Clinton D50 HANIY User manual

ilAl\l tlY

t3 ar:

LJ

m

t,'!

\-'

c[,NroN

D5O HANIY

lllustrat ed Parts List

AND

INSTR,UCTION TIANUAL

l$r,"-r;.;-;.";f ;ri;

i:'i:\

- :}

i itrl'

, .-"9.

it{y

Clinton Engines Corporotion

Choinsow-Outboord Divirion

CLINTON, MICHIGAN

INSIRUCTION MANUAI. NO 402t52

REVTSED 8-t-58

INTRODUCTION AND

lnlroduclion

Specificotions

Principle of 2-Cycle Engine Operotion

Assembly of Guide Bor ond Chipper Choin.

TABTE OF CONTENTS

GENERAI INFORMATION

2 Fuel Preporotion ond Lubricotion.. .. . . .

2 Choin ond Guide Bor Lubricolion. . . .

3 Sofety Precoutions

4 Breok-ln Period.

5

5

5

5

STARTING AND OPERATING PROCEDURE

Controls

Storting Procedure.

Corburelor

Bucking Cut - Smoll Logs. . . .

Bucking Cut - Lorge Logs. . . .

Fuel System

Mognelo Assembly & lgnition. .

Cleoning Volve Poris - Exhousi.

SERVICE AND

Notching ond Felling Cut. .

Choin Moinienonce ond Filing lnslruciions

Guide Bor Moinlenonce l

Service Tips . .

Helper's Hondle

ADJUSTMENTS

6

7

7

I

8

8

9

IO

II

Il

.t I

. II

.... 1l

II

12

12-27

Mointenonce

Unit ldentific'qtion . . . .

lllustroted Ports Seciion

By following the insiructions in this monuol you con look

forword to dependoble service from your Choinsow.

Quolity mode, iime lesled your Choinsow is designed to

provide efficient cutling on o greot voriety of iobs. lt

is checked for high stondords during oll phoses of pro-

duction ond ossembly. Treol your Choinsow right, ond it

will become ihe mosl .voluoble lool you own.

For periodic servicing ond olJ moior repoirs, you should

consull the A,uthorized Clinion Service Stotion in your

INTRODUCTION

SPECIFICATIONS

oreo. Here you will find foctory-lroined mechonics, genu-

ine ports ond prompt, efficienl service ot your disposol.

There ore Clinton Service Stotions throughout the United

Slotes, Conodo ond mony foreign counlries. Consult the

yellow poges of your telephone direciory for list of

Authorized Clinton Service Stotions.

For odditionol informotion oboui your Choinsow'pleose

feel free to write direclly to the foctory.

ENGINE - Clinton lwo cycle, one cylinder, oir-cooled.

BORE - I74".

STROKE _ 1%",

FUEI - Oil ond Gosoline mixed.

SPARKPIUG - Chompion H l0J or equol, Gop .025

inches.

POINT GAP - .020 inches, nominol setling.

IGNITION TIMING - Fixed.

TYPE OF VATVE - Reed.

IDLING SPEED-Approximorely 1500 ro 1800 R.P.M.

TYPE OF BEARINGS - Needle.

OPERATING SPEED - App. 4800 R.P.M.

TYPE OF CARBURETOR - Diophrosm.

FUEI TANK CAPACITY- I qt.

FUEI RATIO -% pint of SAEf40 to,l gol. gosoline.

RECOMTi^ENDED GASOIINE - Any good srode (non-

leoded).

RECOMMENDED Olt GRADE - SAE 140 (non-detersent)

TYPE OF IGNITION - High lension flywheel mognelo.

WPE OF STARTER - Recoil.

TYPE OF CTUTCH - Aulomolic Centrifugol.

CHAIN OIIER CAPACITY - One pint SAE #40

GUIDE BAR TENGTHS - From 16 inches to 26 inches.

2

t

OPER,ATION OF THE T}VO CYCLE ENGINE

tn o two cycle engine, inloke, compression, power

ond exhoust ore completed in two strokes of the

piston. A power stroke results with every revolution

of the cronkshoft, On the upword slroke of the piston,

o portiol vocuum is creoted in the cronkcose. (See

Figure No. l)

First, the vocuum ond outside oir pressure couse the

reed volve between the cronkcose ond the corburetor

to open. The oir-fuel mixture from the corburelor flows

in to the engine cronkcose. Then, the downword move-

ment of the piston couses the reed volve lo close

while continued downword movement of the piston

compresses the fuel chorge in lhe cronkcose. Neor the

bottom of its stroke the piston uncovers the intoke

by-poss port, which connects lhe combustion chomber

ond the cronkcose.

As the piston moves upword on its stroke, it posses

the intoke port, closing the port opening. lts continued

upword movement couses the fuel rnixture in the

cylinder'to be compressed. At the some time o new

fuel chorge is drown into the cronkcose. As the

piston neors the top of the compression stroke, the

fuel mixture in the combustion chomber is ignited by

the spork. The explosion ond exponsion of goses

forces the piston down on its power slroke. Power

is not delivered for the full length of the stroke. Some

time is required to rid ihe cylinder of burned goses,

so thot it moy receive o fresh fuel chorge from the

cronkcose.

