CLIMIA CMK 2950 User manual

CLIMIA

Local room air conditioner CMK 2950/CMK 2950 silver-grey

Operating instructions

Edition 1.0

English

CLIMIA

Local room air conditioner CMK 2950

Table of Contents

Carefully read this operating manual prior to commissioning/using the units!

This operating manual is a translation of the German original.

This manual is an integral part of the unit and must always be kept in the vicinity of the installation location

or on the unit itself.

Subject to modications. No liability accepted for errors or misprints!

1.0 Safety information 4-9

2.0 Guarantee 10

3.0 Intended use 10

4.0 Environmental protection and recycling 10

5.0 Transportation and packaging 11

6.0 Unit description 11

7.0 Operation 12-13

8.0 Before commissioning 14-15

9.0 Commissioning 15

10.0 Shutdown 15-16

11.0 Care and maintenance 16

12.0 Troubleshooting and customer service 17

13.0 Electrical wiring diagram 18

15.0 Unit illustration 20

16.0 Spare parts list 21

17.0 Accessories 21

18.0 Technical data 22

EC Declaration of Conformity 23

3

1.0 Safety information

General safety notes

Carefully read the operating manual

before placing the unit in service

for the first time. It contains useful

tips and notes as well as hazard

warnings to prevent injury or

material damage. Failure to follow

the directions in this Manual can

endanger persons, the environment

and the equipment itself and will

void any claims for liability.

•Keep this operating manual and

the refrigerant data sheet near to

the unit.

•This unit may only be installed

and operated as described in this

manual.

•Independent conversion and/or

modification of any kind is strictly

prohibited.

•National regulations in

connection with installation must

be observed.

•Children must not be left

unsupervised when close to the

unit.

•For safety reasons, people with

mental, physical or other health

limitations must not operate this

unit unattended.

•The unit is not permitted to be

operated with damaged cables.

The unit must be repaired by a

specialist immediately.

•The unit may only be operated

via a power supply with earthing.

•The use of extension cables is not

recommended.

•The air filter must be cleaned

at intervals of no more than 2

weeks.

•The unit is not permitted to be

operated in the vicinity of heat

sources.

•The unit must be transported

upright. Residue from the

condensate must be drained off

before transport. The unit must

be stood upright for 1 hour prior

to commissioning.

•Combustible substances and

pressure containers must be kept

at least 50 cm from the unit.

•The unit must not be stored and

operated in rooms with oil, gas or

sulphur.

•The unit must always be switched

off with the on/off switch.

•Do not place anything on the

device in particular heavy or hot

objects.

•Repairs may only be carried

out by authorised and certified

specialist personnel.

•The unit must not be covered

with plastic sheets.

•This unit must be disposed of

professionally in accordance with

environmental protection.

•The safety notes in regards to the

room sizes and the flammability

of the refrigerant must not be

removed from the machine.

Warning of inflammable

substances

•The unit may only be operated in

well ventilated areas.

•The unit can be used by children

8 years and up and by persons

without physical, mental or

other health limitations if this

knowledge has been obtained

via the necessary safety notes.

•Children must never play with the

unit.

•Cleaning the unit must not be

carried out by children without

parental/guardian supervision.

Additional safety notes when

handling refrigerant R290

•The refrigerant R290 fulfils the

requirements of the European

F-Gas regulation.

•The unit contains 0.3 kg of the

refrigerant R290.

•The maximum permitted amount

of refrigerant R290 is

0.3 kg.

•The unit must not be burned,

drilled or pierced.

CLIMIA

4

Local room air conditioner CMK 2950

Safety instructions for the operator

The operational safety of the units

and components is only assured

providing they are used as intended

and in a fully assembled state.

•This unit may only be installed

and operated as described in this

manual.

•Independent conversion and/or

modification of any kind is strictly

prohibited.

•Children must not be left

unsupervised when close to the

unit.

•For safety reasons, people with

mental, physical or other health

limitations must not operate this

unit unattended.

•The unit is not permitted to be

operated with damaged cables.

The unit must be repaired by a

specialist immediately.

•Only use cleaning agents which

have been approved by the

manufacturer for cleaning.

•The unit must never be operated

in rooms with naked flames (e.g.

gas heaters, open fireplaces, etc.).

•Refrigerant circuit components

must not be deformed.

•The contained refrigerant R290 is

colourless and odourless.

•The unit must not be stored or

operated in rooms which have a

room area of 14.4 m2or less.

•The accumulation of refrigerant

due to leakages can lead to a

fire and explosions in rooms

which are too small due to the

development of heat or ignition

sources.

•The units must be stored

carefully. Mechanical damage

must be avoided.

•Intervention in the refrigeration

circuit may only be done by

certified specialist personnel

taking into account the safety

notes of the manufacturer.

•Maintenance and repairs may

only be carried out by authorised

personnel which have the

corresponding knowledge in

regards to flammable refrigerant.

WARNING!

Do not use anything other than

the agent recommended by

the manufacturer to speed up

a possible defrosting process or

to clean the unit. The unit may

only be operated and stored in

rooms where there are no devices

with potential ignition sources.

Do not go below the minimum

room area of 14.4 m2. Note that

leaking refrigerant is colourless

and odourless. The unit must not

be burned or pierced!

