CLIMIA CMK 2600 User manual

Edition 3.0

English

CLIMIA

Local room air conditioner CMK 2600

Operating manual

CLIMIA

Local room air conditioner CMK 2600

Table of Contents

Carefully read this operating manual prior to commissioning/using the units!

This operating manual is a translation of the German original.

This manual is an integral part of the unit and must always be kept in the vicinity of the installation location

or on the unit itself.

Subject to modications. No liability accepted for errors or misprints!

1.0 Safety information 4-5

2.0 Environmental protection and recycling 5

3.0 Guarantee 5

4.0 Intended use 5

5.0 Transportation and packaging 6

6.0 Unit description 6

7.0 Operation 7-8

8.0 Before commissioning 9-10

9.0 Commissioning 10

10.0 Shutdown 10-11

11.0 Filter cleaning 11

12.0 Care and maintenance 11

13.0 Installation scheme for wall pass-through 12

14.0 Troubleshooting and customer service 13

15.0 Electrical wiring diagram 14

16.0 Unit illustration 14

17.0 Spare parts list 15

18.0 Accessories 15

19.0 Technical data 17

EC Declaration of Conformity 18

3

1.0 Safety information

General safety notes

Carefully read the operating manual

before placing the unit in service

for the first time. It contains useful

tips and notes as well as hazard

warnings to prevent injury or

material damage. Failure to follow

the directions in this Manual can

endanger persons, the environment

and the equipment itself and will

void any claims for liability.

Keep this operating manual and

the refrigerant data sheet near to

the units.

•Only qualified personnel may

set up and install the units and

components.

•The set-up, connection and

operation of the units and its

components must be undertaken

in accordance with the usage and

operating conditions stipulated

in this manual and comply

with all applicable regional

regulations.

•Mobile units must be set up

securely on suitable surfaces and

in an upright position. Stationary

units must be permanently

installed for operation.

•Modification of the units and

components supplied by CLIMIA

is not permitted and can cause

malfunctions.

•The units and components

should not be operated in areas

where there is an increased risk of

damage. Observe the minimum

clearances.

•The electrical power supply

should be adapted to the

requirements of the units.

•The operational safety of the

units and components is only

assured providing they are

used as intended and in a

fully assembled state. Safety

devices may not be modified or

bypassed.

•Do not operate units or

components with obvious

defects or signs of damage.

•All housing parts and unit

openings, e.g. air inlets and

outlets, must be free from foreign

objects, liquids and gases.

•The units and components must

be kept at an adequate distance

from flammable, explosive,

combustible, abrasive and dirty

areas or atmospheres.

•Contact with equipment parts or

components can lead to burns or

injury.

•Installation, repair and

maintenance work may only

be carried out by authorised

specialists. Visual inspections and

cleaning can be performed by

the operator as long as the unit is

disconnected from the power.

•Appropriate hazard prevention

measures must be taken to

prevent risks to people when

performing installation, repair,

maintenance or cleaning work on

the units.

•The units and components

should not be exposed to any

mechanical load, extreme levels

of humidity or direct exposure to

sunlight.

Safety instructions for the

operator

•The units and components must

not be exposed to any mechanical

load, extreme levels of humidity or

extreme temperatures. Operation

in rooms with possible ignition

sources (e.g.open flames, gas

heaters, electric heaters) is also

prohibited.

•During operation of the unit, icing

of the heat exchangers may occur

occasionally. The units feature an

automatic defrosting function

if required. Never thaw the heat

exchangers independently!

•The refrigerant R290 used in the

unit is highly flammable, invisible

and odourless. It is imperative

that the safety instructions in

the installation and operating

instructions are observed.

•The unit may only be stored and

operated in rooms larger than 8

m².

•Possible regional laws and

regulations must be observed.

•Air intake and outlet areas must

be kept clear. Never cover the unit.

•The unit must be stored in such a

way that mechanical damage can

be ruled out. The storage location

must be sufficiently large and well

ventilated.