As the piston neors the bottom of its stroke, it un-

covers the exhoust port opening slightly oheod of the

intoke port. This permits toking odvontoge of the

pressure of the exhoust goses in the cylinder, which

ore still comporotively high, ond ollows ihem lo

stort escoping. Further downword trovel of the piston

uncovers the intoke by-poss port. The incoming chorge

ossists in forcing the exhoust goses out of the cylinder,

to complete the cycle.

The chief ottributes of the two cycle engine ore its

lightweight, low cost ond powerful but simple opero-

lion. With only lhree bosic moving ports (cronkshoft,

piston ond rod), mointenonce costs ore ot o minimum

while efiiciency is ot o moximum.

COMPRESSION

POWER

EXHAUST

Figure No. I

I

ASSEMBLY OF GUIDE BAR. AND CHIPPER, CHAIN

CUITINO

Figure No. 2

l. Slide the guide bor over lhe mounting studs on

the reduction housing to the full length of the

' guide bor slot. (See Figure No. 2)

2. Ploce lhe choin oround the guide bor so lhot

cutling edges of teeth on top of the guide bor

point owoy from the engine unit.

3. Seot the Chipper Choin drive links in the guide

bor groove then over the choin drive sprocket.

4. Pull the guide bor out from lhe engine unit until

the choin slock is token up. Moke sure thot the

choin drive links ot ihe bottom of the bor ore

properly seoted in lhe bor groove.

5. Ploce lhe lension plote on mounting studs with

the flot pod ogoinsl the guide bor.

6. Moke sure thol lhe choin tension hook bolt, lo-

coled in the cover slruls, fils into the guide bor

slot.

7. Ploce lhe spike bumper over the studs on the

reduction housing ond secure with nuls.

Pui woshers ond nuis on the guide bor mounting

studs lo moke them snug, but not light, ogoinst

the guide bor mounling plote.

While holding with upword pressure of the finger

in the hole ot end of guide bor, lurn tension od-

iusling screw on the hook bolt clockwise until ihe

choin hos o free sog of not less thon 7e inch nor

more thon tA inch from lhe bottom of the guide

bor. lf the blode is not in the up positiofi os high

os it will go ogoinst the guide bor studs, it will

couse excessive weor on the top of the guide

bor closesi to lhe sprocket.

Securely tighten the mounting stud nuts ond then

re-check for proper chqin tension. lf the tension

hos chonged, then loosen lhe mounting stud nuts

ond repeot lhe procedure oullined in step 9;

Be sure the choin is properly tensioned ot oll

iimes. Check it often. A choin thot is too iight

will interfere wilh proper cutting ond will couse

serious domoge to the guide bor ond the engine.

CAUTION: Check ond moinioin choin lension for

long life ond best operotion. Use extro core with

o new choin until the stretch, which is most

noticeoble in the first hour of cutfing, is elimi-

noled.

CAUTION - J{svsl Adiust Choin

Tension While Engine ls Running.

I0.

I l.

9.

@

CHAIN

TENSIONET

@o

4

FUEL PREPAR.ATION

Correct fuel mixture is one of the most importont

points in operoting your engine. Follow these in-

struction corefully, ond DO NOT POUR UNMIXED

GASOLINE OR OIL INTO THE FUEL TANK.

Typr of Oil

Use SAE #30 motor oil (non-detergent), such os Mobil-

oil or o comporoble stroight minerol oil. A detergent

oil or oil contoining odditives is not odvised.

Typr of Gorolinc

A good grode of regulor gosoline, ovoiloble ot your

locol filling slotion, is recommended for use in your

choin sow engine. High octone or leoded fuels offer

no odvonioges ond ARE NOT odvised.

Mixing Rotio of Oil ro Gqrolinc

Thoroughly mix Vt pinl of oil with eoch gollon of

gosoline. This rich oil mixture moy couse difticulty

AND LUBR, ICATION

with idling, but it is necessory to properly weor in

the vorious ports of lhe engine.

Choin ond Guide Bor lubricotion

A positive oction oil pump locoted in the lower por-

lion of the fuel tonk (See Figure No. 3) provides omple

lubricotion to the cutting chqin ond guide bor. Fill

this oil reservoir with SAE #30 oil, being sure to keep

the oil level in the reservoir obove the intoke tube

of the oil pump. When lhe reservoir is filled ond cop

reploced, push the oil pump plunger o couple of times

until pressure is felt, or until you see oil oppeoring

on the guide bor opposite lhe convenient oil fitting

in the reduction housing. ln extremely cold weother,

or when cutting wood which conloins o lot of piich,

sop or resin, use o 50-50 mixture of kerosene ond

oil in the oil reservoir. This will provide good lubri-

cqtion os well os keeping the guide bor groove ond

choin comporotively cleon.

SAFETY AND FIR,E

Your Choinsow is well-built for moximum sofety ond

efticiency, but corelessness in operotion con couse

occidents. Reod the following suggeslions corefully,

ond remember them os you work wiih your sow.

L Do not stort the engine in o closed room. Hove

omple ventilotion ot oll times.

2. Do not louch the choin when the engine is

running even ot o slow speed.

3. Keep engine odjusted to on idle speed which

slops the choin completely.

