Cleveland CycleWerks Misfit 250 Gen II User manual

1

© 2018 Cleveland CycleWerks

Cleveland CycleWerks Misfit 250 Gen II

REV.1 –2018-11-25

SERVICE MANUAL OHV 250

2

GUIDE TO THE MANUAL

GUIDE TO THE MANUAL

3

VEHICLE IDENTIFICATION

9

SPECIFICATIONS

10

TIGHTENING TORQUE

14

MAINTENANCE SCHEDULE

15

EMISSIONS CONTROL SYSTEMS

16

MAINTENANCE

18

SEAT/TANK/EXHAUST/ENGINE REMOVAL/INSTALLATION

37

HEAD/CYLINDER

43

CLUTCH/ALTERNATOR/STARTER CLUTCH

53

CRANKCASE/TRANSMISSION/CRANKSHAFT

66

FUEL/AIR SYSTEM

82

FRONT WHEEL/STEERING

90

REAR WHEEL/SUSPENSION

115

BRAKES

126

IGNITION/STARTING SYSTEM

147

CHARGING SYSTEM/BATTERY

153

LIGHTING/HORN/INSTRUMENTS

156

WIRING SCHEMATIC

161

TROUBLESHOOTING

162

3

GUIDE TO THE MANUAL

Your personal safety, and the safety of those around you, is extremely important. Operating this

motorcycle safely is an important responsibility. Cleveland CycleWerks has provided operating

procedures and other information on labels in this manual to help you make informed decisions

about safety. This information will alert you to potential hazards that could harm you or others.

It is not practical or possible to warn you about all possible hazards associated with operating and

maintaining a motorcycle. You must use your own good judgment and common sense. In many

cases “common sense” seems to be less and less common. Please use solid judgment, do not

ride above your ability and respect the fact that you are a sack of water traveling through space at

a high rate of speed. Respect the bike, respect the terrain and use caution.

Safety information will come in a variety of different forms, including:

Safety Labels on the Motorcycle.

Safety Messages preceded by a safety symbol and one of these signal words below:

Sections of text in this manual, which are particularly important in terms of safety or possible

damage to the motorcycle are marked with the following symbols:

You CAN be KILLED or SERIOUSLY INJURED if you do not follow instructions.

You CAN be KILLED or SERIOUSLY INJURED if you do not follow instructions.

You CAN be INJURED if you do not follow instructions.

Safety Headings such as important safety reminders and/or precautions.

Safety Section such as motorcycle safety.

Instructions how to use the motorcycle properly and safely.

Safety Symbols

4

GUIDE TO THE MANUAL

Operating, servicing and maintaining a passenger vehicle can expose you to chemicals such as

lead, phthalates, engine exhaust and carbon monoxide that are known to the State of California

cause cancer and birth defects or other reproductive harm. To minimize exposure, avoid

breathing exhaust, service your vehicle in a well-vented area and wear gloves or wash your

hands frequently when servicing your vehicle.

For more information go to:

www.P65Warnings.ca.gov/PassengerVehicle.

Proper service, maintenance and repair are mandatory to operate any motor vehicle safely.

Keeping your motorcycle in good operating condition is absolutely essential to your safety. It is

essential to ensure your motorcycles longevity. Proper maintenance will ensure you are achieving

maximum performance, avoid breakdowns, and will ultimately have more fun.

The service intervals in this manual are based on average riding conditions. More frequent service

is needed if you subject your motorcycle to severe use, or ride in unusually wet and dusty areas.

Frequent checks of the air cleaner are very important to help you avoid engine damage.

The information contained herein is valid at the time of printing. Cleveland CycleWerks reserves

the right to make changes required by the future development of the above mentioned products.

We do our best to verify the accuracy of this manual, but mistakes do happen, no liability is

accepted for mistakes during the drafting of this manual.

For your safety and reliability of your vehicle, use original

CLEVELAND CYCLEWERKS spare parts ONLY.

!!! DO NOT use the motorcycle or try to service it if you do not possess the

necessary skills, if you have never turned a wrench, please entrust your safety to a

motorcycle service professional!!!

Important Safety Precautions

This vehicle has a minimum age requirement of 16

Always wear necessary and properly fitting protective gear when operating this vehicle.

NOTICE

WARNING

Obtain, review and follow provisional/municipal government laws and regulations pertaining to

owning and operating an on-road vehicle before using this product

5

GUIDE TO THE MANUAL

Make sure the engine is off before you begin any maintenance or repairs. This will help eliminate

the following hazards:

1. Carbon Monoxide Poisoning From Engine Exhaust –Be sure you have adequate ventilation

whenever you operate the engine.

2. Burns From Hot Motorcycle Parts –Let the engine and exhaust system cool before you touch them.

3. Injury From Moving Parts –Do not run the engine unless your hands and body parts are clear from

danger or risk of injury.

