Clinton 323A User manual

CLIITTOII CHI1INSf,IUS

REPTACEMENT ENGINE

..$,

Port No.

A40t t69 PART DESCRIPTION

Power Heod Atst

92

- IYPE 16

l7/a" Bore

* GL[N$T@N$ *

GHAINSAW

Pqrf No. 40ll74

INSTRUCTION TJIANUAL

0nd

PARTS tIST

/

By following the instructions in this

manual you can look forward to de-

pendable service from your Chainsaw.

Quality made, time tested Clinton

Chainsaws are designed to provide ef-

ficient cutting on a great variety of

jobs. They are checked for high stand-

ards during all phases of production

and assembly. Treat your Chainsaw

right, and it will become the most valu-

able tool you own.

For periodic servicing and all major

repairs, you should consult the Author-

ized Clinton Service Station in your

area. Here you will find factory-trained

mechanics, genuine Clinton parts and

prompt, efficient service at your dis-

posal. There are Clinton Service Sta-

tions throughout the United States,

Canada and many foreign countries.

Consult the yellow pages of your tele-

phone directory for list of Authorized

Clinton Service Stations.

For additional information about

your Clinton Chainsaw please feel free

to write directly to the factbry.

INTRODUCTION AND GENERAT INFORMATION

lntroduction SERVICE DEPARTMENT

CHAINSAW DIVISION

CTINTON MACHINE COMPANY

CLINTON, MICHIGAN

Specif ications

Princip.le of 2-Cycle Engine Operation

Assembly of Guide Bar and ihipper Chain. .

3

3

4

5

6

6

Fuel Preparation and Lubrication

Chain and Guide Bar Lubrication

STARTING AND OPERATING PROCEDURE

Sofety. Precoutions

Controls

Storting Procedure

Corburetor (Floot Type)

Break-ln Period

Bucking Cut-Small Logs

N.otching and Felling Cut

SERV!CE AND ADJUSTMENTS

Fuel System

Cleaning Valve Ports-Exhaust

Maintenance

ACCESSORY ITEMS

Bow Sow Attochment

Helpers Handle Assembly

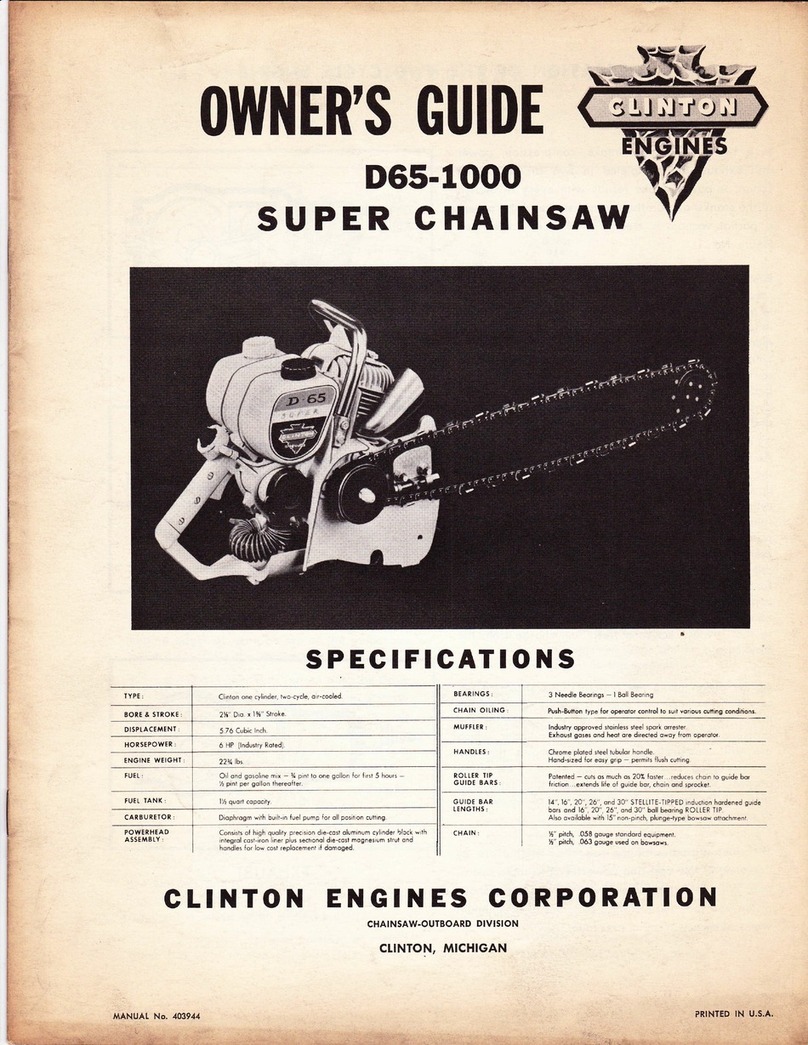

ENGINE-Clinton two cycle, one cylin-

der, air-cooled.

BORE-I7e

STROKE-15/e inches.

FUEt-Oil and Gasoline mixed.

SPARKPTUG-Champion Hll or equal,

Gap .025 inches.

POINT GAP-.020 inches, nominal set-

ting.

IGNITION TIMING-Fixed.

IYPE OF VALVE*Reed.

OPERATING SPEED - Approximalely

4500 R.P.M.

lDLlNG SPEED - Approximotely 1500

to 1800 R.P.M.

TYPE OF BEARINGS-Bo|| ond needle

beorings lhroughout.

TYPE OF CARBUREIOR - Floot.

FUEL TANK CAPACITY - I quort.

FUEI R.AIIO-3/a pint of SAE #30 to I

gal. gasoline.

RECOMMENDED GASOLINE - Any

good grode (non-leoded).

RECOMMENDED OIt GRADE - SAE

#30 (non-detergent).

TYPE OF IGNITION - Clinlon high

tension fly-wheel mognelo.

TYPE OF STARTER-CIinton recoil.

TYPE OF C[UTCH-Automatic Centri-

f ugal.

CHAIN OIIER CAPACIIY - 7z pint

SAE #30.

GUIDE BAR TENGTHS-From l6 inches

to 30 inches (stroight guide bors);

14 & 18 inch Bow Sow Attqch-

ments ovoiloble.

6

7

8

8,9

8

t0

l0

l0

11,12

l3

r3

l3

I3

t4

r5

currTolt 'cHAtilsAw INTRODUCT!ON

w

SPECIFICATIONS

In a two cycle engine, intake, com-

pression, power and exhaust are com-

pleted in two strokes of the piston. A

power-stroke results with every revolu_

tion of the crankshaft. On the Lrpward

stroke of the piston, a partial vacuum

is created in the crankcase. (See Figure

No. l)

First, the vacuunt and outside air

pressure cause the reed valve between

the crankcase and the carburetor to

open. The air-fuel mixture from the

carburetor flows in to the ensine

crankcase. Then, the downward m6u"-

ment of the piston causes the reed

valve to close while continued down-

ward movement of the piston com_

presses the fuel charge in the crank_

case. Near the bottom of its stroke the

piston uncovers the intake by-pass

port, which connects the combirsiion

chamber and the crankcase.

As the piston moves upward on its

stroke, it passes the intake port, closins

the port opening. Its continued ,p*arj

movement causes the fuel mixture in

the cylinder to be compressed. At the

same time a new fuel iharge is drawn

into the crankcase. As the iiston nears

the top of the compression stroke, the

fuel nrixture in the-combustion cham_

ber is ignited by the spark. The explo_

sron and expansion of gases forces'the

piston down on its -power stroke.

Power is not delivered for the full

length of the stroke. Some time is re_

quired to rid the cylinder of burned

gases, so that it may receive a fresh

fuel charge l'ronr the- crankcase.

' As the piston nears the bottom of its

stroke, it uncovers the exhaust oort

opening slightly ahead of the iniake

port. This permits taking advantage of

the. pressure of the exharlst gases ii the

cylinder, which are still coirparatively

high, and allows them to start escaoins.