Warning of inflammable

substances

CLIMIA

4

Local room air conditioner CMK 2600

Disposing of the units and their

components

Only recyclable materials are used

in the manufacture of the units and

components.

Help protect the environment

by ensuring that the units or

components (for example batteries)

are not disposed of in household

waste, but only in accordance

with local regulations and in an

environmentally safe manner,

e.g.using authorised disposal and

recycling specialists or council

collection points.

4.0 Intended use

Depending on the model, the

units and the additional fittings

with which they are equipped are

only intended to be used as an

air-conditioner for the purpose

of cooling or heating the air in an

enclosed space.

Any different or additional use is a

non-intended use.

3.0 Guarantee

As a prerequisite for any guarantee

claims to be considered, it is

essential that the ordering party

or its representative complete and

return the "certificate of warranty"

to Climia Intakt GmbH at the time

when the units are purchased and

commissioned.

The guarantee conditions are

listed in the "General terms

and conditions of business and

supply". Furthermore, only the

parties to a contract can conclude

special agreements beyond these

conditions. In this case, contact

your contractual partner in the first

instance.

Disposal of packaging

All products are packed for

transport in environmentally

friendly materials. Make a valuable

contribution to reducing waste

and sustaining raw materials. Only

dispose of packaging at approved

collection points.

2.0 Environmental

protection and

recycling

•Repairs of any kind may only be

carried out by certified specialist

personnel. Intervention in the

refrigeration circuit by personnel

who are neither certified nor

authorised by the manufacturer

is strictly prohibited.The

prerequisite for personnel being

qualified is knowledge of handling

flammable refrigerants.

•National regulations for the

transport of equipment must be

observed.

•Safety-relevant device stickers

must not be removed.!

Safety instructions for the

certied specialist personnel

•

The refrigerant R290 used in

the unit is highly ammable,

invisible and odourless. Work

on the refrigeration circuit may

only be carried out by certied

specialist personnel. Knowledge

in handling ammable

refrigerants is absolutely

imperative!

•

Before working on the

refrigeration circuit, the

workplace must be checked

for sucient space and good

ventilation. All possible ignition

sources must be removed from

the workplace. Other persons

present must be informed about

possible dangers.

•

Before and during work, the

refrigerant concentration

in the air must be checked

continuously. Suitable

refrigerant detectors must be

used for this purpose.

•

Have re extinguishers ready at

all times.

•

The tool used must be approved

for working with ammable

refrigerants.

•

The refrigerant must be

completely and properly

disposed of before it enters the

refrigerant circuit. R290 is an

oil separator. The refrigeration

circuit must be expertly inerted.

•

The unit must not be overlled

under any circumstances.

The manufacturer/supplier assumes

no liability for damages arising from

non-intended use. The user bears the

sole risk in such cases.

Intended use also includes working

in accordance with the operating

and installation instructions and

complying with the maintenance

requirements.

5

The units are shipped in sturdy

transport packaging. Check the

unit immediately after delivery

and make a note of any damage

(pleasetake photos of the damage)

or missing parts on the delivery note.

Inform the forwarding agent and

contractual partner.

Please keep the packaging safely for

any returns.

Claims under guarantee made at a

later date will not be accepted.

Control panel

Recessed grip

The unit is particularly well suited to

exible use.

The local room air conditioner

comprises a oor-standing unit

for the indoor area and an exhaust

air hose to conduct the heat away.

Theindoor unit extracts the heat

from the room to be cooled by

means of an evaporator (heat

exchanger) and transfers it to the

internal cooling cycle. This releases

the heat back to the outside via

another heat exchanger (condenser)

by means of the exible exhaust air

hose.

The condensate arising during

cooling mode is continually drained

o via the condenser by means of

a condensate pump located in the

unit - the condenser evaporates the

condensate and discharges it to the

outside via the exhaust air hose.

The unit lters and dehumidies the

air thereby creating a comfortable

room climate. It works fully

automatically and oers numerous

additional options thanks to

its microprocessor controller.