Read all instructions before you begin a procedure. Make sure you have all of the tools and skills required.

To help prevent the motorcycle from falling over, park it on a firm, level surface, using the side stand or a

maintenance stand to provide support. To reduce the chance of a fire or explosion, be careful when

working around gasoline. Use only a non-flammable (high flash point) solvent such as mineral spirits to

clean parts. Keep cigarettes, sparks, and flames away from all fuel related parts.

Cleveland CycleWerks LLC., and our authorized Distributor are pleased to explain the emission

control system warranty on your Motorcycle. New motor vehicles must be designed, built and

equipped to meet the state and national emissions laws for which they are certified for. Distributor

must warrant the emission control system on your vehicle for 30 months or 5,000 km, whichever

comes first, provided that there has been no abuse, neglect or improper maintenance of your

vehicle.

Your emission control system includes the carburetor, the ignition system, catalytic converters and

engine control unit. Also included are hoses, connectors and other emission-related assemblies.

Where a warrantable condition exists, Distributor will repair your vehicle at no cost to you,

including diagnosis, parts and labor.

If an emission-related part on your vehicle is defective, the part will be repaired or replaced by

Distributor. This is your emission control system DEFECTS WARRANTY.

The following warranty applies to the noise control system and is in addition to the general

Cleveland CycleWerks Authorized Distributor warranty and the emission control warranty.

Cleveland CycleWerks Authorized Distributor warrants to the first, and each subsequent owner,

that the vehicle was designed and built so as to conform, at the time of sale, with the regulations

at the time of manufacture, was free from defects in materials and workmanship which would

cause the motorcycle not to meet the noise control system warranty extends for a period of six (6)

calendar months starting from the date of purchase. Same warranty applies to a demonstration

motorcycle or company motorcycle.

WE RECOMMEND THAT ONLY FACTORY GENUINE CLEVELAND CYCLEWERKS PARTS

BE USED FOR MAINTENANCE REPAIR OR REPLACEMENT OF THE NOISE CONTROL

SYSTEM.

Emissions Warranty

Noise Control System

6

GUIDE TO THE MANUAL

If Non-Factory Genuine Parts are used

to repair your motorcycle,

warranty claims may be denied.

Owners are warned that the law prohibits:

(A)The removal or rendering inoperative by any person other than for purposes of maintenance,

repair or replacement, of any device or element of design incorporated into any new vehicle

for the purpose of noise control prior to its sale or delivery to the ultimate purchaser or while it

is in use;

(B)The use of the vehicle after such devise or element of design has been removed or

rendered inoperative by any person.

Acts which are likely to constitute tampering include the following;

1. Removal or tampering with the muffler’s, baffles or header pipes or any other component,

which conducts exhaust gases.

2. Removal of or puncturing of any part of the air intake system.

3. Failure to carry out maintenance as prescribed in the owner’s manual.

4. Replacing any part of the exhaust or air intake system with parts other than those specified by

Cleveland CycleWerks.

The following items are not covered by the noise control system warranty;

1. Failures, which arise through misuse, alterations or accident damage.

2. Replacing, removing or modifications of any part of the noise control system (consisting of the

exhaust system and air intake system) with parts not certified to be noise legal for street use.

3. Cleveland CycleWerks Authorized Distributor shall not be liable for loss of use,

inconvenience, lost time, commercial losses or other incidental or consequential damages.

This motorcycle should be checked for repair or

replacement if the motorcycle noise has increased

significantly through use, otherwise the owner may

become subject to penalties under state and local laws

NOTICE

Tampering With Noise Control System

7

GUIDE TO THE MANUAL

As the motorcycle owner, you are responsible for the performance of the required maintenance

listed in your owner’s manual.

Cleveland CycleWerks recommends that you retain all receipts covering maintenance on your

motorcycle, but Cleveland CycleWerks Authorized Distributor cannot deny warranty solely for the

lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

You are responsible for presenting your motorcycle to a Cleveland CycleWerks dealer as soon as

a problem exists. The warranty repairs should be completed in a reasonable amount of time, not

to exceed 30 days.

As the motorcycle owner, you should also be aware that Cleveland CycleWerks Authorized

Distributor may deny you warranty coverage if your motorcycle or a part has failed due to abuse,

neglect, improper maintenance or unapproved modifications.

NOTICE! Use of any Cleveland CycleWerks brand vehicle in any type of competitive

event completely and absolutely voids this and all other warranties offered by Cleveland

CycleWerks Authorized Distributor.

If you have any questions regarding your warranty right and responsibilities, you should contact

Cleveland CycleWerks or Cleveland CycleWerks authorized Distributor.

A. Is designed, built and equipped so as to conform at the time of initial retail purchase with all

applicable regulations of the state and country in which they are authorized to be sold.