4. Do not move the choin from one locolion to

onother without firsl stopping the engine.

ln order to obtoin moximum efficiency ond service

from your choin sow, it is necessory thoi the engine

be operoted during o breok-in period of opproxi-

motely five (5) hours. Never operote the engine with-

out lood or ollow it to become overheoled. Proper

breoking in of key porls will hove much to do with

PRECAUTIONS

Be sure thot the spike bumper (obutment strut)

is flush ogoinst the sowing log to keep the

engine unit from being pulled ogoinst the log.

Do not operqte your choin sow when it needs

repoir.

Do not ollow the sow to run while on o cement

floor.

Do not run sow when it is dull or improperly

filed.

After refueling, move the engine q few feet

owoy from the fueling site. '

Keep choin sow cleon of dust ond inflommobles,

ond check lo see thot spork plug ond electricol

connections ore tight.

the life of your engine. Be sure to check often for

loose nuts ond screws ond moke oll necessory odiust-

ments. Periodic inspection ond service by your outhor-

ized Clinton Service Stotion deoler will result in long

life ond good performonce of your Choinsow.

5.

6.

7.

8.

9.

10.

Never Corry the Choin Sow from Ploce to Ploce with the Engine Running

BR,EAK.IN PER,IOD

I

5

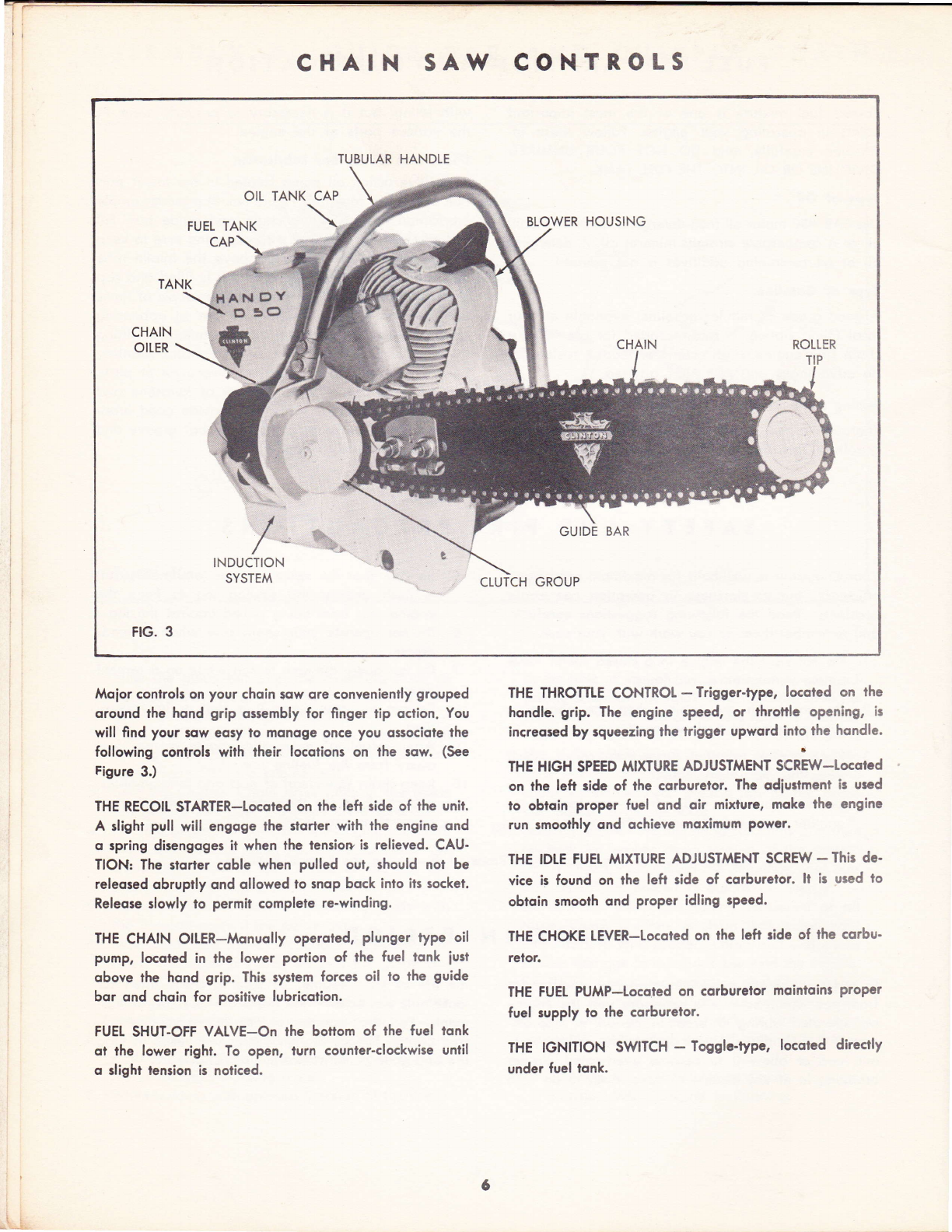

lr CHAIN SAW CONTR,OLS

TUBULAR HANDLE

OIL TANK CAP

FUEL TANK BLOWER HOUSING

CAP

TANK HAN c3Y

c 3c3

GUIDE BAR

tCLUTCH GROUP

FIG. 3

Moior conlrols on your choin sow ore conveniently grouped

oround the hqnd grip ossembly for finger tip oction. You

will find your 3ow eosy io monoge once you ossociole lhe

following control3 wiih their locotions on lhe row. (See

Figure 3.)