Theoperation of the unit can be

conveniently operated by means

of the infra-red remote control

included.

6.0 Unit description

5.0 Transportation and

packaging

Fig. 2 Rear view

IR receiver

Ventilation louvres

Transport castors

Air lter, recirculation

Air inlet, recirculation

Air duct connection

Exhaust air hose

Air outlet

Exhaust air

Condensate drainage

connection (only required

for "Dehumidifying" mode)

Air inlet, exhaust air

Air outlet

Recirculation

Fin locking

vertical

Emergency emptying of condensate

Fig. 1 Front view

CLIMIA

6

Local room air conditioner CMK 2600

The system can be operated by means of the control panel on the unit or via the standard infrared remote controller.

The functional operation of the keys is identical, however, the designation may vary. The batteries must be correctly

inserted before the infrared remote control is used.

7.0 Operation

"ON/OFF" key

Operating mode "Mode" key

"Fan Speed" key

(only on the remote control)

"Timer on" key

(only on the remote control)

For delayed switch-on

"Timer o" key

(only on the remote control)

For delayed switch-o

Temperature setting keys

"+and -"

Enables the setpoint to be

increased or decreased in 1°C

steps.

Display

Shows the temperature setpoint.

"Sleep" mode key

(only on the remote control)

After this function is activated,

the setpoint value increases by

1°C after 30 minutes. After

another 30 minutes, the setpoint

increases by a further 1°C and

then remains at this setting for

7 hours before returning to the

original temperature setpoint.

"LED Display" display

lighting key

(only on the remote control)

Switches the display and the unit

LED on or o.

Green LED operating mode

indicator on the LCD

Indicates the active operating

mode of the unit.

Fig. 3 Control panel

Selection of the operating mode

"Mode"

•

Cooling mode "Cool"

The unit provides room cooling.

It lters and dehumidies the air

thereby creating a comfortable

room climate.

•

Ventilate mode "Fan"

The unit recirculates the room's

air, lters it and provides an even

air ow.

•

Dehumidifying mode "Dry"

In dehumidifying mode,

moisture is removed from the air

in the room.

Fig. 4 Infrared remote control

Infrared transmitter

Infrared receiver

Operating lamp

Timer indicator

Reset key "Short Cut"

(only on the remote control)

Resets the settings to

"Automatic" and "26 °C".

7

Cooling mode "Cool"

1. Attach the exhaust air hose to a

wall pass-through or window.

2. Switch the unit on with the

"On/O" key .

3. Press the "Mode" key until the

"Cool" LED illuminates.

4. Select the setting for the fan via

the "Fan" key :

"High"

high fan speed

"Low"

low fan speed

5. Adjust the desired room

temperature with the

"Temperature setting" key.

The up arrow increases the

setpoint shown in the display

, the down arrow decreases the

setpoint displayed in 1°C steps.

Ventilate mode "Fan"

1. Switch the unit on with the "On/

O" key .

2. Press the "Mode" key until

the "Fan" LED illuminates.

3. Select the setting for the fan via

the "Fan" key :

"High"

high fan speed

"Low"

low fan speed

4. The room temperature cannot

be changed in this operating

mode.

Dehumidifying mode "Dry"

1. Remove the exhaust hose from

the unit

2. Fasten customer-provided

condensate drainage hose to the

condensate drainage connection

on the unit and feed to a drain.

3. Switch the unit on with the

"On/O" key .

4. Press the "Mode" key until

the "Dry" LED illuminates,

the fan will be automatically

switched on at the lowest fan

speed. The temperature cannot

be inuenced. The unit display

shows the actual current

temperature.

"Timer"

With the timer function of the IR

remote control, the unit can be

switched on or off with a time

delay.

Automatic switch off

1. Switch the unit on with the

"On/Off" key .