B. Is free from defects in material and workmanship which cause such vehicle to fail to

conform to applicable regulations.

C. Coverage: Warranty defects shall be remedied during customary business hours at any

authorized Cleveland CycleWerks dealer and/or service center. Any part or parts replaced

under this warranty shall become the property of Cleveland CycleWerks Authorized

Distributor.

. This Emission Control System Warranty shall not cover any of the following:

A. Repair or replacement as a result of

1. Accident(s)

2. Misuse

3. Repairs improperly performed or replacement parts improperly installed

4. Use of replacement parts or accessories which are not genuine Cleveland CycleWerks

replacement parts which adversely affect performance and/or

5. Use in competitive racing or related events.

B. Inspections, replacement of parts and other services and adjustments required for required

maintenance.

C. Any vehicle equipped with an odometer or hour meter on which the odometer mileage or

hour meter reading has been changed so that the actual mileage cannot be readily

determined.

Owner’s Warranty Responsibility

8

GUIDE TO THE MANUAL

D. Limited Liability

A. The liability of Cleveland CycleWerks Authorized Distributor, under this

Emission Control System Warranty is limited solely to the remedying of

defects in material or workmanship by an authorized Cleveland CycleWerks

dealer at its place of business during customary business hours. This

warranty does not cover inconvenience or loss of use of the vehicle or

transportation of the vehicle to or from the Cleveland CycleWerks dealer.

CLEVELAND CYCLEWERKS AUTHORIZED DISTRIBUTOR SHALL NOT

BE LIABLE FOR ANY OTHER EXPENSES, LOSS OR DAMAGE,

WHETHER DIRECT, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY

ARISING IN CONNECTION WITH THE SALE OR USE OF OR INABILITY

TO USE THE CLEVELAND CYCLEWERKS VEHICLE FOR ANY PURPOSE.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU.

B. NO EXPRESS EMISSION CONTROL SYSTEM WARRANTY IS GIVEN BY

CLEVELAND CYCLEWERKS AUTHORIZED DISTRIBUTOR, EXCEPT AS

SPECIFICALLY SET FORTH HEREIN. ANY EMISSION CONTROL SYSTEM

WARRANTY IMPLIED BY LAW, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, IS LIMITED

TO THE EXPRESS EMISSION CONTROL SYSTEM WARRANTY TERMS STATED

IN THIS WARRANTY. THE FOREGOING STATEMENTS OF WARRANTY ARE

EXCLUSIVE AND IN LIEU OF ALL OTHER REMEDIES. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS SO THE

ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

C. No dealer is authorized to modify this Cleveland CycleWerks Authorized Distributor

Limited Emission Control System Warranty.

E. LEGAL RIGHTS. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU

MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

F. THIS WARRANT IS IN ADDITION TO THE CLEVELAND CYCLEWERKS AUTHORIZED

DISTRIBUTOR LIMITED ON ROAD VEHICLE WARRANTY.

G. ADDITIONAL INFORMATION. Any replacement part that is equivalent in

performance and durability may be used in the performance of any maintenance or

repairs. However, Cleveland CycleWerks Authorized Distributor is not liable for these

parts. The owner is responsible for the performance of all required maintenance.

Such maintenance may be performed at a service establishment or by any individual.

The warranty period begins in the date the motorcycle is delivered to an ultimate

purchaser.

