Clei HOME OFFICE 220 User manual

Assembly

Instructions

Home Oce

01

Clei S.r.l.

via G.Marconi 22060 Carugo (CO) Italy

tel. +39. 031. 761666 - fax +39. 031. 762346

EN

MOD. HOME OFFICE

MOD. HOME OFFICE 220

MOUNTING INSTRUCTIONS

02 03

WARNINGS

Read carefully before proceeding

THE INSTALLER SHALL BE SOLELY RESPONSIBLE FOR CORRECT

ASSEMBLY OF THE WALL FIXING AND PANELS INCLUDING TESTING THE

PRODUCT;

INSTALLATION MUST BE PERFORMED BY QUALIFIED PERSONNEL;

WRONG INSTALLATION OF THE MODEL CAN CAUSE ACCIDENTS THAT CAN

LEAD TO SERIOUS INJURY TO THE USER.

The product must be fixed to walls and intact and resistant panels (concrete, brick, stone, tile

blocks in vertical holes, etc.) and placed on perfectly level floors (for minimum drops use the feet

adjustment).

Considering the possible and multiple features of the walls and panels to which the product must

be fixed, which are unknown to the manufacturer, a specific preventive inspection by the installer

prior to running the assembly is mandatory in order to verify the integrity and the level of effective

resistance of the walls and panels.

For this model a minimum of 4 fixing points have to be provided.

It should be noted that in the hardware supplied there are also a series of plugs used only and

exclusively for fixing to the solid-webbed concrete R250 walls structure; please note that, even

in this case, prior verification by the installer is required on the integrity and the level of the wall

structures’ effective resistance

For disclosure purposes,other types of wall structures are indicated as follows:

- for walls in compact material, the use of metallic plugs;

- for walls in hollow bricks, the use of nylon / metallic plugs;

- for walls in plasterboard the use of metallic plugs for plasterboard with tongues fixed to the jamb of

the wall structure;

- For walls of a material different from the previous ones we recommend an analysis of the flow

resistance and the wall itself, in reference to the product being installed.

Furthermore, please note that in case of reassembly of the furniture the same holes in the

wall cannot be used for its fixing, therefore a different placing of the small squares and plugs

as established by the installer is obligatory.

Every screw has to be tightened correctly, no part of the model has to be unstable or loose. Do not

use for any reason models with structural parts broken or lacking.

