Cleantecs SOLA-TECS 0200272 User manual

Operating manual

DI resin lter

®

PHOTOVOLTAIC CLEANING SYSTEM BY CLEANTECS

By selecting the Cleantecs full water desalination unit for your water processing system you have chosen a high-quality

product.

The full water desalination operates using the ion exchange principle. The dissolved minerals responsible for

the water hardness and conductivity (TDS value) are removed from the water.

Using this type of processing lter has the following advantages:

• The PV system can be cleaned using only a SOLA-TECS brush.

• The DI resin lter immediately produces 100% pure water and is thus suitable for rapid

mobile use.

• The manufacture accepts not liability for the functionality of the device:

• When it is handled in other than the usual manner.

• When it is used for applications not specied in the manual (inappropriate use).

• When the safety instructions are not adhered to.

The processing lter can be damaged by:

• Operating and installation errors.

• Incorrectly opening the bottle.

• Swapping over connections and hoses, except by Cleantecs

• Independent structural modications.

• Failure to adhere to the safety instructions (e.g. frost protection).

• The use of chemical additives.

• Insucient maintenance.

All maintenance and repair work must be performed by a qualied technical specialist.

All parts can be disposed of in an environmentally friendly manner. The ion exchange resin can be regenerated and re-used.

Foreword

1

1. Safety regulations

1.1 General

Observe the respectively applicable directives and regulations and the currently valid accident prevention regulations.

Cleantecs accepts no liability for any water damage that may occur.

Ensure that the application location has an adequate water drain.

Close the supply stopcock when the unit is shut down for longer periods (e.g. during the weekend).

1.2 Safety instructions in this operating and installation manual

Hazard warnings and very important information are labelled with a warning triangle symbol.

Notes are labelled with an information symbol.

1.3 Intended use

The unit can present hazards when it has been incorrectly

installed, is not regularly maintained or is

used inappropriately for other than the intended purpose.

This unit is only to be used for processing water in order to achieve an

optimum water quality for cleaning glass surfaces.

Any other use, especially the processing of water for

manufacturing foodstus (e.g. beverages), is regarded as inappropriate use

and is prohibited. The regulations of DIN1988/EN1717 apply to the installation.

1.4 Operating temperatures, pressures and connections

The system must be protected from frost. The temperature in the operating room must be at least 4°C.

The water temperature must not exceed 30°C and the operating pressure must not exceed 10 Bar.

The processed water can be more or less aggressive depending on the composition of the supply water. T

his means that parts coming into contact with the processed water must be made of suitable material.

1.5 Modications and changes to the unit

Independent changes to the unit are not permitted for reasons of safety. Original parts and accessories

are specially designed for the unit.

The manufacturer accepts no liability of any kind for damage resulting from modications to the unit

or from the use of non-original spare parts.

2

2. Technical data

Performance / capacity x 1°dH (1,24°E) x 1 litre 80000

Max. performance (litres) at 10°dH (12,4°E) 8000

Flow / hour up to 600l

Permissible pressure (bar) 10

Water temperature max. (°C) 30

Water temperature min. (°C) 2

Pure water quality (ppm) <10

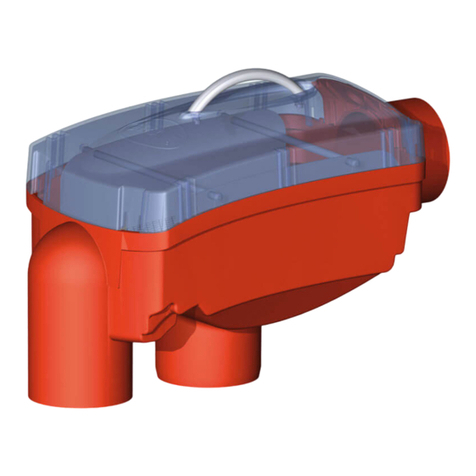

3. Overall view / Scope of delivery

1. Water inlet with stopcock

2. Water outlet with stopcock

3. Pressure tank - resin cartridge

4. TDS measuring unit for inlet and outlet water

5. Sturdy transportation case

6. Microlter (for pre-ltering)

7. Microlter (for post-ltering)

8. Water meter

9. Quick-release tank latch

1

2

3.