9

VEHICLE IDENTIFICATION

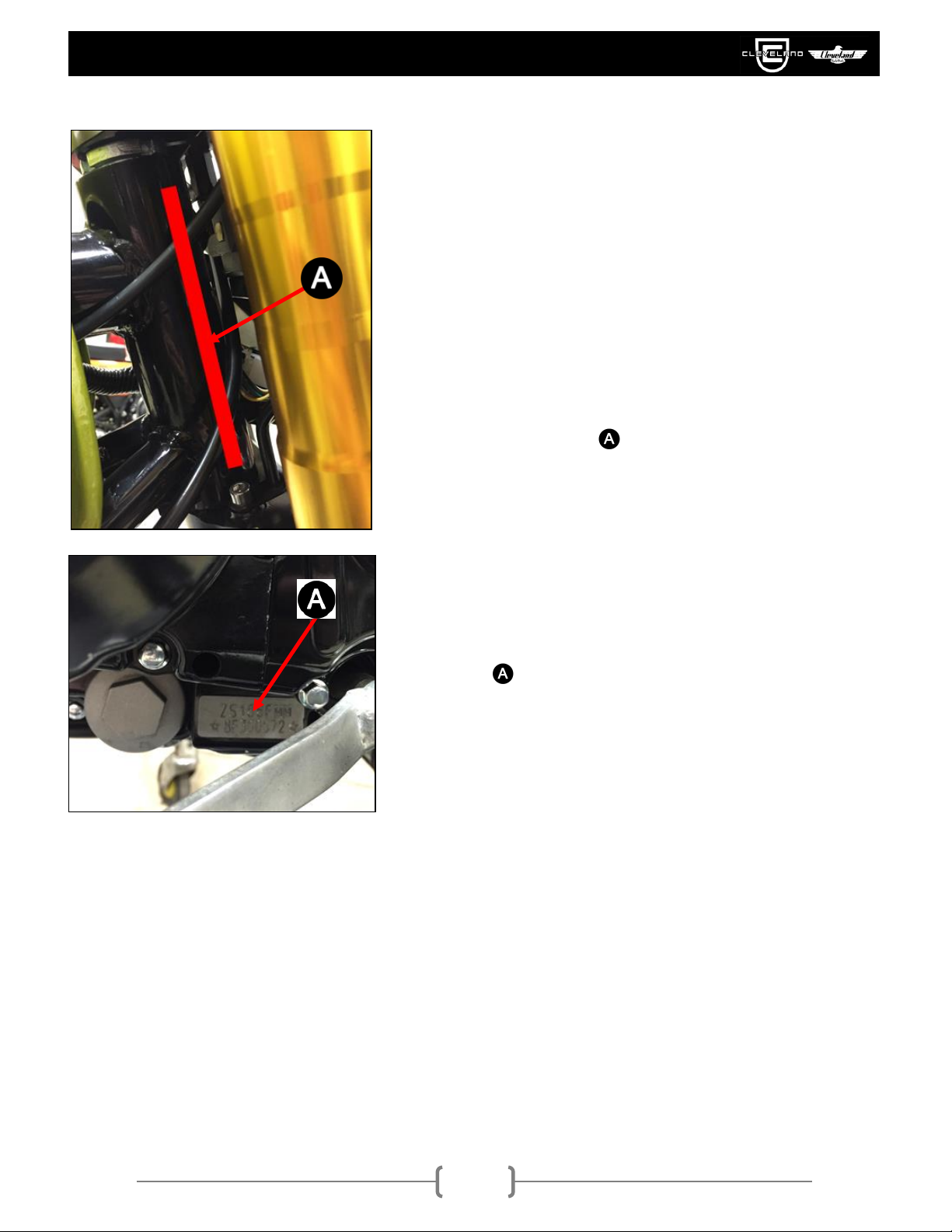

VIN –Chassis Number

The VIN number identifies the motorcycle. When placing

orders for spare parts, you may be required to provide

the VIN, engine serial number and the color of the

motorcycle.

The VIN number is located in one of three places on the

chassis.

1. Right side of frame on compliance sticker.

2. Left side of frame on compliance sticker.

3. Steering head tube right side of frame.

Engine Model & Serial Number

The engine model number and serial number is stamped

on the left side of the engine below the countershaft

sprocket.

10

SPECIFICATIONS

Dimensions

Length

2150mm

Width

780mm

Height

1080mm

Wheelbase

1400mm

Seat height

770mm

Ground clearance

150mm

Curb/wet weight

144kg

Max capacity (not including vehicle weight)

180kg

Chassis

Seat

Rider/pillion seat with pillion strap

Removable pillion seat cover

Foot rests

Spring loaded rider foot rests

Folding pillion foot rests

Frame type

Tubular backbone, double cradle

High carbon steel

Rake

25 degree

Trail

114mm

Swing arm

Large diameter tubular arms.

Needle roller axial bearings

Needle roller side thrust bearings

Fork clamps

Billet CNC 6061 aluminum

Handle bar

7/8" Tubular steel

Handle bar clamp

Billet CNC 6061 aluminum black anodized

Stem bearings

Tapered needle caged bearings

25mm x 47mm x 15mm

11

SPECIFICATIONS

Front suspension

Inverted forks, 38mm stanchions

Cartridge type damping

Shim stack valving for rebound and

compression

Fork seals 33 x 45 x 10.5

Rear suspension

Twin coil over, oil damped shocks

325mm length eye to eye

Spring pre load adjustable 5 stage

Rear wheel travel

90mm

Front wheel travel

110mm

Front wheel

2.50" x 18" steel

Front tire

Kingstone 100/90-18 tube type 6P.R. 62P

Max. load 583 lbs.

Max. load 265 Kg.

Tire pressure front

200kPa (29psi)

Front axle diameter

15mm

Rear wheel

2.75" x 18" steel

Full floating cush sprocket carrier

Rear tire

Kingstone 120/90-18 tube type 6P.R. 71M

Max. load 759 lbs.

Max. load 345 Kg.