THE RECOII STARTER-Locoted on the left side of ihe unit.

A slight pull will engoge lhe rtorler with the engine ond

o spring disengoges it when lhe lensiop is relieved. CAU-

TION: The 3lorter coble when pulled out, should not be

releosed obruptly qnd ollowed io 3nop bock into ils cocket.

Releose slowly to permit complete re-winding.

THE CHAIN OILER-Monuolly operoted, plunger type oil

pump, locoted in the lower portion of the fuel lonk iurt

obove lhe hond grip. This system forces oil to the guide

bor qnd choin for positive lubricotion.

FUEI SHUT-OFF VATVE-On the bottom of the fuel tonk

ot lhe lower right. To open, turn counler-clockwise until

o slight tension is noticed.

THE THROTTLE CONTROL - Trigger-typc, locoted on the

hondle. grip. The engine speed, or throttle opening, is

increosed by rqueezing the triggcr upword into ?he hqndle.

THE HIGH SPEED MIXTURE ADJUSTMENT SCR;W-LOCqICd

on the left side of the corburetor. The odiurtment is urcd

to obtoin proper fuel ond oir mixlure, mokc the engine

run rmoolhly ond qchieve mqximum Powcr.

THE lDLE FUEL MIXTURE ADJUSTMENT SCRBT - Thir dc'

vice is found on lhe left ride of corburelor. lt ic used lo

obroin smoolh ond proper idling rpeed.

THE CHOKE LEVER-Locoted on the left ride of lhe cqrbu'

retor.

THE FUEL PUMP-Locqted on corburelor moinloin3 ProPer

fuel supply lo lhe cqrburelor.

THE IGNITION SWITCH - Togglc-type, locoted directly

under fuel lqnk.