Further downward travel of the pisto"n

uncovers the intake by-pass port. The

incoming charge assists in forcing the

exhaust gases out of the cylindei, to

contplete the cycle.

'The chief atfributes of the two cvcle

engine- are its lightweight, low cost ind

powerful but simple operation. With

only three basic moving parts (crank_

shaft, piston and rod)],'muirteninc"

costs are at a minimum while efficiency

is at a maximum. Figure No. 2 cHArN

l Slide the guide bar over the

mounting'studs on the reduction

housing to the full length of the

guide bar slot. (See Figure No. 2)

Place the chain around the guide

bar so that cutting edges of teeth

on top of the guide bar point away

fronr the engine unit.

Seat the Chipper Chain drive links

in the guide bar groove then over

the chain drive sprocket.

Pull the guide bar out from the en-

gine unit until the chain slack is

taken up. Make sure that the chain

drive links at the bottom of the

bar are properly seated in the bar

groove.

Place the cover strut on mounting

studs with the smooth pad against

the guide bar,

Make sure that the chain tension

hook bolt. located in the cover

strut, fits into the guide bar slot.

7. Place the spike bumper over the

studs on the reduction housing

and secure with nuts.

8. Put washers and nuts on the guide

bar mounting studs to make them

snug, but not tight against the

guide bar mounting plate.

While holding with upward pres-

sure of the finger in the hole at

end of guide bar, turn tension ad-

justing screw on the hook bolt

clockwise until the chain has a

free sag of not less than 7e inch

nor more lhan Vt inch from the

bottom of the guide bar. lf the

blade is not in the up position as

high as it will go against the guide

bar studs, it will cause excessive

wear on the top of the guide bar

closest to the sprocket.

Securely tighten the mounting

stud nuts and then re-check for

proper chain tension. If the ten-

sion has changed, then loosen the

mounting stud nuts and repeat the

procedure outlined in step 9.

Be sure the chain is properly ten-

sioned at all times. Check it often.

A chain that is too tight rvill in-

terfere with proper cuttin,s and

rvill cause serious damage to the

guide bar and the engine. CAU-

TION: Check and maintain chain

tension for long life and best oper-

ation. Use extra care with a new

chain until the stretch, which is

most noticeable in the first' hour

of cutting, is eliminated.

9.

COMPRESSION

POWER

EXHAUST

Figure No. I

2.

3.

4.

10.

I l.

5.

6.

CAUTION - ]rlsysl Adjust Chain

Tension While Engine Is Running.

5

4

ASSEMBLY OF GUIDE BAR AND CHIPPER CHAIN

Correct fuel mixture is one of the

most important points in operating

your engine. Follow these instructions

carefully, and DO NOT POUR UN-

MIXED GASOLINE OR OIL INTO

THE FUEL TANK.

Type of Oil

Use SAE #30 motor oil (non-deter-

gent), such as Mobiloil or a comparable

straight mineral oil. A detergent oil or

oil containing additives is not advised.

Type of Gasoline

A good grade of regular gasoline,

available at your local filling station, is

recommended for use in your Chain-

saw engine. High octane or Ieaded

fuels offer no advantages and ARE,

NOT advised.

Mixing Ratio of Oil to Gasoline

Thoroughly ntix 3/+ pint of oil with

each gallon of gasoline. This rich oil

mixture may cause difficulty with idl-

ing, but it is necessary to properly wear

in the various parts of the engine.

Chain and Guide Bar Lubrication

A positive action oil pump located

in the upper portion of the fuel tank

(See Figure No. 3) provides ample

Iubrication to the cutting chain and

guide bar. FiU this oil reservoir with

SAE #30 oil, being sure to keep the

oil level in the reservoir 4bove the in-

take tube of the oil pump. When the

reservoir is filled and cap replaced,

push the oil pump plunger a couple of

times until pressure is felt, or until you

see oil appearing on the guide bar op-

posite the convenient oil fitting in the

reduction housing. In extremely cold

weather, or when cutting wood which

contains a lot of pitch, sap or resin,

use a 50-50 mixture of kerosene and

oil in the oil reservoir. This will pro-

vide good lubrication as well as keep-

ing the guide bar g,roove and chain

comparatively clean.

Be sure that the spike bumper

(abutment strut) is flush against

the sawing log to keep the engine

unit from being pulled againsithe

log.

Do not operate your Chainsaw

when it needs repair.

Do not allow the saw to run while

on a cement floor.

Do not run saw when it is dull or

improperly filed.

After refueling, move the engine

a. few feet away from the fue-ling

site.

Keep Chainsaw clean of dust and

inflammables, and check to see

that spark plug and electrical con-

nections are tight.

Your Clinton Chainsaw is well-built

for maximum safety and efficiency, but

carelessness in operation can cause

accidents. Read the following sugges-

tions carefully, and remember them as

you work with your saw.

l. Do not start the engine in a closed

room. Have ample ventilation at

all times.

2. Do not touch the chain when the

epgine is running even at a slow

speed.

3. Keep engine adjusted to an idle

speed which stops the chain com-

pletely.

4. Do not move the chain from one

location to another without first

stopping the engine.

Never Carry the Chainsaw from Place

5.

Major controls on your Clinton

chainsaw are conveniently grouped

around the hand grip assembly for

finger tip action. You will flnd Your

saw easy to manage once you associate

the following controls with their loca-

tions on the saw. (See Figure No. 3).

THE THROTTLE CONTROL

Trigger-type, located on the handle

grip. The engine speed, or throttle

cpening, is increased by squeezing the

trigger upward into the handle.

THE HIGH SPEED MIXTURE AD-

JUSTMENT SCREW Projects

through an opening in the B'Nose on

the left. The adjustment is used to ob-

tain proper fuel mixture, make the

engine run smoothly and achieve maxi-

mum power.

THE IDLE FUEL MIXTURE AD-

JUSTMENT SCREW - This device

is found on the left side of car-

buretor. It is used to obtain smooth

and proper idling speed.

THE CHOKE LEVER-Located on

the right side of the carburetor project-

ing through an opening in the B'Nose.

THE FUEL PUMP-Located on side

of fuel tank and maintains proper

fuel supply to the carburetor.

THE IGNITION SWITCH-Toggle-

type, located on top of the blower

housing to the right of the fuel cap.

THE RECOIL STARTER-Located

on the right side of the unit. A slight

pull will engage the starter with the

engine and a spring disengages it when

the tension is relieved. CAUTION:

The starter cable when pulled out,

should not be released abruptly and

allowed to snap back into its socket.

Release slowly to permit complete re-

winding.

THE CHAIN OILER - Manually

operated, plunger type oil pump, lo-

cated in the upper portion of the fuel

tank just below the tubular handle.

This system forces oil to the guide bar

and chain for positive lubrication.

FUEL SHUT-OFF VALVE-On the

bottom of the fuel tank at the lower

left. To open, turn counter-clockwise

until a slight tension is noticed.

6.

7.

8.

9.

10.

IGNITION SWITCH

OII. PUMP (CHAIN

OII, TANK C^P-\

FUEI IANK CAP+ CHIPPER CHAIN

Er.OwtR HOUSING

GUIDE SAR

,/

TUEUIAR HANDI,ING FRAME

Figurc No. 3

to Place with the Engine Running

FUEL PREPARATION AND LUBRICATION

CHAINSAW CONTROLS

SAFETY AND FIRE PRECAUTIONS

In order to obtain maximum effici_

ency and service from your Chainsaw,

it is necessary that the engine be oper-

ated during a break-in period of ap-

proximately five (5) hours. Never

operate the engine without load or

allow it to become overheated. proper

breaking in of key parts will have

1 Fill fuel and oil tanks according to

Fuel Preparation Instructions on

Page 6.