•The unit may only be operated

via a power supply with earthing.

•The use of extension cables is not

recommended.

•The air filter must be cleaned

at intervals of no more than

2weeks.

•The unit is not permitted to be

operated in the vicinity of heat

sources.

•The unit must be transported

upright. Residue from the

condensate must be drained off

before transport. The unit must

be stood upright for 1 hour prior

to commissioning.

•Operating the units in rooms with

potential ignition sources (naked

flames, gas or electrical heaters,

fireplaces) is prohibited.

•The unit may only be installed,

operated and stored in rooms

larger than 14.4 m2.

•Protective covers (grilles) over

moving parts must not be

removed from units that are in

operation.

•Do not operate units or

components with obvious

defects or signs of damage.

•Contact with equipment parts or

components can lead to burns or

injury.

•The units and components

must not be exposed to any

mechanical load, extreme

levels of humidity or extreme

temperatures.

5

•Never drill through the housing

cover or have the unit come into

contact with fire.

•Rooms in which refrigerant may

escape must be adequately

aerated and ventilated.

Otherwise there is danger of

suffocation.

•All housing parts and unit

openings, e.g. air inlets and

outlets, must be free from foreign

objects, liquids and gases.

•The local room air conditioners

are designed for flexible use

in living and work spaces.

Year-round operation is not

recommended. Use in server

rooms is prohibited.

•Do not leave the units running

for an extended period

unsupervised.

Improper use can cause serious

damage to the unit.

Read this manual carefully before

commissioning!

Never cover the air inlets and

outlets.

Do not allow children to play with

the unit

Do not stand or sit on the unit.

Unplug the power plug before

cleaning the unit.

Do not disassemble housing parts

(consult a specialist company).

Unplug the power plug when not in

use for a long period.

Ensure the voltage is correct

(220-240 V AC, 50 Hz).

Do not operate the unit with

defective cables or sockets.

The unit and in particular the

control panel must not come into

contact with water.

CLIMIA

6

Local room air conditioner CMK 2950

Safety instructions for certied

specialist personnel

•

Check the work area

Before starting work on units

with combustible refrigerants,

ensure that any potential

ignition sources are removed

and the risk of igniting the

refrigerants is eliminated. The

aforementioned safety notes

for repairing the units must

be observed at all times. Work

may only be carried out by

authorised specialist personnel

with knowledge of handling

combustible refrigerants!

•

Prepare the work area

Any persons present must

be informed about the repair

process accordingly and

persons not involved must

vacate the work area. Working

in rooms with limited space

is prohibited. Ensure that

sucient space is available at

the workplace. Ensure that the

ambient conditions are suitable

for working with combustible

refrigerants.

•

Identify refrigerant leaks, check

the atmosphere

Refrigerant may unexpectedly

escape when working on the

refrigerant circuit. Ensure that

the atmosphere in the workplace

is not combustible at all times

by using suitable refrigerant

detectors. Be sure to ensure

that the refrigerant detector

used is suitable, approved

and calibrated for use with

refrigerant R290.

•

Provide re extinguishers

Provide appropriate re

extinguishers before starting

work. For this purpose, dry

powder or CO2re extinguishers

are suitable.

•

Remove any potential ignition

sources

Leaking refrigerant in

combination with corresponding

ignition sources can lead to an

explosion. All ignition sources

must therefore be kept away

from the work area at all times!

This also includes the smoking

of cigarettes. Inform all persons

present that this includes the

axing of safety notes and the

closing o of the work area.

•

Sucient ventilation

Before starting work, ensure

that the work area is outdoors

or has sucient ventilation.

Acontinuous ventilation stream

is required while working.

The safety of the persons

working must be guaranteed

by the exhaust air equipment:

potentially leaking refrigerant

must be lead away safely and

drained into the atmosphere in

an optimum manner.

•

Checking the refrigerant circuit

If electronic components need

to be replaced, ensure that

the spare parts have the same

function and identical technical

specications. The maintenance

and replacement regulations of

the manufacturer must always

be observed and complied with.

Please contact the support of the

manufacturer with any problems

or queries.

The following safety checks

must be carried out when using

combustible refrigerants:

- The ll level adjusts to the size

of the rooms in which the unit is

located.

- The exhaust air equipment and

its outlets function properly and

are not blocked or obstructed.

•

Checking the electronic

components

A component and safety check

must be carried out before

repairing and maintaining

electronic components. If

safety cannot be ensured due

to a defect on a component,

installation must not take place

until safety can be guaranteed

again. If the defect on the spare

part cannot be remedied and

downtime of the unit is no

longer acceptable, an adequate

temporary solution must be

arranged. The owner/operator

of the unit must be informed

about this. The detailed safety

check must include the following

aspects:

- Capacitors are discharged.

Discharging must be done in a

safe process to prevent ying

sparks.

- There must be no electronic

components active or

uninsulated wires while lling,

repairing or cleaning.

- There must be no earthing of

the system.

7

•

Repairs to closed components

Before repairing closed

components/housing parts, the

unit must be free from voltage.

If carrying out the repairs free

from voltage cannot be avoided,

the critical points of potential

refrigerant leakages must be

checked using a leak detector.

The following notes must be

observed when working on

electronic components if the

housing is changed in such a

way that its safety is inuenced.

This also relates to cases where

the lines are damaged, there

is excessive or incorrect pin

assignment, connections are

not assigned in the original

way or similar deviations to

the expected condition are

determined.

•

Repairing of intrinsically safe

components

Do not introduce permanent

inductive or capacitive loads

into the existing circuits without

ensuring that the maximum

permitted voltages and

amperages of the assemblies

and lines are not exceeded.

Intrinsically safe components are

individual components that can

be operated in the presence of

ammable substances. The test

equipment must be adjusted

according to the situation-

dependent conditions. Only use

components which are ocially

approved by the manufacturer

as spare parts. Unapproved

components can cause a re

in the event of a leakage in the

refrigerant circuit.

•

Wiring

Lines must be checked for the

following damage:

- Damage to the insulation -

Corrosion at the contact points

- Excessive pressure on the lines

- Damage due to vibrations

- Damage due to sharp edges

- Damage due to other

inuences not mentioned here

Also consider the ageing of

the material and continuous

vibration loads due to

compressors or fans when

checking.

•

Identify combustible refrigerant

Do not use any potential

ignition source when searching

for refrigerant leaks under any

circumstance. The use of a leak

detection lamp or other similar

devices with a naked ame is not

permitted.

1. Ensure that the components

are installed correctly.

2. Ensure that sealing materials

are not changed in such a way

that combustible gases or

objects could penetrate into the

interior of the components.

3. Spare parts must correspond

to the manufacturer’s

specications.

•

Leak detection methods

The following leak detection

methods are permitted for

systems with combustible

refrigerants. Electronic

equipment must be used

for detecting leaks. These

must be selected with the

sensitivity matched to the

situation and recalibrated if

necessary (calibration must

take place in a refrigerant-free

environment). The leak detection

device must be adjusted to

the lowest ammability limit

(LFL) of the refrigerant. Liquid

leakage instruments are

permitted for most refrigerants.

Chlorinated substances are

the exception here as the

chlorine in combination with

the refrigerants can cause

corrosion on the copper cables.

If a leak is detected, all potential

open ignition sources must be

removed immediately. If a leak

has been detected in the system

which requires reworking of the

piping in the form of soldering,

the system must be completely

free of refrigerant or, if possible,

the aected part disconnected

from the system using stopcocks.

The aected system parts must

be ushed with oxygen-free

nitrogen run before and during

the repair work.

•

Emptying and evacuating the

system

If the refrigerant circuit must

be opened for repairs or other

reasons, this must be carried out

in a safe and professional way. In

any event, proceed with extreme

caution since ignition may occur

at any time!

NOTE!

The use of silicones can inuence

the eectiveness of leak

detection devices!

Intrinsically safe components

must not be insulated before

starting work!

CLIMIA

8

Local room air conditioner CMK 2950

Stick to the following procedure:

1. Drain the refrigerant

2. Flush the system with insert

gas

3. Evacuate

4. Repeat steps 2 to 3 if required

5. Opening the system by cutting

or soldering

The system must be ushed with

oxygen-free nitrogen in order to

guarantee safety. The ushing

process must be repeated

multiple times if necessary.

Do not use compressed air or

oxygen for the ushing process!

After evacuating, ushing

takes place by lling with dried

nitrogen until the operating

pressure is reached and then

the system must be evacuated

again. This ushing process must

often be repeated until there

is no more refrigerant in the

system. After the last ushing,

the system must be brought to

the ambient pressure in order

to start work. The ushing

process is indispensable when

soldering work is required on the

piping. Ensure that the vacuum

pump outlet is not near an

ignition source and continuous

ventilation is guaranteed.

•

Filling process

The following requirements for

the general specications must

also be fullled during the lling

process:

- Ensure that no contamination

occurs from other refrigerants

(residues in the lling

equipment).

- Keep the lines as short as

possible to minimise the

likelihood of residues forming.

- Filling bottles and cylinders

must be stood upright.

- Ensure that the system is

earthed before lling.

- Label the system with the

refrigerant type designation

after lling

- Never exceed the maximum

ll level. The system must be

checked for leaks (pressure

test!) before lling. The system

must be checked for leaks once

more after lling and before

commissioning. Check for leaks

again when leaving the work

space.

•

Labelling when shutting down

If a unit must be taken out of

operation and the refrigerant

must be disposed of, the unit

must be labelled with the date

and a signature. Ensure that the

note remains attached to the

combustible refrigerant.

•

Transportation of units

which contain combustible

refrigerants

National provisions must be

observed.

•

Storing of units which contain

combustible refrigerant

National provisions must be

observed.

•

Transportation without the

original packaging

If the units are transported

without the original packaging,

they must be packed in such a

way that mechanical damage

is prevented. The units must be

transported upright.

9

Disposing of the units and their

components

Only recyclable materials are used

in the manufacture of the units and

components.

Help protect the environment

by ensuring that the units or

components (for example batteries)

are not disposed of in household

waste, but only in accordance

with local regulations and in an

environmentally safe manner, e.g.

using authorised disposal and

recycling specialists or council

collection points.

2.0 Guarantee

As a prerequisite for any

guarantee claims to be considered,

it is essential that the ordering party

or its

representative complete and return

the

"certificate of warranty" to Climia

Intakt GmbH

at the time when the units are

purchased and commissioned.

The guarantee conditions are listed

in the "General terms and conditions

of business and supply". Further-

more, only the parties to a contract

can conclude special agreements

beyond these conditions. In this

case, contact

your contractual partner

in the first instance.

Disposal of packaging

All products are packed for

transport in environmentally

friendly materials. Make a valuable

contribution to reducing waste

and sustaining raw materials. Only

dispose of packaging at approved

collection points.

4.0 Environmental

protection and

recycling

3.0 Intended use

Depending on the model, the units

and the additional fittings with

which they are equipped are only

intended to be used as an air-condi-

tioner for the purpose of cooling or

heating the air in an enclosed space.

Any different or additional use is a

non-intended use.

The manufacturer/supplier assumes

no liability for damages arising from

non-intended use. The user bears the

sole risk in such cases.

Intended use also includes working

in accordance with the operating

and installation instructions and

complying with the maintenance

requirements.

CLIMIA

10

Local room air conditioner CMK 2950

The units are shipped in sturdy

transport packaging. Check the unit

immediately after delivery and make

a note of any damage (please take

photos of the damage) or missing

parts on the delivery note. Inform

the forwarding agent and contrac-

tual partner.

Please keep the packaging safely for

any returns.

Claims under guarantee made at a

later date will not be accepted.

Control panel

Recessed

grip

The local air conditioning unit is

particularly well suited to exible

use.

The local room air conditioner com-

prises a oor-standing unit for the

indoor area

and an exhaust air hose to conduct

the heat away. The indoor unit

extracts the heat from the room to

be cooled by means of an evapora-

tor (heat exchanger) and transfers

it to the internal cooling cycle.

This releases the heat back to the

outside via another heat exchanger

(condenser) by means of the exible

exhaust air hose.

The condensate arising during

cooling mode is continually drained

o via the condenser by means of

a condensate pump located in the

unit - the condenser evaporates the

condensate and discharges it to the

outside via the exhaust air hose.

The unit lters and dehumidies

the air thereby creating a comfort-

able room climate. It works fully

automatically and oers numerous

additional options thanks to its mi-

croprocessor controller. The opera-

tion of the unit can be conveniently

operated by means of the infra-red

remote control included.

6.0 Unit description

5.0 Transportation and

packaging

Fig. 2 Rear view

Transport castors

Air lter, recirculation

Air inlet, recirculation

Exhaust air hose

connection facility

Air outlet

Exhaust air

Air inlet, exhaust air

Air outlet

Recirculation

Ventilation louvres

Condensate

emergency drain with

stopper

Fig. 1 Front view

Condensate drainage

with stopper

11

The system can be operated by means of the control panel on the unit or via the standard infrared remote controller.

The functional operation of the keys is identical, however, the designation may vary. The batteries must be correctly

inserted before the infrared remote control is used.

7.0 Operation

Legend:

Key "I/0" (On/O)

This key switches the unit on or

o.

Operating mode "Mode" key

Actuation of this key allows

the operator to select between

the cooling mode (COOL),

dehumidication mode (DRY)

or circulated air mode (FAN).

The LEDs indicate the selected

operating mode.

"FAN" speed key

With this key it is possible to set

the fan speed and therefore the

air ow. It is possible to select

between the speed stages low

(LO), medium (MED) and high

(HI). The LEDs show the selected

fan speed.

“TIMER” key

This key can be used to activate

a switch-on or switch-o delay.

The switch-on delay is activated

when the unit is switched o,

whilst the switch-o delay

is activated when the unit is

switched on. Using the arrow

keys, it is subsequently possible

to set the desired delay in 1-hour

steps. If no further change is

made for a few seconds, the unit

saves the setting and the set

time is shown on the display. The

LED lights up when the timer is

activated.

Fig. 3 Remote control and control panel

CLIMIA

12

Local room air conditioner CMK 2950

“▲/▼” keys- THERMO/TIMER

CONTROL“

By pressing the “▲/▼” keys

the target temperature can be

set. This can be adjusted in a

range of 16 to 32 °C in 1 °C steps.

“ALARM” indicator

The condensate arising will

be collected in an internal

reservoir, fed to the condenser

and evaporated there. The

evaporated condensate will

then be fed to the outside via

the exhaust air hose. If the

condensate cannot be fed

away then a fault shut-down is

initiated along with an LED

signalling this.

OUR TIP

You will achieve a pleasant room

temperature if you set the desired

target temperature max. 4 to 7 °C

below the outside temperature.

Infrared remote control - General

notes

•

With the unit switched on any

change to the settings will be

automatically transferred to

the room air conditioner.

The proper receipt of data will be

acknowledged with an audible

"beep".

•

To operate the infrared remote

control it should be pointed

towards the receiver. The receipt

of data is only possible if there

are no objects between the

transmitter and the receiver.

•

If the system is shut down for an

extended period it is advisable

to remove the batteries from the

remote control. OUR TIP

Help by reducing energy usage

in stand-by operation! If the unit,

the system or the components

are not being used, we

recommend disconnecting the

power supply.

Our recommendation does

not apply to safety relevant

components.

OUR TIP

Never use new and used batteries

at the same time, remove

discharged batteries immediately

and replace these with new

batteries of the prescribed quality

as there is a danger of discharged

batteries leaking.

Inserting the batteries into the

remote control

Before initial commissioning, insert

the supplied batteries (2 each, type

AAA) into the remote control.

1. Slide the battery compartment

cover on the rear of the remote

control to open it.

2. Insert the batteries with the

correct polarity. Observe

marking in the battery

compartment.

3. Close the battery compartment

again.

In order to put the unit back into

operation again after this fault shut-

down, proceed as follows:

1. Switch the unit o with the“I/0”

key and pull out the power plug.

2. Place a suitable container

underneath the condensate

drain of the internal reservoir.

The condensate drain is located

on the lower centre on the rear

of the unit.

3. Pull out the stopper from the

condensate drain and collect the

condensate that drains out.

4. Then insert the stopper once

again.

13

In cooling mode the unit creates

warm moist exhaust air, which must

be conducted away from the room

to be cooled. For this reason it is

necessary to plug the exhaust air

hose into the outlet opening on the

rear of the unit.

•

Ensure that

the catches

for the

exhaust air

hose latch

securely

into the

two openings of the connection

aperture. Do not lay the exible

exhaust air hose with tight

bends and do not kink it in

order to be sure of eective

operation and to avoid this

causing damage to air ducting

components!

•

The exhaust air of the unit

contains a certain amount of

moisture. For this reason it is

advisable to feed the exhaust

air to the outdoor area or to

outdoors.

Exhaust air routing variants

You can route the exhaust air out of

the building as follows:

Via a at nozzle

The at nozzle supplied can be used

in various dierent ways. It is pos-

sible to feed the at nozzle through

an open window and fasten it by

means of Velcro and a window suc-

tion cup (Fig. 4, page 15).

Likewise the at nozzle can be hung

in a tilted window (Fig. 6, page 15).

8.0 Before commissioning

The unit is positioned at the desired

location with the discharge side

pointing into the room. When

positioning, observe the following

notes.

•

After unpacking the unit let it sit

on its transport rollers for at least

5 minutes before you switch it

on.

•

Set the unit down in a stable

position on

a level and

rm oor. If

the oor is

uneven then

this can lead

to vibrations

and disturbing

noises.

•

Check whether

the stopper in

the condensate

drain is present

and correctly

installed. There

is a risk of

uncontrolled

condensate

leakage after

commission-

ing.

•

Never operate

the unit without

the air inlet

lter.

Otherwise, the

ns of the heat

exchanger can

become dirty

and the unit

loses performance.

•

Ensure that persons and sensitive

objects, such as plants, are not

placed directly in the air ow

emerging from the unit.

Recirculated air

lter

•

All extensions

to the power

supply must be

of a sucient

cable size and

must only

be used fully

rolled out.

Conduct the warm exhaust air away

CAUTION!

There must be a minimum

clearance of 30 cm between the

rear of the unit and the wall.

OUR TIP

In addition, with direct solar

radiation close the curtains and

blinds and keep the windows and

doors closed during operation.

CAUTION!

The exhaust air hose should

always be laid rising in the

direction of air ow and must not

be extended.

Condensate emer-

gency drain with

stopper

Condensate

drainage with

stopper

CLIMIA

14

Local room air conditioner CMK 2950

9.0 Commissioning

Before every commissioning the air

inlet and outlet openings should be

checked for foreign bodies and the

air inlet lter must be checked for

dirt. Blocked or soiled grills and lters

must be cleaned immediately, see

"Care and maintenance" chapter.

Cooling mode

1. Switch the unit on with the“I/O”

key.

2. Select cooling mode with the

"MODE" key.

3. Set the desired target

temperature with the "THERMO/

TIMER CONTROL" keys. The

selected target temperature will

be shown in the display. If the

fan speed selected is too large

or too small then this can be

adjusted with the "FAN" key.

Recirculation mode

1. Switch the unit on with the“I/O”

key.

2. Select recirculation mode with

the "MODE" key.

Via a wall pass-through

The hose supplied is rmly attached

to a wall pass-through. A suitable

wall pass-through is available as an

accessory (Fig. 6).

10.0 Shutdown

Temporary shutdown

If it is planned to shut down the unit

for longer periods e.g. during the

winter, proceed as follows:

1. Let the unit run in recirculating

operation for approx. 2 hours

in order to dry the surfaces

of the evaporator ns. This

will transport the remaining

moisture out of the unit and

this will avoid unpleasant

odours when the unit is re-

commissioned.

2. Switch the unit o with the "I/O"

key, pull out the power plug

and wind up the power supply.

Ensure that the cable is not

kinked or too severely bent. The

line can be fastened to the rear

of the unit.

3. Place a suitable container

underneath the condensate

drain of the internal reservoir.

The condensate drain is located

on the lower rear side of the unit.

4. Pull out the stopper from the

condensate drain and collect the

condensate that drains out.

5. Then insert the stopper once

again.

A missing stopper or an

incorrectly inserted stopper will

result in condensate leaking out

after re-commissioning.

NOTE

In some circumstances routing

the exhaust air via a rmly

attached exhaust air hose,

e.g. through closed doors or

windows, can lead to negative

pressure in the room in which the

unit is being used. If this should

reduce the performance of the

unit then arrange for the pressure

to be equalised.

Fig. 4 Exhaust air with open window

Fig. 5 Exhaust air with tilted window

Fig. 6 Wall pass-through

NOTE

Never switch o a running unit

by pulling out the power plug!

15

Ensure that units and components

are disposed of in accordance with

local regulations, e.g. through

authorised disposal and recycling

specialists or at collection points.

Intakt GmbH or your contractual

partner will be pleased to provide a

list of certied rms in your area.

11.0 Care and maintenance

Regular care and observation

of some basic points will ensure

trouble-free operation and a long

service life.

•

Only clean the unit using a damp

cloth.

Do not use a jet of water.

•

Do not use any caustic, abrasive

or solvent-based cleaning

products.

•

Only use suitable cleaning

agents, even in the event of

severe soiling.

•

Ensure that no moisture gets

into the unit. Clean the exhaust

air and outlet openings regularly

and thoroughly.

This is where dirt most often

collects rst.

•

Clean the air lter on the indoor

unit at regular intervals, and

more frequently if necessary.

•

We recommend that you take

out a maintenance contract with

an appropriate specialist rm.

This will guarantee that your

equipment always operates

reliably!

Permanent shutdown

Fig. 7 Changing the lter

Fig. 8 Cleaning with lukewarm water

Filter cleaning

The unit is equipped with an air

lter. This can be withdrawn from

the rear of the unit. The lter must

be cleaned at regular intervals.

Clean the air lter at intervals of no

more than 100 operating hours.

Reduce this interval in the case of

heavily contaminated air.

1. Switch the unit o and pull out

the power plug.

2. Pull the lter out of the unit (Fig.

7).

3. Clean the dust o the lter. Use

a vacuum cleaner in the event of

slight soiling.

4. In the event of heavy soiling,

clean the lter carefully in

lukewarm water (Fig. 8).

5. Allow the lter to dry in the air.

6. Insert the lter back into the

unit.

7. Ensure that the lter is dry and

undamaged.

CAUTION!

Never operate the indoor unit

without the original lter.

Without the lter, the heat

exchanger ns on the indoor unit

will be contaminated and the

unit will become less ecient.

CAUTION!

Care and maintenance work may

only be carried out if the unit

is disconnected from electrical

power.

6. Store the unit in an upright

position in a cool, dry and dust-

free location protected from

direct sunlight. Cover the unit

with a synthetic cover to protect

it against dust if desired.

NOTE

Check the level of dirt on the heat

exchanger ns as required.

CLIMIA

16

Local room air conditioner CMK 2950

The unit and components are manufactured using state-of-the-art production methods and tested several times to

verify that they function correctly. If malfunctions should occur, please check the unit as detailed in the list below.

Please inform your dealer if the unit is still not working correctly after all the function checks have been performed.

12.0 Troubleshooting and customer service

Operational malfunctions

Malfunction Possible cause Remedial measures

The unit does not start or

switches itself off.

Power failure Check the voltage and if necessary wait for it

to come back on.

Mains fuse faulty.

Master switch off.

Replace the mains fuse.

Switch on the master switch.

Power supply cable damaged. Repair by specialist firm.

Operational temperature range too low or

exceeded.

Observe operational temperature range 16 to

35 °C.

Internal reservoir full. Empty reservoir.

The ambient temperature of the unit lies

outside the operating range (16 to 35 °C).

Do not operate the unit outside the operating

range.

The unit works without

or at reduced

cooling capacity.

Exhaust air hose kinked,

extended, routed downwards or blocked.

Ensure that there is a clear path for the exhaust

air.

Filter contamination. Inlet or outlet blower

openings blocked by foreign bodies. Clean the filter and reinsert it.

Minimum clearances too small. Observe minimum clearances.

Windows and doors open/

heat load was increased.

Close doors and windows/

reduce heat load.

Negative pressure in the installation room

whilst the unit is operating with wall pass-

through.

Balance out pressure in the installation room.

"Cooling" operating mode is not selected. Set "Cooling" operating mode.

Unit will be switched by means of the timer

function. Press "I/0" key again.

Temperature setting too high. Reduce temperature.

Overvoltage due to local lightning strike. Switch unit off and separate from the power

supply for 5 mins., then start anew.

The unit does not respond to

the infra-red remote control.

Batteries in the remote control are empty or

the distance to the receiver is too great.

Insert new batteries/reduce distance or change

its location.

After battery exchange, incorrect polarity of

batteries.

Insert the batteries with the correct polarity.

Observe marking.

Condensate discharge on unit.

Unit standing at an angle. Stand upright and ensure a secure footing.

The stopper for the condensate drain is not

correctly inserted or is damaged. Insert stopper correctly or replace if necessary.

Error indication by code

Error code Error description Remedial measures

E1 Ambient temperature probe defective Replace probe

E2 Probe, evaporator defective Replace probe

E5 Control board defective Replace the control board

17

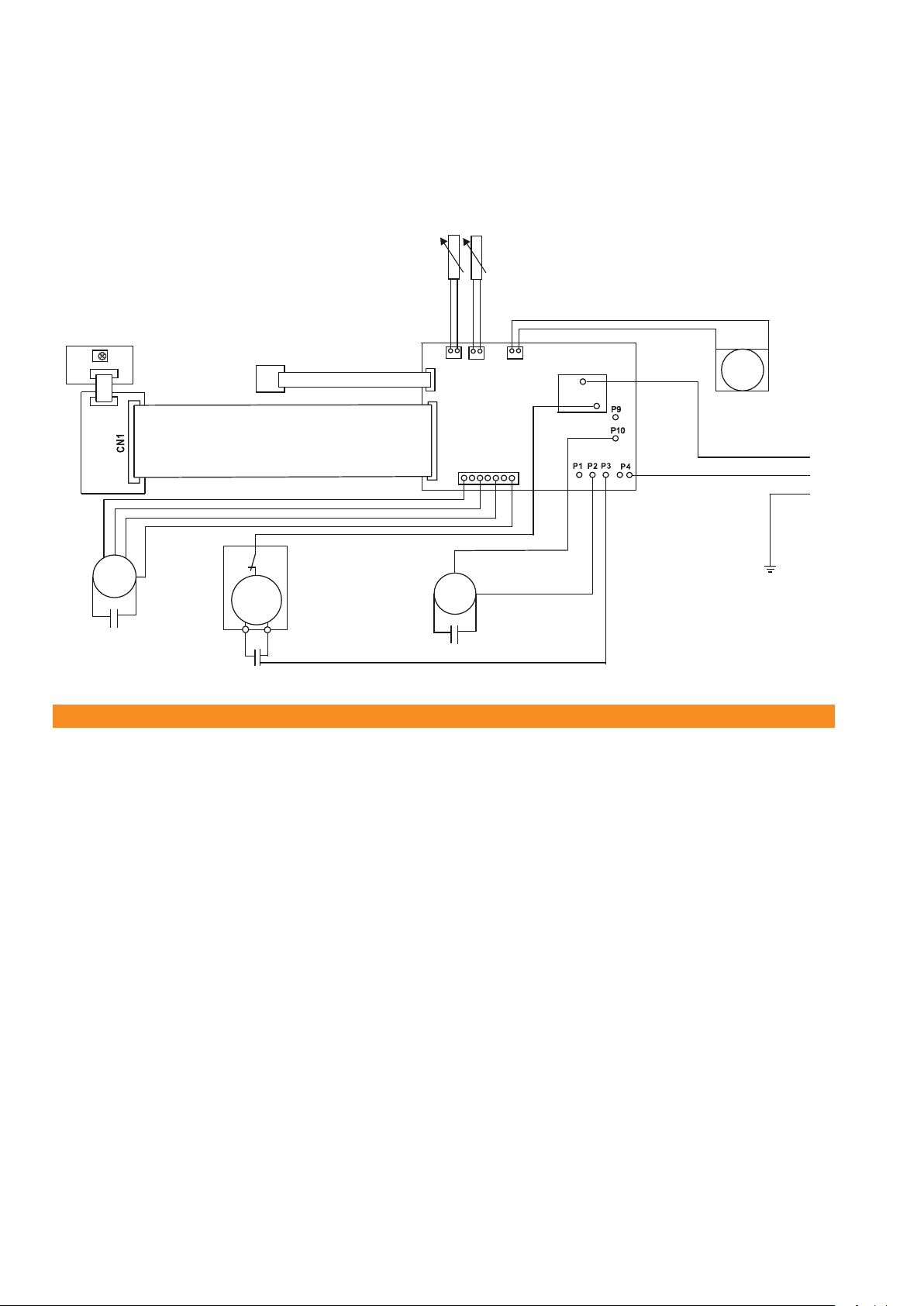

13.0 Electrical wiring diagram

CN 5

COMNO

CN 1

CN 2

CN 4 CN 6

M

CN 3

CN1

CN2

L

N

PE

M

MM

Fig. 9 Wiring diagram

Power

supply

Infrared receiver

Liquid level switch

Temperature probe Temperature probe

Condensate

pump

Fan motor

Evaporator

Compressor

Compressor overheating

protection

Fan motor

Condenser

CLIMIA

18

Local room air conditioner CMK 2950

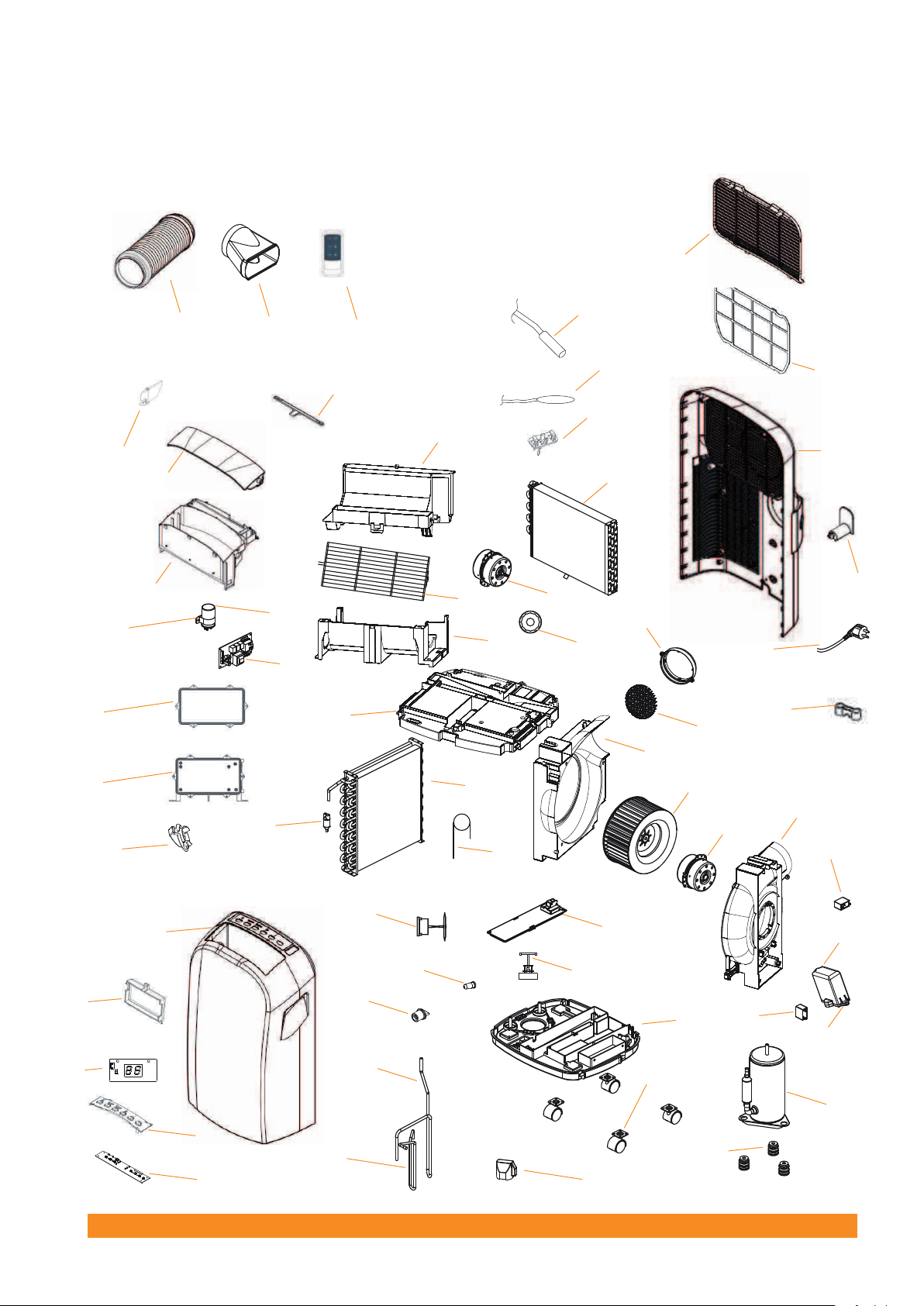

14.0 Unit illustration

6

13

54

49

53 34

40

39

38

Fig. 10 Unit illustration

57 58 59

52

51

50

46

47

48

17

21

45

44

43

42

41

14 2

4

3

5

1

7

10

22

20

28

29

30 31

32

33

36

35

56

8

9

37

16

15

26

25

24

55

23

18

19

27

11

12

19

15.0 Spare parts list

No. Designation

1 Base plate

2 Conveyor rollers

3 Rubber stopper

4 Sealing cap

5 Condensate pump

6 Protective cap

7 Condensate tray cover

8 Protection grid hose connection

9 Exhaust air hose connection nozzle

10 Liquid level switch

11 Compressor

12 Vibration dampers

13 Hot gas line

14 Suction pipe

15 Power supply cable strain relief

16 Power supply cable with Schuko plug

17 Exhaust air hose interlock

18 Capacitor cover

19 Capacitor box fastening

20 Condenser

21 Venturi distributor

22 Capillary tube injection

23 Housing part, exhaust air fan right

24 Exhaust air fan motor

25 Exhaust air fan wheel

26 Housing part, exhaust air fan left

27 Capacitor for exhaust air fan motor

28 Housing intermediate part

29 Housing part, recirculating fan motor bottom

30 Protection grid recirculating fan

31 Recirculating fan motor

32 Fan bearing

33 Housing part, recirculating fan motor top

34 Evaporator

35 Temperature probe, recirculation

36 Recirculation probe fastening

37 Power supply cover

38 Air lter

39 Air lter cover

40 Unit rear

41 Display board

CLIMIA

20

When ordering spare parts, please state the EDP no., unit number and type (see name plate)!

Table of contents

Other CLIMIA Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu Airstage AJYA72LALH installation manual

CLIMAVENETA

CLIMAVENETA ACCURATE AXO installation manual

Mitsubishi Electric

Mitsubishi Electric PUMY-SP112VKM.TH Technical & service manual

DeLonghi

DeLonghi GWHD18A1NK3EA Service manual

Panasonic

Panasonic S-1821PT3H-8 operating instructions

GUTFELS

GUTFELS CM 81457 we instruction manual

Svan

Svan SVAN3009 WiFi User’s manual

Panasonic

Panasonic CS-A182KR Service manual

Sandtoft

Sandtoft Continuous dry verge installation guide

kronings

kronings A2000-50/EU Installation guide and user's manual

Movincool

Movincool Office Pro 10 Operation manual

Armstrong

Armstrong HWC PREMIER 122 Service reference manual