2. The "Timer OFF" key on the

IR remote control enables

the desired time delay for

unit switch-off, to be set in

0.5 hour steps. After successful

programming, the timer

indicator on the unit illuminates

green.

Automatic switch on

1. Select the desired temperature

and fan speed during unit

operation. Switch the unit off

with the "On/Off" key .

2. The "Timer ON" key on the

IR remote control enables

the desired time delay for

unit switch-on, to be set in

0.5 hour steps. After this time

has passed, this unit will switch

on with the settings selected in

point 1.

OUR TIP

You will achieve a pleasant room

temperature if you set the desired

target temperature max. 4 to 7 °C

below the outside temperature.

OUR TIP

Help by reducing energy usage

in stand-by operation! If the unit,

the system or the components

are not being used, we

recommend disconnecting the

power supply.

Our recommendation does

not apply to safety relevant

components.

NOTE

The "Auto" mode can be selected

on the display of the infrared

remote control. The function

is identical to the "Cooling"

operating mode.

CLIMIA

8

Local room air conditioner CMK 2600

In cooling mode the unit creates

warm moist exhaust air, which

must be conducted away from the

room to be cooled. For this reason

it is necessary to plug the exhaust

air hose provided into the outlet

opening on the rear of the unit.

•

Ensure that the catches for the

exhaust air

hose latch

securely

into the two

openings

of the

connection aperture. In order to

be sure of eective operation,

do not lay the exible exhaust

air hose with tight bends and do

not kink it.

•

The exhaust air of the unit

contains a certain amount of

moisture. For this reason it is

advisable to feed the exhaust

air to the outdoor area or to

outdoors.

Exhaust air routing variants

You can route the exhaust air out of

the building as follows:

Via a at nozzle

The at nozzle supplied can be

used in various dierent ways. It

is possible to feed the at nozzle

through an open window and fasten

it by means of Velcro and a window

suction cup (Fig. 5, page 9).

Likewise the at nozzle can be hung

in a tilted window (Fig. 6, page 9).

8.0 Before commissioning

The unit is positioned at the desired

location with the discharge side

pointing into the room. When

positioning, observe the following

notes.

•

After unpacking the unit let it sit

on its transport rollers for at least

5 minutes before you switch it

on.

•

Set the unit down in a stable

position on

a level and

rm oor. If

the oor is

uneven then

this can lead

to vibrations

and disturbing

noises.

•

Check

whether the

stopper in the

condensate

drain is present

and correctly

installed. There

is a risk of

uncontrolled

condensate leakage after

commissioning.

•

Never operate

the unit without

the air inlet

lter.

Otherwise, the

ns of the heat

exchanger can

become dirty and the unit loses

performance.

•

Ensure that persons and sensitive

objects, such as plants, are not

placed directly in the air ow

emerging from the unit.

Condensate

drainage with

stopper

Recirculated air

lter

•

All extensions

to the power

supply must be

of a sucient

cable size and

must only

be used fully

rolled out.

Conduct the warm exhaust air away

CAUTION!

There must be a minimum

clearance of 30 cm between the

rear of the unit and the wall.

OUR TIP

In addition, with direct solar

radiation close the curtains and

blinds and keep the windows and

doors closed during

operation.

CAUTION!

The exhaust air hose should

always be laid rising in the

direction of air ow and must not

be extended.

9

9.0 Commissioning

Before every commissioning the air

inlet and outlet openings should

be checked for foreign bodies and

the air inlet lter must be checked

for dirt. Blocked or soiled grills and

lters must be cleaned immediately,

see "Care and maintenance"

chapter.

Cooling mode

1. Switch the unit on with the

"On/O" key.

2. Select cooling mode with the

"MODE" key.

The "COOL" LED must illuminate.

3. Set the desired target

temperature with the

"Temperature setting" key. The

selected target temperature will

be shown in the display. If the

fan speed selected is too large

or too small then this can be

adjusted with the "FAN" key.

Recirculation mode

1. Switch the unit on with the

"On/O" key.

2. Select ventilation mode with the

"FAN" key.

