Cleveland

™

Project ________________________________

Item __________________________________

Quantity _______________________________

FCSI Section ____________________________

Approval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COOK CHILL SYSTEMS Cook/Chill Systems

SECT. XIV PAGE 49

0707

AIR COOLED

CONDENSING UNITS

MODELS:

c

BLH7.5H2

c

BLH25H2

c

JLD50H2*

c

BLH10H2

c

BLH30H2

c

JLD60H2*

c

BLH15H2

c

BLH35H2

c

BLH20H2

c

BLH40H2

*These units have two (2) compressors

and are not supplied with fused disconnects

Cleveland Standard Features

nAir cooled condensing unit for outdoor installation

nFor operation with R-22, 404A or R507 refrigerant

(please specify)

nLiquid line filter with replaceable core and sight glass

nHigh efficiency Copeland discus compressor

nGalvalume weather housing with raised base compressor

nThermally protected

nPermanently lubricated condenser fan motor(s)

nAccess panels for easy servicing of internal components

nElectrical controls are mounted in control box with hinged

door

nReceivers include service valves

nSuction and discharge vibration eliminators

n180 lbs. head pressure valve

nCrankcase heater for cold temperature operation

nSuction filter with replaceable core

nSuction accumulator

nOil separator

nLow ambient kit

nAnti short cycle timer

nLiquid line solenoid valve (shipped loose)

nDry contacts for compressor alarm

nAccepted for use in U.S.D.A. Inspected Facilities

Options & Accessories

pWater Cooled Condensing Units

pLarger models available upon request

pExtended four (4) year compressor warranty

(domestic only)

