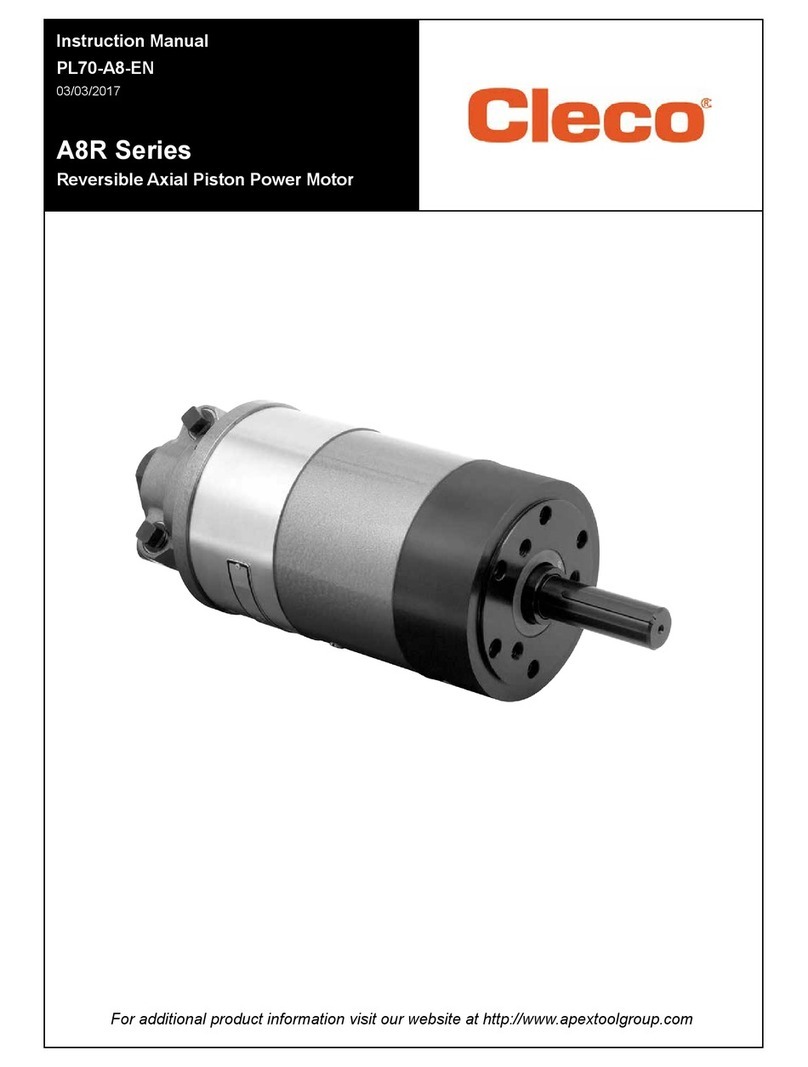

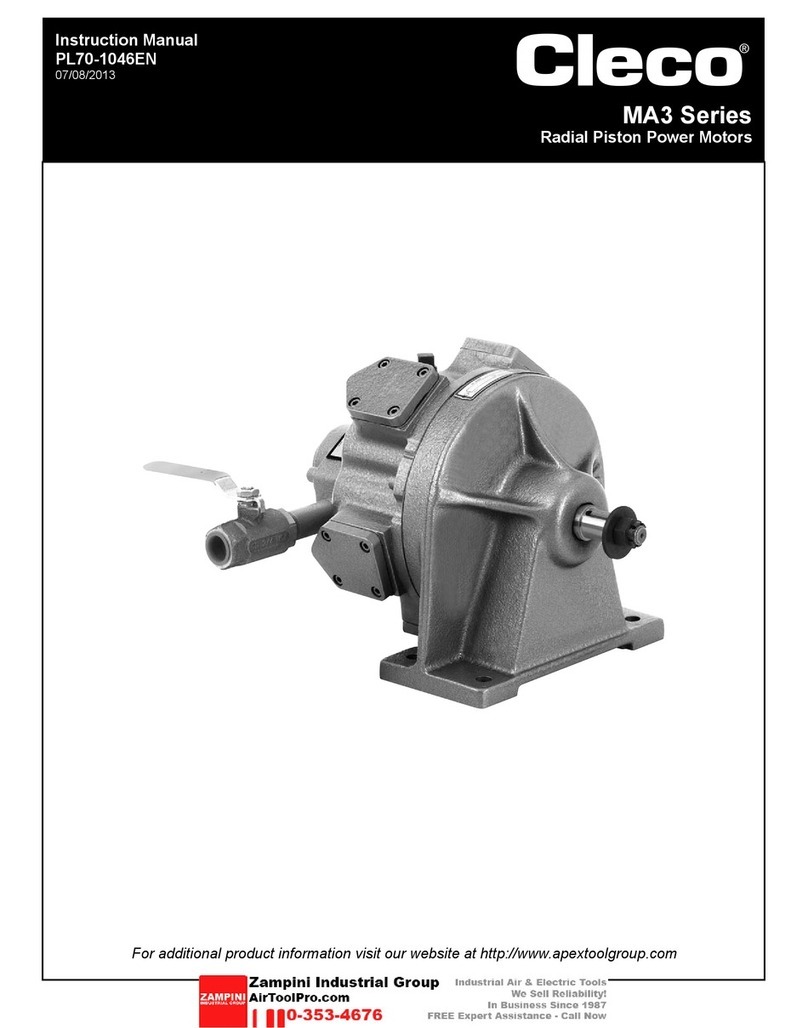

Cleco MA3W-2238 User manual

For additional product information visit our website at http://www.apextoolgroup.com

Parts Manual

PL70-1042EN

07/26/2012

MA3W-2238

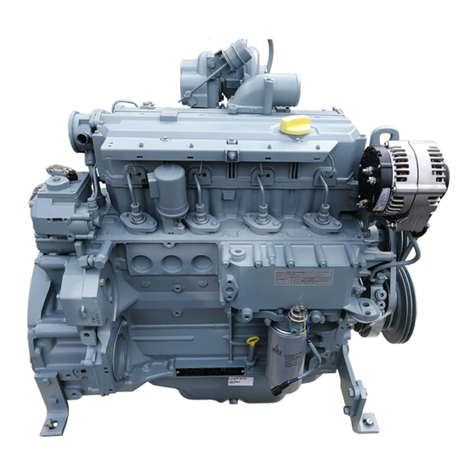

Radial Piston Power Motor

Page 3

PL70-1042EN

07/26/2012

Language Version:

This Parts Manual is the “Original Instructions”

intended for all persons who will use or repair these

tools.

Product Identication:

Refer to the Specications Table.

Noise and Vibration:

Refer to documents CE-1005DC and CE-1005TD.

General Description:

The Cleco MA3 series motors are of the ve-cylinder

radial piston style. This ve-cylinder radial design, with

it’s overlap of power impulses, provides even torque at

all speeds, and full power in either direction of rotation.

At least two pistons are always on a power stroke.

These motors are designed for continuous service on

60 to 100 PSI air pressure. If overloaded beyond their

power capacity, the air motor will simply stall without

damage.

These motors are available without directional valving or

they can be equipped with a single direction air valve or

a 4-way reversing valve.

Intended Use:

These pneumatic motors are intended to be a power

source for other equipment. Use only for their designated

purpose. Do not use in an improper manner that can

cause motor damage and operator injury.

Copyright protection:

Apex Tool Group, LLC reserves the right to modify,

supplement or improve this document or the product

without prior notice. This document may not be reproduced

in any way, shape or form, in full or parts thereof, or

copied to another natural or machine readable language

or to a data carrier, whether electronic, mechanical,

optical or otherwise without the express permission of

Apex Tool Group, LLC.

Cleco®

Specifications and Description

@ Max. H hp Free Speed ft. lbs. Nm ft. lbs. Nm lbs. kg cfm m3/min lbs. kg

MA3W-2238 95 200 299 405 161 218 67 30.1 90 2.55 12.5:1 2560 1161

* Note: Geared models assume overhung load located at 1.000" (25.40mm) from face of motor.

Gear Ratio

Max. Overhung

Load @ Stall*

No Valving

Model

Maximum Allowable RPM

Stall Torque

Starting Torque

Weight

Air Consumption

Specications Table:

Page 4

PL70-1042EN

07/26/2012

Installation:

Make certain the airline is clean and free of scale and

dirt before connecting to the air motor. Check all pipe

ttings to make sure there are no air leaks.