/

/

INDUCTION

SYSTEM

6

STAR.TING PROCEDURE

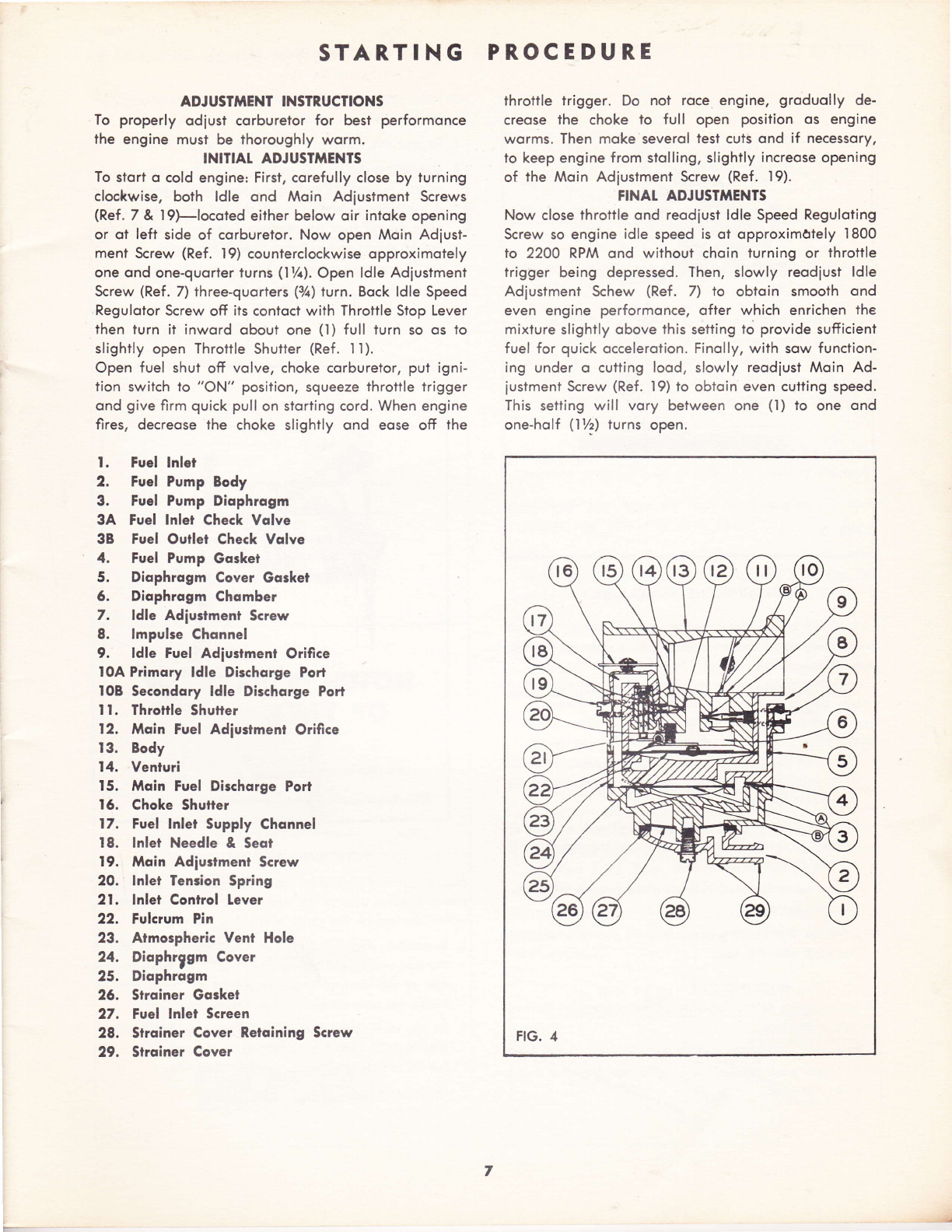

ADJ USTftIENT INSTRUCTIONS throtlle trigger. Do not roce engine, groduolly de-

To properly odiust corburetor for best performonce creqse the choke to full open position os engine

To stort o cold engine: First, corefully close by turning of the Moin Adiustment Screw (Ref. l9).

cloc*.wise, both ldle ond Moin Adiustment Screws FINAT ADJUSTiAENTS

(Ref.7& l9)-locoted either below oir intoke opening Now close throttle ond reodiust ldle Speed Reguloiing

or ot left side of corburetor. Now open Moin Adjust- Screw so engine idle speed is ot opproxim0tely I800

ment Screw (Ref. l9) counterclockwise opproximotely to 2200 RPM ond without choin turning or throttle

one ond one-quorier turns (l%). Open ldle Adiustment trigger being depressed. Then, slowly reodiust ldle

Screw (Ref. 7) three-quorters (32) turn. Bock ldle Speed Adiustment Schew (Ref. 7) to obtoin srnooth ond

Regulotor Screw off its contoci with Throttle Stop Lever even engine performonce, ofler which enrichen the

then turn it inword obout one (l) full turn so os lo mixlure slightly obove this setting to provide sufiicient

slightly open Throttle Shulter (Ref. ll). fuel for quick occelerotion. Finolly, wilh sow function-

Open fuel shut off volve, choke corburetor, put igni- ing under o cutting lood, slowly reodiust Moin Ad-

tion switch to "ON" position, squeeze throttle trigger iustment Screw (Ref. l9) lo obtoin even cuiting speed.

ond givefirm quick pull on storting cord. When engine This setting will vory between one (l) to one ond

fires, decreose the choke slighily ond eose off the one-holf (l7z) turns open.

the engine must be thoroughly worm.

INITIAT ADJUSTfrIENTS

l. Fuel lnlet

2, Fue! Pump Body

3. Fuel Pump Diophrogm

3A Fuel lnlet Check Volve

38 Fuel Ouilet Check Vqlve

4. Fuel Pump Gosket

5. Diophrogm Cover Gqsket

6. Diophrogm Chqmber

7. ldle Adiusrmenl Screw

8. lmpulse Chonne!

9. ldle Fuel Adiustment Orifice

l0A Primory ldle Dischqrge Port

IOB Secondory ldle Dischorge Port

t l. Throttle Shutter

12, Mqin Fuel Adiustment Orifice

13. Body

I4. Venturi

15. Mqin Fuel Dischorge Port

I6. Choke Shutter

17. Fuel lnlet Supply Chqnnel

18. lnlei Needle & Seot

19. Moin Adiuslmenl Screw

20. lnlet Tension Spring

2l . lnlei Control Lever

22. Fulcrum Pin

23. Atmospheric Vent Hole

24. Diophrggm Cover

25. Diophrogm

26. Strqiner Gqsket

27. Fuel lnlet Sqeen

28. Strqiner Cover Retoining Screw

29. Strqiner Cover

worms. Then moke severol tesl cuts ond if necessory,

to keep engine from stolling, slightly increose opening

FIG. 4

7

FIG. 5

BUCKING CUT-Smol! Logs

Try bucking o few slove wood lenglhs, iust to get the feel

of your sow.

l. Select o suitoble log opproximotely I2 to l8 inches

in diometer.

2. Stort your sow occording lo insiructions. ..

3. Ploce one hond on the hondle grip for complete control

of the engine. Use the other hond on the tubulor hondle

to support the unit.

4. Choin should be ollowed to feed itself with o minimum

omounl of pressure on the unit by the operolor to

ochieve best cutting results.

5. As the cut is compleled, releose the throtlle which dis.

engoges ihe clutch.

6. Continue this bucking proctice until you ore well oc-

quointed with the sow.