CLEI DECLINES ANY RESPONSIBILITY DERIVING FROM THE NON-

OBSERVANCE OF THIS PROVISION

04 05

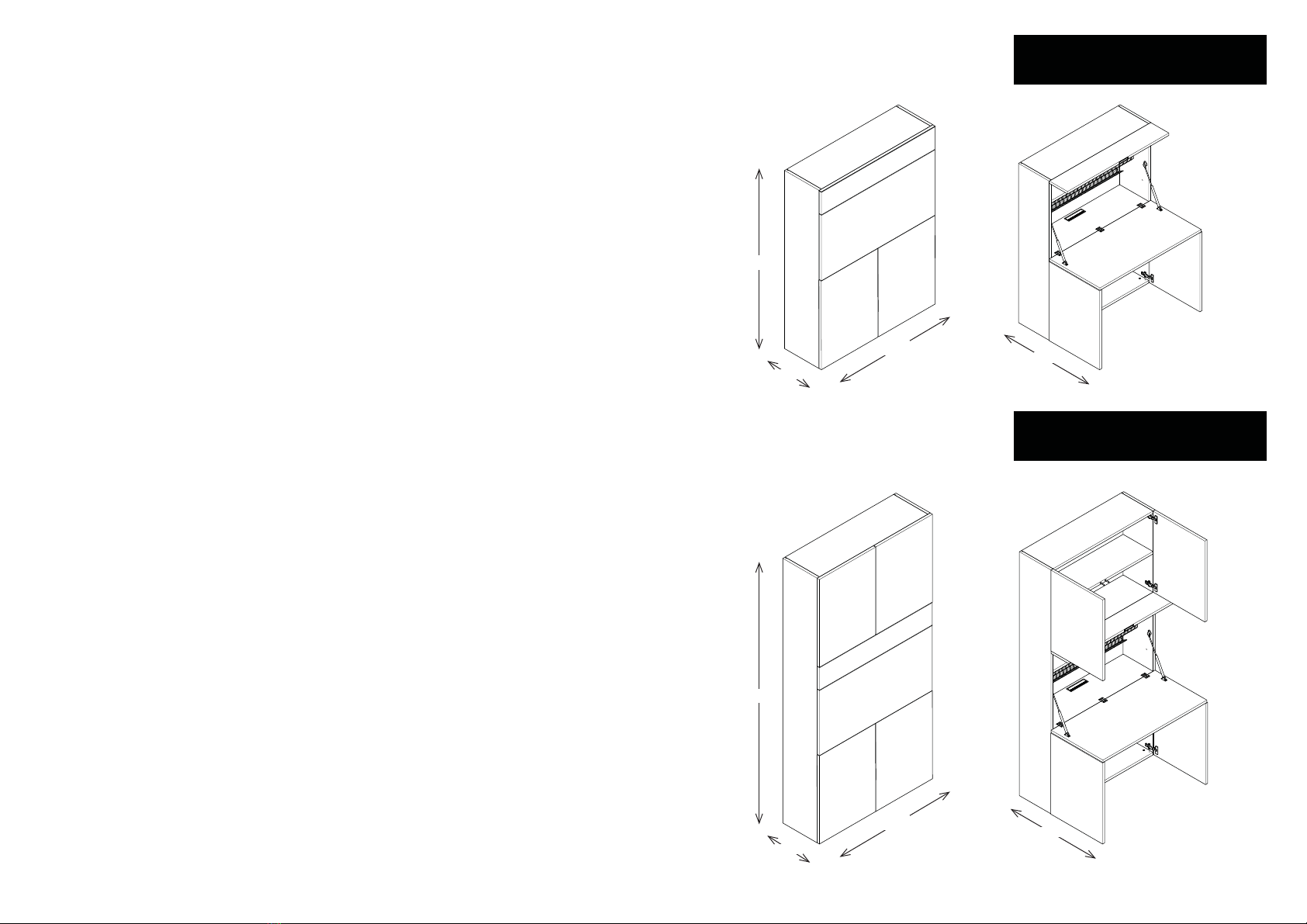

350 864

864

350

1478

2200

1080

1080

HOME OFFICE

HOME OFFICE 220

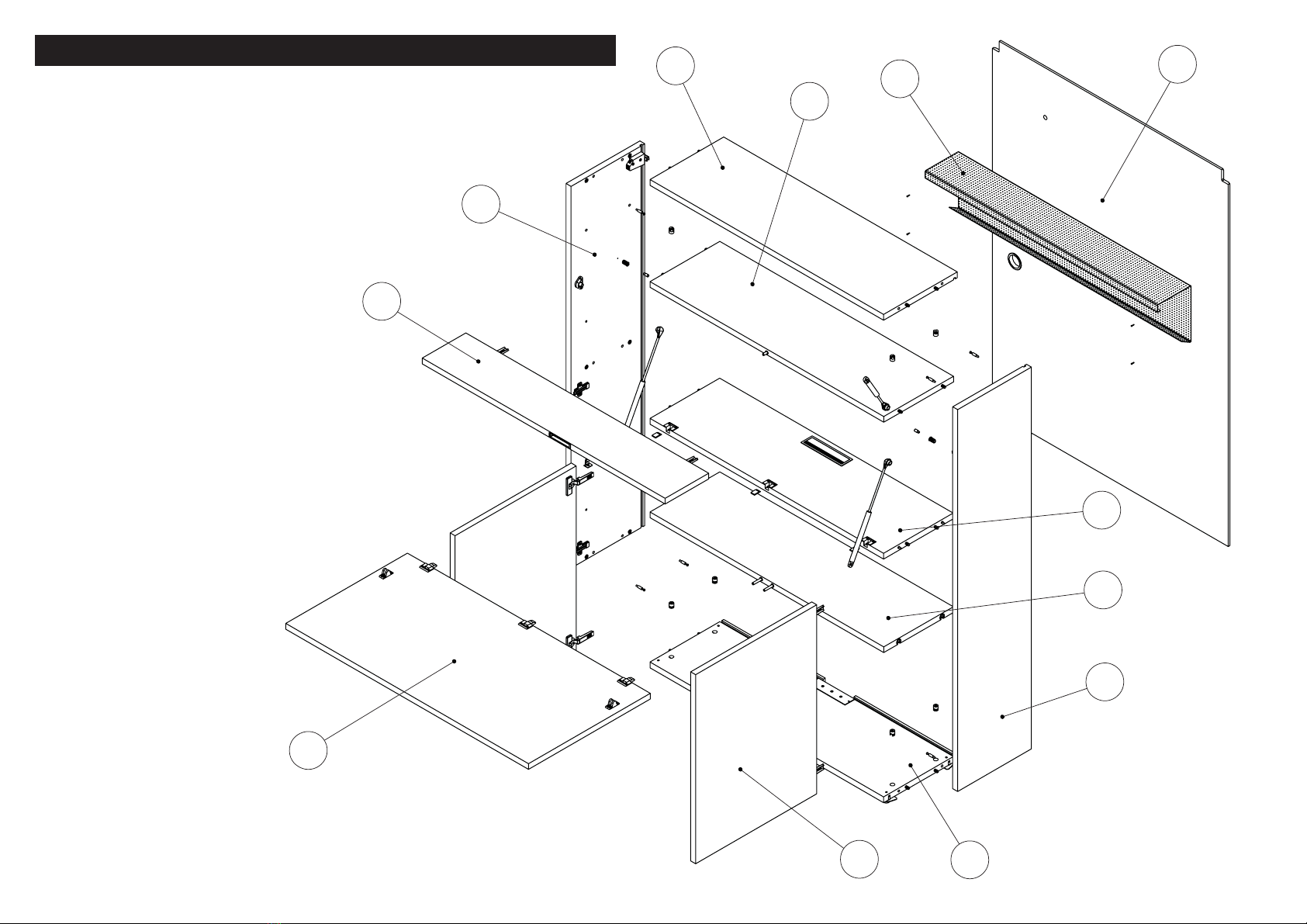

06 07

OVERALL DESIGNS

08 09

HOME OFFICE

2

8

9

5

1

6

10

13

11

7

4

3

10 11

HOME OFFICE 220

2

13

8

9

5

1

6

10

12

11

7

4

3

12 13

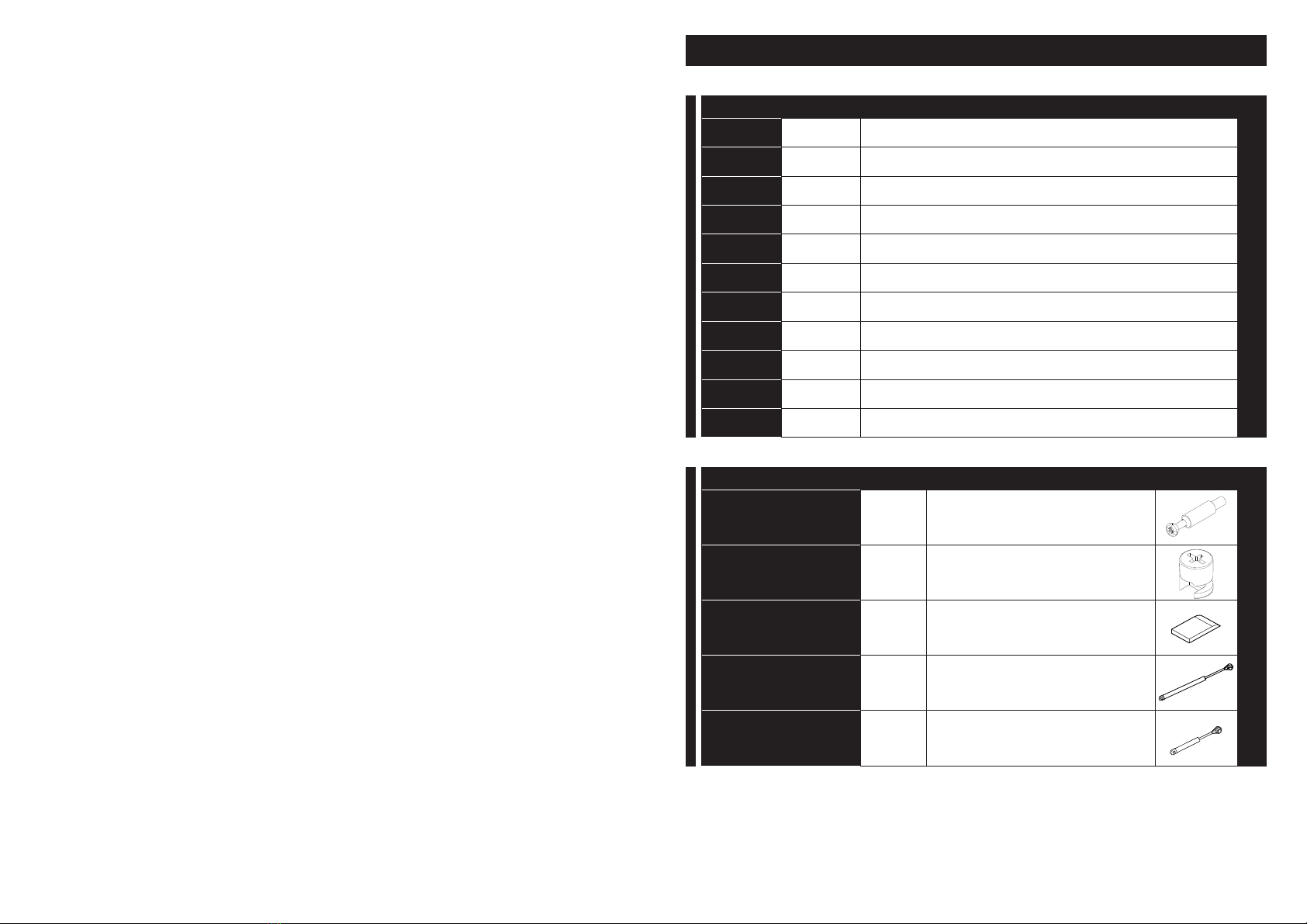

COMPONENTS AND HARDWARE LIST

14 15

HOME OFFICE

CODE QNT. COMPONENT

1 1RIGHT SIDE

21LEFT SIDE

31INSPECTION CEILING

41BASE

51BACK

61LAMPHOLDER FACING

71UPPER FOLDING PANEL

81FOLDING PANEL

91FOLDING PANEL FACING

10 2HINGED PANEL

11 1FACING

HARDWARE PART QTY DESCRIPTION