During continuous service, these air motors should not

operate faster than 65% of their rated free speed. Refer to

the Specications Table. An airline lter/lubricator should

be installed as close to the air motor as possible.

During intermittent service, the splash lubrication from

the motor case is adequate.

Check all cap screws to make sure they are properly

tightened.

If an excessive amount of water is present in the airline,

a water trap should be installed to trap as much as

possible before it reaches the motor.

Lubrication:

Fill the motor case to the proper level before operating

the motor.

Use Engine Oil* API Service Classied “SC” in the

following weights:

Above 32° F - SAE 30W

Below 32° F - SAE 10W

Check the oil level daily and ll as necessary. If an

airline lubricator has been installed, check daily and ll

as necessary.

Motor Case: Approximately one (1) quart of oil is

required to ll the motor case to the proper level.

To check the motor case for proper oil level, open the oil

level pet cock. If oil does not ow from the pet cock, add

the appropriate oil until it starts to ow and then close

the oil level pet cock.

If the airline carries an excessive amount of water and

a water trap can not be installed, use a good grade of

motor oil (an oil that will emulsify with water) to prevent

damage to vital motor parts.

Gear Case: Approximately one (1) quart of oil is required

to ll the gear case to the proper oil level.

Use Engine Oil* API Service Classied “SC” in the

following weights:

Above 32° F - SAE 30W

Below 32° F - SAE 10W

The oil must ow at all times to properly lubricate the

gears and bearings.

To check the gear case for proper oil level, open the oil

level pet cock. If oil does not ow from the pet cock, add

the appropriate oil until if starts to ow and then close

the oil level pet cock.

Care and Maintenance:

Service the air motor regularly. The breather cap should

be inspected frequently to make sure it is not plugged

with dirt.

The drain plug in the motor case should be removed

occasionally to allow any water or condensate in the

bottom of the case to drain off. This should be done

before adding new oil and after the motor has been idle

long enough to permit the water and oil to separate.

Excessive use of oil is usually due to worn pistons and

rings, a worn distributing valve and bushing, a damaged

oil seal or a clogged breather cap.

Assembly Instructions:

Place the motor case face up (cylinder opening up) on

a table. Install the valve bushing into the motor case

counterbore from the outside until it bottoms out.

NOTE: The valve bushing must be put in a freezer

before assembling into the motor case.

Install the ve cylinder liners in the cylinder holes of the

motor case until they bottom out. Lightly oil all pistons

and cylinder liners.

Insert the master piston assembly directly across

from the breather cap hole and attach the rod retainer

assembly. Assemble the piston pin (threaded side up).

Place the master piston washer over the connecting

rod (washer ears go to the side of the connecting rod).

Tighten the master piston nut and bend the washer ears

over the nut.

Assemble the other four pistons to the rod retainer

assembly using the piston pins. After all piston pins have

been installed, secure with the retaining ring.

Place the cylinder gaskets and cylinder caps over the

cylinder holes of the motor case and secure with the

screws (tighten to 7 ft. lbs. torque).

Cleco®

General Instructions

Page 5

PL70-1042EN

07/26/2012

Geared Models:

Press the bearing (60148) onto the pinion gear until it

bottoms out. Tap the key (35D2) into the keyway and

press the pinion gear into the crankshaft (drive end).

Press the bearing (12J33) onto the crankshaft (valve

end) and install the crankshaft (valve end) into the valve

bushing. Assemble the rod retainer assembly over the

crankshaft. Center the piston assembly to the breather

port. Press the bearing (12P5) onto the small diameter of

the crankshaft (valve end) until it bottoms out. Slide the

valve chest over the valve bushing and secure with the

two screws and washers (tighten to 21 ft. lbs. torque).

Apply air to test run the assembly. Place a key (35D2)

into the crankshaft (valve end) keyway and assemble

the crankshaft (drive end).

Press the oil seal (60G117), at side out, into the gear

housing until it is ush with the outer edge of the housing.

Press the bearing (12J9) into the gear housing until it

bottoms out. Press the bearing (12J34) onto the gear

and pinion (large gear end).