4

5

6

7

89

3

4. Transport & packaging

4.1 Incoming goods inspection of the cartridges

Cleantecs cartridges are carefully checked and packed before shipping. However, damage incurred during transport cannot

be ruled out.

Check the packaging in the presence of the delivering party for signs of external damage.

4.2 Incoming goods inspection of the entire unit

• Check that the unit is complete according to the illustration.

• Visually inspect the unit for signs of transport damage.

• The calibrated water meter (without lter) has been checked and therefore shows a meter reading >0.

4.3 Complaints

If the packaging is damaged, have this veried by the supplying party.

Store the packaging and transport carton in a safe place in case the unit needs to be returned.

Complaints relating to transport damage that has not been veried by the shipping company

cannot be accepted.

The specialist dealer must be immediately notied of any damage not detected until after commissioning,

and this must occur no later than 6 months after the date of purchase.

The dealer invoice is essential for verication of the date of purchase.

The General Terms and Conditions of Business of Cleantecs GmbH apply in all cases

4

5. Installation and commissioning

5.1 Installation location and on-site prerequisites

• Water supply connection

• The supply water must conform to the German Drinking Water Directive

.

• Supply water temperature max. 30°C

• Temperature at application location 4° to 40°C

• Do not erect in the immediate vicinity of heat sources or in direct sunlight.

• The processed water is more or less aggressive depending on the

composition of the supply water. The parts that come into contact with the processed

water must therefore be made of suitable corrosion-resistant

material (e.g. glass, plastic or aluminium).

Copper and other non-ferrous metals are not suitable.

5.2 Assembly and commissioning

1. Connect the hose to the water inlet (1). Slowly open the ballcock and ll the bottle.

Open the cock (2) to vent the unit.

2. Close the ballcock (2) and connect the hose of the high-pressure cleaner to the water outlet (2),,

then open the pure water outlet (2) again.

3. Remove the hoses and close all ballcocks for transport,

so that water cannot ow out of the unit.

Open the ballcocks to drain the water and depressurise the unit before transport.

5.3 Integrated TDS measuring unit

• Sturdy measuring device designed for industrial applications. Watertight, shielded cable.

• Displays the TDS input and output values from two probes.

• Auto-o feature for maximum battery life. Switches o after 30 seconds of inactivity.

(requires 2x AA batteries, max. service life of approx. 12-18 months)

• Dual-range 0-9990 ppm (resolution of 1 ppm from 0-999, resolution of 10 ppm from 1000-9990)

indicated by a ashing "x10" symbol.

• Factory-calibrated using a 342 ppm NaCl solution. Can be recalibrated using a small screwdriver.

Can be performed together or individually for each probe.

No warranty is provided in the case of incorrect handling or misadjustment of the unit.

5

6. Capacity

Since the DI resin lter is used at dierent lling locations with water

of diering hardness, the available volume of fully desalinated

water is also dierent.

The water meter and conductivity measurements are used for

monitoring the water quality . The cartridge is exhausted when the conductivity measurement

indicates a value of > 30 μS/cm (20 ppm). The bottle must be changed.

The quality of the supply water can be determined in various ways:

a) Through information provided by the water supply authority responsible (specication of the overall hardness).

b) By measuring the mineral content using the TDS meter (4).

6.1 Maintenance and replacement of the bottles

1. Close the supply water stopcock (1).

2. Depressurise the system.

Do this by opening the water outlet stopcock (2).

3. Remove the cartridge from the carriage by releasing the hose clips and hose connections (9).

4. Replacement of the resin can be organised by the specialist dealer.

5. The 50 litre replacement lter can be obtained through Cleantecs sales channels.

Note that water in the hoses escapes on disassembly!

6

Cleantecs GmbH

Grundweg 10

89250 Senden, Germany

Phone: +49 (0)7307 - 9265 0

Fax: +49 (0)7307 - 9265 20

Email: info@cleantecs.de

Table of contents

Popular Water Filtration System manuals by other brands

Bluewater

Bluewater CLEONE Complete user's manual

Atlas Filtri

Atlas Filtri DOSAPROP quick start guide

Quincy Compressor

Quincy Compressor QED-1250 Instruction book

Graf

Graf Optimax-Pro Instruction for installation and maintenance

Everpure

Everpure H-54 Installation and operation guide

Franklin Water Treatment

Franklin Water Treatment PKLX Series Installation instructions and owner's manual

Anchor

Anchor AF-4003 Quick setup guide

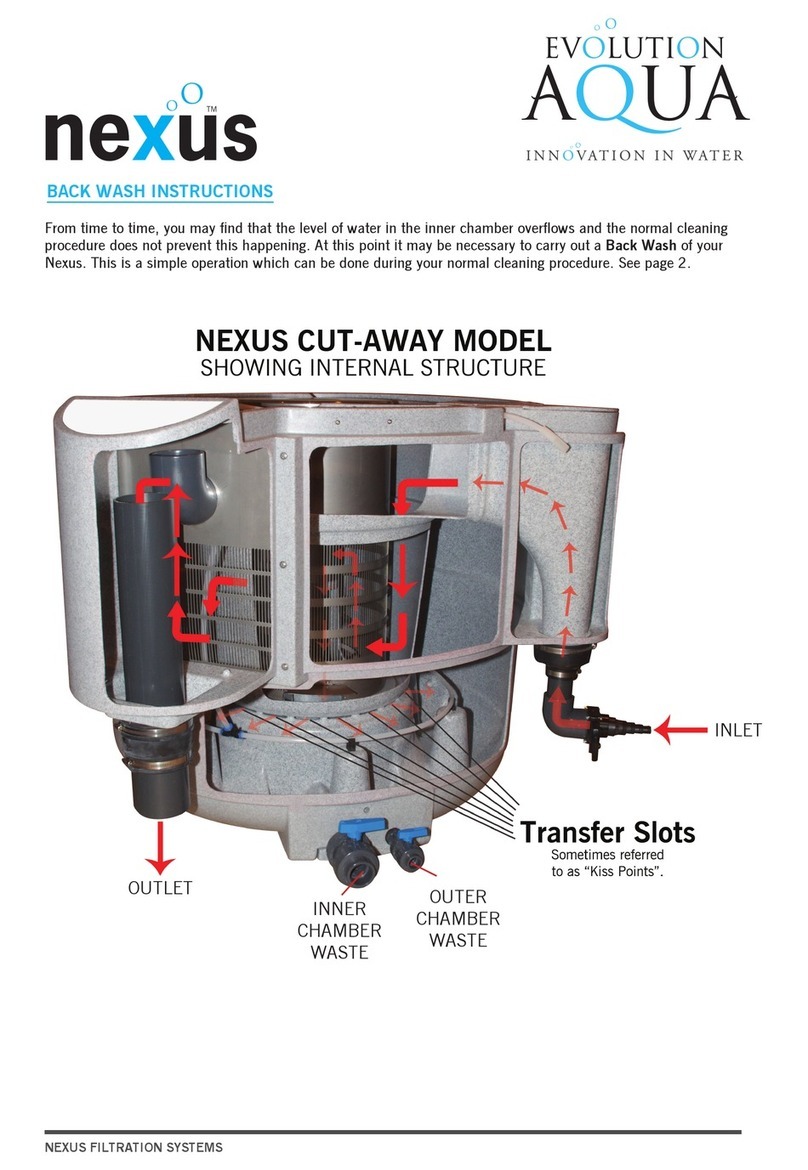

Evolution Aqua

Evolution Aqua NExus 300 instructions

Laica

Laica MikroPLASTIK-STOP DUF1P00 manual

Speedaire

Speedaire 4ZL16 Operating instructions & parts manual

Hozelock

Hozelock Vorton 1550 Installation and operating instructions

AquaScape

AquaScape SIGNATURE Series Instructions & maintenance