PIN 7x36 6MA 12 PINS TO JOIN STRUCTURE

CAM D15 L17 12 CAMS TO JOIN STRUCTURE

FLAP COVER 3FLAP COVER CLOSURE

BIG GAS SPRING 2BIG GAS SPRING

SMALL GAS

SPRING 1SMALL GAS SPRING

16 17

HARDWARE PART QTY DESCRIPTION

WALL HANGING

BRACKET COVER 2FOR WALL FIXING

BAR 1FOR WALL FIXING

METAL SHEET SHELF FITTING

CODE QNT. COMPONENT

13 1METAL SHEET SHELF

HARDWARE PART QTY DESCRIPTION

AUT.SCREW TC

CROSS 3,5x12 4SCREWS FOR SMALL SHELF FIXING

BEARINGS D8 L15 2BEARING FOR SMALL SHELF

FIXING

PIVOT 2PIVOT FOR SMALL SHELF FIXING

HOME OFFICE 220

IRON FITTINGS FOR WALL FIXING

CODE QNT. COMPONENT

1 1RIGHT SIDE

21LEFT SIDE

31INSPECTION CEILING

41BASE

51BACK

61LAMPHOLDER FACING

71UPPER FOLDING PANEL

81FOLDING PANEL

91FOLDING PANEL FACING

10 4HINGED PANEL

11 2FACING

12 1UPPER SHAFT FACING

HARDWARE PART QTY DESCRIPTION

PIN 7x36 6MA 16 PINS TO JOIN STRUCTURE

CAM D15 L17 16 CAMS TO JOIN STRUCTURE

FLAP COVER 3FLAP COVER CLOSURE

BIG GAS SPRING 2BIG GAS SPRING

SMALL GAS

SPRING 1SMALL GAS SPRING

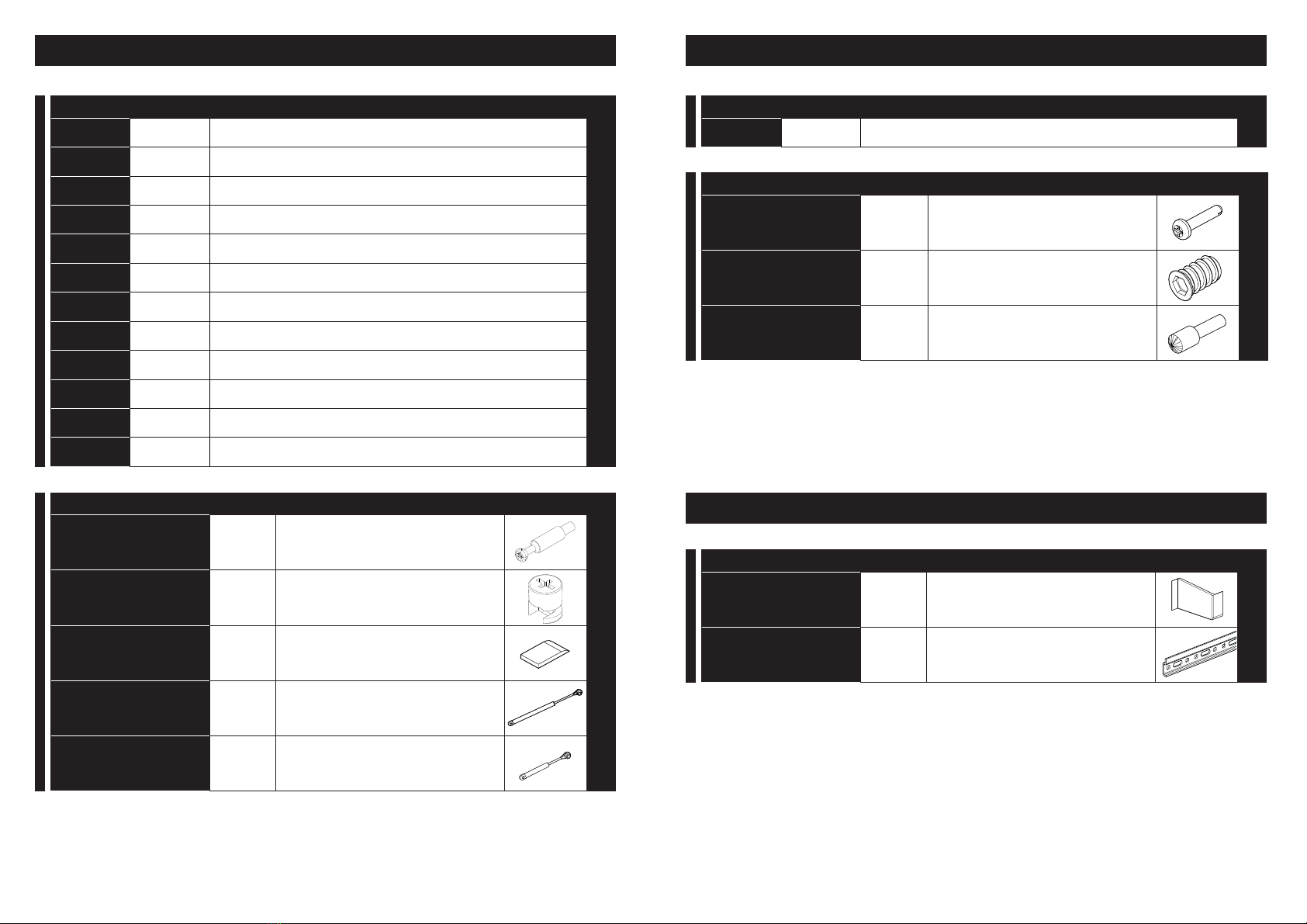

18 19

ASSEMBLY SEQUENCE

20 21

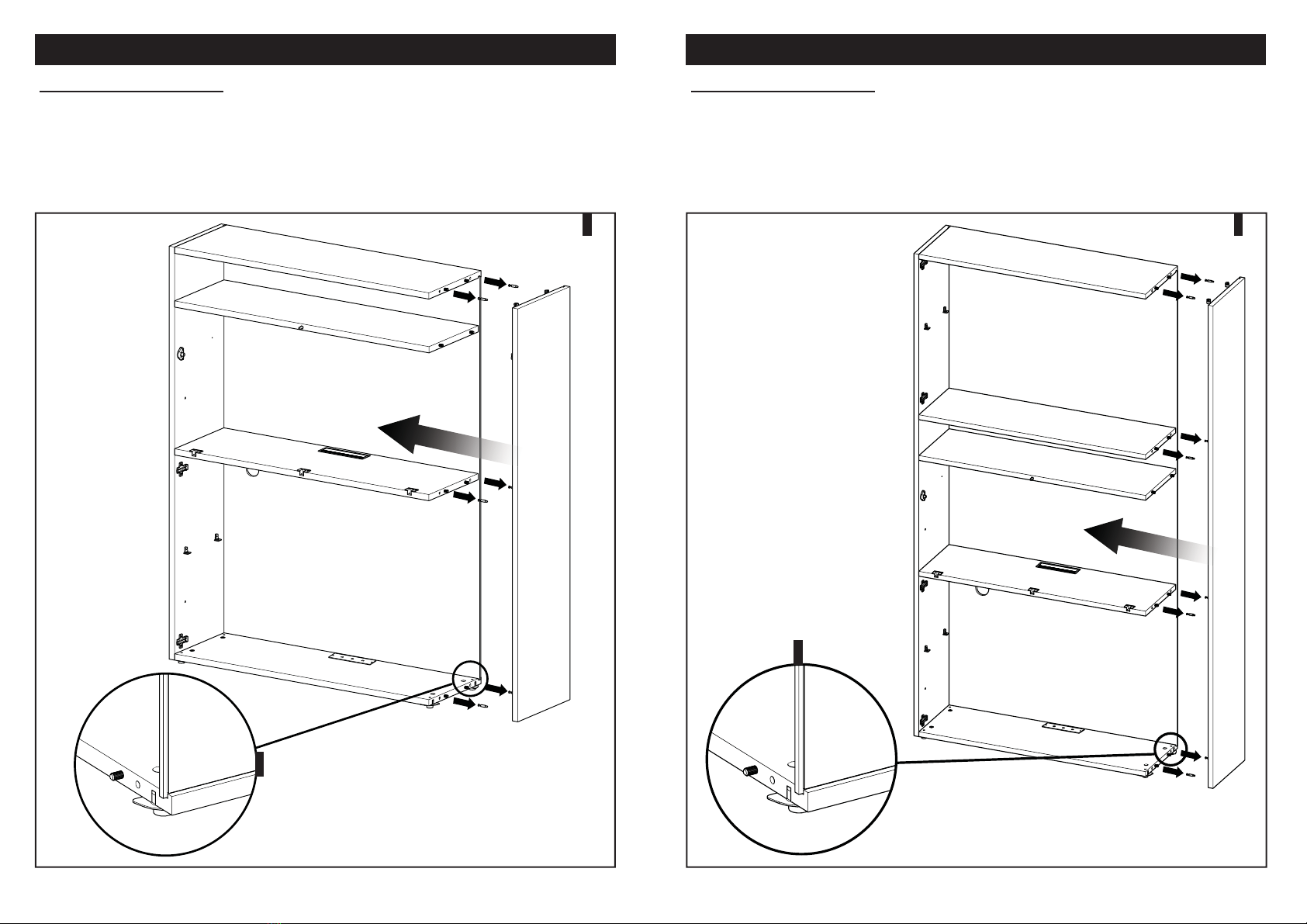

1 2

det.1a

det.2a

STRUCTURE ASSEMBLY

IMG.1: Screw the right side (1) and left side (2) 12 PIVOTS 7x36 6MA; assemble the structure

combining their backs to the ceiling (3), to the base (4), to the folding panel facing (9) and lamp

holder facing (6) by inserting and tightening 12 D15 L17 ECCENTRICS (pay attention to the correct

passage of the lamp power cord into the hole located on the back - see also page 22) the back (5) is

inserted into the appropriate mills present on the other elements of the structure (det.1a).

STRUCTURE ASSEMBLY

IMG.2: Screw the right side (1) and left side (2) 16 PIVOTS 7x36 6MA; assemble the structure

combining their backs to the ceiling (3), to the base (4), to the folding panel facing (9) and lamp

holder facing (6) by inserting and tightening16 D15 L17 ECCENTRICS (pay attention to the correct

passage of the lamp power cord into the hole located on the back - see also page 22) the back (5) is

inserted into the appropriate mills present on the other elements of the structure (det.2a).

