6

Safety Precautions

Anyone operating the machine should read the

following carefully and be informed of potentially

dangerous operating conditions. Operators should

be familiar with the location and use of all safety

devices on the machine. Do not use the machine

if it is not in proper operating condition, and report

any damage or operation faults immediately.

DANGER! Operate this machine in a well-ventilated

area. It is the responsibility of the machine operator,

machine owner, and the site manager to ensure that the

air exchange system where the machine is to be used is

in compliance with local building codes and is operating

properly. Failure to operate this machine in a well-

ventilated area could lead to sickness, injury, or death

from carbon monoxide (CO) exposure.

DANGER! This machine emits CO, which is colorless,

odorless, non-irritating gas. The first symptoms of CO

exposure include headache, drowsiness, dizziness,

and nausea. If you should experience any of these

symptoms while operating the machine, shut off the

machine and go outside to get fresh air. Have the

machine tested for CO emissions by a qualified service

technician before using it again.

DANGER! Prolonged or high exposure to CO may

result in vomiting, confusion, and collapse in addition

to loss of consciousness and muscle weakness. If

such symptoms occur, call 911 for emergency medical

attention. If you have experienced these symptoms,

DO NOT operate this machine or any other propane

machine again until cleared by a physician. Excessive

exposure to CO can result in death.

DANGER! Propane is a highly flammable fuel. If you

smell propane, shut off the machine immediately and

take it outside the building. DO NOT use the machine

again until a qualified service technician has corrected

the propane leak. DO NOT use or allow another person

to use an ignition source such as a cigarette lighter

near the propane machine. DO NOT smoke near the

propane machine. DO NOT vent a propane cylinder

inside a building. DO NOT store propane cylinders

inside a building.

DANGER! This machine has parts, including the pad

assemblies, that can cause severe injury if these parts

are contacted while they are moving. DO NOT allow

any part of the body or clothing to come in contact

with these parts while they are moving. DO NOT try

to change attachments while the machine is running.

DO NOT allow other people to come near the machine

while it is in operation. DO NOT allow the machine to

run unattended. DO NOT leave the machine in a place

where unauthorized or untrained personnel could use

the machine. DO NOT run the machine with the pad off

center, damaged or missing. DO NOT run machine with

unsecured guards and shields. DO NOT operate the

machine if the machine has loose parts.

DANGER! Federal law and California State law

prohibits the following acts or the causing thereof: (1)

the removal or rendering inoperative by any person

other than for purposes of maintenance, repair,

or replacement, of any device or element of design

incorporated into any new engine for the purpose

of emission control prior to its sale or delivery to the

ultimate purchaser or while it is in use, or (2) the use of

the engine after such device or element of design has

been removed or rendered inoperative by any person.

Among those acts presumed to constitute tampering are

the acts listed below: DO NOT tamper with the original

emission related part.

l Throttle body and internal parts

l Spark plugs

l Magneto or electronic ignition system

l Air cleaner elements

l Crankcase

l Cylinder heads

l Breather chamber and internal parts

l Intake pipe and tube

l Regulator

l Fuel lock-off

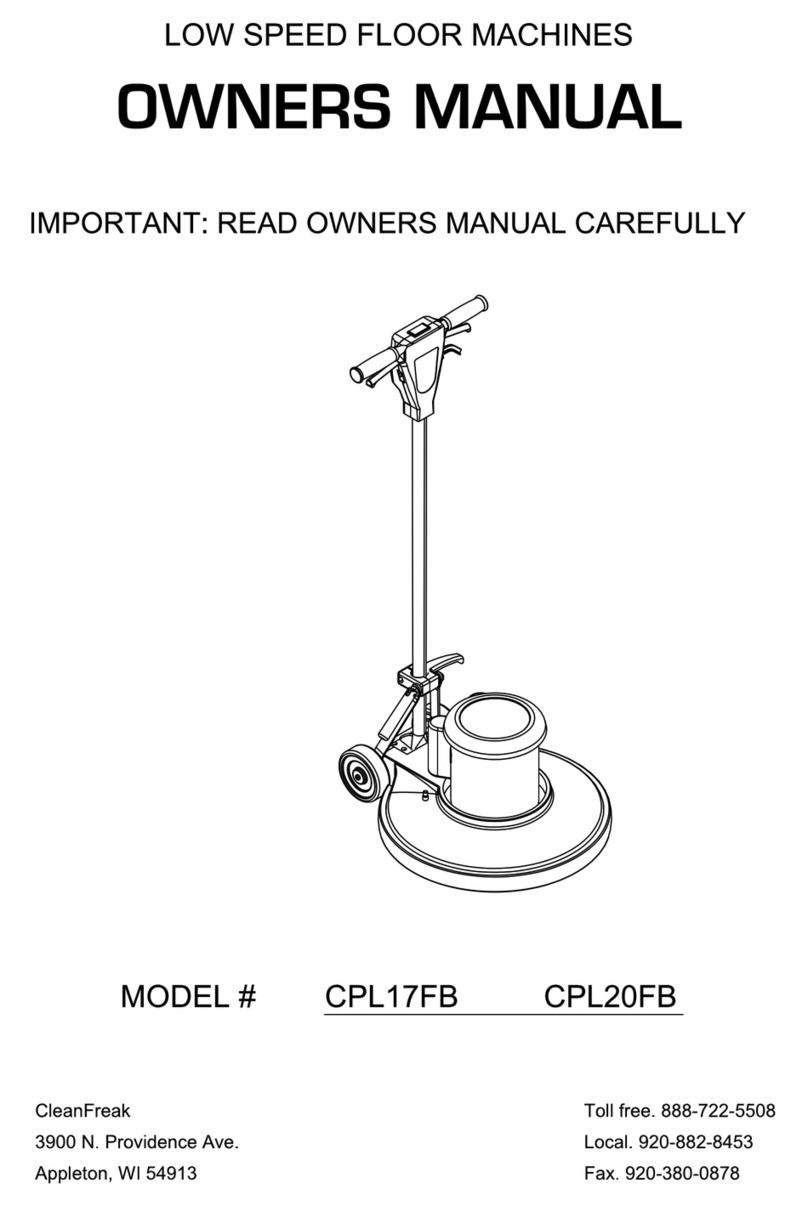

WARNING! Overfilled or liquid withdraw cylinders can

damage the fuel system and create a fire hazard. DO

NOT overfill the cylinder or use a liquid withdraw

cylinder on the machine. If the regulator freezes stop

the burnisher and take the cylinder outside. Inspect

cylinder, if a vapor withdraw cylinder, use gloves or

pliers to open bleeder valve and purge cylinder until

only vapor is escaping. If it is a liquid withdraw cylinder,

replace with a vapor withdraw cylinder. Both cylinders

are shown below.