The "FAN" LED must illuminate.

Via a wall pass-through

The hose supplied is rmly attached

to a wall pass-through. A suitable

wall pass-through is available as an

accessory (Fig. 7).

10.0 Shutdown

Temporary shutdown

If it is planned to shut down the unit

for longer periods e.g. during the

winter, proceed as follows:

1. Let the unit run in recirculating

operation for ca. 2 hours in

order to dry the surfaces of

the evaporator ns. Thiswill

transport the remaining

moisture out of the unit and this

will avoid unpleasant odours

when the unit is

re-commissioned.

2. Switch the unit o with the

"On/O" key, pull out the

power plug and wind up the

power supply cable. Ensure that

the cable is not kinked or too

severely bent.

3. Place a suitable container

underneath the condensate

drain of the internal reservoir.

The condensate drain is located

on the lower rear side of the unit.

4. Pull out the stopper from the

condensate drain and collect the

condensate that drains out.

5. Then insert the stopper once

again.

A missing stopper or an

incorrectly inserted stopper will

result in condensate leaking out

after re-commissioning.

6. Store the unit in an upright

position in a cool, dry and dust-

free location protected from

direct sunlight. Cover the unit

with a synthetic cover to protect

it against dust if desired.

NOTE

In some circumstances routing

the exhaust air via a rmly

attached exhaust air hose,

e.g. through closed doors or

windows, can lead to negative

pressure in the room in which the

unit is being used. If this should

reduce the performance of the

unit then arrange for the pressure

to be equalised.

Fig. 5 Exhaust air with open window

Fig. 6 Exhaust air with tilted window

Fig. 7 Wall pass-through

CLIMIA

10

Local room air conditioner CMK 2600

Ensure that units and components

are disposed of in accordance with

local regulations, e.g. through

authorised disposal and recycling

specialists or at collection points.

Intakt GmbH or your contractual

partner will be pleased to provide a

list of certied rms in your area.

12.0 Care and maintenance

Regular care and observation

of some basic points will ensure

trouble-free operation and a long

service life.

•

Cleaning the housing:

Only clean the unit using a damp

cloth.

Do not use a jet of water.

•

Do not use any caustic, abrasive

or solvent-based cleaning

products.

•

Only use suitable cleaning

agents, even in the event of

severe soiling.

•

Ensure that no moisture gets

into the unit. Clean the exhaust

air and outlet openings regularly

and thoroughly.

This is where dirt most often

collects rst.

•

We recommend that you take

out a maintenance contract with

an appropriate specialist rm.

This will guarantee that your

equipment always operates

reliably!

11.0 Filter cleaning

The unit is equipped with an air

lter. This can be withdrawn from

the rear of the unit. The lter must

be cleaned at regular intervals.

Clean the air lter at intervals of no

more than 100 operating hours.

Reduce this interval in the case of

heavily contaminated air.

1. Switch the unit o and pull out

the power plug.

2. Take the lter out of the unit

(Fig. 8).

3. Clean the dust o the lter.

You can use a vacuum cleaner

for this (Fig. 9).

4. In the case of heavy soiling, clean

the lter carefully in lukewarm

water (Fig. 10).

5. Allow the lter to dry in the air.

6. Insert the lter back into the unit

(Fig. 8).

7. Ensure that the lter is dry and

undamaged.

Permanent shutdown

Fig. 8 Changing the lter Fig. 9 Cleaning with a vacuum cleaner

Fig. 10

Cleaning with lukewarm water

CAUTION!

Never operate the unit without

the air lter.

CAUTION!

Care and maintenance work may

only be carried out if the unit

is disconnected from electrical

power.

11

13.0 Installation scheme for wall pass-though (accessory)

Installation instructions

1. Create a core hole in the exterior

wall (max. wall thickness

480mm) with a diameter of at

least 135mm.

Watch out for any supply lines in

this area!

