1 - Inside air 24°C-50%, Cond. temperature 45°C - ESP 20 Pa

5 - measured at a height of 1.5 m and 2 m from the front of the unit in free field

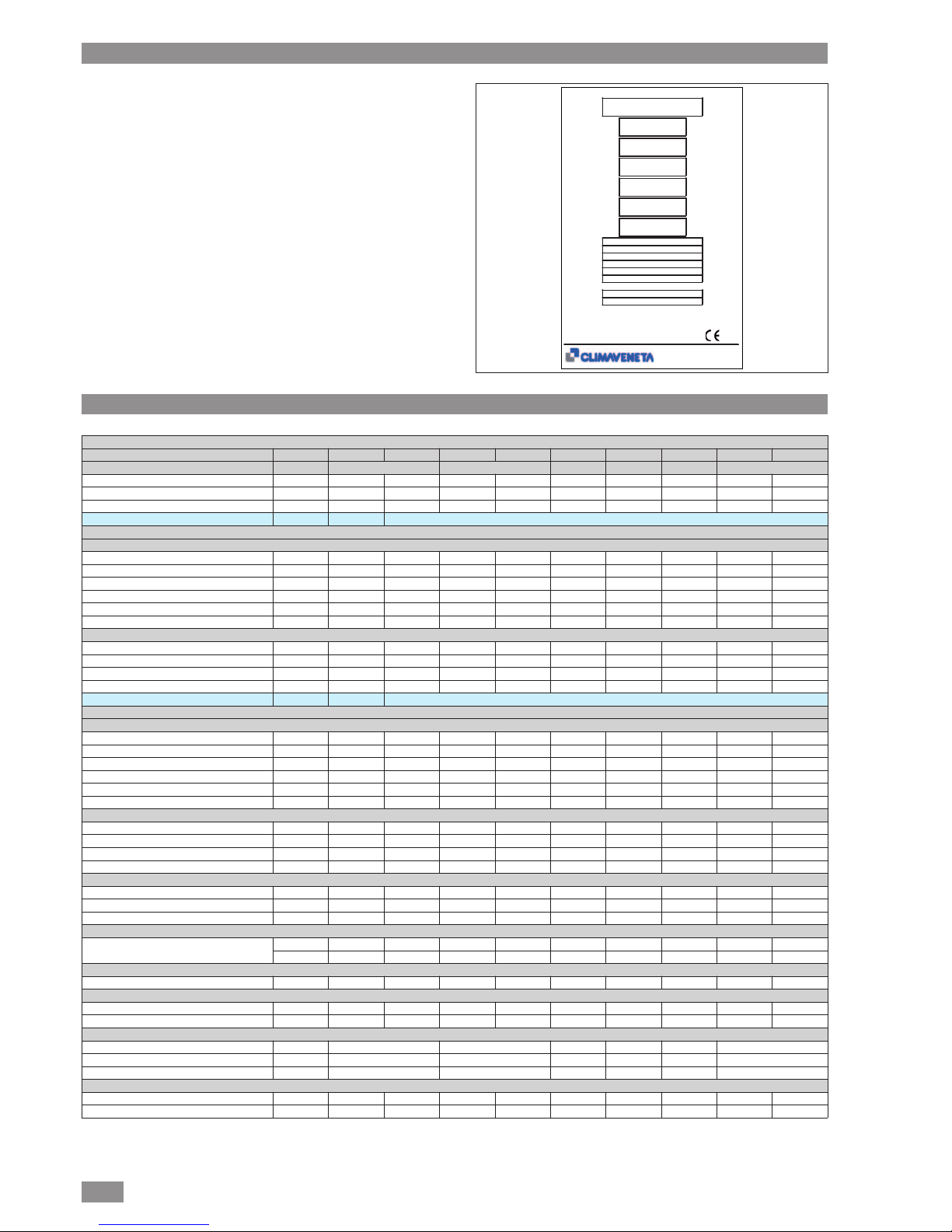

ACCURATE - i-AX Air-cooled direct expansion unit

Model 12 18 20 29 50 70 90 130 150

Frame F2 F3 F4 F5 F6 F7

No. of circuits / no. of compressors 1/1 1/1 1/1 1/1 1/1 2/2 2/2 2/3 2/3

Refrigerant R410A R410A R410A R410A R410A R410A R410A R410A R410A

Rated air flow-rate mc/h 3500 4900 6500 8000 13500 19000 25000 30000 30000

Power supply V/Ph/Hz 230/1/50 400/3N/50

CAPACITY DELIVERED

Maximum speed

Gross total capacity (1) kW 11,1 16,60 19,32 28,07 55,00 70,20 86,50 135,9 151,8

Gross sensible capacity (1) kW 10,6 16,60 19,32 28,07 51,10 68,10 85,50 116,2 124,1

SHR (1) 0,95 1,00 1,00 1,00 0,93 0,97 0,99 0,86 0,82

Compressor power consumption kW 2,54 4,09 4,44 7,14 13,20 15,80 20,30 30,80 35,00

Power cons. with std. EC radial fans kW 0,35 0,84 1,35 1,80 3,20 4,50 6,10 - -

Power cons. with HP EC radial fans kW 0,27 0,47 0,89 1,51 3,13 5,11 6,72 6,90 6,90

Minimum speed

Gross total capacity (1) kW 4,34 6,27 7,24 10,62 25,39 23,60 24,30 24,70 24,70

Gross sensible capacity (1) kW 4,34 6,27 7,24 10,62 25,39 23,60 24,30 24,70 24,70

SHR (1) 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00

Compressor power consumption kW 0,88 1,24 1,33 1,96 4,31 4,40 4,30 4,60 4,60

Power supply V/Ph/Hz n.a 460/3/60 - 380/3/60

CAPACITY DELIVERED

Maximum speed

