5

CORONA DISCHARGE (CD) OZONE SYSTEMS

Ozone is manufactured in the CD ozone generator by drawing in air, which is composed of 20% oxygen (O2), and exposing

it to multiple high voltage electrical discharges. This causes a percentage of the oxygen molecules to dissociate and reas-

semble as ozone (O3). The ozone is drawn into the water by an injector/mixer, killing any bacteria, viruses or mold spores

it contacts. Ozone is generated on-site, eliminating the need to store toxic and corrosive chemicals. The corona discharge

method is the most efficient way to produce large amounts of ozone.

3 - O2 2 - O3

Chemical Formula (simplified)

for Corona Discharge Ozone

In contrast to ultraviolet ozone generators, corona discharge systems produce a much higher concentration of ozone and

in much larger quantities. In addition, the annual expense of replacing lamps and checking ballasts is unnecessary with

corona discharge systems. Corona discharge ozone generation is the most economical and effective method to use on

most water treatment applications.

ClearWater Tech manufactures high output corona discharge systems capable of producing enough ozone to oxidize iron,

sulfide, manganese and act as an efficient sanitizer in a variety of applications. Ozone reacts to water-borne

contaminants significantly faster than other disinfectants and the primary by-product is pure oxygen.

ClearWater Tech ozone systems are built with the finest components available. All are air cooled and are most efficient

when used with a venturi injection system to create the best possible contact and mixing of ozone while maintaining a

high level of safety. The CD15/O2 and CD20/O2 ozone generators have been tested and certified by the Water Quality

Association according to NSF/ANSI 50.

UNCRATING AND INSPECTION

Shipping Terms

Unless special arrangements have been made, the ozone equipment will be shipped FOB ClearWater Tech’s factory in

San Luis Obispo, CA. The freight charges will be prepaid and billed or shipped freight collect. Transfer of liability to the

freight company and the customer occurs as the equipment leaves the factory loading dock and is accepted by the freight

line.

Freight Inspection

All equipment should be thoroughly inspected immediately upon delivery. If any damage is noticed, promptly notify the

freight line and request an on-site inspection.

Unpacking

Typically, the equipment will arrive on a pallet. Compare the components with the packing list. Thoroughly inspect all

packing materials prior to discarding. Inspect all plumbing fittings and tubing for packing material inadvertently lodged in

any openings.

