Climate RENTAL SOLUTIONS SK1000 User manual

SK1000

TWO DOOR CHILLER FRIDGE

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

OPERATING MANUAL

OPERATING MANUAL SK1000 TWO DOOR CHILLER FRIDGE

Page 2

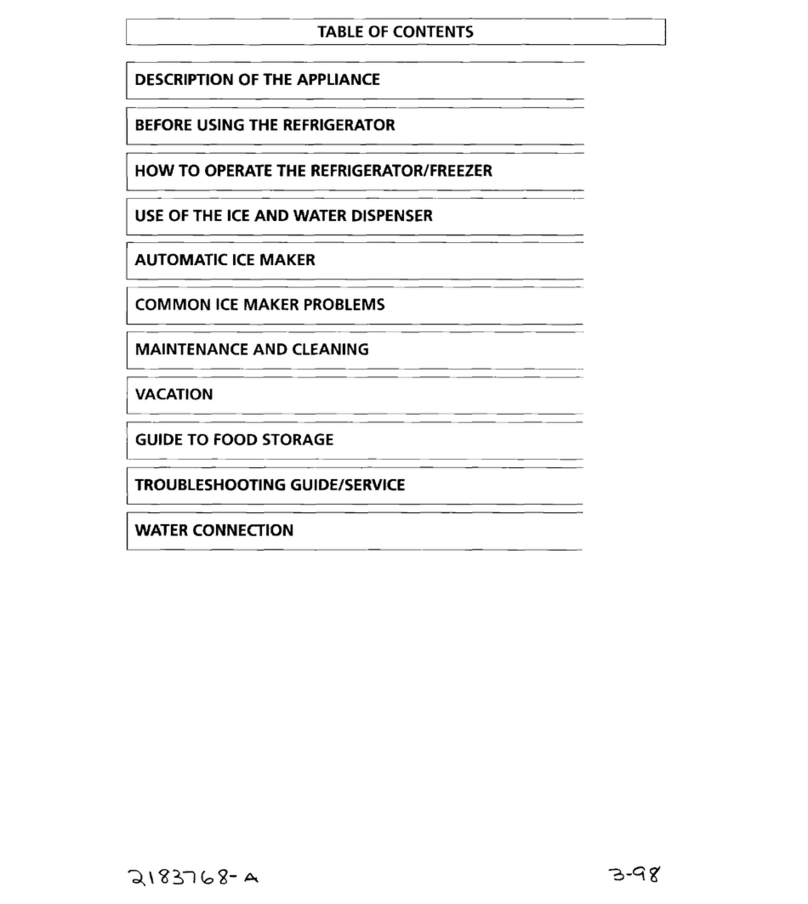

TABLE OF CONTENTS...........................................................................................2

SPECIFICATIONS...................................................................................................3

Cabinet and Refrigeration Unit ................................................................................3

INSTALLATION .......................................................................................................4

Positioning of Machine ............................................................................................4

OPERATION............................................................................................................4

Safety Information ...................................................................................................4

Operation of Machine ..............................................................................................5

Loading....................................................................................................................5

Cleaning ..................................................................................................................5

Servicing..................................................................................................................6

SERVICE INSTRUCTIONS.....................................................................................6

Trouble Shooting .....................................................................................................6

TABLE OF CONTENTS

OPERATING MANUAL SK1000 TWO DOOR CHILLER FRIDGE

Page 3

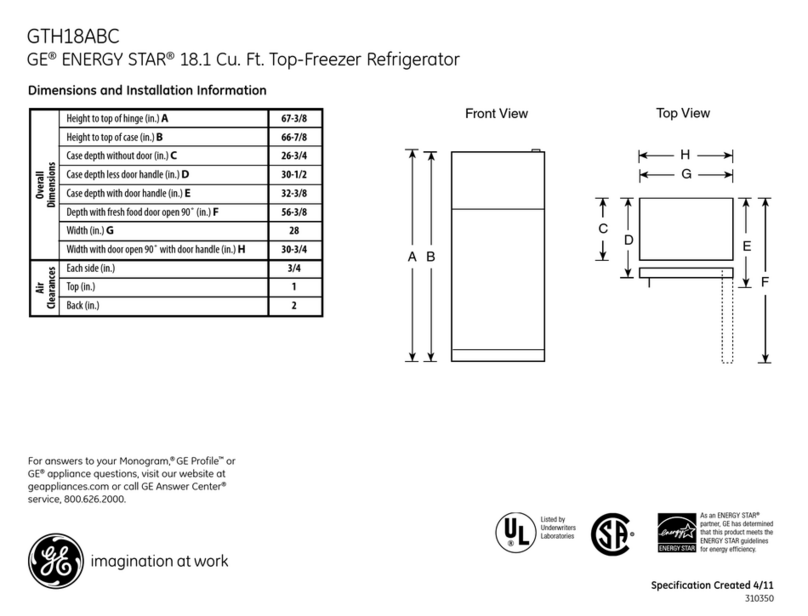

Cabinet and Refrigeration Unit

Cabinet Construction

Exterior/Interior: White powdercoat on galvanised steel

Insulation: 50mm thick, polyurethane foam Cyclo-iso Pentane blowing agent: C5H10/C5H12

Dimensions

Height: 2195mm - with standard castors tted

Width: 1130mm

Depth: 700mm

Floor area: 0.79m2

Internal volume: 980 litres

Refrigeration

Top mounted SKOPE Cyclone® refrigeration unit:

Nominal capacity: 820 Watts

Compressor: Danfoss SC12G

Refrigerant: R134a

Charge: 400 grams

Electrical

230-240 Volts a.c. 50 Hz, single phase power supply

Run Amps: 5.2 Amps

Lighting

2 x interior side lights: 58 Watt uorescent tube, Ø26mm x 1524mm

Illuminated Sign

370mm high at sign: 1 x 30 Watt uorescent tube, Ø26 x 915mm

Doors

Self-closing, aluminium framed, double glazed, toughened safety glass

Shelves

Adjustable height, white powder coated, steel wire shelves

SPECIFICATIONS

OPERATING MANUAL SK1000 TWO DOOR CHILLER FRIDGE

Page 4

Positioning of Machine

Mains Flex

The mains ex exits below the rear panel behind the refrigeration units. For convenience, the ex should be retrieved

before the machine is positioned, when walls and partitions may make access dicult.

Siting chiller

When siting the chiller, avoid direct sunlight, and warm draughts etc. Adequate allowance should be made for door

openings. The cabinet must be positioned on a level surface for the door to shut and seal correctly, and to prevent

the condensate tray from overowing.

Remove all packaging material from the shelves. Clip shelf support brackets into the shelf support strips at the

desired heights, and relocate shelves.

Ventilation

When positioning the chiller, a gap must be left between the top of the sign panels and ceiling, of at least 200mm.

For ecient operation of the chiller, it is essential that adequate ventilation be provided above the refrigeration unit.

Maximum recommended operating ambient temperature is 40°C.

Never store cardboard cartons or other items on top of the refrigeration unit.

OPERATION

Safety Information

When using any electrical appliance, safety precautions should always be observed. Read these instructions carefully,

and retain for future reference.

Warning:

Do NOT overload power supply.

Machine rated at 5.2 Amps @ 240 Volts

• Do not use this appliance for other than its intended use.

• Only use this appliance with voltage specied on the rating label.

• Ensure adequate ventilation of SKOPE refrigeration unit.

• Condenser coil MUST be kept clean. To ensure trouble free performance, it is recommended that on a regular

basis the unit be isolated from the power supply and a vacuum cleaner used to remove dust and u from the

condenser.

• Be careful not to touch moving parts.

• Do NOT cover the grilles or block the entry or exhaust of airow by placing objects up against or on top of re-

frigeration unit.

• Do NOT probe any opening.

• Regulations require that all electrical work be carried out by authorised persons. For your own safety and that of

INSTALLATION

OPERATING MANUAL SK1000 TWO DOOR CHILLER FRIDGE

Page 5

others, ensure this is done.

• If the refrigeration unit is required to be installed or removed from the cabinet, ensure all necessary safety pre-

cautions are observed.

Caution:

Disconnect the cabinet from mains power supply before attempting any electrical servicing, cleaning or maintenance.

Operation of Machine

Plug in machine and check operation of the refrigeration unit, illuminated sign, and cabinet lights. The compressor,

evaporator and condenser fans should all operate initially. This may be veried by listening for compressor switch-on,

and by checking air movement around the refrigeration unit and out of the rear duct inside the cabinet.

Checking Operation

• Compressor and condenser fan should switch o when cabinet internal temperature reaches approximately

+1°C, and on again at approximately +4°C. The internal cabinet air will continue to circulate at all times.

• The lights which illuminate the top sign and cabinet interior are permanently on.

• Ensure the door gaskets form a good seal with the cabinet.

Loading

Shelves may be positioned at dierent heights to suit various products. Always ensure that the shelf clips are securely

engaged in each of the four shelf support strips. Support strips are marked ‘+’ for easy location of shelf clips.

Product

For even cooling and ecient operation, allow air space around packages etc. Do not allow products to overhang the

front of the shelf as this could prevent the door from shutting or cause glass breakage. Leave an airspace of at least

75mm (3”) above packages etc. on the top shelf.

Cleaning

When necessary, wipe both the interior and exterior of the cabinet with a damp cloth. Ensure the cabinet is disconnected

from the mains power supply before cleaning. The exterior of the cabinet may be waxed with automobile polish for

extra protection.

Do not wipe the sealant o the door gaskets, as the sealant ensures the door gaskets form a good seal with the

cabinet.

Periodic cleaning of the condenser coil is also recommended.

Condenser Coil

The condenser coil MUST be kept clean for ecient and reliable operation. Clean the condenser coil with a brush

and vacuum cleaner regularly.

Access to the condenser coil is gained by removing the sign unit. See page 16 for instructions on how to remove the

sign unit.

The preventative maintenance recommendation is to clean the condenser at one to three month intervals. Certain

conditions may necessitate more regular attendance, such as dusty, humid or steamy environments.

OPERATING MANUAL SK1000 TWO DOOR CHILLER FRIDGE

Page 6

Caution:

The cabinet MUST be disconnected from the mains power supply before cleaning the condenser coil.

Servicing

Servicing should be carried out by an authorised service agent.

SERVICE INSTRUCTIONS

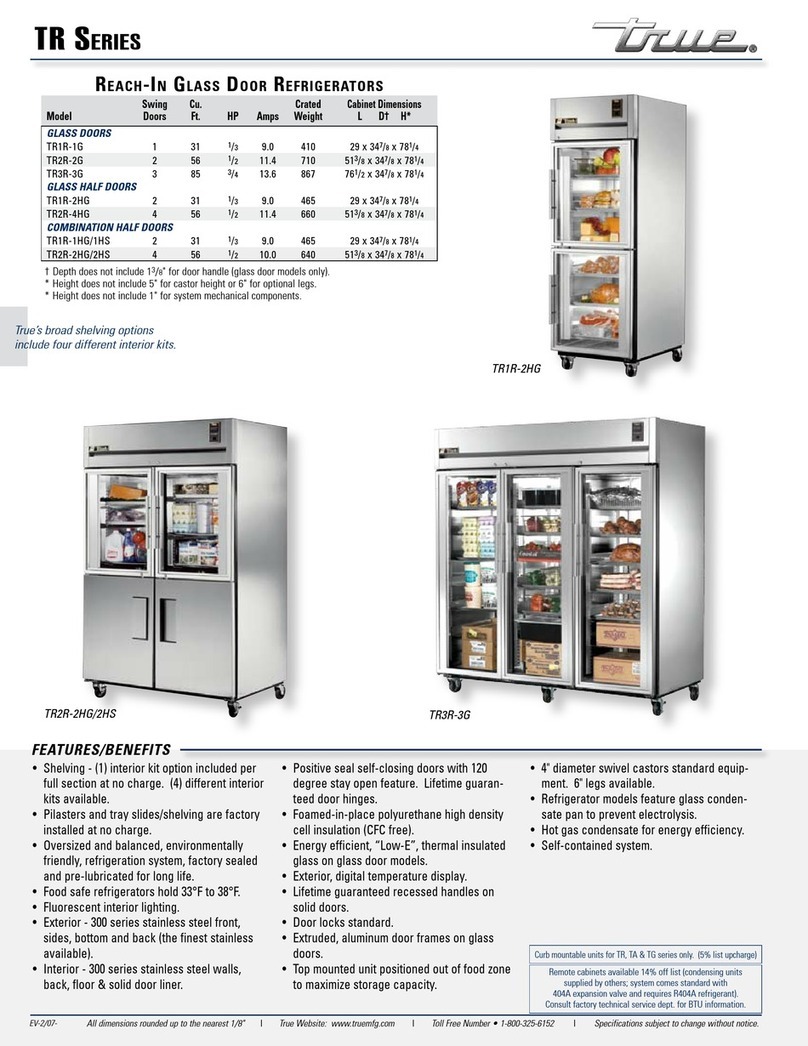

Trouble Shooting

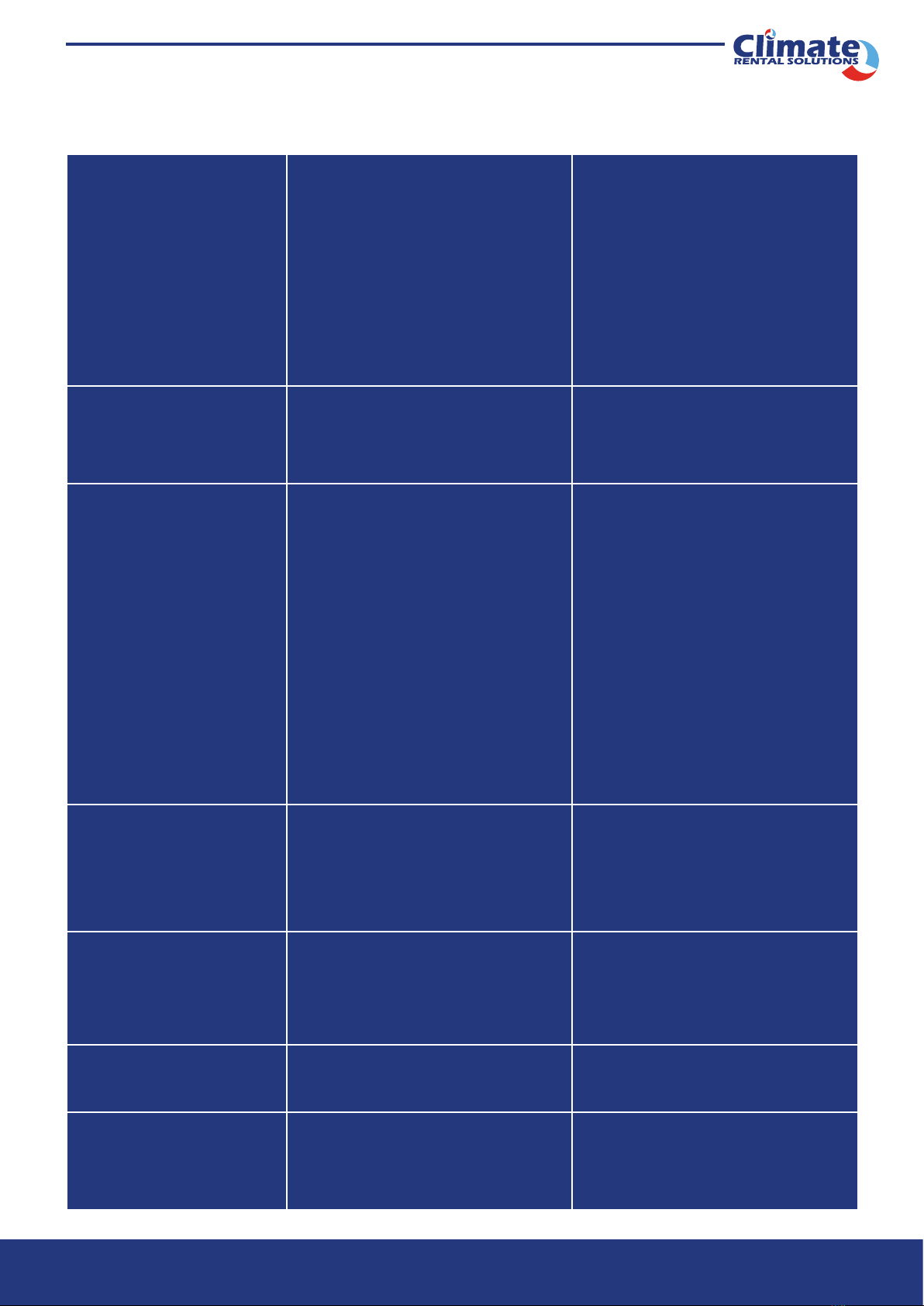

COMPLAINT POSSIBLE CAUSE REPAIR

1. Cabinet not operating - lights

etc not going.

Loss of power supply.

High pressure switch cut-out, due to over

heating.

Check power supply.

Check, and clean condenser. Check unit

operation, and reset pressure switch (see p.7).

2. Compressor will not start - no

hum.

Fuse removed or blown. No power.

Overload protector tripped.

Thermostat stuck in open position.

Thermostat o, due to cold location.

Wiring improper, or loose.

Replace fuse. Check reason.

Refer to electrical section.

Repair or replace control.

Relocate control.

Check wiring against diagram.

3. Compressor will not start -

hums but trips on overload

protector.

Improperly wired.