Press the bearing (12j36) onto the geared end of the

gear and shaft. Press the bearing (12J7) and the wear

ring onto the threaded end of the gear and shaft until

they bottom out.

Place the gear and pinion, with bearing, into the bearing

housing (MA3G20). Make sure the bearing bottoms out

in the housing. Assemble the bearing housing (MA3G39)

to the bearing housing (MA3G20) and secure with two

screws and washers (tighten to 21 ft. lbs. torque).

Slide the gear and shaft into the gear housing and tap

in until it bottoms out. Place the gasket over the bearing

housing and assemble the bearing housing to the gear

housing. Secure with three screws and washers (tighten

to 21 ft. lbs. torque). Place the gasket over the motor

case and assemble the motor case to the gear housing

assembly (breather hole up). Secure with the ve screws

and washers; two screws (75P56) to the left of the

breather hole and three screws (75P5) to the right of the

breather hole. Tighten all screws to 21 ft. lbs. torque.

Assemble the pipe plugs and drain cocks. Fill the motor

case with 3/4 pint of oil and the gear housing with 1-1/2

pints of oil.

Cleco®

General Instructions

Page 6

PL70-1042EN

07/26/2012

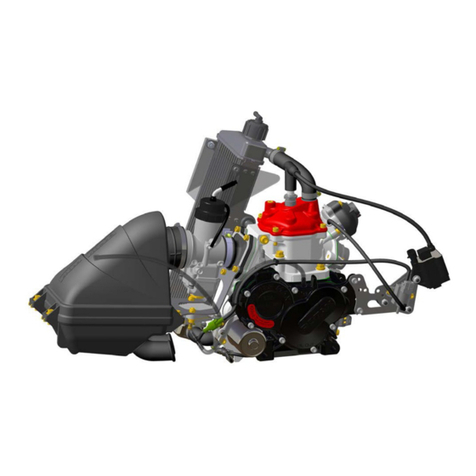

“A”