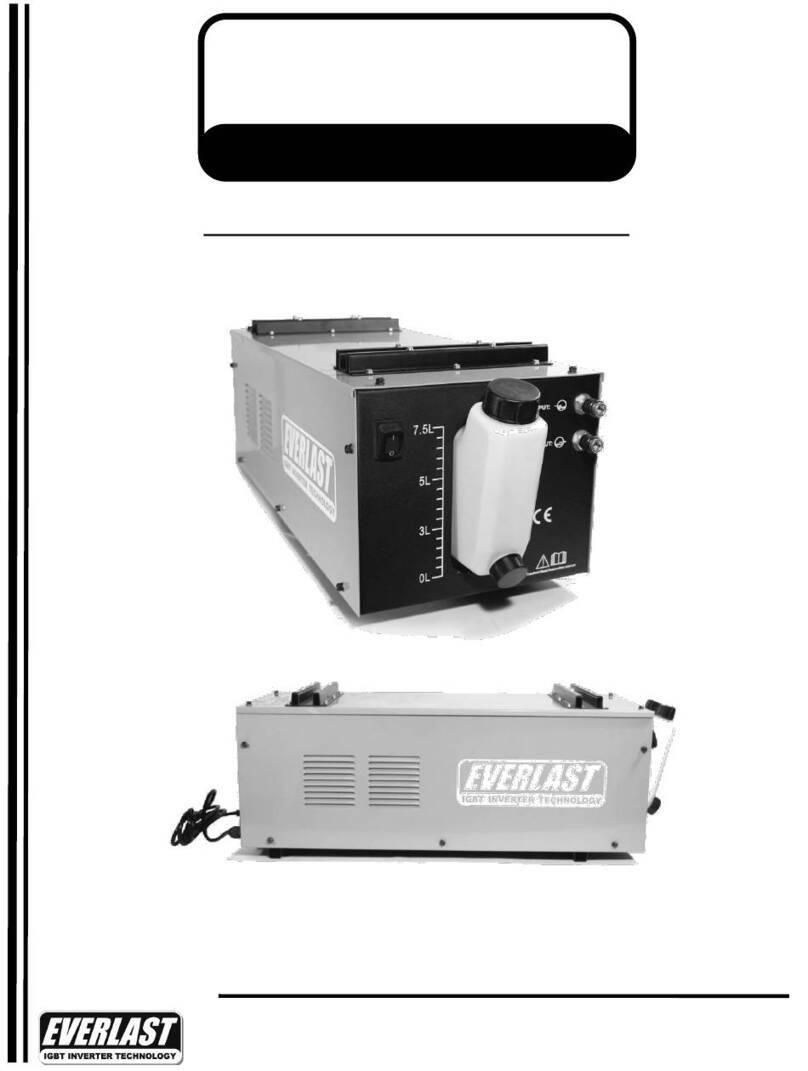

PRODUCT DESCRIPTION

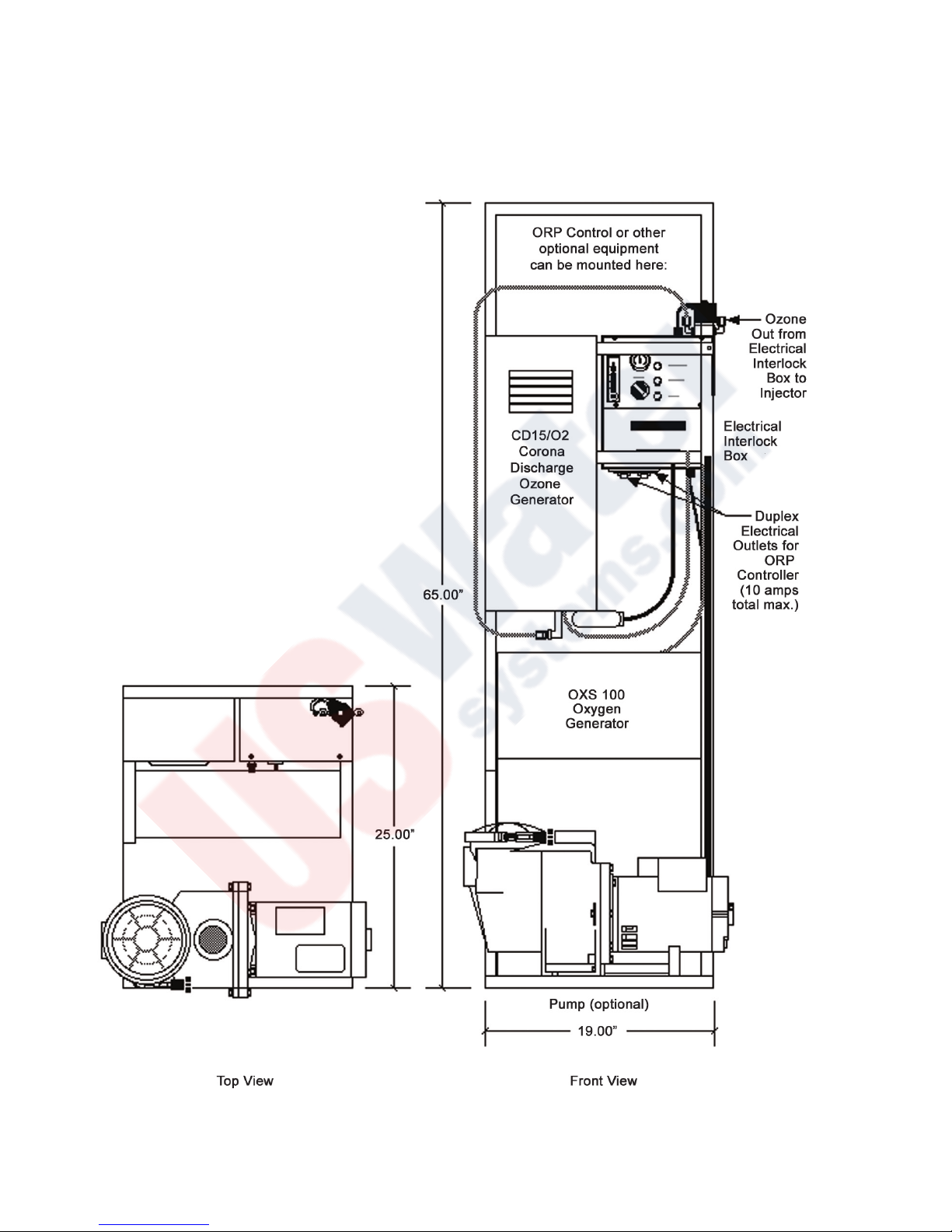

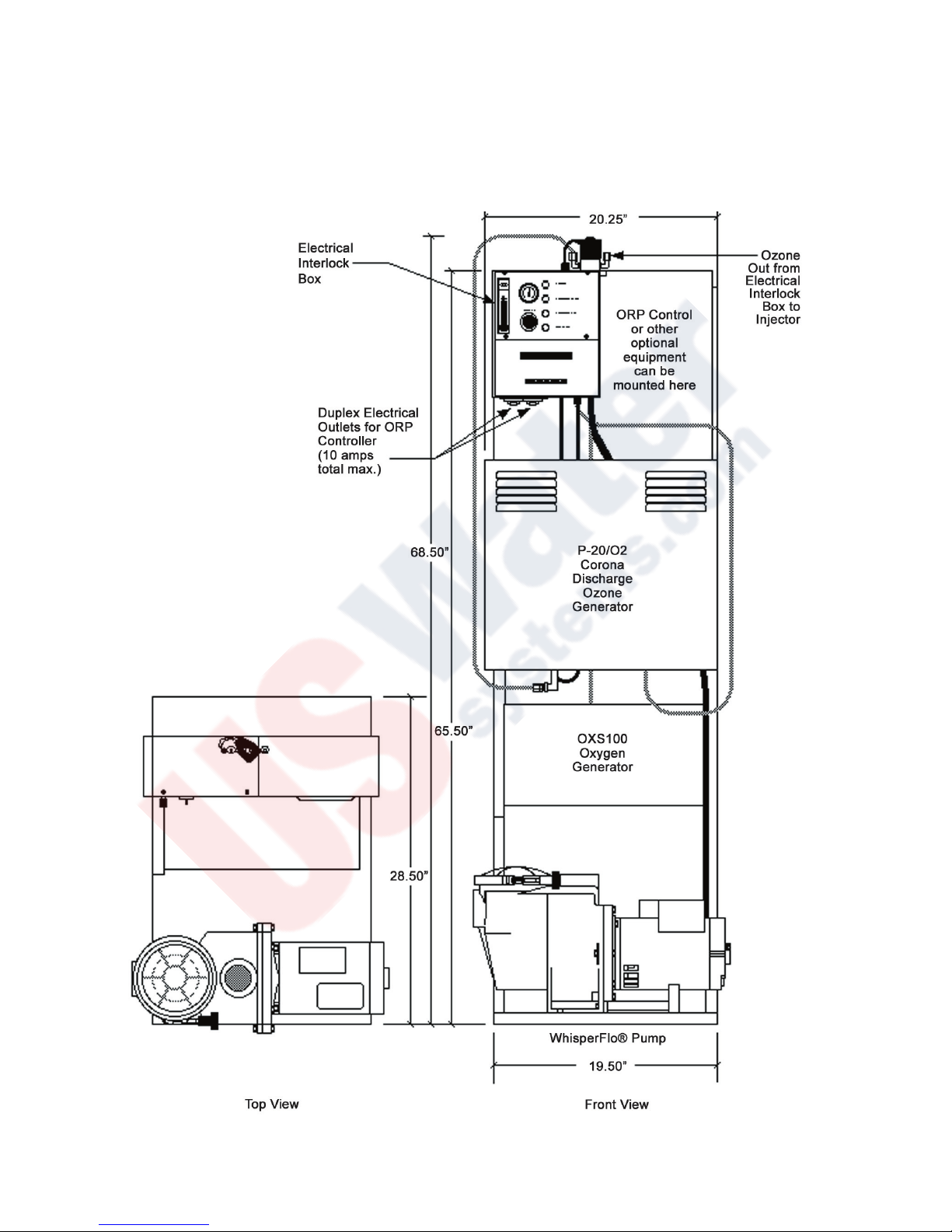

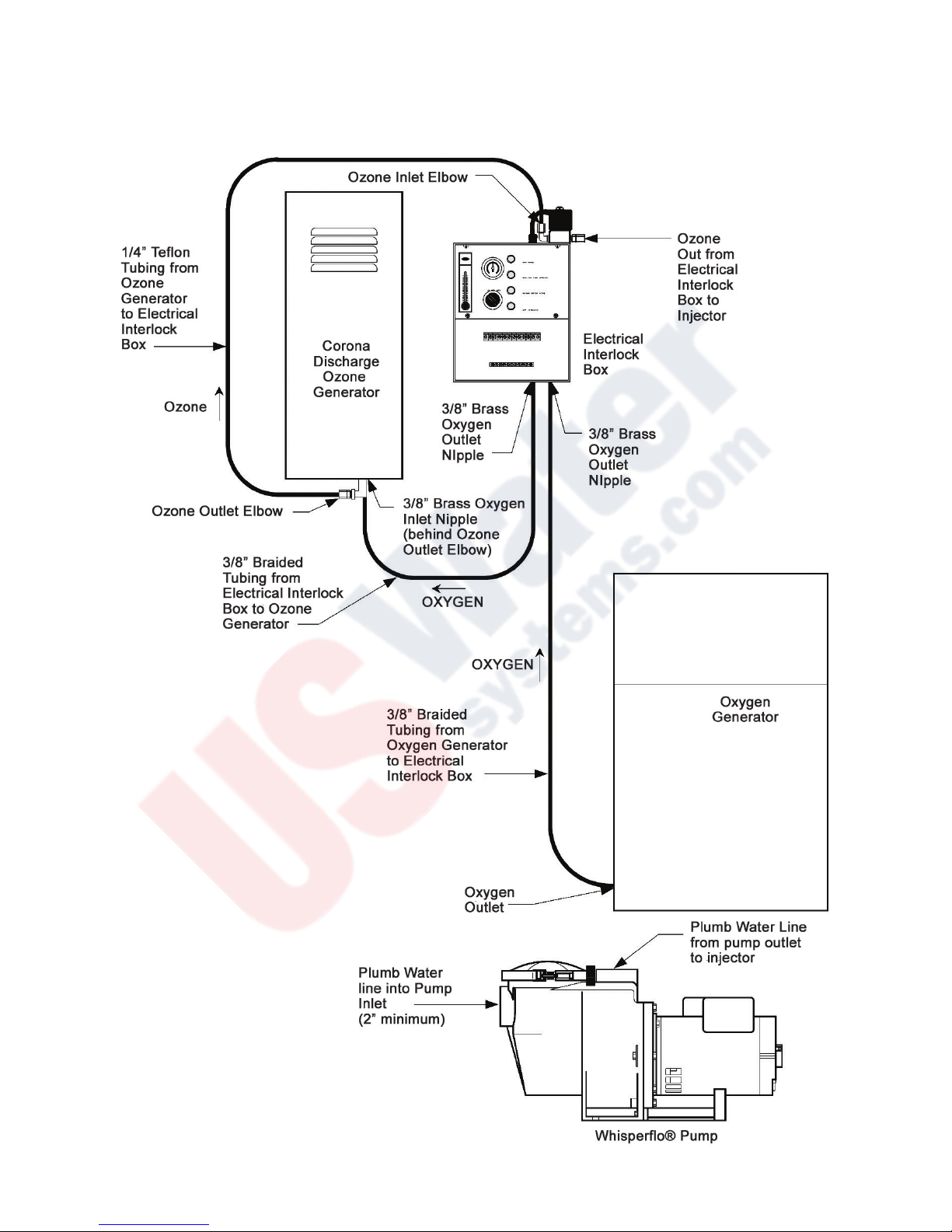

The complete systems are skid mounted and comprised of the ozone generator, air preparation system and an electrical

interlock box for the efficient production and control of ozone gas. The feed gas is approximately 55% dried oxygen at 20

standard cubic feet per hour (SCFH), supplied by the self-contained oxygen generator.

