrate,

OrderPartNo.398421. Toorder Clarkare®

Defoamer,order PartNo.398420.For instructions

forpreparation andoperation ofyour floor tool,

readtheoperator's manual

supplied with your floor tool.

1

3

2

Figure 2