Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53420028-01 Printed in U.S.A. Form No. 42B-6SI Pg 1 1-24 Replaces: 42B-5SI

Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Step 1 — Unpack and Inspect Unit . . . . . . . . . . . . . . 2

Step 2 — Protect Unit from Damage . . . . . . . . . . . . . 2

Step 3 — Prepare Jobsite . . . . . . . . . . . . . . . . . . . . . . 2

Step 4 — Prepare Unit . . . . . . . . . . . . . . . . . . . . . . . . 9

Step 5 — Position Unit . . . . . . . . . . . . . . . . . . . . . . . . 9

• TOTAL WEIGHT UNIT CORRECTION FACTOR (LB)

Step 6 — Make Piping Connections . . . . . . . . . . . . 11

•DRAIN

• WATER SUPPLY/RETURN CONNECTIONS

• WATER TREATMENT

• HYDROSTATIC TEST

• INSULATION

• MAXIMUM EXTERNAL STATIC PRESSURES

Step 7 — Make Electrical Connections . . . . . . . . . . 15

• SERVICE SWITCHES:

Step 8 — Make Duct Connections . . . . . . . . . . . . . 16

Step 9 — Install Mixing Box . . . . . . . . . . . . . . . . . . . 16

Step 10 — Make Final Preparations . . . . . . . . . . . . 18

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Air System Balancing . . . . . . . . . . . . . . . . . . . . . . . . 19

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Clean Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Check Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fan and Motor Bearings . . . . . . . . . . . . . . . . . . . . . . 19

Align Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adjust Fan Belt Tension . . . . . . . . . . . . . . . . . . . . . . 20

Clean Fan Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Clean or Replace Air Filters . . . . . . . . . . . . . . . . . . . 20

Recommended Maintenance . . . . . . . . . . . . . . . . . . 20

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . 20

Excessive Condensation on Fan Coil Unit Parts . . 20

Motor Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . . . CL-1

SAFETY CONSIDERATIONS

Air-handling equipment is designed to provide safe and reliable

service when operated within design specifications. To avoid inju-

ry to personnel and damage to property or equipment, use good

judgment and follow safe practices as outlined below when in-

stalling and operating this equipment.

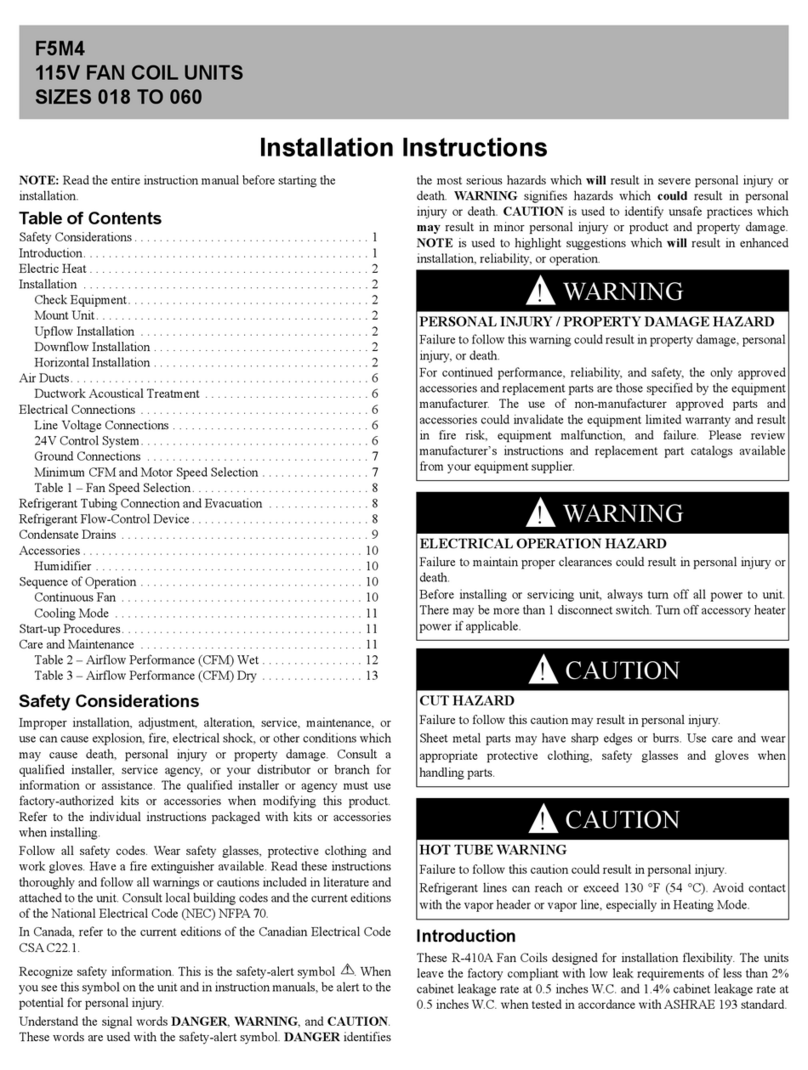

See Fig. 1 Proposition 65 warning label. Fig. 1 — Proposition 65 Warning Label

DANGER

NEVER REACH INTO a unit while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect

switch before working on unit. In addition, remove the fuses

and take them with you after noting this on tag.

DISCONNECT ALL POWER before attempting any

installation or service. More than one power source may be

supplied to a unit. Power to remote mounted control devices

may not be supplied through the unit.

CHECK THE WEIGHT of assembly and components to be

sure that rigging equipment can handle them safely.

NEVER PRESSURIZE a coil with a non-liquid for leak

testing. A dangerous burst may occur.

DO NOT STEAM-CLEAN coils until you are sure all

personnel are clear of the area.

Failure to follow these warnings will result in severe personal

injury or death.

IMPORTANT: Children should be supervised to ensure that they

do not play with the appliance.

This product can expose you to chemicals

including Acrylamide, which is known to the

State of California to cause cancer and birth

defects or other reproductive harm.

For more information, go to

www.P65Warnings.ca.gov

WARNING

!

!

!

AVERTISSEMENT

ADVERTENCIA

Ce produit peut vous exposer à des produits

chimiques, y compris l’acrylamide, qui est

connu dans l’État de Californie pour causer

le cancer et des malformations congénitales

ou d’autres problèmes de reproduction. Pour

de plus amples informations, prière de

consulter www.P65Warnings.ca.gov

Este producto puede exponerlo a productos

químicos como la acrilamida, que en el

estado de California es causante de cáncer

y defects de nacimiento u otros daños

reproductivos. Para mayor información, visite

www.P65Warnings.ca.gov

343839-101 REV.A

AirStream™

42BHE,BVE06-40

System Fan Coil Air Conditioners