2. Open fuel tank. Shut-off valve.

3. Open high speed adjustment screw

lVq to lVz trtrns.

4. Push choke lever into .,Choke', po_

sition.

5. Turn ignition switch to ,.On.',

6. Pull on recoil starter handle, then

let it slowly return to the socket.

7 . After two or three pulls, engine will

start. Then return ..choke,' lever to

"run" position.

8. Before cutting with saw, pump the

chain oiler (See Figure No. 3) a few

times to lubricate grooye in guide

bar. Use the pump frequently while

the chain is in operatron.

9. Run the engine for a few minutes

much to do with the life of your en_

gine. Be sure to check often for loose

nuts and screws and make all neces_

sary adjustments. Periodic inspection

and service by your Authorized Clin-

ton Service Station dealer will result

in long life and good pdrformance of

your Chainsaw.

POWER RANGE ADJUSTMENTS

1. Start engine and allow it to run at

Vz throttle for a few minutes until

the engine acquires uniform tem-

perature. Never race the engine

when not under load.

2. Put the saw in cut, under load and

while cutting check to see if engine

backfires. If it does, speed mixture

is too lean.

TO CORRECT: Slowly turn high

speed mixture needle valve counter-

clockwise until the engine runs

smoothly. (Refer to Figure No. 5)

If the engine loads up, is sluggish

and has heavy exhaust, the mixture

is too rich.

TO CORRECT: Turn the adjust-

ment device clockwise until the en-

gine runs normally under cutting

load.

The richest mixture between these

two points will allow satisfactory

acceleration.

Remember:' Clockwise movement

of the needle will lean the mixture.

Counter-clockwise movement will

richen it.

IDLE MIXTURE ADJUSTMENT

1 Following power range adjustment,

adjust throttle stop set screw to a

fast idle.

Remove carburetor and air cleaner

cover. Turn idle adjustment needle

clockwise until engine starts miss-

ing or losing speed.

Then turn needle counter-clockwise

until engine runs more smoothly

agaln.

The point at which the engine be-

gins to run smoothly is the proper

idle mixture adjustment. Final ad-

justment can be made with throttle

stop screw set at approximately

1800 R.P.M.

If you detect any serious trouble in

the carburetor, which may make a

tearing-down operation necessary,

be sure to consult your Authorized

Clinton Service Station Dealer for

adjustment and overhaul.

2.

at Yz speed to engage the clutch,

and when chain is moving around

the guide bar, check to make sure

chain is being lubricated. Never

operate saw at wide open throttle

without load.

3.

4.

J.

4.

5.

5.

CHOKE TEVER

SPEED ADJUST

HIGH 'MENT

Figure No, 5

CARBURETOR ADJUSTMENTS

89

3.

4.

5.

After tilting the unit to the maxi-

mum angle (about 35") for the ini-

tial cut, pull the Chainsaw toward

you.

Repeat this rocking motion until

the cut is completed.

CAUTION: As the cut nears com-

pletion you must be careful to keep

the sawing unit from entering the

ground. It is sometimes possible to

roll the log forward and complete

the cut from the oppdsite side, but

often this cannot be done, and ex-

treme care is necessary.

Release the throttle as you complete

the cut, and this action disengag:s

the clutch.

Figure No. 7

NOTCHING AND FEILING

For this type of operation rotate

the guide bar in a horizontal position

against the tree. DO NOT allow

spectators within six feet of the chain

when it is running.

Remember that the undercut notch

guides the fall of the tree and should

be made with care. By holding your

saw at the desired angle any type of

notch can be made, but plan care-

fully. (See Figure No. 7)

As you start your felling cut remem-

ber to LEAVE HOLDING WOOD

(See Figure No. 7) or the tree might

spin out of control.

Think before you cut!

SPECIAL TOOLS NEEDED: CST'I t File Holder Assembly

CST'34 DePrh Gauge

Figure No. 6

BUCKING CUT

Small togs

Try your hand at bucking a few

stove wood lengths, just to get the feel

of your saw.

l. Select a suitable log approximately

12 to 18 inches in diameter.

2. Start your saw according to in-

structions on page 8.

3. Place one hand on the handle griP

for complete control of the engine.

Use the other hand on the tubular

handle to support the unit.

4. Chain should be allowed to feed

itself with a minimum amount of

pressure on the unit by the operator

to achieve best cutting results.

5. As the cut is completed, release the

throttle which disengages the clutch.

6. Continue this bucking practice un-

til you are well acquainted with the

saw. BUCKING CUT

Large Iogs

. To cut a log up to the capacity of

the guide bar, start at the top of the

log.

l. Raise the power unit and lower the

cutting mechanism to begin your

cut t>n the side of the log that faces

away from you.

2. Notice that sawing action holds the

saw against thc log. (See Figure No.

6)

Clinton Chainsaws are Precision

sharoened at the factory and come to

you'ready for general use' To obtatn

ihe b"rt iervice from Your saw KEEP

iHn--cnetN sHARP AT ApL

TIMES. Remember that Your sawrng

chain and guide bar are a worklng

;;. An irfrProPerlY seated chain' or

l"i tt ut is iooily sharpened .or ten-

iioneO. will but a serious strain upon

the suide bai and the engine' ,

t. A Outt chain forces the guide.bar to

exert more Pressure' and this maY

soread the bar groove or cause un-

"'uin *"ut on t[e edges' Check the

suide bar regularlY with a square

ind file the edges Parallel'

z. ii-itte saw is n-ot cutting straight' do

- .tot trv to remedY this in the cut-

tine. BY forcing [he guide bar Y.ou

cati berid or burn it. Stop the engrne

and chect for the trouble on the bar

or chain'

the onlv important Parts of it' The

aeoth suidei or riders have much to

a"' *l?t, the effectiveness of the

Ii*'t op"tution and must be filed

about every third time the teeth are

sharpened to maintain the ProPer

cleaiance. Use CST-34'

s. coii"it tools are a vital P?tt 9l u

successful maintenance lob' - Y ou

mav have some of these tools on

iiaria, urt if you do not they.arg..all

avaitiUte at your Authorized Ciln-

ton dealers'

i. i'to* round (not taPered) file'

Clinton dealers stock the Irle

[unat", holder with guide-marks

and coirect file. Ask for CST-11'

(See Figure No' 9)

U. e nat file (cross-cut or mill bas-

tard) for use with dePth gauge

in maintaining ProPer rlcler

clearance.

.. P"Ptt, gauge (CST-34) with ad-

- iusiabli d-ial for determining

tl"utun.". (See Figure No' 9)

d. Filine clamP or straight edg€

vise to hold the chain while tt ts

being sharPened.

6.

3.

4.

Careful maintenance and sharPen-

i* *ltt minimize all these troubles'

LSok carefully at the chain illustra-

tion ffinut. No. 8) and You will

notice th-at the cutting teeth are not

l.

2.

3.

NOTCH h brr

OF TREE

csr'il FltE HOI'OER csT-34 DEPTH GAUGE

Figgre No. 9

t0

1. Place chain in file clamp or straight

edge vise.

2. Place the file so that it is level with

and at a 35' angle to the cuttins

tooth. (See Figure No. l0) Avoid

low cutting which Ieads to ..hooks.'

on reerh. Keep about l/5 of the file

diameter showing above the cutter

plate. (For proper filing use CST_ I I

File Holder Assembly, which gives

you the 35" angle and holdi the

file at a proper position.)

3. Two or three firm strokes (with

strength applied on the forward

stroke) will give a keen edge to the

tooth.

4. For best results:

u. {9"p the same cutting angle on

alt teeth.

b. Use the right size file.

".. [..rp side curting edge vertical.

d. Shape -the cutti-ng iooth angle

correctlv.

5. File guidei or riders about everv

third tinte.you file rhe cutting teetir

1o^-ry.ain-tgin the proper cleirance

(.035). If the guiiles'are too high

Figure No. l0 Figure No. I I

FUEI sYsTEM

The fuel system in your Chainsaw

is composed of fuel lines and orifices.

It utilizes an automatic f uel pump

which puts the proper mixture into

action throughout the system. Fuel sys-

tem defects can cause serious trouble

throughout your Chainsaw. At the first

sign of trouble of this kind, consult

your Authorized Clinton Service Sta-

tion. OIt PUMP OPERATION

Since proper lubrication of chain and

guide bar is so important, be sure to

notice any failure in this system. If oil

fails to flow to the guide bar and chain

when the oil pump plunger is pushed,

or if there is no pressure on the plunger,

the pump is not functioning. See your

Authorized Clinton Service Station

Dealer.

GAS CAP AND GASKET

The plastic filler cap differs from

most gas caps in that it has no air-hole

in it. This is because the Fuel Tank is

pressured, and it must be perfectly

sealed throughout to hold the pressure.

The filler cap is provided with a rub-

ber gasket to insure a good seal with

the tank. If the filler cap should be-

come cracked, or the gasket fractured

or hardened, discard them.

MAGNETO ASSEMBTY

AND IGNITION SYSTEM

(Flywheel Type)

Remember the magneto should be

inspected after every 100 hours of op-

eration. If the engine refuses to start

or is hard to start, check the gas sup-

ply, carburetion systen.r and spark plug.

(If the latter is badly burnt, replace.)

If the engine still does not start see

your Authorized Clinton Service Sta-

tion Dealer for magneto inspection

and repair.

CTEANING VATVE PORTS

Exhaust

The only servicing required for the

valve ports is an occasional cleaning

to remove carbon deposits.

l. Renrove nruffler assembly from

Chainsaw Engine which will expose

the exhaust valve ports.

2. Clean with suitable instrument cap-

able of scraping and removing car-

bon deposits within these ports.

3. The engine should be turned over

by hand until the piston moves be-

low the port openings, which will

allow greater access for the cleaning

of these ports.

4, Carc should be taken not to damage

or score top of piston when clean-

tng.

MAINTENANCE

By making the following practices a

habit you can help keep your saw in

good running order and avoid repairs

that neglect might make necessary.

l Remove sawdust and dirt daily so

that a thorough inspection can be

made.

2. Tighten any loose nuts or screws.

3. Check fuel and oil lines for leaks,

especially at connection points.

4. Check air filter and brush off dirt.

5. Do not use compressed air to re-

move dust or dirt from the OUT-

SIDE of the carburetor, since parti-

cles may be blown into the mechan-

ism if you do.

6. Check muffler and exhaust ports

periodically, when the loss of power

is apparent. lf ports are dirty, clean

them.

As often as necessary remove the

cutting chain from the guide bar

and allow it to soak overnight in a

pan of kerosene to remove the sap

and resin deposits and to provide

lubrication for all parts of the chain.

If you notice symptoms of trouble

but cannot find the cause, check

with an Authorized Clinton Service

Station, and be sure your saw is in

good running order.

teeth will not take a big enough

bite, and if guides are rod low t[e

chain will grab or gouge. proceed

as follows:

a. Turn the dial on the depth sause

(CST-34) to rhe right ilntii it'is

closed, then turn iito the left to

the desired measurtment (.035).

Place gauge_ on top of cutting

tooth wirh the dial up and thE

flat lip pointed in the same di-

rection as the cutting edge of

the tooth. (See Figure No.l t)

b. Be sure that the rider protrudes

through the slot in tlie lip of

gauge.

c. Take a flat file and file off all of

the rider that shows above the

filing notch in the gauge lip.

(You needn't worry a6oui huit_

ing the lip itself, since it is hard_

chronred for reasonable wear.)

d. Renrove the gauge and round off

the leading edge of the rider so

it will. not grab at wood when

cnaln ls cuttlng.

7.

8.

t2 l3

SERVICE TIPS

Filing Angle 35'

venrrcrL-->l

1. Remove straight guide bar and

chain.

2. Mount the Bow Saw blade on the

guide bar studs.

3. Place the cover strut over the

mounting studs and secure with the

two replacement nuts in the parts

Bag.

4. For easy installation of chain

a. Loosen the tension adjustment.

b. Place the chain over the drive

sprocket and continue to seat it

along the blade groove.

c. Adjust the chain to proper ten-

sion by using the adjirstment

nut.

d. Start the engine and use the

chain oiler freely while the chain

is in motion. '

CLITTOIT GHAINSAWS

HOW IO IDENTIFY

ldenlificotion of your Clinton Choinsow con eosily be mode by consulting

the Nome Plote found on ihe Blower Housing which show both o Model Number

ond o Six Digit Type Number i.e.,Modet 323A Type 16-lO-12-5-9-8.

TYPE OF

CHAINSAW POWER

iIODEI. HEAD

TYPE OF TYPE Of TYPE OF TYPE OF TYPE OF

FUET INDUCIION SHROUD TRANSAAIS5ION TUBUI.AR

TANI( sYsTEM STYIE OR RED. HsG. HANDI.E

323A CLINTON 16 l0 \2

Figure No. l2

For specialized sawing operations

which require the use of the long guide

bar, the Clinton Chainsaw can be fitted

with a Helpers Handle for two-man

use.

This assenrbly is in two parts. A

mounting stud on the handle-and-guard

half slips through rhe slotted hole in

the rounded end of the guide bar. Note

that the lugs on either side of the

mounting stud engage the slot to posi-

tion the handle securely. The cover half

is then placed over the stud lnd se-

cured with a washer and wing nut. (See

Figure No. I3)

BOW SA

EXPLANAIION OF "TYPES"

xxx x xx

POWER

HEAD FUEI.

TANK INDUCTION

SYSTEM SHROUD

STYTING TRANSMISSION TUBUTAR

OR RED. HSG. HANDI.E

HELPERS

HANDLE

t4

Figure No. l3

I5

BOW SAW INSTALLATION

GLINTOT GHIIII|SIIWS

ITRST DIGIT_POWTR HEAD GLINTON GHAITSf,WS

FIRST DIGII_POWET HEAD

NOIE: The Power Heod is represenled by lhe firsl digil in lhe six digit Choinsow Type Number found on the

Nome Plole.

Ref,

No. PqIt No. PART DESCRIPTION IYPE USAGE 16 QIY.

----- I

I

I

,f 31

t::37

2

3

4

5

6

7

8

8A

9

t0

t2

t3

t4

I5

I6

l7

l9

20

2t

22

23

24

38

39

.|(l

233

820

4q)I96

4q)I44

5q)

P400792

400683

?400789

P400788

400777

5595

400195

842

.l{rcO75

896

2037

401079

400954

7@743

7@O38

4q)609

&1252

400438

1m795

958

4002t3

838

28r

40080t

240

400070

.lOO455

rloI068

P/IOO692

4@182

,l()IO80

376

239

231

366

40(N39

aq)21 I

25

26

27

28

29

30

3I

32

33

BEARING - Needle .... 2

BASE PTATE - Mufrler 'l

BTOCK A55'Y - Cylinder (1h" Bore).... ........ ... I

BRACKEI - Blower Housing lo Cylinder Block I

BREAKER POINT ASS'Y , . I

CAM - Breoker Point i

COlt - Mogneio (Without Lominotions). .... I

COll. & tAI INATION A55'Y - Mqgnero (Used W/400054 Ftywheel). I

CONDENSER - Mogneto I

COVER - Dusl (Breoker Point). I

BODY-Muffler. 'l

COVER & IEAD - Spork Plus ... 'l

€RANKSHAFI I

DECAT - Arrowheod (Blower Housing) ... I

DEFTECTOR - Air (Cylinder) I

DEFTECTOR - Air. I

FIYWHEEI ASSEMBI.Y I

GASKET - Beoring Plote io Block. I

GASKET - Muffler ro Block I

GASKET - Dusi Cover I

GATKET KIT - Overhoul. I

HOUSING AISEMBIY - Blower. .l

NOIE: Ass'y includes Ref. Nos.5,34.39.

INSULATOR - Terminol I

KEY - Flywheel...... I

,IAUFFLER ASS'Y - (with Spork Arresler). I

NUf-StorlerPulley-Hex.,7/16-20. .. I

NUT ..._ Recoil Storter to Blower Housing, Hex., #10- 92 .................. 4

NUT - Terminol, #6 - 32 I

PIN - Wrist .l

PISTON - 17/e" Bore I

NOTE: Pistons ore ovoiloble in .020 (Oversize) (Specily size when ordering)

PISTON ASSEMBLY - (lVa" W/Guided Rod) . ... I

NOTE: Assembly includes Ref. !os. 31, 32, 36, 37.

PIATE - Beoring (WfAir Seol & NeeSte Suoiingi).. .. ... ....... ......... .. r

PTATE ASS'Y - Beoring & Mognero I

NOTE: Assembly includes Ref. Nos. 6, 9,9, 13, 46, 52, 54, 67.

PTATE - Nome (CMC)... I

PULLEY ; Storter I

iETAINER - Wrist Pin 2

nlNG - Pislon ..... 2

NOTE: Rings ore ovoiloble in .020 (Oversize) (Specify size when ordering)

UNG - Beoring Retoiner I

- Moin, Boll (Cylinder Block)

iIVET - O.H., t/8 x 3/16

TODASS'Y-Connecting.. .... ... ...

NOTEr Assembly includes Re{. Nos. 41, 59.

ROl,tER - Topered, Cronk Pin W/Guided Rod .....

57

#

H-o

E

.w?

l't

lm

59

TT

2ts fr r:

26 10

n6{ 332

r

{t

I6

.I

l7

25

T

4

31 39 0

12 l2

u

JsG 8,5

It aq

l''

5t

7

Jf.4

-"\ J'

12 30

CLINTOI| CHAINSf,WS

TIRST DIGIT_POWER HEAD

NOTE: The Power Heod is represented by the firsl digil in lhe six digit Choinsow Type Number found on the

Nome Plote.

Ref.

No. Port No. PART DESCRIPTION TYPE USAGE 16 QTY.

SCREEN - Muffler Spork Arrester..............

SCREW - Connecting Rod Cop (A.H.M., #10-24 x 3/e)..... .. .......

SCREW - Beoring Plote lo Block (H.H.C., 1A-2O x'A)..... ... .....r.

SCREW - Breoker Point Terminol G.H.M., #6-32 x 7/16),...........

SCREW - Breoker Poinl to Beoring Plote (F.H.M., #8-32 x 5/16l

SCREW ..._ Blower Housing to Beoring Plote (F.H.M., th - 20 x 1/zl. .

SCREW - Muffler Body to Bose Ploie (F.H.M., 1A -28 x lYq) . ... .

SCREW - Dust Cover io Beoring Plote (O.H-S.T., #6 - 32 x %) . .

SCREW - Muffler to Block (F.H.N., Yr - 20 x 21/zl.

SCREW & L'WASHER ASS'Y - Condenser lo Beoring Plote

(F.H.M., #8 - 32 x 5h)

SCREW & I,'WASHER AS!'Y - Brocket to Cylinder Heod

(H.H.C., #10 -24 x Ve)

SCREW & L'WASHER ASS'Y - Coil to Beoring Plole

(P.H.S.T., #tO -.24 x l) . . .... ... . . .

SCREW - Terminol (F.H., 6 - 32 x 3A) .

sEAt - oil .

sEAt - oil

SH|M - Cronkshoft End Ploy (.002)

SHIM - Cronkshofr End Ploy (.005)

SPACER - Pislon lo Conn. Rod (Use WrPision 400070).................

SPACER - Oil Seol Ride

SPARK PIUG & GASKET A5SEIABLY..,,.,,.

STARTER ASSEMBI.Y - Recoil (Clinlon)...

SWITCH ASS'Y - Shorting........

WASHER - Storfer Pulley (Flot, 7/16')............

WASHER - Muffler to Block (Flot, Yi'\ .

WASHER - Muftler io Body to Muffler Bose Plole (Flot, Yo")

WASHER - Beoring Plole fo Block (Flot, th")............

WASHER - Beoring Plote 1o Block (Lock, h").

WASHER .- Blower Housing to Beoring Plote (Lock, Vt")..... .........

WASHER - Muffler lo Block (Lock, Yn"). .. .

WASHER- Breoker Poinl to Beoring Plote (Lock, #8) . ... ..

WASHER - Recoil Storter lo Beoring Plole (Lock, #12)

WASHER - Slorter Pulley (Lock) . . ..

WASHER - Tob, Lock

WASHER - Breoker Spring Screw ... .

WASHER - Terminol Screw ...

WASHER - Lock #8

WIRE ASS'Y - Shorling

42

43

44

45

46

47

4A

49

5l

57

53

54

55

56

57

58

59

60

6I

62

63

54

65

66

67

68

69

70

71

72

73

74

4q)3r4

244

400I 78

400802

4@799

400246

70,0117

268

400475

400798

936

5430A

400797

257-l

247

400t 98

5t5

400237

296

859

40I0t7

860

402

657

657

557

t14

4(x)o40

192

400a74

400471

400800

400796

400803

379

2

I

,l

,l

.os req.

os req.

2

6

6

4

2

2

I

6

6

3

2

I

4

I8

GLIITTOII

SECOND DIGIT GHf,IITSf,WS

- TANI( ASSEiABIY

NoTE: The Tank Assembly is represented by the second digir in ihe .i, digir chuir.u*-frGllfEilf

on fhe name plate.

Ref.

t

2

3

4

5

6

7

8

I

IO

tl

t2

No. Port No. PART DESCRIPTION TYPE USAGE IO QTY.

40031 8BODY - Fuel Pump

124 CAP & GASXET ASS,Y - Fuel (tncludes Ref. No. i6) ....

125 CAP & GASKET AtS,y - Oil Tonk (tncludes Ref. No. 19)

400516 CASE - Oil Pump .

976 CUP - Spring (Ftexible Line) .....

816 CONNECTOR - Fuet pump (Flexibte Line).. .. ..... . .

4OO223 CONNECTOR - Fuel pump (pressure Line)...

4OOO77 COVER - Fuel Tonk..

849 DECAI - Fuel Tonk (,,Courion,,)........... . .....

400933 DECAT - Fuel Tonk ("lnstructions,,) ....

4O{n79 DIAPHRAGTYI - Fuel pump ..

FltIER. - Fuel Tonk (lnternol pick-Up) .. .

FUEI PUMP & TANX COVER A!S,y (Nor Shown) ..

NOTE: Ass'y includes 400077 ond 400458

4OO458 IUELpUMpASS,Y_(tncludesRef. Nos. t, 11,24,25,27,35,36, 41, 42) .1

15 395 GASKET - Conneclor . I

16 89I GASKET - Fuel Cop I

17 400176 GASKET - Fuel Tonk Cover.. . .. I

18 4OO477 GASKET - Oit pump plore.. I

19 106 GASKET _ Oil Tonk Cop ... . ..... I

20 4O0O83 LINE - Fuel Dischorge (41/a,, Long) 1

21 400304 UNE - Fuel pick_Up (3%,, Longj. ....... .l

22 832 UNE - Fuel (Neoprene) I

23 B2 NUT - Tonk Flonge (Lock, Hex., yt x 2O). 2

24 4OO082 PIN - Fuel pump, Locofing 2

25 400317 PIATE - Fuel pump, Center Tronsfer. I

27 4Oq)84 PIUNGER - Fuel pump _ Vent I

t9

I30

400076

12

1..,.

m't5

Yir

Irl

lt

3{

IL178 32

J

3I

+1

T f\,

ts

,-l

1l-_.>o

.5

t2

38

j

)^o

:@,2

11 3E

GLIITITON CHf,ITSf,WS

SECOND DIGIT_TANK ASSEMBLY

NOTE: The Tank Assembly is represented by the second digii in ihe six digii Chainsaw Type Number found

on the name plaie.

Ref.

No. PortNo. PART DESCRIPTION TYPE USAGE IO QTY.

28

29

34

35

30

3I

32

33

40

4I

42

43

44

4005 I 5

40044I

400127

400177

70,0204

400I 78

4006I 3

400085

400085

400453

699

400421

834

400081

700205

ll3

657

PTUNGER A55'Y - Oil Pump

PUMP ASS'Y - OiI

NOTE: Ass'y lncludes Ref. Nos. 4, 18, 28,34,37. ,

SCREW...._Fuel Tonkto Beoring Plqte(F.H.M., 1/e -20 x 2t/a) ... ..

SCREW - Fuel Tonk Flonge (H.H.S., % - 20 x I Nylock)

SCREW & I'WASHER ASS'Y - Fuel Tonk Cover (F.H.M., #8-32 x 5/a')

SCREW & I'WASHER ASS'Y - Tonk lo lnduction Brockei

(H.H.C., Y4 - 20 x %, Nylock)

SCREW & I'WASHER A55'Y - Oil Pump ro Tonk (H.H.S.T., #8-32 x3/a)

SCREW & I'WASHER AsS'Y - Fuel Pump to Tonk Cover

(R.H.M., #8 32 x le)

SPRING - Fuel Pump, Vent

SPRING - Oil Pump Plunger

TANK BODY - Fuel .

TANK BODY & COVER ASS'Y - Fuel.

NOTE: Assembly lncludes Ref. Nos. 13, 17,20,21,38, 40.

VATVE - Fuel Shut-Off

VATVE - Fuel Pump. Fluller

WASHER - Fuel Pump to Tonk Cover (Flot, #8 Steel)

WASHER - Fuel Tonk lo Beoring Plole (Lock, %)

WASHER -'Flot, t/4

I

2

9

4

I

I

I

l

36

37

38

I

I

4

4

6

20 2t

GLIIYTOIU CHf,IISf,WS

THIRD DIGIT _ INDUCTION ASSEMBLY

*otr, Ii;fiX.["J,ffi"Jf,,J,.: represenred by rhe third disit in rhe six disir Choinsow Type Number

Rtr

No. PortNo. pART DESCRTpTION

-. 441 BODY - Hond Grip (tndexi-q)

4oo468 BODY ASS,Y - Hond Grip

8 400655 COVER - Air Cleoner . ..

e 4cri214 covER _ a;,;,;;;"; s,ir N"," I

to 164 ET.EMENT - Filrer feir CieonJ I

rPrII UE)LXIFTION TYPEUSAGET2 QIY.

t 441 ro?I ---l:.d Grip (tndexing) 1

4oo468 BODY ASS,Y _ Hond Grip I

3 400026 BUs#N?t-fl:::Y.I';,i"t ** t, ts, a,oit, ts

4 t4O TNSERT - tndex Slide pin I

6 5052 CONNECTOR _ Corbureror (Elbow) - - .. l

7 337 aoNNE.T^D

21

Iott

lul

$r

12

tc

n

1

\{3

I

{5 qr

3t

J

4

{t

41 A

lt

GLINTOI| GHAIIUSf,WS

THIN,D DIGIT _ INDUCT]ON ASSEMBTY

=:.-

NOfE: The lnduction Assembly is represented by the third digit in the six digit Choinsow Type Number

found on lhe Nome Plole.

Ref.

No. Port No. PART DESCRIPTION TYPE USAGE 12 OTY.

GASI(ET - Air Cleoner Mounting Plote ................

GASKET - Corburetor

GASKET - Connector (lnduclion Brocket) ........... . .. .a .

GASKET - lnduclion Brocket io Block .....

GROMI ET - Fuel Line (Hond Grip Body) ........

HAND GRIP ASSEMBTY

NOTE: Ass'y lnc. Ref. Nos. 18, 19, 24, 27 , 32. 35, 36, 42, 48

INDUCIION BRACKET - Corburetor

INDUCIION BRACKET ASS'Y ,,, ,,,

NOTE: Ass'y lnc. Ref. Nos. 4, 17,23,33, 44, 47

GLII{TON CHAINSAWS

FOURTH DIGIT _ SHROUD ASSEMBIY

NOTE: The Shroud Assembly is represented by the fourth digit in the six digit Choinsow Type Number

found on the Nome Plote.

II

12

t3

14

I5

I6

l7

I8

I9

20

21

22

23

24

25

26

27

28

29

30

3t

32

33

34

35

36

37

38

39

40

4I

42

43

44

45

46

47

48

49

50

920

400034

293

r37

677

919

400047

907

r60

I52

8oo

400462

40o352

801

28r

t45

400657

162

r63

I59

541

4qx)35

6s5

374

400707

653

652

400178

4@179

400650

I43

414

4I3

t6I

354

I36

r44

{00706

t35

657

lI4

tr3

1

I

I

I

I

I

LEVER - lndex I

TEVER - Throttle I

llNE - ldle By-Poss (Flexible) . . .... .... l

LINE ASS'Y - Pps53gpg I

UNK - Throttle I

NIPPIE - Long, ldle By-Poss (lnd. Brkl.) .. I

NUT - Hond Grip (Lock, Hex., #10-32) . ... .. 2

NUT & L'WASHER ASS'Y - Corb. Studs (Hex., Yt - 28) 2

NUT PIATE ASS'Y - Air Cleoner ....... 'l

PIN - lndex Lever Hinge . .... I

PIN - lndex Lever Slide (Position Lock) I

PIN - Throllle Lever .. I

RETAINER ASS'Y - Boil Hook I

RETAINER - Ring (Hond Grip Body to lnd. Brkt.) . ........ . ........ I

SCREW - Hondle lo Hond Grip (F.H.M., % - 20 x %, Nylock) 4

SCREW - Reed Volve lo Plote (#8-32 x 3/a) . .......... .. 2

SCREW - (H.H.S.L, #8-32x3/sl 2

SCREW - Hondle (F.H.M., #10-32x l) ... .. . ... . . ...... ... I

SCREW - Hqndle (O.H.M., #lO-32 x s/e) I

SCREW L'WASHER ASt'Y - lnduction Brocket lo Block

(H.H-C., th - 20 x %, Nylock) I

SCREW & L'WASHER A55'Y - lnduction Brocket fo Block

(F.H.M., Y4 - 20 x 3/t) . ..... .. . 5

SCREW - Thumb ........ I

SEAI, - Hond Grip lo Induclion Brockel, Closure I

SHIM - Hond Grip lo lnduction Brockel (.005) os req.

SHll - Hond Grip io lnduction Brocket (.002) . ...... .... .. os req.

SPRING - lndex Lever ... . . ... I

SPRING - Corburetor Throiile .... I

STOP - Reed Volve l

STUD ..._ Corburetor ...... ...... .. 2

TAB - Lock 2

VALVE - Reed I

WASHER - Hond Grip to Body & lnduclion Brockel lo Block (Flot, %"). .. lO

WASHEn - Hqnd Grip to Body (lock,|h") .... ............ .. 6

WASHER - Lock, Yt ...... ..... 6

Ref.

No.

2

3

Pqrt No, PART DESCRIPTION TYPE USAGE 5QTY.

400t94

598

4q)t90

GROMr\^EI - Spork plug Cover

SCREW - Shroud ro Block (R.H.S.T., #B - 32 x Tz)

SHROUD ASSEMBTY - Cylinder

z5

22

2--.rg

i

4

I

GLII{TON GHAINSf,WS

FIFTH D]GII - TRANSMISSION ASSEMBTY

NOrE: The Transmission Assembly is represenied by lhe fifih digil in ihe six digii chainsaw Type Number

found on the name Plate'

lj: portNo. pARr DEscRlpItoN IYPEUsAoEg Otv'

r 196 B"o@ 2

n

I 196 Eeollng - LourrrtsIsrrurr \uvrr' " " 2

2 4OOl35 Beoring - Clutch Drum Needle

3 4OOI35 Beoring Rqce - Clulch Drum " I

4 4OOI3I Belt - D'i'" (1" Wide) I

5 .lOOt59 BodY - Clutch (Elgin) I

6 4OOO87 BodY - Torsion Drive"' I

7 400985 Boll & Plote As!'y - Choin Tension I

8 4ool6c clurJ lssembly'- Centrifugol (Elgin) I

NOTE; Assembly lncludes Ref. Nos' 5' 27, 30'

I 2O5 Connettor - Reduclion Housing Oil Line " I

I

tO 173 Countershoft - Reduction Housing.' i

ll 4q)316 Cover - Reduction Housing '

12 400065 orr- A"t'y - Clutch (tnc' Re{ No 3) " "" "' "' I

{00239 Drum ArsemblY - Clutch I

NOTEr Assembly lncludes Ref. Nos 2, 3, 12, 34'

=--+--

YtI-4

tr4,)

1w_,

33

U

i

m

24 25

GLITTOT CH*ITSAWS

FITIH DIGTT - TRANSMISSION ASSEAABLY

IOfE: The Transmission Assembly is represenled by rhe fifth digit in lhe six digit Chainsaw Type Numbor

found on lhe name plate.

Ref.

No. Port No. PATT DESCTIPTION TYPE USAGE 9 Qry.

Gdrkot - Oil Line................

Gorket - Reducfion Horring Cuor . . .. ..

Guidc - Sprcket ... ..

Houainl - Reduction.........

Koy - Counlershoft (Woodruff)

line Arembly - Oil. .

Nul - Countershoft (Hex.,7/16-20)

Nut t L'worhcr Ar'y - Guide Bor Stud (Hex., % - 24) .

Ring - Counlershofl Beoring Retoiner....................... .

ling - Torsion Drive Tru.Arc..... .

Screw & t'worher Ar'y - Reduction Housing to Block

(H.H.C.,5/16 - l8 x l, Nylock).........

Scrow I ltothcr Arr'y - Reduction Housing Cover

(H.H.C., #10 - 24 x %, Nylock).....

Shim - Clurch (Avoiloble in: .005, & .0lO)................

Shck Abrorbor - Torsion Drive........... ...

Sho - Clutch (Elgin)

Sleevc - Counlershoft

Spocer - Sprcket

Spiko lumper (5 Spike)

Spring - Clulch (Elgin, 2500 R.P.M.).....

Sprocket - Choin, Drive (6 Tooth)...

Sprclct Arembly - Choin, Drive (6 Tooth)...

NOfE: Assembly lrrc. Ref. Nos. 15, 31.

Stud - Guide Bor.

lUorh.r - Cluch Drum Beoring, Fe|t.......

Worher - Countershoft (Flot, 7 / 16"1

Worher - Guide Bor Slrut (Flot, 13/32 x 13/ 16 x I / 16)

Worher - Reduction Housing, Cover (Flot #10) ... .. .

fob lock - Reduction Housing to Block (Upper Tob)...

fob lcl - Reduction Housing to Block (Lower Tob) ...

$s3lrel - Cluich Drum to Blck Thrust..

Whccl - Torsion Drive Cog...................

Wheel Auembly - Torsion Drive Cog...........

NOIE: Assembly lnc. Ref. Nos.6,22,26,41.

t3

I4

l5

r6

t7

I8

t9

20

2t

22

23

2a

25

25

27

28

284

2?

30

3I

32

33

31

35

36

97

38

39

40

4l

12

395

IIE

400220

4q)I4I

t8a

4003 I 3

I85

949

t95

aoo2a5

{00I 85

aq)I89

4to

aoot26

8ta

t7a

4q)2t9

aq,lE6

7e1

/ro02l8

10717

aool 55

692

102

507

671

6at

612

177

a(xx)88

aqx)89

'|

I

2

I

2

I

2

4

2

I

,5

os req.

.l 2

I

,l

.l

.2

,l

,l

2

2

2

4

5

til

t -ru

**"

Y, q ..El

w

o,!i7v

(ffiEED

'iiV CLIITTON CHAII{SAIYS

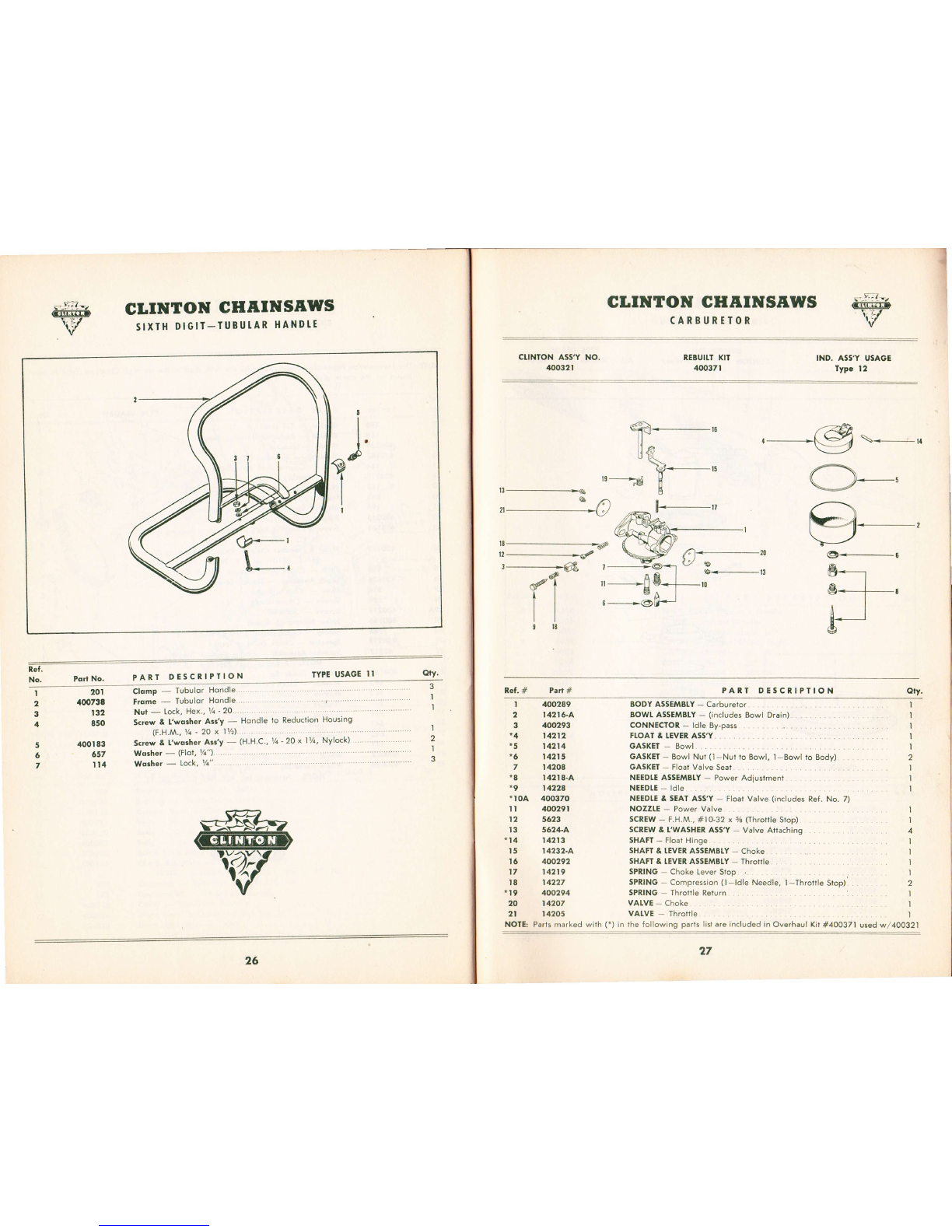

SIXIH DIGIT_TUBUI.AR HANDTT

I

2

3

4

5

6

7

20I

.000738

I32

850

4001 83

657

II4

26

Clomp - Tubulor Hondle.

Frome * Tubulor Hondle. ,'"" "r'' "

Nut - Lock, Hex., Vt -20.. .. ... ..

Screw & L'wosher Arr'y - Hondle to Reduclion Housing

(F.H.M., Yr - 20 x 11h)....

Screw & l'worher As:'y - (H.H.C., tA '20 x l7r, Nylock)

Wo3her - Glot, th")...... .

Worher ._ Lock, V". .......

I

GLINTON GHAINSAWS

CARBURTTOR

REBUITT KIT

400371 IND. ASS'Y USAGE

Type 12

ffi..-$

II

tJ {.1

,s----E Y-.u

r3--->r 4

,-@\-,1

O-,

9.-,

t8

t2

3

--.......----------...--------*o/

-@dT

tl

II

918

Ref. # Part #

I 400289

2 14216-A

3 400293

r42t2

14214

I42t5

7 14208

I42 t 8.A

1422a

.r0A 400370

NOTE: Parlsmarkedwith(")inlhefollowingpartslistareincludedinOverhaul Kit#40037lusedw/400321

PART DESCNIPTION Qty.

I

2

I

3

BODY ASSEMBLY - Carburetor

BOWL ASSEMBTY - (includes Bowl Drain).

CONNECTOR - ldle By-pass

FTOAT & IEVER ASS'Y

GASKET - Bowl.

GASKET - Bowl Nul (l-Nut fo Bowl, l-Bowl to Body) . .

GASKET - Float Valve Seat.

NEEDTE ASSEMBLY - Power Adiustment

NEEDI.E - ldle

NEEDTE & SEAT ASyY - Float Valve (includes Ref. No. 7)

NOZZIE * Power Valve

SCREW - F.H.M., #10-32 x % (Throtlle Stop)

SCREW & L'WASHER ASS'Y - Valve Attaching

SHAFT - Float Hinge

SHAFT & IEVER ASSEMBTY - Choke

SHAFT & TEVER ASSEMBTY - Throttle

SPRING - Choke Lever Siop

SPRING - Compression (l- ldle Needle, 'l-Throrle Stop)

SPRING - Throltle Return .

VAIVE - Choke.

VALVE - Throtlle

t2 5623

t3 s624-A

*14 14213

t6 400292

17 14219

18 14227

*I9 400294

20 14207

2l I420s

2

I

I

I

I

I

4

I

I

I

,|

2

I

I

,|

27

Ref.

No. PoriNo. PART DESCRIPTION TYPE USAGE II

CTINTON ASS'Y NO.

40Gt2t

G-6

B*-----

^t

e*--t-,

F

61+-20

U,@+13

a

lt

-->l

I

g

oiy'

I

GLINTON GHAINSAWS

RTCOII. STARITR

STARTER AsS'Y NO

40I0 t 7DESCN,IPTION

CLINTON TYPE (Clock-Wi*) TYPE USAGE

Att TORSION DRIVE MODEIS

ffi

ll

Clock-Wise

Ref # Port #PARTS DESCRIPTTON

I 40IO80

2 400990

3 400978

4 40to02

5 40lq)3

6 40I0t3

7 40too7

I 700597

9 40to25

t0 40lo2l

I I 40IO40

t2 401006

Div. B

28

CUP - Siorler (Nof Supplied with Assembly)

HANDIE - Recoil Slorter

HOUSING - Recoil Siorter

PAWL - Storter

PIAIE - Powl Aclivqling

PULtEY - Slorier Rope, Recoil

RING - Retoining

ROPE - Pull

SPRING - Powl Plote, Friction

SPRING - Slorler, Recoil

SPRING - Storter Powl, Tension

WASHER - Flot

GLINTON CHIIINSAWS

GUIDE EARS & CHAINS

Ref, #?drt #PART DESCRTPIION Qtv'

I

2

3

4

A564

A55s

A407

4409

H48I

H2r6

H370

H36t

A477

Azt7

4369

4360

4563

4250

AI56

A.406

,.567

At67

A4OI

A408

Al57

A56'

BODY ASS'Y - Helpers Hondle

COVER - Helpers Hondle

CUTTER - Chipper Choin, Lefr. .

CUITER - Chipper Choin, Righr

CUTIING CHAIN - 16' #9, --

curTtNG cHAtN _ 20,, #9.

CUTTING CHAIN - 26" #9

CUTIING CHAIN - 30" #9

I

,|

,|

I

I

I

I

,|

I

I

I

I

I

I

I

I

I

I

t

I

I

I

7

8

9

IO

II

t2

I3

I4

GUTDE BAR - 16"........ .. ....

GUTDE BAn - 20,,. .. . .

GUIDE BAR - 26" . ,, .

GUIDE BAn - 30" ... .....

HEI.PERS HANDTE AS5"r, ..,,,

.-._ NoTE: Assembly irlfrJ., n.i. N"",. l, zi, c, ta

l(lf - Mosrer Link Repoir......

Assembly includes Ref. Nos. Z, 10, 13.

llNK - Moster Chipper Choin....

LUG - Chipper Choin Drive.

NUI - wing tH"tpuo ionJtl) . . .. .... . .. ,

PIN - Mosier tink.................

llYEr - chipper Choin ii.ria"r.. .. .. .... ... . ...

SIRAP - Chipper Choin Tie...

WASHEI - % S.A.E. 1n.fp.r. X.nai"y..... . ..... ......

29

Quon.

I

I

I

2

GLIilTOIf GHf,IilSf,WS

B0w sAw

CTINTON ASSEMBLY NUMBER

A40!062 Bow Sow AsscmblY-14"

tcf.# Pad# PAtr DESCnIPTION OrY'

BAI - Bow, Guide .. ....... ....

BUIVIPER - Bow, Front . ... a '

NUT-Yr'20....... . . ...

SCRBT - H.H.,V ' 20 x l% ....

SCREW - H.H.,Y. - 20 x Yt . ..

SPACER - Bow Front BumPer '

SfRUT - Bow ........ ..

WASHEI - Flot, t/.

WASHET- lock,t/< . ..... .. ..

NOfE: Use Choin Assembly H4Oll54 - 6l'5 inch

t A401069

2 A/tol065

3 400584

4 400264

5 r38

6 A4OO887

7 A401066

8 657

9 II4

30 3t

GLINTOIU GHAINSAWS

B0w sAw

CTINTON ASSEMBTY NUAABER

A400962 Bow Saw Arsembly - 18"

f.t. # ?ta #PANT DESCTIPTION otv.

'|

2

6

2

4

2

I

6

6

I

2

3

4

5

6

7

8

9

to

lt

t2

t3

I4

BAR - Bow, Guide

EUMPER - Bow, Front

CONNECTOR - Chain, Tension Bracket

HANDIE Bow

HOSE - Oil line Extension

NUT- 7a - 20 (Grip)

SCREW - H.H., t/q .20 x lVc

SCREW -- H.H., t/a - 20 x 1s

SCREW - Chain, Adiusfment

SPACER Bow, Front Bumper

STRUI Bow

WASHER - Flat, rzr

WASHER Lock, t/a

NOTE: Use Chain Assembly H400968 - 72 inch

I

I

2

I

,|

'|

I

2

6

I

2

,l

6

8

&I

A4{Xr963

A4q)523

A4{D888

A4{x)524

A&O967

A4q)965

132

@o2&

40,01)02

400548

A4q)887

A400969

657

It4

I

Table of contents

Other Clinton Chainsaw manuals