Tire pressure rear

265kPa (38psi)

Rear axle diameter

17mm

Front brake

Single 320mm full floating wave rotor

4 piston radial mount caliper

Braided and bonded DOT stainless steel brake

hose

Rear brake

220mm wave rotor

2 piston slide caliper

Braided and bonded DOT stainless steel brake

hose

Engine

Type

CCWCG250

OHV single cylinder four stroke push rod

Air cooled

Counter balanced

Bore

67.0mm

Stroke

65.0mm

Displacement

229.0cc

Compression ratio

9.2:1

Maximum power

11.5 kW /15.4 HP @7000RPM

Maximum torque

16.0 N-m @6000 RPM

Maximum speed

8500RPM

Idle speed

1500±100RPM

12

SPECIFICATIONS

Minimum fuel consumption

≤354g/kW-h

Starting

Electric and kick

Ignition type

CDI

Ignition advance

15° @1500RPM

Spark plug

DR8EA, DPR8EA-9, Torch D8TC

Spark plug gap

0.6-0.8mm

Intake Valve Open (BTDC)

10°

Exhaust Valve Open (BBDC)

40°

Intake Valve Closed (ABDC)

40°

Exhaust Valve Closed (ATDC)

10°

Intake valve clearance (cold)

0.08mm

Exhaust valve clearance (cold)

0.13mm

Clutch

Wet multi-plate

Clutch lever free play

3-5mm at ball end

Transmission

Constant mesh, five-speed

Primary Reduction 21/70

3.333

First gear ratio 11/32

2.909

Second gear ratio 15/28

1.867

Third gear ratio 19/25

1.316

Fourth gear ratio 23/23

1.000

Fifth gear ratio 24/20

0.833

Final drive

520 roller chain

Front sprocket

13T

Rear sprocket

36T

Fuel

Unleaded gasoline

Minimum fuel octane

87 (R+M/2), 95(RON)

Carburetor model 2016-2017

Sheng Wey PZ30 with accelerator pump

Main jet #98

Pilot jet #40

Needle #145S1

Mixture screw 2.5 turns

Float height 14mm

Carburetor model 2018

KF PZ30

Main jet #100

Pilot jet #38

Needle #K140+washer

Mixture screw 1.5 turns

Float height 14mm

Air filter

Stainless steel mesh (clamp filter)

Pleated paper element (air box)

Exhaust emission system

3 x three way catalyst in muffler

PAIR air injection

Engine lubrication

Pressure-splashed

Oil Pump Type

Inner/outer rotor

13

SPECIFICATIONS

Electrical

Battery

YTX9-BS AGM maintenance free

Battery capacity

12V /9 Amp/hour

Generator

Three-phase A.C. generator

Generator output

160 watts.