Cleco®

MA3W-2238 Geared

1

3

2

51

52

6

4

9

5

7

8

10

11

16

12

13 15

14

19

20

24

23

21

17 18 25

22

26 27

44

39

34

28

29

31

36

37

35

30

38

32

33

38

31

40

41 42 26

46

26

49

45

43

26

50

47

48

Page 7

PL70-1042EN

07/26/2012

EN

Description

1 MA323 5 15 Cylinder Gasket

2 MA322 5 Cylinder Cap

3 75V10 20 20 Cylinder Screw

4 60G117 1 3 Oil Seal

5 MA3G1 1 Gear Housing

6 90C12 1 2 Drain Cock

7 12J9 1 2 Ball Bearing

8 MA3G38D 1 Gear and Pinion

9 12J34 1 2 Ball Bearing

10 MA3G40R 1 3 Wear Ring

1 1 12J7 1 2 Ball Bearing

12 35C114 1 2 Gear and Shaft Key

13 MA3G40N 1 Gear and Shaft

14 12J36 1 2 Ball Bearing

15 B150G 3 3 Bearing Housing Screw

16 W161PT 3 3 Flat Washer

17 MA3G39 1 Bearing Housing

18 MA3RM38 1 Pinion Gear

19 35D2 1 3 Woodruff Key

20 60148PT 1 2 Ball Bearing

21 MA3G25 1 3 Bearing Housing Gasket

22 MA3G20 1 Bearing Housing (includes Ref. 23)

23 DP162 1 Pin

24 64AA4 1 Pipe Plug

25 B110E 1 Pipe Plug

26 93G33 10 10 Flat Washer

27 75P60 3 3 Bearing Housing Screw

28 MA330D 1 Crankshaft (Drive End)

29 65W1 1 1 Retaining Ring

30 MA328X 1 Connecting Rod Retainer Assembly (includes Ref. 31)

31 800168 2 4 Needle Bearing

32 MA327 4 Connecting Rod

33 MA326B 1 Connecting Rod (Master)

34 MA326WA 1 Connecting Rod Washer (Master)

35 MA326N 1 Connecting Rod Nut (Master)

36 MA324 5 Piston

37 65A225 10 10 Piston Ring

38 MA325 10 Piston Pin

39 MA331 1 Crankshaft (Valve End)

40 12J33 1 2 Ball Bearing

41 MA319 1 3 Motor Case Gasket

42 MA318E 1 Motor Case (includes Ref. 43)

43 DP114 1 Motor Case Pin

44 540805 1 2 Low Profile Breather Cap

45 B156U 3 3 Motor Case Screw

46 845676 2 2 Motor Case Screw

47 MA311 1 Distributing Valve Bushing

48 12P5 1 2 Ball Bearing

49 533701 1 Valve Chest

50 B158S 2 2 Valve Chest Screw

51 64AA5 2 Pipe Plug

52 MA318L 5 Cylinder Liner

(#) Quantity

(X) Recommended Spare Parts (quantity shown based on 1-5 tools in operation)

Illustration "A"

Ref

Number

#

X

Cleco®

MA3W-2238 Geared

PL70-1042EN/Printed in USA 07/2012/Copyright © Apex Tool Group, LLC

Apex Tool Group, LLC

1000 Lufkin Road

Apex, NC 27539

Phone: 919-387-0099

Fax: 919-387-2614

www.apextoolgroup.com

Sales & Service Centers

Note: All locations may not service all products. Please contact the nearest Sales & Service Center for

the appropriate facility to handle your service requirements.

Detroit, MI Houston, TX Lexington, SC Los Angeles, CA

Apex Tool Group Apex Tool Group Apex Tool Group Apex Tool Group

Sales & Service Center Sales & Service Center 670 Industrial Drive Sales & Service Center

2630 Superior Court 6550 West Sam Houston Lexington, SC 29072 15503 Blackburn Avenue

Auburn Hills, MI 48326 Parkway North, Suite 200 Tel: 800-845-5629 Norwalk, CA 90650

Tel: 248-391-3700 Houston, TX 77041 Tel: 803-951-7544 Tel: 562-623-4457

Fax: 248-391-7824 Tel: 713-849-2364 Fax: 803-358-7681 Fax: 562-802-1718

Fax: 713-849-2047

Seattle, WA York, PA Canada Germany

Apex Tool Group Apex Tool Group Apex Tool Group Apex Tool Group

Sales & Service Center Sales & Service Center Sales & Service Center GmbH & Co. OHG

2865 152nd Avenue N.E. 3990 East Market Street 5925 McLaughlin Road Industriestraße 1

Redmond, WA 98052 York, PA 17402 Mississauga, Ont. L5R 1B8 73463 Westhausen

Tel: 425-497-0476 Tel: 717-755-2933 Canada Germany

Fax: 425-497-0496 Fax: 717-757-5063 Tel: 905-501-4785 Tel: +49 (0) 73 63 81 0

Fax: 905-501-4786 Fax: +49 (0) 73 63 81 222

England France China Mexico

Apex Tool Group Apex Tool Group SAS Cooper (China) Co., Ltd. Cooper Tools

GmbH & Co. OHG 25 rue Maurice Chevalier a company of de México S.A. de C.V.

C/O Spline Gauges 77330 Ozoir-La-Ferrière Apex Tool Group, LLC a company of

Piccadilly, Tamworth France 955 Sheng Li Road, Apex Tool Group, LLC

Staffordshire B78 2ER Tel: +33 1 6443 2200 Heqing Pudong, Shanghai Vialidad El Pueblito #103

United Kingdom Fax: +33 1 6443 1717 China 201201 Parque Industrial Querétaro

Tel: +44 1827 8741 28 Tel: +86-21-28994176 Querétaro, QRO 76220

Fax: +44 1827 8741 28 Fax: +86-21-51118446 Mexico

Tel: +44 1827 8741 28 Tel: +52 (442) 211-3800

Fax: +52 (442) 103-0443

Brazil Hungary

Cooper Tools Industrial Ltda. Cooper Tools Hungaria Kft.

a company of a company of

Apex Tool Group, LLC Apex Tool Group, LLC

Av. Liberdade, 4055 Berkenyefa sor 7

Zona Industrial - Iporanga Pf: 640

18087-170 Sorocaba 9027 Györ

SP Brazil Hungary

Tel: +55 15 2383929 Tel: +36 96 66 1383

Fax: +55 15 2383260 Fax: +36 96 66 1135

Table of contents

Other Cleco Engine manuals