ONLY HOME OFFICE VERSION 220ONLY HOME OFFICE VERSION

22 23

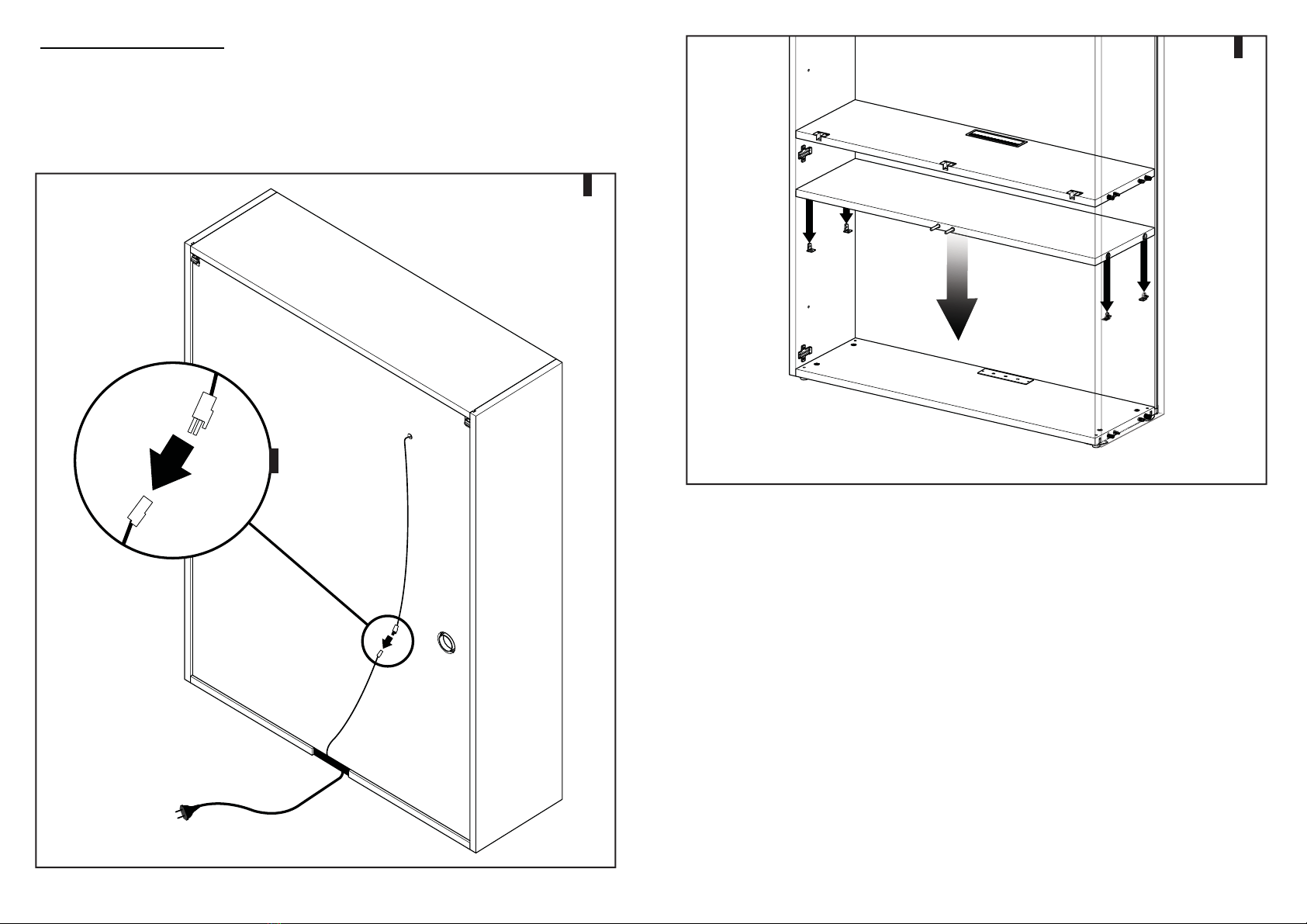

3

det.3a

4

STRUCTURE ASSEMBLY

IMG.3: Pass the cable of the lampholder facing (6) through the hole on the back (5), connect the cable

of the LED light with that of the transformer (det.3a). Leave the cable of connection to the electrical

current free while the furniture is placed against the wall. If necessary, pass cables of electrical objects

placed inside the cabinet through the circular fairleads.

IMG.4: Insert facing (11) on the appropriate shelf holder.