Main fuse

15A

Secondary fuse

15A

Headlight

H4 35/35W

High/low/passing

Brake/Tail light

12V 21/5W

Speedometer

Cable driven

Electronic stepper motor needle

LCD odometer/trip meter

Tachometer

Electronic stepper motor needle

Emergency lighting

Four way flasher

Side stand safety switch

Stops engine if driven with side stand down

Turn signal light

12V 21W

License plate light

12V 5W

Neutral indicator light

12V LED

High beam indicator light

12V LED

Turn signal indicator lights

12V LED

Capacities

Fuel tank capacity including reserve

15L

Engine oil capacity

1200ml

Engine oil

SAE10W-40, 15W-50, 20W-50

API SF/SG or SH/SJ with JASO MA

Fork oil capacity

270cc per fork

10W fork oil

Air gap level 115mm

14

TIGHTENING TORQUE

Chassis

Front axle

65N-m

Front axle pinch bolts M6 x 1.0

11N-m

Rear axle

65N-m

Rear axle adjuster nuts M8 x 1.25

20N-m

Swing arm pivot nut

65N-m

Rear shock nuts M10 x 1.25

39N-m

Front brake caliper bolt M10 x 1.25

39N-m

Rear brake caliper bolt M8 x 1.25

23N-m

Front brake rotor bolt M8 x 1.25

23N-m use thread lock

Rear brake rotor bolt M8 x 1.25

23N-m use thread lock

Engine mount bolts M8 x 1.25

23N-m

Engine mount bolts M10 x 1.25

39N-m

Steering stem top nut

65N-m

Steering stem bearing adjust nut

30N-m then turn back 1/4 turn

Handle bar clamp bolts M8 x 1.25

20N-m

Fork clamp bolts M8 x 1.25

20N-m

Fork cartridge bolt M10 x 1.50

39N-m

Fork top

20N-m

Rider footrest bolts M10 x 1.25

39N-m

Pillion rest bolt M10 x 1.25

39 N-m

Seat bolts M8 x 1.25

23N-m

Rear sprocket nut M8 x 1.25

23N-m use thread lock

Front sprocket retainer bolt M6 x 1.0

11N-m

Engine

Spark plug

18N-m

Oil filter screen cover

20N-m

Oil drain bolt M12 x

20N-m use a new aluminum crush washer

Valve clearance adjusting screw lock-nut

15N-m

Cylinder head nut M8 x 1.25

37N-m

Rocker arm holder bolts M8 x 1.25

23N-m

Cylinder base bolts M6 x 1.0

11N-m

Flywheel bolt M10 x 1.25

39N-m

Shift drum detent bolt M6 x 1.0

11N-m use thread lock

Clutch spring bolts M6 x 1.0

11N-m

Centrifugal oil filter nut M12 x 1.25

32N-m use 24mm OD nut tool

Crank case bolts M6 x 1.0

11N-m

Engine side cover bolts M6 x 1.0

11N-m

Exhaust nuts M8 x 1.25

23N-m

Kick starter bolt M8 x 1.25

23N-m

15

MAINTENANCE SCHEDULE

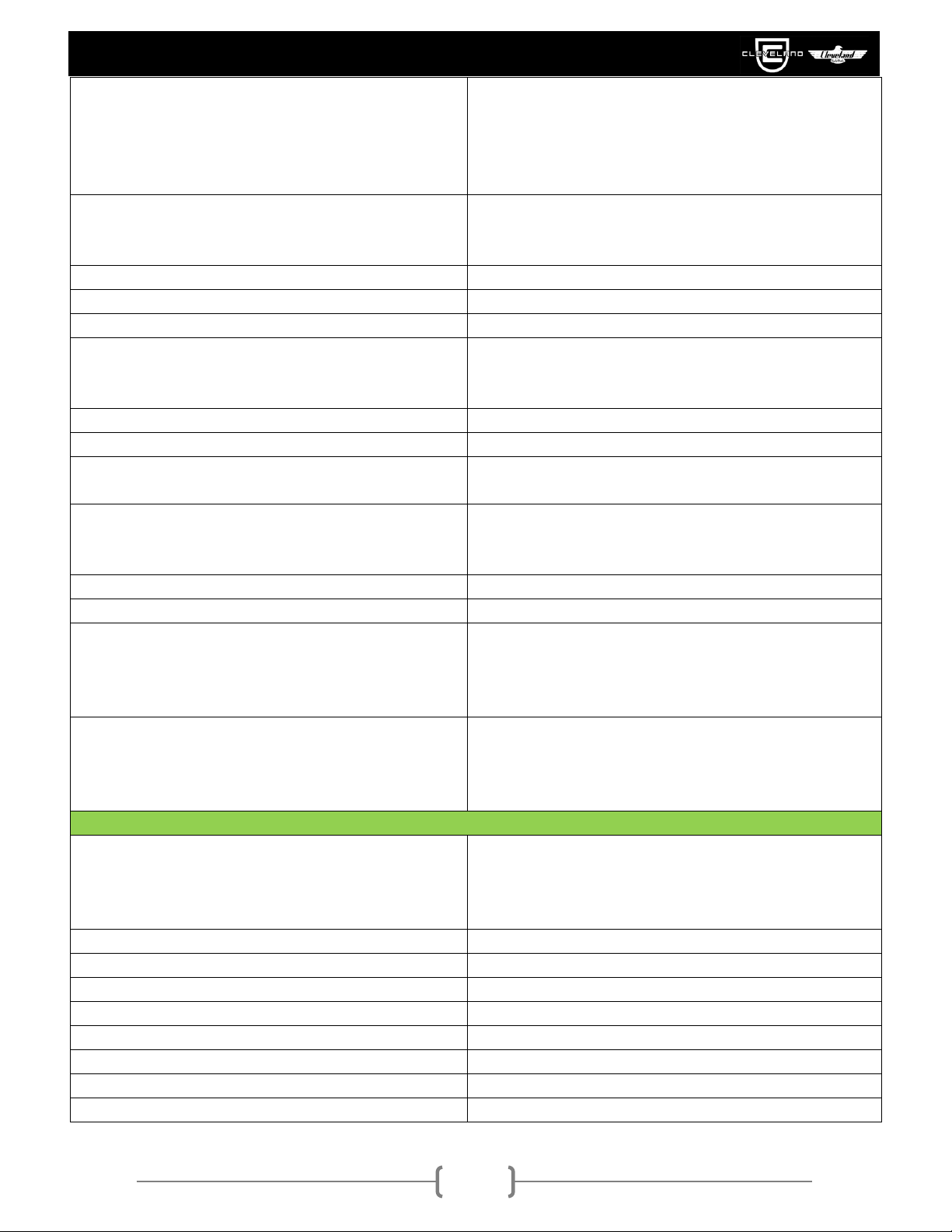

Please use this guide as reference to the maintenance schedule mileage chart:

I = Inspect condition and clean, adjust, lubricate, or replace as necessary. Replace more

frequently under extreme conditions, heavy use, or in wet or dusty environment.

C= Clean

R = Replace

L= Lubricate

A= Adjust

*First Service is critical and required for Warranty.

