17

We make air handling technology. Better.

Air Handling Unit

Installation, Operation, and Maintenance Manual

April 2021

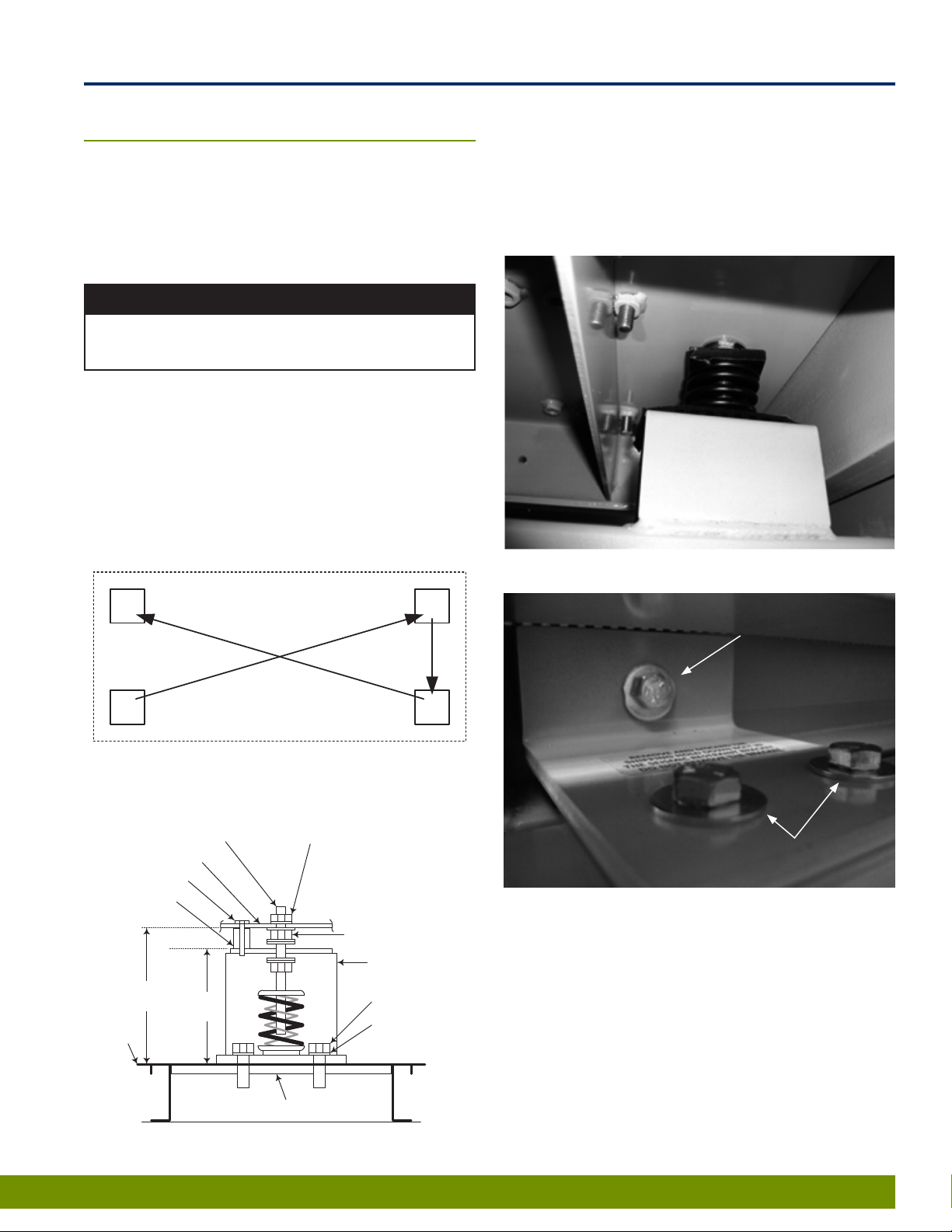

11.0 Startup

Once the ClimateCraft air handling unit is fully assembled,

installed and all utilities have been connected, the unit is

now ready for operation. However, before doing so, check

the following:

a) Conrm building supply voltage matches

the voltage for which the unit is wired. If the

unit receives 575V power or the VFD has

100’ or more wire between it and the motor,

ClimateCraft recommends the insertion of a load

reactor between the VFD and the motor;

b) Check contractor-made pipe and wire

penetrations for water tightness. Penetrations

must be watertight to prevent water damage to

the unit and building;

c) Manually rotate fans to ensure free operation.