Gross total capacity (1) kW / 16,6 19,3 28,1 55,0 71,5 84,9 139,0 147,7

Gross sensible capacity (1) kW / 16,6 19,3 28,1 51,1 68,7 83,8 117,6 121,9

SHR (1) / 1,00 1,00 1,00 0,93 0,96 0,99 0,85 0,82

Compressor power consumption kW / 4,09 4,44 7,14 13,20 16,29 19,83 31,94 33,97

Power cons. with std. EC radial fans kW / 0,84 1,35 1,80 3,20 4,50 6,10 - -

Power cons. with HP EC radial fans kW / 0,47 0,89 1,51 3,13 5,11 6,72 6,90 6,90

Minimum speed

Gross total capacity (1) kW / 6,27 7,24 10,62 25,39 23,60 24,30 24,70 24,70

Gross sensible capacity (1) kW / 6,27 7,24 10,62 25,39 23,60 24,30 24,70 24,70

SHR (1) / 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00

Compressor power consumption kW / 1,24 1,33 1,96 4,31 4,40 4,30 4,60 4,60

FANS

No. of std. EC radial fans 2 2 1 1 2 3 3 - -

No. of HP EC radial fans 2 2 1 1 2 3 4 3 3

Sound pressure level (5) dB(A) 49 53 56 60 64 67 67 69 69

REFRIGERANT CONNECTIONS

Refrigerant connections (ODS Ø) IN - LIQ 12 12 16 16 16 16 18 22 22

OUT-GAS 12 18 22 22 22 22 22 35 35

HUMIDIFIER

Capacity kg/h 3 5 5 5 5 8 8 8 8

ELECTRIC HEATERS

Steps 3 3 3 3 3 3 3 3 3

Heating capacity kW 4 8 9 9 15 18 18 24 24

DIMENSIONS

Length mm 1000 1000 1550 2100 2650 2650

Depth mm 500 790 790 790 790 890

Height mm 1980 1980 1980 1980 1980 2180

OUTDOOR UNIT COMBINATIONS

i-BRE remote condenser 014m 027m 027m 044m 065m 100b 116b 190b 190b

BRE remote condenser 014m 027m 027m 044m 065m 100b 116b 190b 190b

TECHNICAL DATA