Maintenance Schedule

Item

300 Mile/

500km First

Service *

Every

1800Miles/

3000km

Every

3600Miles/

6000km

Every

5400Miles/

9000km

Fuel Hose

I

I

I

R

Petcock Sediment Bowl

C

C

C

Fuel Cap and Gasket

I

I

I

I

EVAP Control System

I

I

Secondary Air System

I

I

Spark Plug

I

I

R

Valve Clearance

I/A

Engine Oil

R

R

R

R

Oil Filter Screen

C

C

C

C

Centrifugal Oil Filter

C

Air Cleaner

C

C

C

R

Throttle Adjustment

I

I

I

I

Carburetor Choke

I

I

I

I

Clutch

I

I

I

I

Idle Speed

I

I

I

I

Drive Chain

I/L

I/L Every 300 miles/ 500Km.

Battery

I

I

I

I

Brake Pad/Disc Wear

I

I

I

I

Brake Fluid

I

I

I

R

Headlight Aim

I

I

I

I

Brake Switches, Horn, Side

Stand Switch

I

I

I

I

Bolts, Nuts, Fasteners

I

I

I

I

Tire Pressure

I/A

I/A

I/A

I/A

Wheels, Spokes

I

I

I

I

Steering Head Bearings

I

I

I

A

Suspension

I

I

I

I

16

EMISSIONS CONTROL SYSTEMS

Secondary Air Injection System

Catalyst Exhaust

The pulsed secondary air injection system allows atmospheric air to enter the exhaust

system and mix with the exhaust gas to promote complete burning of excess

hydrocarbons. The pulsed air injection (PAIR) valve contains a one way reed valve and an

air cut diaphragm valve. During normal engine operation, negative pressure periods in the

exhaust head pipes draws fresh air through the one way reed valve into the exhaust.

During engine deceleration, manifold vacuum closes the diaphragm valve and prevents air

from entering the reed valve and the exhaust.

The exhaust system is equipped with metal substrate three-way catalysts to convert

pollutants in the exhaust gas to less toxic pollutants.

17

EMISSIONS CONTROL SYSTEMS

EVAP/ Crankcase Emissions Control System

The Cleveland CycleWerks motorcycle is equipped with an evaporative emissions control

system (EVAP) to prevent fuel and oil vapors from escaping into the atmosphere and

polluting the environment. Fuel vapors evaporating in the fuel tank and oil vapors from the

crankcase are collected in the charcoal canister when the motorcycle is not being ridden.

The vapors in the fuel tank are vented through the vent hose into the canister. During

normal operation of the motorcycle, vacuum from the intake manifold opens a diaphragm

valve to allow engine vacuum to purge the vapors collected in the canister to be burned in

the engine.

Combustion blow by and oil vapors generated in the crankcase during engine operation

are directed into the air box and therefore burned in the engine.

18

MAINTENANCE

Introduction

Routine maintenance of your motorcycle is required to keep it running well and keep it in top condition.

Lack of proper lubrication will let parts wear or rust prematurely; dirt or salt will harm paint and plated parts.

Washing your motorcycle when it becomes dirty will prevent dirt from abrading the paint and keep it looking

good. A mild sop with water is recommended. Oiled surfaces may be washed with an engine degreaser,

rinsed with plenty of water. Do not wash your motorcycle when hot, or in the direct sun. Soaps may harm

the finishes if it is allowed to dry on the motorcycle, rinse the motorcycle with water if the soap is drying. Do

not pressure-wash the motorcycle or spray direct water into the air filter, electrical connectors or air box.

The first service at about 300 mi /500 km is critical as this is when the engine is run-in and parts bed in.

All service procedures are recommended with the engine cool to the touch. Park the motorcycle on

the side stand on level firm ground or in a service stand. Motorcycle are heavy, do not take the risk

of having the motorcycle fall on you during maintenance!

Note: The service intervals are based on average riding conditions. Service the motorcycle more

frequently in harsh, dirty conditions or if the motorcycle is run hard.