Remove any dirt or debris that may have

accumulated during installation;

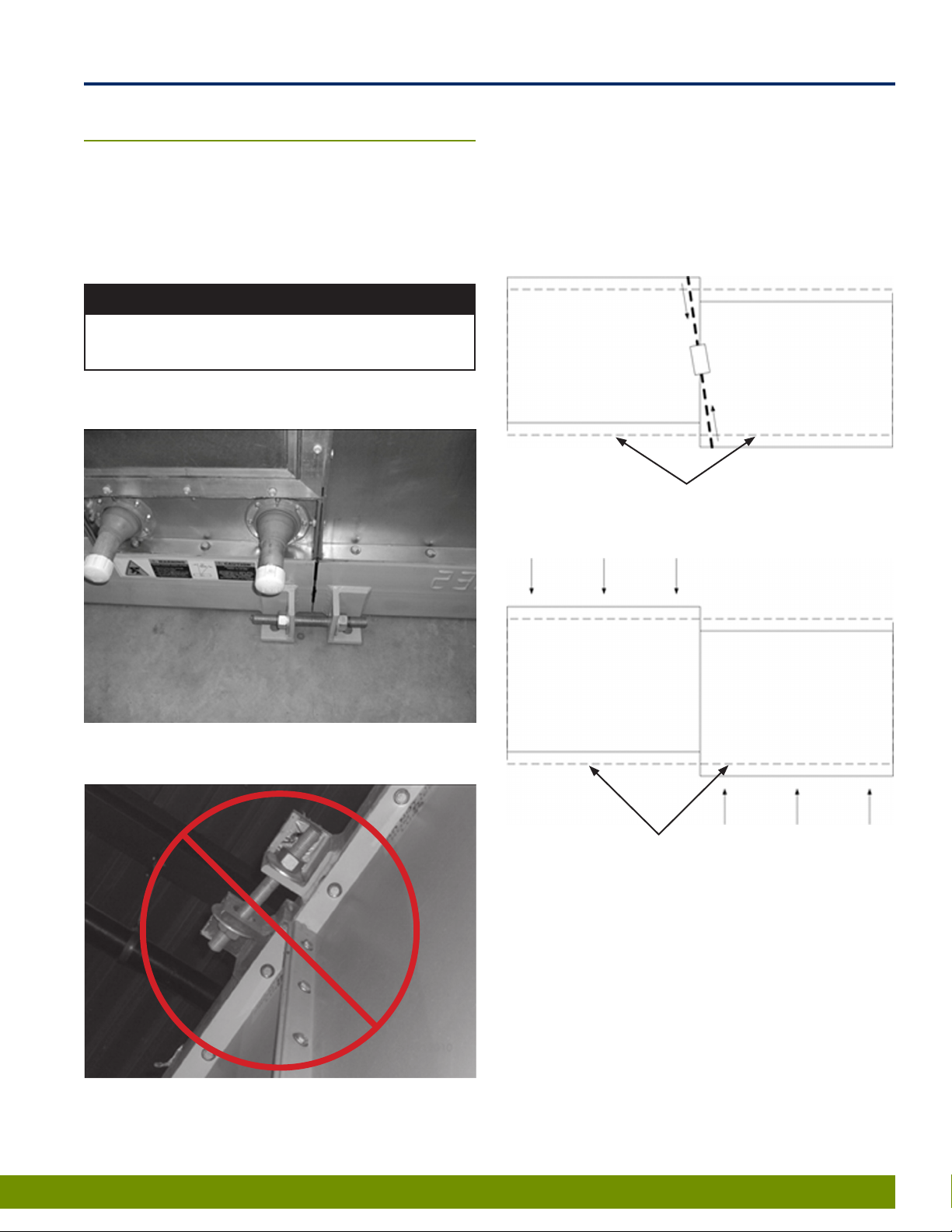

d) Verify all shipping bolts from fan bases have

been removed so fan/motor assemblies are free

oating on isolators;

e) Check the fan bearing setscrews for tightness;

f) Check alignment of sheaves and V-Belts (see

maintenance section);

g) Inspect all fasteners to ensure none have

loosened during shipment or installation;

h) Verify all lters are installed;

i) Verify damper blades have free movement;

j) Verify proper rainhood installation, if applicable.

11.1 Fan Startup

a) Connect power to the unit;

b) Turn on disconnect;

c) Momentarily energize fan contactor and verify

fan rotation; (Typically, a fan rotation arrow is

clearly marked on the side of the fan.) If the fan

rotates the wrong direction, disconnect power

and reverse rotation of the fan by interchanging

any two of the three-phase power leads at the

fan contactor. If the unit has multiple fans, take

care not to interchange power leads for correctly

operating fans.

d) Repeat steps “b” and “c” until all fans have been

veried.

e) Check bearing and motor lubrication after the

initial run.

f) Variable pitch sheaves should be replaced with

xed pitch sheaves once the system is balanced.

This will reduce the potential for belt failure and

possibly quiet the unit.

A ClimateCraft startup form is available for recording

startup conditions by contacting ClimateCraft Service by

email at support@climatecraft.com.

12.0 Maintenance

Disconnect all electric power, including remote disconnects

before servicing. Follow proper lockout/tagout procedures

to ensure the equipment cannot be inadvertently energized.

Verify with an appropriate voltmeter that all capacitors have

discharged. Failure to disconnect power and discharge

capacitors before servicing could result in death or serious

injury.