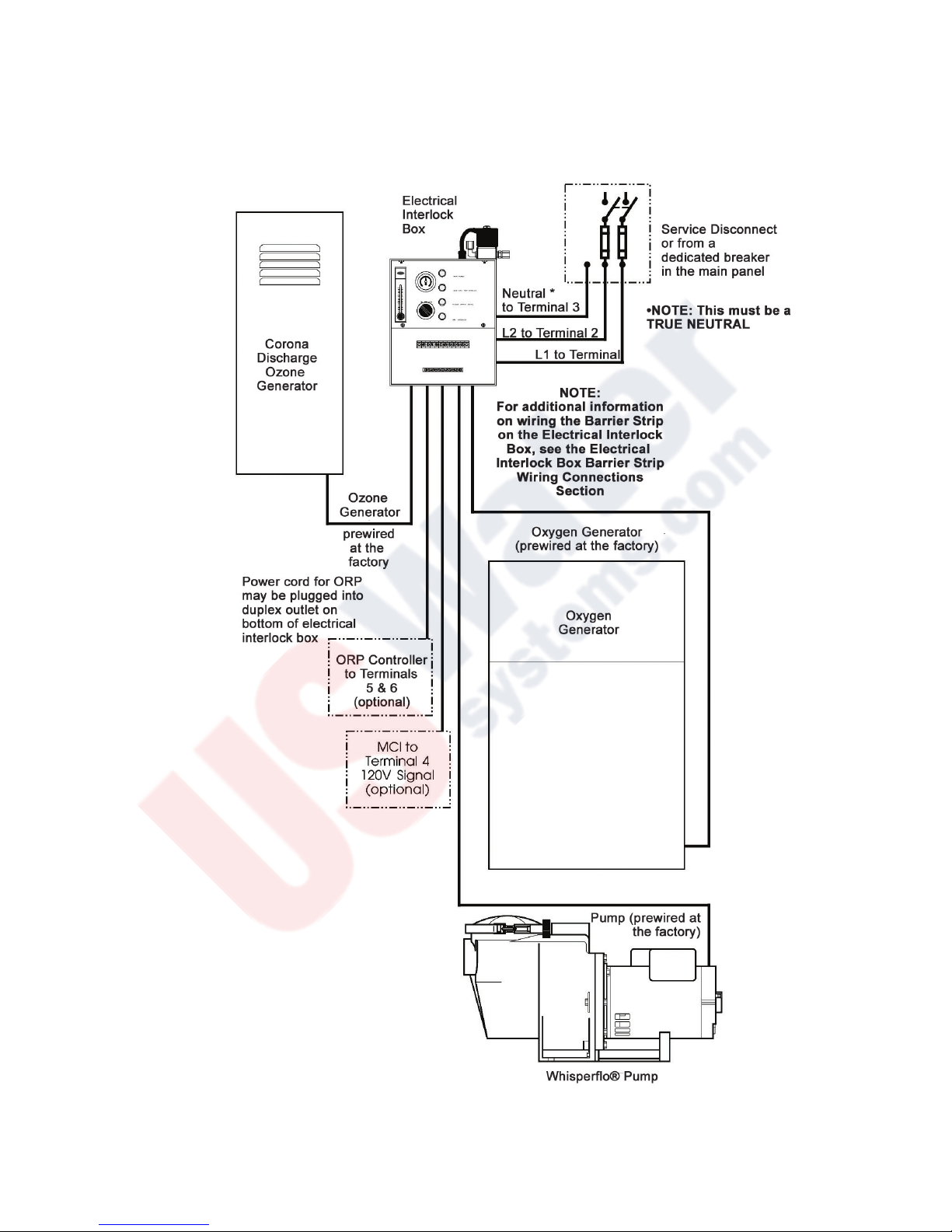

The ClearWater Tech System can be interlocked with an ORP controller, ozone monitor, booster pump or a variety of other

controls. The ozone generator will automatically shut down if the cooling system fails or if the vacuum to the unit is

interrupted.

ClearWater Tech M-15/O2 & P-20/O2 corona discharge ozone systems consist of three main skid-mounted

components:

• Ozone Generator • Air Preparation Unit • Electrical Interlock Box

In addition to this basic unit, optional equipment includes:

• Ozone Injector Manifold • Contact Vessel(s) • Booster Pump • ORP Controller