19

MAINTENANCE

Maintenance Table of Contents

FUEL HOSES/FUEL FILTER

AIR FILTER

EVAP CONTROL SYSTEM

SECONDARY AIR INJECTION SYSTEM

THROTTLE OPERATION

SPARK PLUG

VALVE CLEARANCE

ENGINE OIL/OIL FILTER SCREEN

CENTRIFUGAL OIL FILTER

ENGINE IDLE SPEED

CARBURETOR CHOKE

DRIVE CHAIN

BATTERY

BRAKE SYSTEM

ELECTRICAL COMPONENTS/SIDE STAND SWITCH/LIGHTING SYSTEM

BOLTS/NUTS/FASTENERS

WHEELS/SPOKES/TIRES

STEERING HEAD BEARINGS

SUSPENSION

CLUTCH SYSTEM

20

21

21

22

22

23

24

26

28

29

29

30

32

32

34

34

34

35

35

36

20

MAINTENANCE

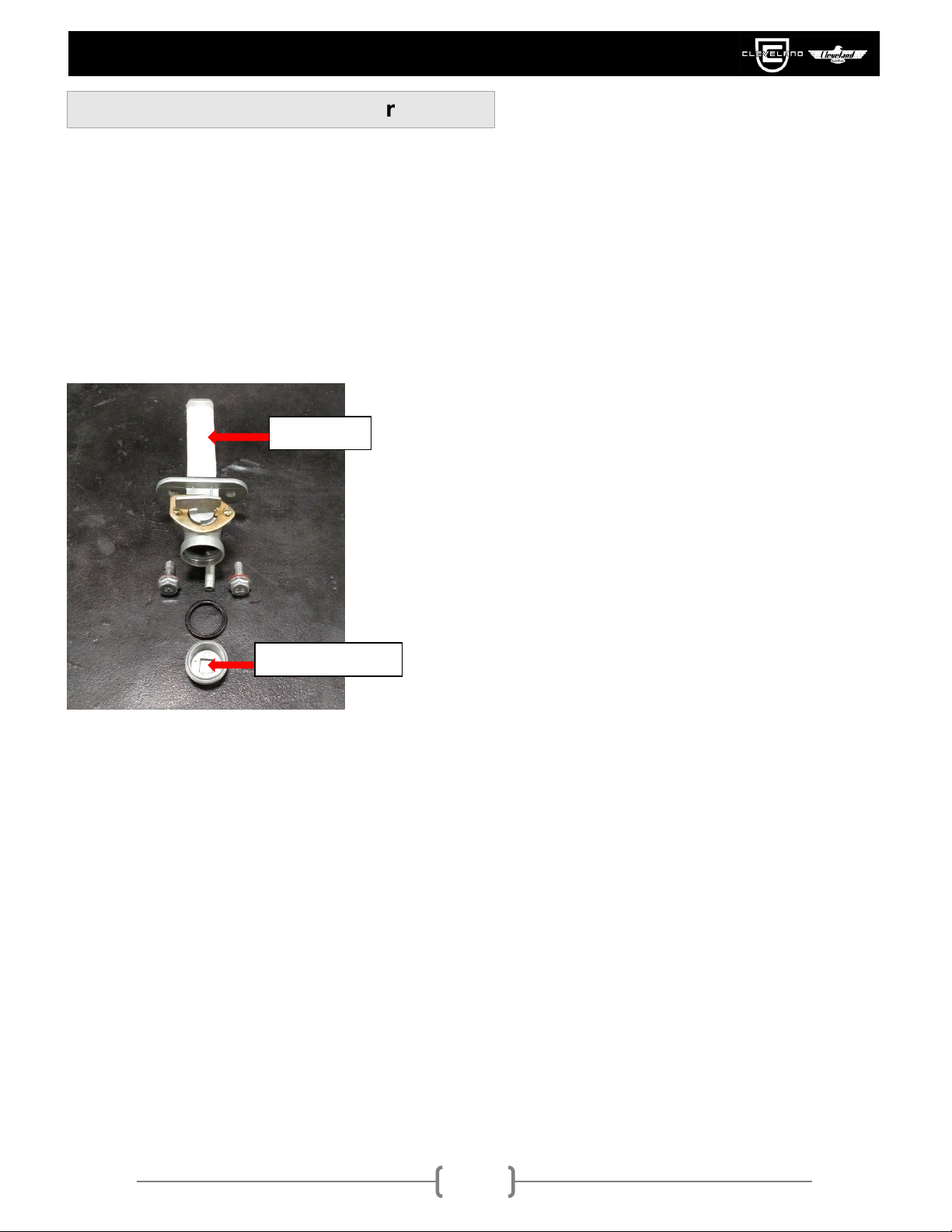

Fuel Hoses/Fuel Filter

1. Inspect the fuel hoses, petcock and carburetor for fuel leaks. Repair as necessary. All fuel

hoses should have a metal retaining clamp on each end. Fuel leaks are a fire hazard; do

not operate the motorcycle with a fuel leak.

2. The petcock features a sediment bowl on the bottom. Remove the bowl and clean of water or

dirt. Replace the bowl O-ring if it is damaged.

3. The fuel filter is a plastic screen inside the fuel tank. Excessive debris caused by poor fuel or

rust in the fuel tank may clog the fuel flow. If fuel flow is restricted, the tank may be removed,

drained of fuel and the petcock removed to clean or replace the filter screen as necessary.

See page 38 for fuel tank removal.

4. Replace the fuel hoses at 5400 mi /9000 km with the original fuel-resistant type.

Sediment bowl

Fuel filter

Other manuals for Misfit 250 Gen II

1

Table of contents

Other Cleveland CycleWerks Motorcycle manuals