2. Insert the slide tube into the wall

pass-through created such that

the outer tube (larger diameter)

is on the inside of the wall.

In order to avoid cold bridges

insulate the telescopic tube with

suitable insulation material.

3. Brick the slide tube into the core

hole such that it sits ush on

both sides of the wall.

4. Fasten the protection grid on the

outside of the wall with 4 screws.

Take rain ingress into account

when tting the grid.

5. Insert the interior ap valve and

fasten this likewise with 4 screws.

The "Top" legend on the ap

valve must be visible from the

inside!

6. When shutting down the unit,

e.g. before the start of the winter

period, seal the opening in

the ap valve with the sealing

cover in order to prevent air

circulation.

Sealing cover

Non-return apExternal grill

Telescopic tube

min. 400 mm

Fig. 11 Installation example

CLIMIA

12

Local room air conditioner CMK 2600

The unit does not operate, the

control panel remains dark

•

Ensure,

· that the power plug is properly

plugged in.

· that there is no power failure.

· that the mains power is present

(fuse/breaker).

•

Check the power supply cable

for damage.

The unit does not work, LED

indicator "Timer" illuminates

The "Timer" time delay is

programmed if a green LED is

illuminated in the right hand corner

of the display underneath the

temperature display. Deactivate the

timer function.

The unit does not operate,

... the display shows "EC"

•

No cooling capacity after

30 minutes. Possible lack of

refrigerant, contact your dealer.

... the display shows "E1"

•

Recirculation temperature probe

faulty

... the display shows "E2"

•

Suction pipe (pipe contact

sensor) temperature probe faulty

... the display shows "E4"

•

Communication error between

display and control board

... the display shows "P1"

•

The unit's condensate collection

tray is full.

Proceed as follows to empty the

reservoir:

1. Switch unit o, pull out power

plug.

2. Place a shallow container

underneath the drain outlet and

loosen the stopper.

3. After the condensate has drained

o, plug the stopper back in

again rmly.

4. Switch the unit back on.

Is the fault still present?

Contact your dealer.

The unit does not cool properly

•

Check the operating mode:

The"Cool" LED indicator on the

LCD must illuminate.

•

For optimum cooling capacity,

you should close curtains and

blinds. Also, ensure that windows

and doors are closed.

•

Ensure that the exhaust air hose

is properly attached.

It must not be kinked, sloping

downwards or laid in bends that

are too tight.

... that there are no foreign

bodies impairing the air supply

or air exhaust (observe minimum

clearance).

... that the ventilation louvres are

free of dirt and foreign objects.

... that the target temperature is

not set too high (unit operating

range 17 to 35 °C).

The unit does not respond to

the remote control

•

Ensure that the batteries are in

good working order, otherwise

replace the batteries.

... that the batteries have been

inserted with the correct polarity

(see markings).

... that there are no objects

between the remote control and

the unit (range ca. 5m).

The unit and components are manufactured using state-of-the-art production methods and tested several times to

verify that they function correctly. If malfunctions should occur, please check the unit as detailed in the list below.

Please inform your dealer if the unit is still not working correctly after all the function checks have been performed.

14.0 Troubleshooting and customer service

CAUTION!

Never open the

unit housing.

CAUTION!

Never carry out work on

the cooling cycle or on the

electrical equipment.

NOTE

Contact your dealer or

contractual partner if the unit

cannot be activated.