Low voltage to unit.

Start capacitor defective on CSIR or CSR motor.

Run capacitor defective on PSC motor.

Relay failing to close.

Compressor motor has a winding open or

shorted.

Internal mechanical trouble in com¬pressor.

Check wiring against diagram.

Determine reason and correct.

Determine reason and replace.

Determine reason and replace.

Determine reason and correct. Replace if

necessary.

Check resistance values. Replace compressor if

neces¬sary.

Replace compressor.

4. Compressor starts, but does

not switch o- startswinding.

Improperly wired.

Low voltage to unit.

Relay failing to open, due to welded contacts or

relay incorrectly mounted.

Run capacitor defective on CSR motor.

Excessively high discharge pres¬sure.

Compressor motor has winding open or shorted.

Check continuity and resistance.

Internal mechanical trouble in com¬pressor

(tight). May be lubrication.

Check wiring against diagram.

Determine reason and correct.

Determine reason and correct. Replace if

necessary.

Determine reason and replace.

Clean condenser. Check power input. Possible

overcharge, insucient condenser cooling, or

non-condensible gasses.

Replace compressor if faulty.

Replace compressor.

OPERATING MANUAL SK1000 TWO DOOR CHILLER FRIDGE

Page 7

5. Compressor starts and runs,

butshort cycles on overload

protector (relay may chatter on

RSIR, CSIR and CSR motors).

Additional current passing through overload

protector.

Low voltage to unit.

Overload protector defective.

Run capacitor defective on CSR motor.

Excessive discharge pressure.

Suction pressure too high.

Compressor too hot - insucient suction gas

cooling.

Comp’r motor has a winding shorted.

Check wiring diagram. Check for added

fan motors etc., connected to wrong side of

protector.

Determine reason and correct.

Check current, replace protector.

Determine reason and replace.

Check condenser, check ventilation, check for

restrictions in refrigeration system.

Check for possibility of misapplication.

Check refrigerant charge (x leak), add if

necessary. Check return vapour temperature

and suction superheat.

Replace compressor.

6. Unit runs OK, but short cycles.

Overload protector.

Thermostat: requires adjustment or incorrectly

positioned.

Incorrect refrigerant charge.

See section 4 on p.21.

Adjust or relocate thermostat.

Adjust refrigerant charge.

7. Unit operates long or continu-

ously.Unsatisfactory cabinet

tem¬perature.

Short of refrigerant.

Overcharge of refrigerant.

Thermostat not cooling correctly.

Freezer has excessive load.

Evaporator coil iced.

Restriction in refrigeration system.

Dirty condenser.

Inadequate air circulation.

Compressor not pumping eciently.

Filter dirty (if applicable).

Faulty fan motor.

Fix leak, and add charge.

Remove refrigerant to correct charge.

Adjust thermostat (clockwise colder), and check

thermostat bulb location. If necessary, replace

thermostat.

Establish load within limits.

Defrost evaporator, check refrigeration. Check

thermostat. Check door closing, seals etc.

Determine location and clear restriction.

Flush with dry nitrogen. Replace component if

blockage will not clear.

Clean condenser. Advise client how to regularly

clean condenser.

Internal: Improve air movement, alloe airow

around stock.External: Remove any restrictions

to condensing ventilation.

Replace compressor.

Clean or replace.

Check rotation. Replace if necessary.

8. Start capacitor open, shorted

or blown.

Relay contact not opening properly.

Prolonged operation on start cycle due to:(a)

Low voltage to unit.(b) Improper relay.

Excessive short cycling.

Improper capacitor.

Clean contacts, or replace relay if necessary.

(a) Determine reason and correct.(b) Replace

relay.

Determine reason for short cycling (see section

5 on p.21), and correct.

Determine correct size and replace.

9. Relay defective or burned out.

Incorrect relay.

Line voltage too high or too low.

Excessive short cycling.

Relay being inuenced by loose vibrating mount.

Check and replace.

Determine reason and correct.

Determine reason (see section 5 on p.21), and

correct.

Remount rigidly.

10. Suction line frosted. Evaporator fan not running.

Overcharge of refrigerant capillary systems.

Determine reason and correct.

Correct charge.

11. Unit noisy.

Loose parts or mountings.

Tubing rattle.

Bent fan blade causing vibration.

Fan motor bearing worn.

Find and tighten.

Reform to be free of contact.

Replace blade.

Replace motor.

Table of contents

Other Climate RENTAL SOLUTIONS Refrigerator manuals