⚠

WARNING

12.1 Belt-Driven Fan Maintenance

A scheduled maintenance program is required for proper

operation of the belt-driven fans in your ClimateCraft

air handling unit. A preventive maintenance schedule

should be developed and coordinated with maintenance

personnel. Following is a list of items that should be

included in the preventive maintenance program:

a) Verify fan is rotating in the intended direction;

b) Remove dirt, oil and grease build-up on and

around the fan and motor bearings and on

shafts;

c) Check sheave alignment;

d) Check sheaves and belts for wear and proper

tension;

e) Check set screws on sheaves;

f) Lubricate fan and motor bearings on a regular

basis in accordance with usage guidelines.

g) Verify integrity of extended lube lines, if

installed. Extended lube lines should be

securely attached and free of kinks, cracks or

other damage.

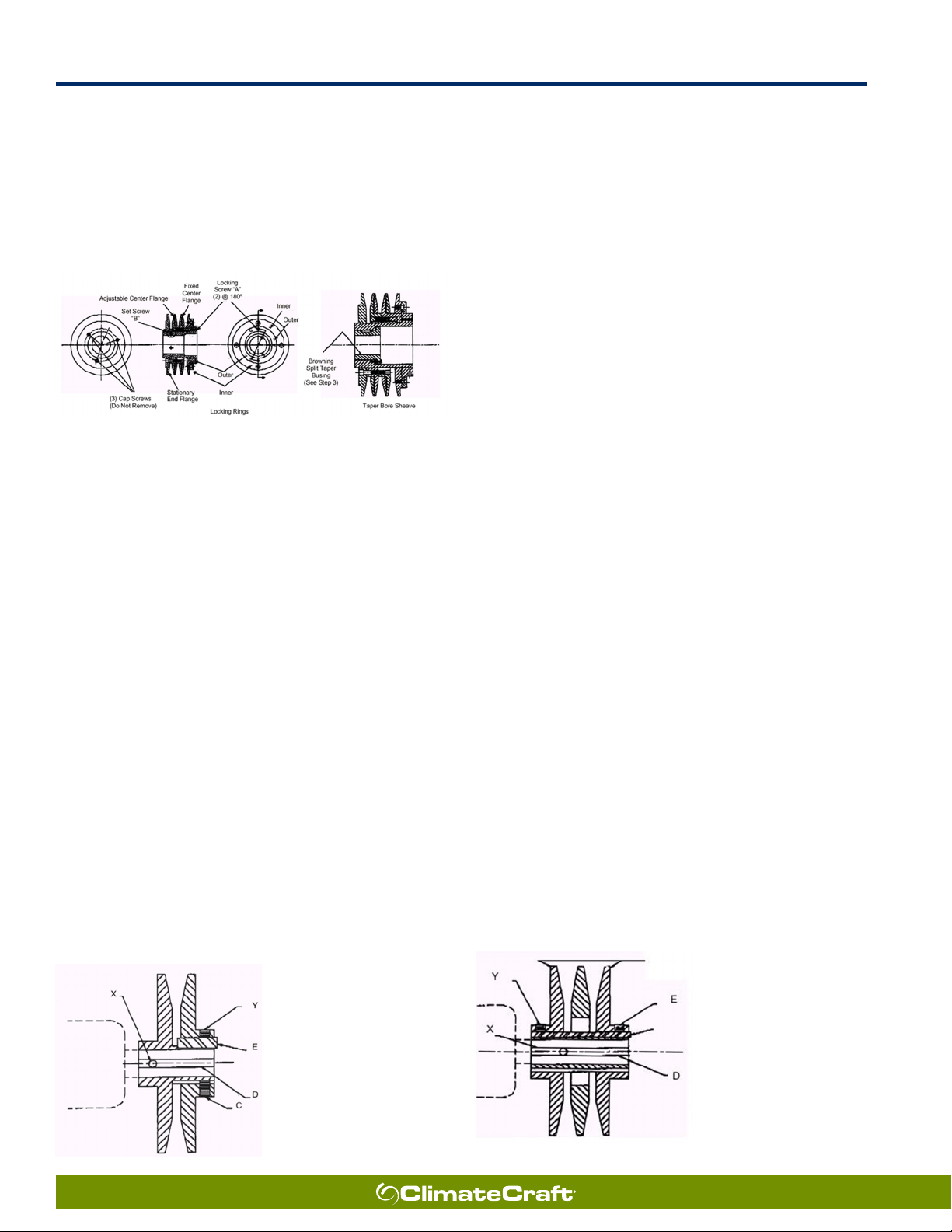

12.2 Sheave Adjustment

MVP Variable Speed – Figure 12-1

a) Slack off all belt tension by moving motor

towards driven shaft until belts are free of

grooves. For easiest adjustment, remove the

belts from the grooves.

b) Loosen both locking set screws A in outer

locking ring.

c) Adjust Sheave to desired pitch diameter by

turning the outer locking ring. Three holes 120º

apart are provided for a spanner wrench or drift

for ease of turning.

d) Any pitch diameter can be obtained within the

sheave range. One complete turn of the outer

locking ring will result in .233” in pitch diameter.

e) Do not open “B” sheaves more than 4 ¾ turns

for “A” belts or 6 turns for “B” belts.

f) Do not open “C” sheaves more than 9 ½ turns

g) Do not open “D” sheaves more than 13 turns.

h) Do not open “5V” sheaves more than 6 turns.