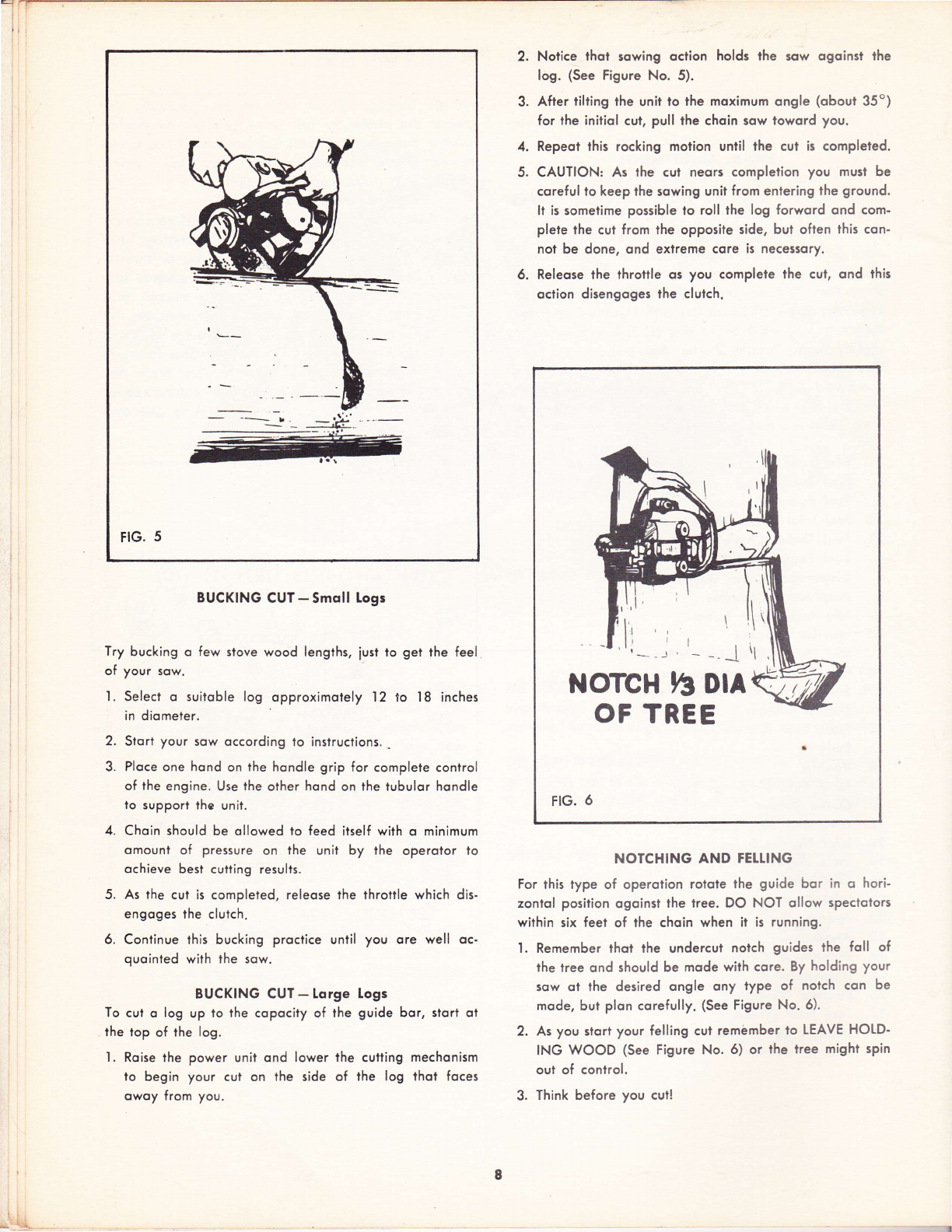

BUCKING CUI - lorge Logs

To cui o log up to the copocity of the guide bor, slort oi

the lop of the log.

'I . Roise the power unit ond lower ihe cutting mechonism

to begin your cui on the side of the log thol foces

owoy from you.

2. Notice lhot sowing oction holds lhe sow ogoinst the

log. (See Figure No. 5).

3. Afier tilting rhe unii lo the moximum ongle (obout 35o)

for the initiol cui, pull the choin sow loword you.

4. Repeol this rocking motion until the cut is completed.

5. CAUTION: As the cul neors completion you must be

coreful to keep the sowing unit from enlering the ground.

ll is sometime possible to roll the log forword ond com-

plete the cut from the opposite side, bul often this con-

not be done, ond exlreme core is necessory,

6. Releose the throttle os you complete lhe cut, ond this

oclion disengoges the clutch.

NOTCH h Orr

OF TREE

FIG. 6

NOTCHING AND FEILING

For this type of operotion roloie the guide bor in o hori-

zontol posiiion ogoinst lhe lree. DO NOT ollow spectotors

within six feet of the choin when it is running.

'l . Remember thot the undercul notch guides the foll of

the tree ond should be mode with core. By holding your

sow ot the desired ongle ony type of nolch con be

mode, but plon corefully. (See Figure No. 6).

2. As you slorl your felling cul remilmber ro LEAVE HOID'

ING WOOD (See Figure No' 6) or lhe tree might spin

oul of conlrol.

3. Think before you cul!

CHAIN IAAINTENANCE AND FIIING INSTRUCT!ONS

Hold File Hoider

Arr'y Level. I9O to

Side ol Guide Bor.)

FIG.

Hold tilc Lcvel.

{90 to Sida ol

Guidc Bor.)

Hold File level . . l9O lo Side o,

Guide Bor.)

FIG. ll

FrG. l2

'l . Ploce choin in choin filing vise or stroighi edge vise if

possible.

2. Ploce file holder ossembly over rounded cutting tooth.

(See Fig. 9) The left hond cutting tooth should be

shorpened from the right side ond the right hond

tooth from the left hond side. Line up filing ongle morks

on holder with guide bor. Hold Sle level or 90o to

the guide bor.