pIce Water Control Panel for location in production area

pIce Builders

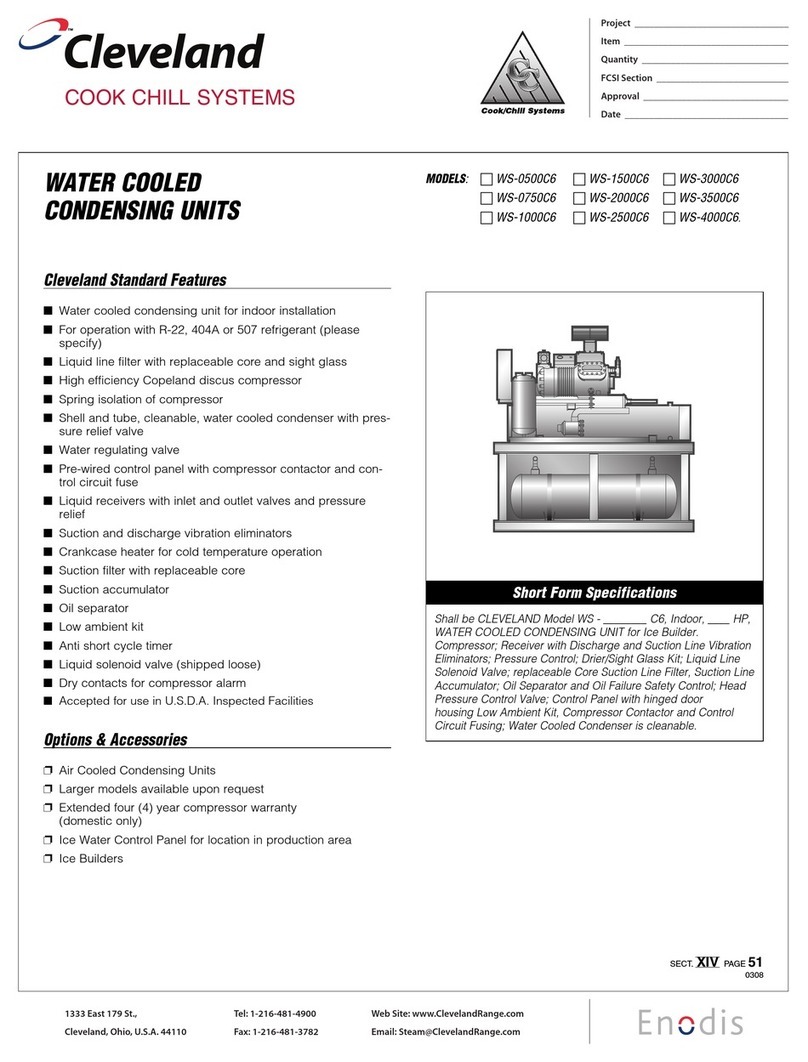

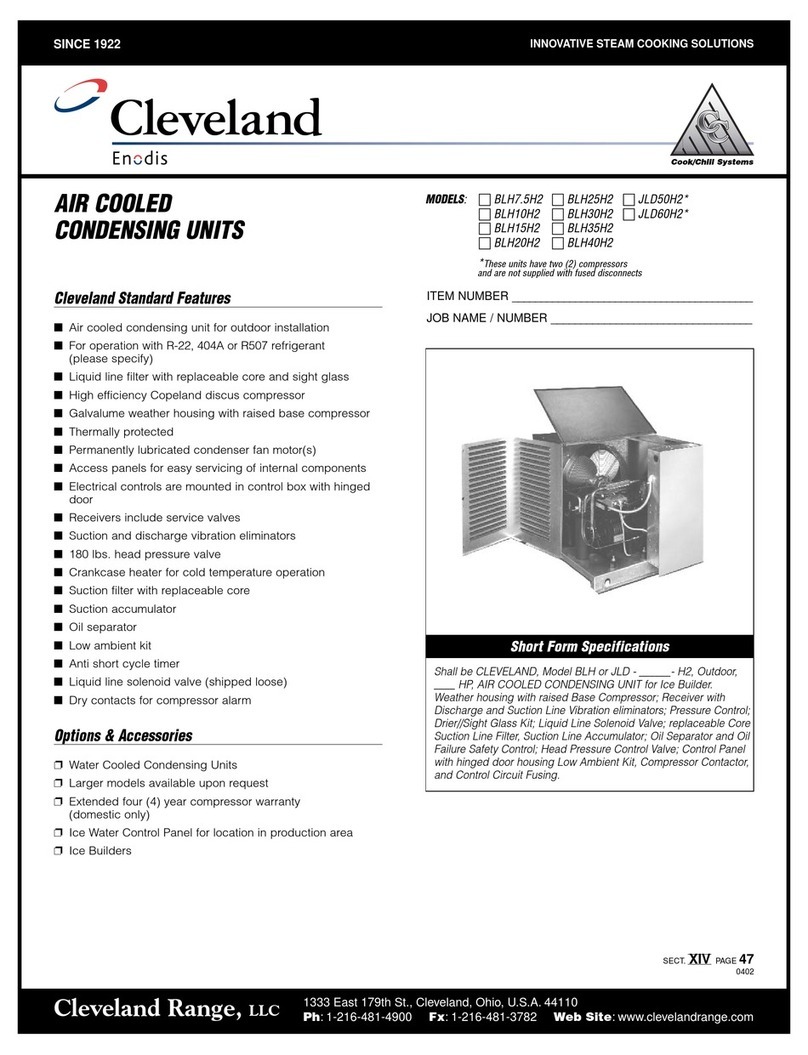

Shall be CLEVELAND, Model BLH or JLD - ______- H2, Outdoor,

____ HP, AIR COOLED CONDENSING UNIT for Ice Builder.

Weather housing with raised Base Compressor; Receiver with

Discharge and Suction Line Vibration eliminators; Pressure Control;

Drier//Sight Glass Kit; Liquid Line Solenoid Valve; replaceable Core

Suction Line Filter, Suction Line Accumulator; Oil Separator and Oil

Failure Safety Control; Head Pressure Control Valve; Control Panel

with hinged door housing Low Ambient Kit, Compressor Contactor,

and Control Circuit Fusing.

Short Form Specifications