24 25

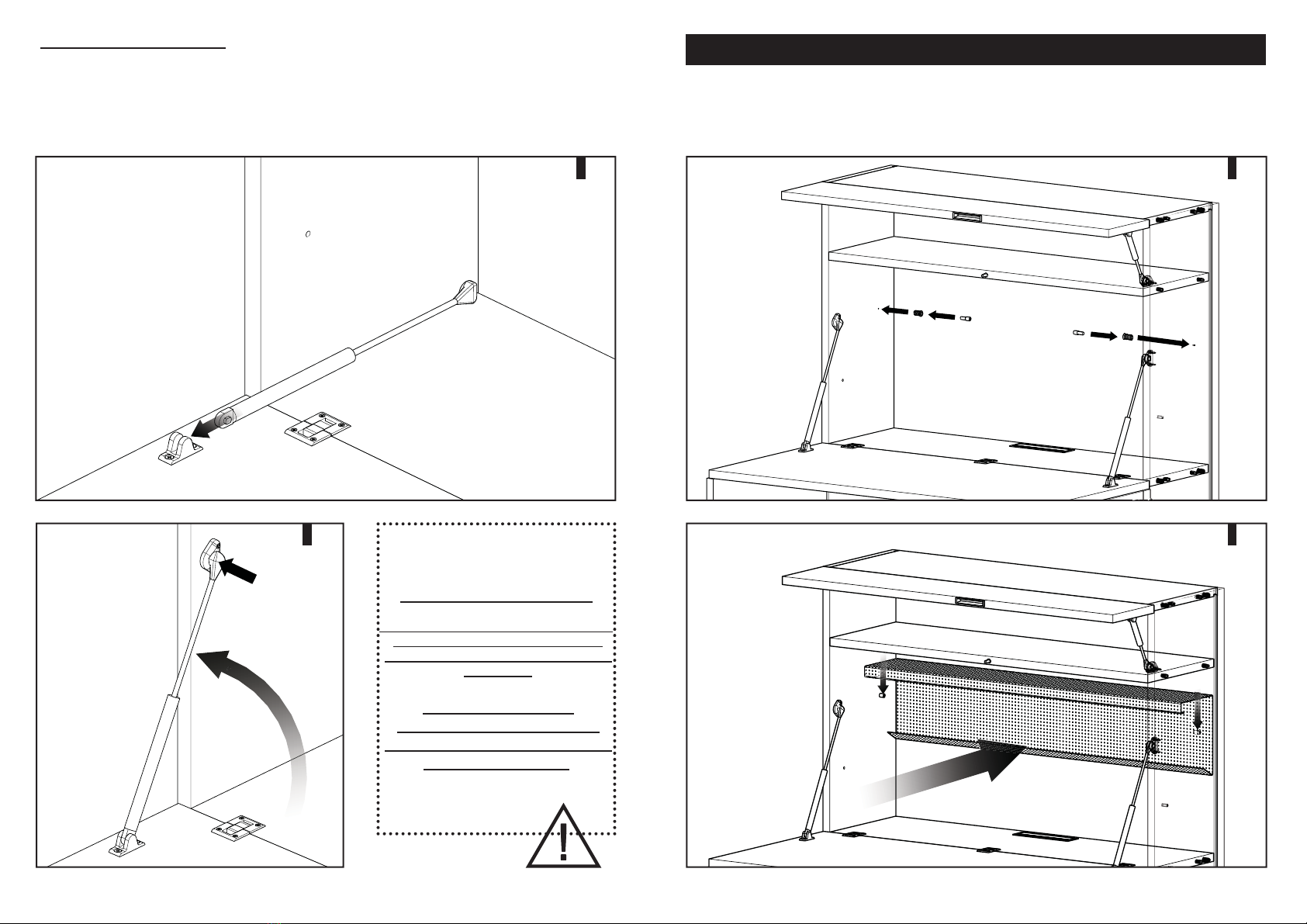

FIXING THE FURNITURE TO THE WALL

IMG.5: While preparing the furniture for the wall fixing, pay attention at keeping a constant distance

between the top and lower part of the back of the furniture and the wall itself; align the furniture to the

floor, verifying that the furniture is perfectly horizontal; to compensate possible irregularities of the floor,

adjust the adjustable feet of the furniture (det.5a).

IMG.6: Turn the two screws to adjust the clamping arm of the hanging bracket, attach the hanging

bracket on the drawbar previously fixed to the wall.

IMG.7: Cover the hanging bracket with aluminum cover provided.

det.5a SAFETY RULES FOR THE FIXING OF THE FURNITURE TO THE WALL

READ CAREFULLY BEFORE PROCEEDING

THE INSTALLER SHALL BE SOLELY RESPONSIBLE FOR CORRECT ASSEMBLY OF THE WALL

FIXING AND PANELS INCLUDING TESTING THE PRODUCT; INSTALLATION MUST BE PERFORMED

BY QUALIFIED PERSONNEL; WRONG INSTALLATION OF THE MODEL CAN CAUSE ACCIDENTS

THAT CAN LEAD TO SERIOUS INJURY TO THE USER.

The product must be fixed to walls and intact and resistant panels (concrete, brick, stone, tile blocks in

vertical holes, etc.) and placed on perfectly level floors (for minimum drops use the feet adjustment).

Considering the possible and multiple features of the walls and panels to which the product must be fixed,

which are unknown to the manufacturer, a specific preventive inspection by the installer prior to running the

assembly is mandatory in order to verify the integrity and the level of effective resistance of the walls and

panels.

For this model a minimum of 4 fixing points have to be provided.