3. Two or ihree firm strokes (with pressure opplied on the

forword stroke) should give o keen edge to the tooth.

4. All teeth must hove the some filing ongles, ihe some

lenglh, ond riders lhe some height.

5. The cenler cutlers, locoted belween the curved cutiing

teeth, should be filed with o flot file (See Fig. I0)

ofter oll the curved culling teeth hove been filed.

6. Using o flot file the center cutters should be filed on

leoding edge ot 35o ongle or ot the some ongle os

cutting teeth. Hold file 90' to the guide bor. Toke core

thot the top of the center cutters ore even with the top

of curved cutting teeth or .0o5 below curved cutting

teeth. Moke sure lhot they ore never obove the curved

cutiing teeth. When finished the center cqtters should

oll be the some length ond height.

7. The finol step is to file the riders down. This is done

with the use of o depth gouge (See Fig. I l). Core should

be token thot oll riders hove lhe some height ond thot

the leoding edge is rounded off ofter filing. Set riders

on direcl drive choin sows ol .025. Sei riders on re-

duction drive models ot .035. See picture.

NOTE: ln so{t wood, the sow choin depth riders on direct

drive moy be set ot .035 on reduclion drive ol .015 br

fosler cutting.

CHAIN MAINTENANCE KIT

DIRECT DRIVE: A402684

REDUCTION DRIVET A,{02685

-1

FIG. l0

9

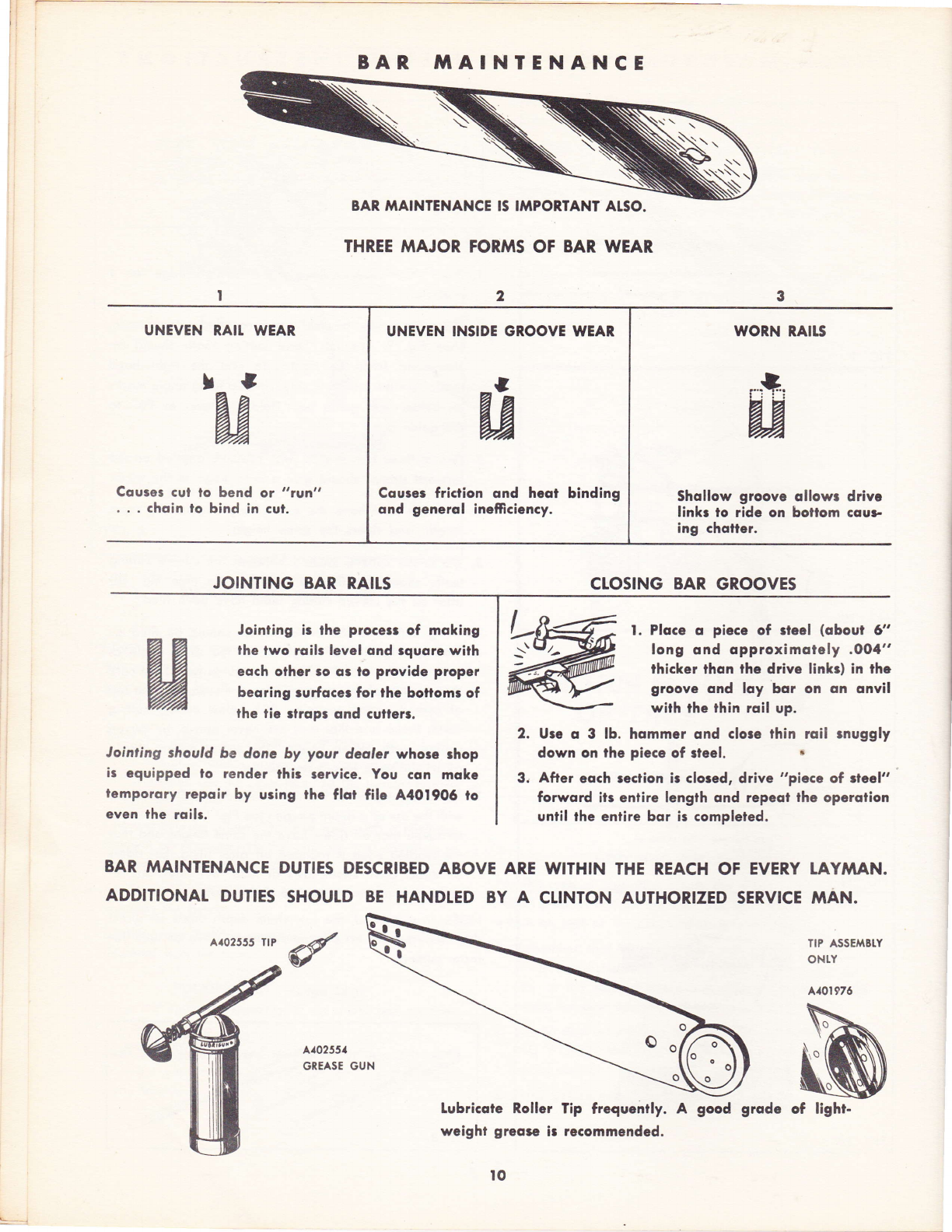

BAR fiTAINTENANCE

8AR MAINTENANCE !S IMPORIANT ALSO.