13

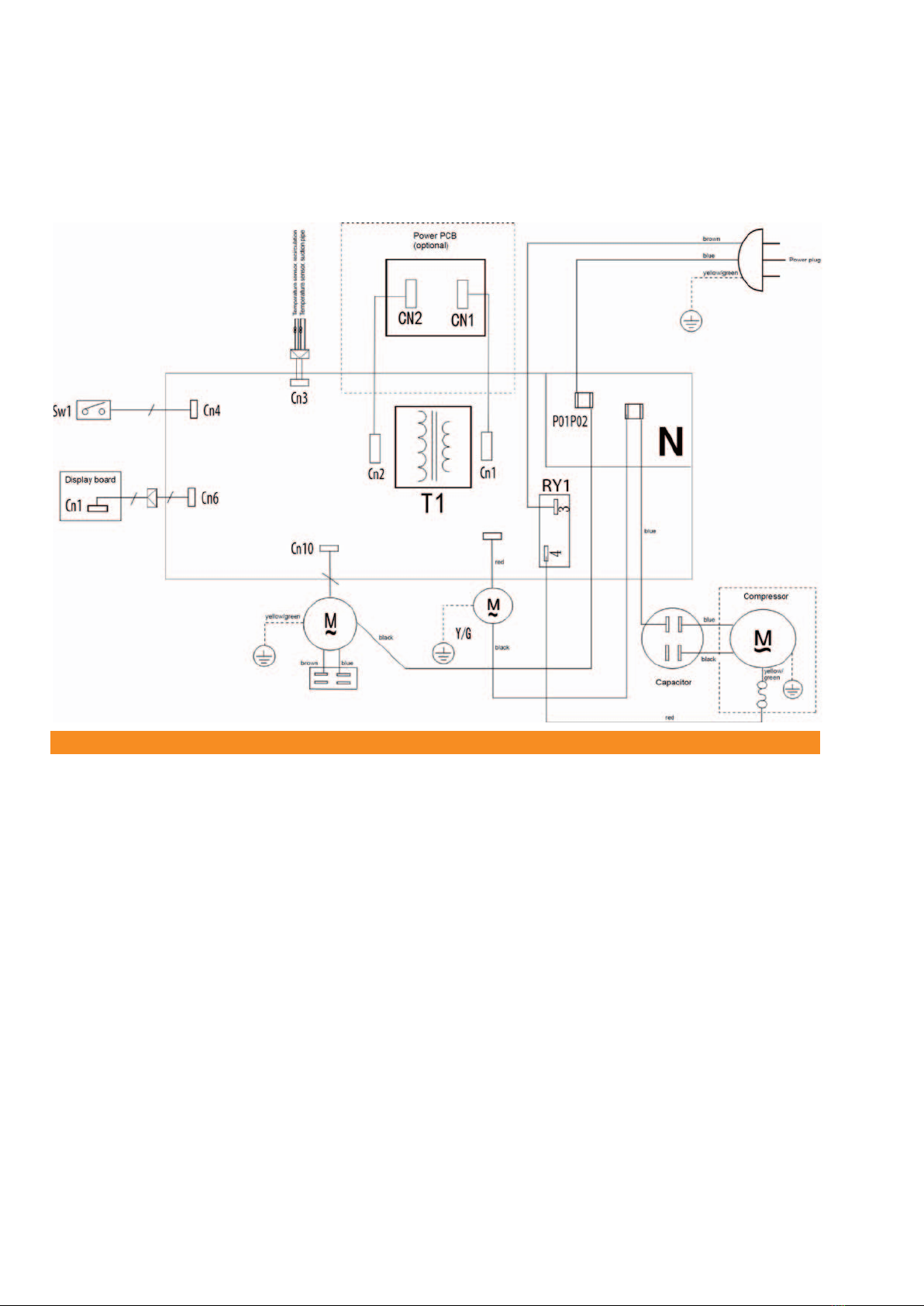

15.0 Electrical wiring diagram

Fig. 12 Connection diagram CMK 2600

CLIMIA

14

Local room air conditioner CMK 2600

16.0 Unit illustration

1

2

3

4

5

67

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Fig. 13 Exploded view of unit CMK 2600

15

17.0 Spare parts list

No. Designation

1 Unit base

2 Conveyor rollers

3 Condensate pump

4 Impeller for condensate pump

5 Liquid level switch

6 Compressor

7 Condenser

8 Evaporator

9 Front wall

10 Fins

11 Fan impeller (condenser fan)

12 Fan motor

13 Fan impeller (evaporator fan)

14 Filter grille

15 Back wall

16 Display board

17 Unit cover

18 Control board

19 Suction pipe (pipe contact sensor) temperature probe

20 Temperature sensor, recirculation

21 Infrared remote control

22 Unit connection port

23 Exhaust air hose

24 Window nozzle / wall pass-through connection port

25 Sealing cover

18.0 Accessories

No. Designation

Not shown Wall pass-though

Not shown Window seal

CLIMIA

16

When ordering spare parts, please state the EDP no., unit number and type (see name plate)!