It should be noted that in the hardware supplied there are also a series of plugs used only and exclusively

for fixing to the solid-webbed concrete R250 walls structure; please note that, even in this case, prior

verification by the installer is required on the integrity and the level of the wall structures’ effective resistance

For disclosure purposes,other types of wall structures are indicated as follows:

- for walls in compact material, the use of metallic plugs;

- for walls in hollow bricks, the use of nylon / metallic plugs;

- for walls in plasterboard the use of metallic plugs for plasterboard with tongues fixed to the jamb of the wall

structure;

- For walls of a material different from the previous ones we recommend an analysis of the flow resistance

and the wall itself, in reference to the product being installed.

Furthermore, please note that in case of reassembly of the furniture the same holes in the wall

cannot be used for fixing, therefore a different placing of the small squares and plugs as established

by the installer is obligatory.

CLEI DECLINES ANY RESPONSIBILITY DERIVING FROM THE NON-OBSERVANCE OF THIS

PROVISION

76

5

26 27

9

det.9a

8

PANEL ASSEMBLY

IMG.8: Attach the hinged panel (10) to the brackets placed on the sides (1.2).

IMG.9: Pull the folding panel (8) to the structure and hook the two hinge parts with 3 COVER (det.9a).

Hook the two hinges of the upper folding panel (7) to the structure bearing.

28 29

IMG.12: Open the two pre-drilled holes on the back (1.2) and insert 2 BEARINGS D8 L15 N° 2 PINS.

IMG.13: Pull the metal sheet shelf (12) to the backrest (5), resting it on the pins.

ONLY MODEL WITH METAL SHEET SHELF FITTING

13

GAS SPRINGS CLEANING

To keep the gas spring perfectly efficient

a soft cloth must be used WITHOUT

the help of any solvent for the cleaning

operations.

CLEI DECLINES ANY

RESPONSIBILITY DERIVING

FROM THE NON-OBSERVANCE

OF THIS PROVISION

GAS SPRING ASSEMBLY

IMG.10: Insert the GAS SPRINGS horizontally in the folding panel bearing (8) and the upper folding

panel (7).

IMG.11: Attach the pin of the GAS SPRINGS to the side bearings (1.2).

10

11

12

30 31

14

IMG.14: Fix the shelf to the back (5) with n° 4 AUT. SCREWS TC CROSS 3,5x12.

32 33

PRODUCT FILE

34 35

GENERAL

INFORMATION

Home Office is a container equipped with a workstation and integrated

with the system woodwork.

The central folding panel, turns into a desk top with pass cables and

integrated LED illumination.

The single version 148 cm high and version with additional storey 220 cm

high are both integrated with the Living and Young System.

USE AND

DISPOSAL

INSTRUCTIONS

Assembly and safety

Home Office needs to be fixed to the wall. The models are supplied

disassembled and are provided with instructions of assembly. For

installation, specifically follow the instructions on page 3.

A yearly check of the integrity of the furniture and of its opening system

by the user is suggested, in order to verify possible wears due to use.

Use

Avoid intervening for maintenances on the components of the product

and for all eventualities contact the retailer.

The edges do not have to be placed near heat sources higher than

45°C. The possible presence of particular smells emitted by the product

immediately after it is removed from the pack is not a source of danger

and disappears with the exposure in an aired environment.

Disposal

Once disposed of, the product and its components do not have to be

dispersed in the environment, but brought to the public disposal system

in compliance with the regulations in force.

Maintenance wood and lacquered parts

It is advisable to execute the cleaning of the wood and lacquered parts

using water only with a soft cloth. The exposure to direct sunlight may

alter the colour of the wood and the lacquering. Avoid products containing

acetone, ammonia, chlorine and solvents, abrasive products and waxes

for the furniture.

Maintenance painted metal parts

The cleaning of the painted metal parts can be executed with neutral

detergents immediately drying them, using a soft cloth.

Springs maintenance

In order to maintain the gas spring perfectly efficient, to clean the stands,

a cloth which does not leave textile residual, WITHOUT the help of any

solvent, must be used.

MAINTENANCE

INSTRUCTIONS

36 37

FAMILY OF HOME OFFICE PRODUCTS ELEMENT

Structure

Back

Lightning

Shelf fitting

MATERIAL DETAILS

Panels

Finishes

All the panels used are in wood particles, consistent with the regulation

UNI EN 717-2: 1996 E1 class with emission with minimum formaldehyde

content.

In the panels production ABS edges and wood are used and applied

with polyurethane glue.

(only for the shaped boards the thermo –melting glue is used).

All the panels with melamine covering have surfaces dignified on two

sides with printed melamine.

All the panels covered in wood have a layer glued with non-toxic

products on wood particles supports.

All the lacquered panels are in colour embossed finish with water

based painting.

The products used for painting do not contain formaldehyde and

their composition makes them classified as non-toxic; moreover

these products are free from the heavy metals in compliance with the

regulation EN 71-3: 2002.

Clei reserves the right to make changes to the products

MATERIAL

• Wood particles panel thickness 22 mm, dignified on two sides with printed melamine or essence.

• The base of the furniture is equipped of nylon adjustable feet.

• Wood particles panel thickness 10 mm, dignified on two sides with white melamine.

• 5,76 W LED lamp with warm light (3500K), with 24 V feeder integrated in the structure.

• Perforated metal sheet shelf 1.2 mm thick bent and painted.

Table of contents

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual