Climer ECOHEAT PRO RF EH160 User manual

INSTALLATION AND USER MANUAL

ECOHEAT PRO RF

EH160

EH200

EH260

EH160

EH160

EH200

EH260

Installation and user manual

EH PRO RF 160 - 200 –260

2

Equipment’s serial number

(Filling by technical staff is recommended)

Installation and user manual

EH PRO RF 160 - 200 –260

3

Contents

Introduction..................................................................................................................................................................................... 5

General indications ....................................................................................................................................................................... 5

Safety notes................................................................................................................................................................................ 5

Safety indications for refrigerant R290 ........................................................................................................................ 6

Installers’ qualifications........................................................................................................................................................... 8

Package contents ..................................................................................................................................................................... 8

Instructions for transportation and unpacking .............................................................................................................. 9

Technical information ................................................................................................................................................................10

Operating principle................................................................................................................................................................10

Parts of the ECOHEAT PRO RF unit .................................................................................................................................11

Dimension drawings..............................................................................................................................................................12

Technical data..........................................................................................................................................................................13

Nameplate ................................................................................................................................................................................14

Installation steps ..........................................................................................................................................................................15

Placing ECOHEAT PRO RF...................................................................................................................................................16

Hydraulic connection ............................................................................................................................................................17

Condensate drain..............................................................................................................................................................19

Air connection .........................................................................................................................................................................19

Suction filter ........................................................................................................................................................................21

Electrical connection .............................................................................................................................................................21

Comissioning. Controller .....................................................................................................................................................23

User interface description ..............................................................................................................................................23

Use..........................................................................................................................................................................................25

Operating modes ..............................................................................................................................................................29

Manual reset .......................................................................................................................................................................35

Alarms y solutions.............................................................................................................................................................35

Common failures and possible solutions ............................................................................................................................36

Maintenance..................................................................................................................................................................................37

End of the equipment’s life cycle......................................................................................................................................38

List of spare parts ........................................................................................................................................................................39

Warranty.........................................................................................................................................................................................40

After-sales service sheet...........................................................................................................................................................42

Installation and user manual

EH PRO RF 160 - 200 –260

4

Installation and user manual

EH PRO RF 160 - 200 –260

5

Introduction

You have just acquired a product manufactured by CLIMER TECHNOLOGY. At CLIMER, we

appreciate the trust placed in our company. This product has been manufactured following the

quality standards set by the European Union, incorporating top-quality materials, and its proper

functioning has been tested before leaving our facilities.

Through this installation and start-up manual, you will be guided for the correct setup

of this product. It is essential to carefully read this manual before any handling to avoid

issues arising from improper use of the product.

The company CLIMER TECHNOLOGY reserves the right to modify the information included in

this document at any time without prior notice.

General indications

The following instructions must be followed to avoid any accidents or equipment

malfunctions. Please refer to them again if in doubt or contact technical support.

Do not alter any permanent instructions, labels, or warning plates attached to the

equipment.

Safety notes

The incorrect or inappropriate use of this product could lead to hazardous situations, causing

damage or injuries to the user, third parties or even to the product itself or material goods.

Follow these instructions to avoid any risks.

The installation of the minimum safety devices indicated in this manual (electrical and

hydraulic) is necessary for proper equipment operation. The absence of any device

may cause burns or other injuries in the event of a failure.

As a safety measure, earthing verification is also necessary. The earthing

must comply with the applicable installation standards. Failure to implement

this measure may result in accidents or death.

It is the responsibility of the installer to inform the user about the function and

location of the safety devices installed on the equipment.

The water temperature at the equipment outlet may reach up to 70°C (depending on

the model). Do not touch the pipes during operation to avoid the risk of burns.

The equipment must not be operated by minors or individuals with reduced physical,

sensory, or mental capabilities, or lack of experience and knowledge, without

supervision, unless they have been instructed on the safe use of the device and

understand the associated risks.

Only perform the operations referred to in these operating instructions.

Installation and user manual

EH PRO RF 160 - 200 –260

6

Safety indications for refrigerant R290

The refrigerant R290 in the heat pump circuit does not cause a risk to the

environment; however, the product evaporates quickly and should not be

discharged into the atmosphere or water network. Care should be taken with

its use, mainly for its high flammability.

Do not bring flames or flammable sources near or inside the equipment.

Smoking is forbidden in the proximity and inside the installation compartment.

Do not expose the equipment to environments that can reach extremely high

temperatures to avoid the risk of explosion due to increased internal pressure.

Do not store chemicals or flammable materials near the equipment.

Do not handle sprays near the equipment due to the risk of flammability.

Avoid the accumulation of electrostatic charge in the equipment enclosure.

Do not damage the pipes of the refrigeration circuit.

Do not consume polluted water with refrigerant.

There is a risk of freezing upon contact with the refrigerant.

Avoid all skin and eye contact with the refrigerant at all costs. Otherwise, seek

medical attention.

The following health consequences due to improper use of the refrigerant might

be caused:

▪Burns and cryogenic injury

▪Suffocation

▪unconsciousness

▪Oxygen deprivation

▪Death

The materials and components of this equipment comply with the relevant regulations

against fire and explosion risks, regarding the temperature that can reach the surfaces of

the equipment in contact with the refrigerant in case of leakage.

In the case of detecting a leak, you should be aware of its danger and consider

the following indications:

The coolant should not smell bad. It is completely odourless.

Do not inhale vapours or gases emanating from refrigerant circuit leaks.

The refrigerant vapours are heavier than air; therefore, there may be a decrease

in the oxygen content in the enclosed space, leading to asphyxiation.

Avoid the risk of injury from contact with refrigerant.

Do not operate electrical switches, sockets, doorbells, telephones or intercoms.

Installation and user manual

EH PRO RF 160 - 200 –260

7

You must disconnect the equipment from the power source and ventilate the

area, preferably mechanically, before handling the equipment. If possible, fully

open doors and windows to ensure proper airflow.

While ventilating the area, you must ensure that the refrigerant does not enter

neighbouring buildings through ventilation holes, doors, windows, trapdoors, or

similar openings.

Do not bring any open flames near the area where the leak occurred, do not

operate electrical appliances, and refrain from smoking.

Leave the contaminated enclosure and prevent third parties from entering.

Contact after-sales service.

The appliance is supplied with 150 g of R290 refrigerant gas inside the equipment. The

device is not provided with any charging or recharging valve because this operation must

not be conducted in any case by the user. Refill can only be made at the manufacturer’s

establishment or by specially qualified professionals authorised by the manufacturer.

In case of an accident, here are some first-aid steps you can take:

Symptom

Step

Inhalation

Remove the affected person from the enclosure. Consult a doctor.

Contact with skin

- Rinse thoroughly with lukewarm water.

- Do not remove clothes, which can stick to the skin.

- If burns appear on the skin, seek medical attention immediately.

Contact with

eyes

Rinse with plenty of water with the eyelids open for at least 15

minutes. Consult an ophthalmologist immediately.

In the event of a fire, the appropriate extinguishing means are:

Water atomiser

Dry powder (for example: fire extinguisher)

Carbon dioxide, CO2 (for example: fire extinguisher)

Never attempt to extinguish the flames with a strong water jet. Cool exposed containers

spraying water on them. Firefighting staff must wear self-contained breathing devices

and full-body protection to act.

Installation and user manual

EH PRO RF 160 - 200 –260

8

Installers’ qualifications

Maintenance should only be performed by specially qualified and authorized personnel with

a valid refrigeration technician certification. All maintenance staff and other individuals

working near the appliance must be instructed about the nature of the work to be carried

out.

The installer must inform the user about the product's applications, its use,

handling, and provide all the documentation supplied with the equipment.

The personnel in charge of the equipment installation must have the necessary

tools, including a refrigerant leak detector in the environment, with a sensitivity

equal to or greater than 10-6 Pa·m3/s, and a fire extinguisher.

Package contents

The ECOHEAT system comprises the following components:

ECOHEAT PRO RF unit

Safety valve (6 bar)

Silent-blocks

Drainage nozzle

Blockage for the condensate drain on the heat pump tray

User manual

Security Kit G3 (Optional)

•T&P valve, ½”

•Inlet group reduction of 3 bar and safety of 8 bar

•Tundish Ø15mm x Ø22mm

Installation and user manual

EH PRO RF 160 - 200 –260

9

Instructions for transportation and unpacking

The unit is supplied packed into a wooden pallet properly secured to prevent damage during

transport.

The material used to the packing are recyclables, so dispose it in an appropriate container.

Be careful when using knives or cutters to open the cardboard box so as not to damage the

equipment.

Use a forklift or hand pallet truck to transport the unit to the installation site, always

introducing the forks into the bottom of the pallet being careful not to damage or knock over

the unit.

Illustration 1: Methods of transport of equipment

In case of manual transport, it is forbidden to carry equipment with an inclination greater

than 15º to the vertical for long period of time. Otherwise, the equipment should be in this

position only for the necessary time. After transportation in this way, the equipment needs to

remain still in a vertical position for at least 6 hours to ensure the proper return of oil within

the equipment. All manual operations must always be carried out by minimum 2 people to

prevent accidents.

In case you identify any damage at the time of the reception of the unit, it is mandatory to

register it in the reception note of the transport company, and then, submit the complaint.

For this reason, it is recommended to make a thorough visual inspection of the goods before

signing the reception note.

Installation and user manual

EH PRO RF 160 - 200 –260

10

Technical information

All relevant technical information about the equipment is provided in this manual.

However, according to regulations, CLIMER TECHNOLOGY is available to provide

additional information about the equipment if required.

The ECOHEAT PRO RF equipment has been designed and manufactured in compliance with all

applicable current regulations.

Operating principle

Illustration 2: Operating principle

Installation and user manual

EH PRO RF 160 - 200 –260

11

Parts of the ECOHEAT PRO RF unit

Illustration 3: Detailed view of the unit

1.

Front cover

2.

EVCO touch control

3.

Plastic top cover

4.

Air filter

5.

Back cover

6.

Side covers

7.

Silent-Blocks

8.

Electric heater 1500 W

9.

DHW probe NTC1

10.

PVC protective cover

11.

T&P valve

12.

Low pressure switch

13.

High pressure switch

14.

Compressor

15.

Evaporator

16.

Solenoid valve

17.

Expansion valve

18.

Air box part 1

19.

Air box part 2

20.

Fan

21.

Air temperature probe NTC2

22.

Drain fitting (plugged)

23.

Filter drier

24.

Heat pump tray

25.

Drain fitting

26.

Fan capacitor

27.

Compressor capacitor

28.

Safety thermostat

29.

Terminal strip

Installation and user manual

EH PRO RF 160 - 200 –260

12

Dimension drawings

Illustration 4: Side and up views. Dimensions (mm)

A

B

C

D

E

F

G

EH160 PRO RF

584

624

1311

216

350

80

80

EH200 PRO RF

584

624

1540

216

355

305

80

EH260 PRO RF

584

624

1907

216

355

672

80

Illustration 5: Back (left), front (center) and top connections

H

Condensate drain, 20 mm

M

Hot water outlet, ¾“ F

I

Power supply, 230 V / 1 PH / 50 Hz

N

Electrical heater, 1500 W /

Temperature sensor

J

Exhaust air connection, 150/160/200

mm

O

Cold water inlet, ¾“ F

K

Intake air connection, 150/160/200

mm

P

Drainage outlet, ¾“ F

L

T&P valve, ½“ F

Installation and user manual

EH PRO RF 160 - 200 –260

13

Technical data

Model

EH160

PRO RF

EH200

PRO RF

EH260

PRO RF

Cylinder

Capacity (l)

160

200

260

Maximum operating pressure (bar)

6

Heat pump data

Load profile

L

L

XL

Heating capacity range (W)

1005 - 1750

Power input range (W)

405-500

Water heating energy efficiency, average

climate (%)

118

123

133

COP (average climate, 7ºC)

2.83

2.95

3.24

COP (warm climate, 14ºC)

3.09

3.16

3.55

Energy efficiency class

A+

A+

A+

Ambient temperature range (ºC)

-10 / 40

DHW temperature range (ºC)

35 / 60

Maximum DHW temperature with HP (ºC)

60

Refrigerant / Charge (g)

R290 / 150

Sound power (dB(A))

58

Sound pressure at 2 m (dB(A))

47

Auxiliary electric heater

Electrical heater power (W)

1500

Maximum absorbed power (W)

2000

Maximum water temperature with electrical

heater (ºC)

70

Air data

Maximum air flow rate (m3/h)*

Low speed

264

High speed

370

Maximum available static

pressure (Pa)

Low speed

30

High speed

100

Connection diameter (mm)

150 / 160 / 200

Connections

Power supply (V/ph/Hz)

230 / 1 / 50

Inlet/outlet water connections (inch)

¾” F

Hydraulic connection safety valve / T&P

(inch)

½” F

*: Air flow rate without conducting

Installation and user manual

EH PRO RF 160 - 200 –260

14

Nameplate

The nameplate contains product details and important information:

Type of product

Date of production

Serial number (also available in this

manual)

Power supply

Operating pressure

Electrical supply

IP class

Type of refrigerant

The nameplate must always be accessible and

remain legible throughout the equipment's

entire lifespan. If it becomes damaged or

illegible, replace it immediately. Never remove or

cover the nameplate or labels affixed to the heat

pump equipment.

Illustration 6: Nameplate’s location

Installation and user manual

EH PRO RF 160 - 200 –260

15

Installation steps

Before starting the installation, the installer must perform safety checks to minimise the risks

entailed working with flammable refrigerants. Also, the availability of all the necessary

components and tolls must be checked:

Drill

Screwdriver

Hydraulic installation components

Electric installation components

Fire extinguishing equipment (dust or CO2)

Once it has been checked that it is available all the necessary components and tools, the

installer should follow the next steps:

1) Placing the ECOHEAT

2) Hydraulic installation

3) Air connections

4) Electric installation

5) Commissioning

Before and during the work, the site should be checked with a refrigerant detector to

monitor the presence of toxic or flammable gases or vapours.

The original design allows easy removal of the casing, the front cover, to make easier access

during installation, inspection and maintenance tasks.

If the electrical supply to the dwelling and the product is interrupted during an extended absence,

request a specialized installer to protect it from frost to prevent fatal damage to the product.

Installation and user manual

EH PRO RF 160 - 200 –260

16

Placing ECOHEAT

The place where the system will be installed should allow an easy access in order to make

maintenance work or inspection; in addition to abide by safety measures of refrigerant R290.

It is recommended to meet the following minimum distances in the enclosure:

Illustration 7: Minimum recommended distances at the equipment’s site (in mm)

The equipment has been designed for indoor installation. The enclosure must be equipped

with the following minimum requirements:

Minimum temperature 5 ºC.

Adequate water and electricity supplies.

Drainpipes to discharge water in case of emptying the tank, using the safety valve or

breaking the hydraulic circuit; in addition, for the condensation water outlet

connection.

For potential major water leaks, a containment system or procedure.

Sufficient illumination.

Volumetric capacity not less than 10 m3. Otherwise, adequate minimum ventilation

must be ensured.

Dry and protected from frost.

The air outlet temperature of the device is approximately 5-10°C below the inlet temperature.

So, in case that the exhaust air would not be ducted, the room temperature will be

considerably reduced.

Installation and user manual

EH PRO RF 160 - 200 –260

17

Besides these factors, it is important to consider the following guidelines regarding the

location:

The surface where the unit will be installed must be capable of supporting its weight.

Moreover, it should be flat or have a maximum inclination of 2º.

Since the equipment may cause vibrations or noise, it is recommended to install it

away from resting areas.

Installer must install the supplied Silent blocks to avoid the transmission of vibration.

Hydraulic connection

For the hydraulic connection, it is essential to be aware of local regulations. Respect the

minimum and maximum water pressure and temperature to ensure the proper functioning

of the appliance.

It is recommended to fill the unit with water that meets the characteristics indicated in the

Warranty section located at the end of this manual. To ensure better performance and

durability, the installation of a water softener treatment system is also recommended.

The hydraulic connections are shown in the following scheme. The installer must place the

indicated components as shown.

Installation and user manual

EH PRO RF 160 - 200 –260

18

Illustration 8: Standard hydraulic connection

1.

Cold water inlet

7.

T&P valve

2.

Ball valves

8.

Expansion vessel

3.

Pressure reducing valve

9.

Y merger

4.

Non-return valve

10.

Tundish

5.

Lined filter strainer (Y-type)

11.

DHW outlet

6.

Drainage

There are other possible connection options; as some examples below:

Connection to thermal solar installation

Connection to support existing DHW equipment (heater, boiler, etc.)

Setting electrolytic hoses in the water connections should be considered to prevent galvanic

corrosion in the pipes.

Once the hydraulic connections are made, vent the circuit to avoid the air inside the

installation.

Installation and user manual

EH PRO RF 160 - 200 –260

19

Condensate drain

The condensation in the evaporator could produce a constant water flow that has to be

drained properly; also, to avoid unwanted odours of equipment in ambient air.

The condensate drain is in the back or in the front of the system. (Illustration 5, H).

Connect the condensate drain to the wastewater network making a siphon through a

flexible tube with inner diameter 20 mm. Ensure that water can flow freely.

Air connection

The ECOHEAT unit has two air connections located on the top cover of the equipment. There

are different connection possibilities, as shown below, which can be installed in compliance

with the current regulations. However, the cold air outlet must always be ducted to the

outside of the enclosure, except when it is in technical room.

Illustration 9: Air duct positions and locations

There is the possibility of ducting the cold air to a specific area for cooling. Through a damper,

it can be redirected outside when cooling that area is not necessary.

The ECOHEAT design provides the option to choose between 3 different pipe diameters for

air ducting. The selection of the pipe size to be used is at the discretion of the

installer/technician responsible for the design and calculation of the installation.

Installation and user manual

EH PRO RF 160 - 200 –260

20

Illustration 10: Options for connecting air conduction to equipment and its measurements

When ducting air connection, the tube which will be used for must be rigid PVC or a material

with similar stability.

For the accessories, the following table is provided with the equivalent distance of pressure

drop. The values are calculated for the total length of suction and air discharge ducts. Special

attention should be given when installing the following elements and their pressure drop:

Corrugated pipe for air conduction

Anti-insect grids on the end of air inlet and outlet tubes

Accesories

Equivalent distance of pressure drop (m)

150

160

200

Maximum available

length

V1

11

15

30

V2

16

30

50

Elbow 90º

V1

1.5

2.0

2.5

V2

1.5

2.5

3

Vertical tube (1 m)

V1

1

1

1

V2

1

1

1

Flexible/corrugated

pipe

V1

5

5

5

V2

5

5

5

Anti-insect grid

(at air inlet and outlet)

V1

5

5

5

V2

5

5

5

V1: fan’s low speed V2: fan’s high speed

To prevent condensation, it is recommended to insulate the air evacuation pipes and air duct

connections with a vapor-tight thermal coating.

This manual suits for next models

2

Table of contents

Other Climer Chiller manuals

Popular Chiller manuals by other brands

Data Aire

Data Aire MINI CEILING SERIES Installation, operation and maintenance manual

Conair

Conair PCW-1.5 user guide

Gree

Gree B Series Service manual

RC GROUP

RC GROUP TRIPACK Series Installation, use and maintenance manual

Carrier

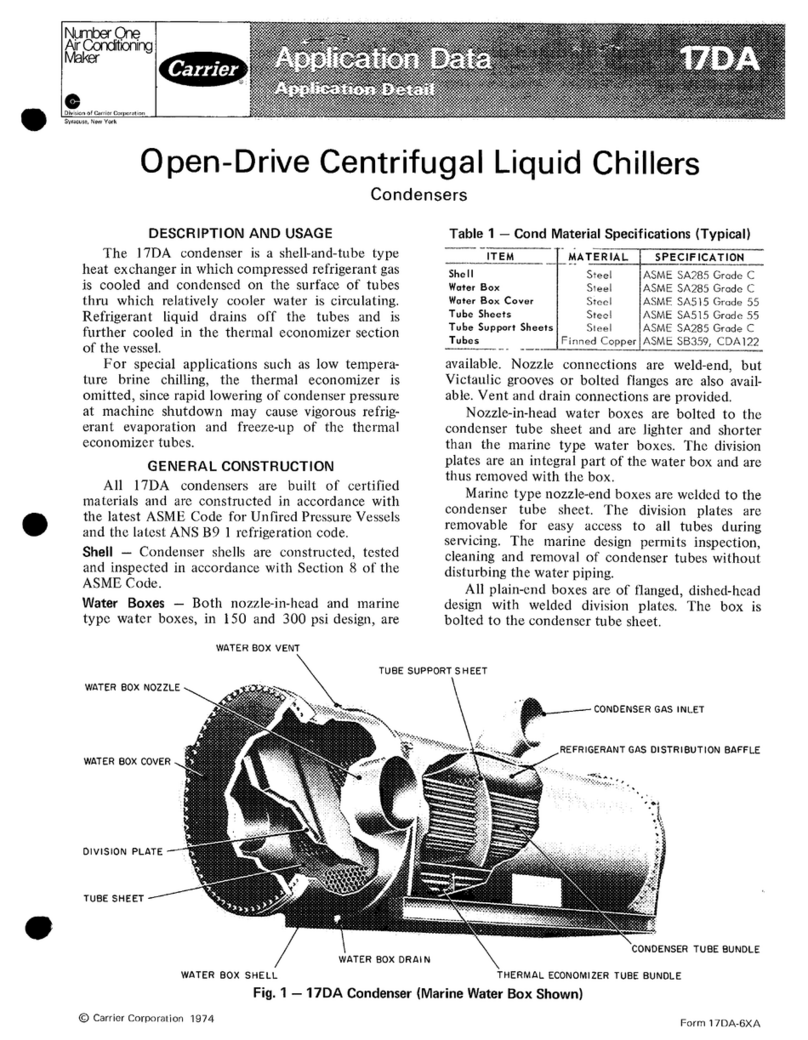

Carrier 17DA Application data

Carrier

Carrier AquaEdge 19DV series installation instructions

York

York YCWL0056SE Installation operation & maintenance

Comet

Comet XRCA-3023-WA manual

Trane

Trane CGWH 115 Installation operation & maintenance

AIRTAK

AIRTAK C-25 through C-8000 Installation, operation and maintenance instructions

AERMEC

AERMEC NLC 0280 installation manual

Daikin

Daikin EWYD-4Z B Installation, operation and maintenance manual