Local room air conditioner CMK 2600

19.0 Technical data

Series CMK 2600

Operating mode Local room air conditioner for cooling

Nominal cooling output 1) kW 2.3

Energy eciency ratio - cooling A

Energy eciency ratio cooling EER 1) 2.6

Power consumption, annual, (500h) kWh 452

Application area (room volume), approx. m³ 80

Adjustment range indoor unit °C +17 to +30

Operating range - indoor unit °C / % r.H. +16 to +35 / +35 to +65

Refrigerant R290

Max. operating pressure, cooling cycle kPa 4200/1500

Refrigerant, basic quantity kg 0.15

Refrigerant, CO2equivalent t 0.00

Recirculation air volume ow min./max. m³/h 194/286

Sound pressure level min./max. 2) dB(A) 47/53

Sound power level max. dB(A) 62

Power supply V/Ph/Hz 230/~/50

Enclosure class IP X0

Electr. rated power consumption 1) kW 0.90

Electr. rated current consumption 1) A 4.10

LRA

A

18

Exhaust air hose, length / diameter

mm/mm

1400/138

Dimensions - Height mm 703

Width mm 345

Depth mm 355

Weight kg 25.5

1) Room temperature TK 35 °C, FK 24 °C

2) Distance 1m free eld

17

EU – Declaration of Conformity

Original Declaration of Conformity

We hereby declare that the units named below, as produced and sold by us, satisfy the relevant basic requirements

of the EU directives, EU safety standards and product-specic EU standards.

Name of Manufacturer: Intakt GmbH

Climia - Klima- und Wärmetechnik

Niemeierstraße 13

D - 32758 Detmold

Name of the CE representative: Intakt GmbH

Climia - Klima- und Wärmetechnik

Niemeierstraße 13

D - 32758 Detmold

Equipment (machinery) variant: Local room air conditioner

Series/ Class: CLIMIA CMK 2600

Series/ Class Number: 1897...

Applicable provisions

(EU Directives)

The aforementioned products comply

with the following EU directives: 2014/35/EU - Low-Voltage Directive

2014/30/EU - Electromagnetic Compatibility

206/2012 for implementing directive 2009/125/EU

626/2011 for implementing directive 2010/30/EU

RoHS II 2011/65/EU

Applicable standards: DIN EN 55014: 2012

DIN EN 60335: 2012

DIN EN 14511: 2013

DIN EN 12102: 2013

DIN EN 50564: 2011

Detmold, 5/04/ 2019 Intakt GmbH

................................................................

Signature, Manager Director

CLIMIA

18

Intakt GmbH

Climia - Klima- und Wärmetechnik

Niemeierstraße 13

D - 32758 Detmold

Table of contents

Other CLIMIA Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

Friedrich

Friedrich ZoneAire Compact P08SA owner's manual

GE

GE AEC14 Owner's manual and installation instructions

McQuay

McQuay MCK020A Technical manual

Frigidaire

Frigidaire FAZ12ES2A installation instructions

Friedrich

Friedrich WallMaster WS10 Installation and operation manual

TemperZone

TemperZone OSA 840RKTB installation guide

Eberg

Eberg QUBO Q40HD instruction manual

Frigidaire

Frigidaire LRA257ST216 installation instructions

Carrier

Carrier 42TOVG010 owner's manual

Midea

Midea BREEZELESS Technical manual

EIC Solutions

EIC Solutions AAC-145A-4XT Series Installation and operation manual