THREE MAJOR FORMS OF BAR WEAR

UNEVEN RAII, WEAR

Couset cut to bend ot "?vn"

. . . choin to bind in cut.

JOINTING BAR RAILS

Jointing is the proces of moking

the two roilr level ond rquore with

eoch other 30 q3 lo provide proper

beoring rurfocer for the bottomr of

the tie llrops ond culler.

tointing should be donc by your dcalcr whore rhop

ir equipped lo render thir tsrvice. You con mokc

lemporory repoir by uring the fld file A4019O6 ro

even lhe roilt.

WORN RAITS

Shollow groove ollow: drivc

linkr to ride on bollom cqur-

ing chotter.

CLOSING BAR GROOVES

l. Ploce o piccc of ricel (obout d'

long ond opproximotely .0O4"

thicker thon the drive linkr) in thc

groov€ ond loy bor on on onvil

wilh the thin roil up.

2. Ure o 3 lb. hommer ond clore thin roi! rnuggly

down on the piece of rteel. .

3. After eoch seclion ir clored, drive "piece of rleel"

forword iis enlire length ond repeot the operotion

uniil the enlire bor ir completed.

II

a3

BAR MAINTENANCE DUTIES DESCRIBED ABOVE ARE WITHTN THE REACH OF EVERY IAY'IAAN.

ADDITIONAL DUTIES SHOUTD BE HANDTED BY A CIINTON AUTHORIZED SERVICE MAN.

A,r02555 TrP TIP ASSETTiBIY

ONTY

A/aOI976

A102551

GREASE GUN

Lubricote Roller Tip frequently. A good grode of light.

weight greo$ ir recommended.

to

UNEVEN INSIDE GROOVE WEAR

Couser friction ond heot binding

ond generol ineftcicncy.

r#:

aJ

SER,VICE TIPS

FUEL SYSTEM

The fuel system in your Choinsow is composed of

fuel lines ond orifices. lt utilizes on outomotic fuel

pump which puts the proper mixture into oction

throughout the system. Fuel system defects con couse

serious lrouble throughout your Choinsow. At lhe

first sign of trouble of this kind, consult your deoler.

OIt PUAAP OPERATION

Since proper lubricotion of choin ond guide bor is so

imporlont, be sure to nolice ony foilure in this system.

lf oil foils to flow lo the guide bor ond choin when

lhe oil pump plunger is pushed, or if lhere is no

pressure on the plunger, the pump is not functioning.

See your outhorized Clinton Service Stoiion Deqler.

GAS CAP AND GASKET

The plostic filler cop like most gos cops hos on oir-hole

in it. This is becquse the Fuel Tonk is not pressured,

ond it must not be perfectly seoled.

,ITAGNETO ASSEMBTY AND IGNITION SYSTEAA

(Flywheel Type)

Remember the mogneto should be inspected ofter

every 100 hours of operotion. lf ,he engine refuses

to stort or is hord to stort, check the gos supply,

corburetion system ond spork plug. (lf the lotter is

bodly burnt, reploce.) lf the engine still does not stort

see your outhorized Clinton Service Siolion Deoler for

mognefo inspeciion ond repoir.

CTEANING VATVE PORTS

Exhoust

The only servicing required for the volve ports is on

occosionol cleoning to remove corbon deposits.

l. Remove muffler ossembly from Choinsow engine

which will expose the exhqust volve ports.

2. Cleon with suitoble lnstrument copoble of scroping

ond removing corbon deposits within these ports.

3. The engine should be turned over by hond until

the piston moves below the port openings, which

will ollow greoter occess for the cleoning of these

ports.

4. Core should be token not to domoge or score top

of piston when cleoning.

HETPERS HANDTE

For speciolized sowing operotions which require the

use of the long guide bor, ihe Clinton Choinsow con

be fitted with o Helpers Hondle for.two-mon use.

This ossembly is in two ports. A mounling stud on the

hondle-ond-guord holf slips through the slotted hole

in the rounded end of the guide bor. Note thot the

lugs on either side of the mounting stud engoge the

slot to position the hondle securely. The cover holf is

then ploced over the stud qnd secured with o wosher

ond wing nut.

MAINTENANCE

By moking lhe following proctices o hobit you con

help keep your sow in good running order ond ovoid

repoirs ihot neglect might moke necessory.

l. Remove sowdust ond dirt doily so thot o thorough

inspection con be mode.

2. Tighten o6y loose nuts or screws.

3. Check fuel ond oil lines for leoks, especiolly ot

connection points.

4. Check oir filter qnd brush oft dirt.

5. Do not use compressed oir to remove dust or dirt

from the OUTSIDE of the corburetor, since porticles

moy be blown into the mechonism if you do.

6. Check muffler ond exhoust ports periodicoelly,

when the loss of power is opporent. lf ports ore

dirty, cleon them.

7. As often os necessory remove'the cutting choin

from the guide bor ond qllow it to sook overnight

in o pon of kerosene to remove the sop ond resin

deposits ond to provide lubricotion for oll ports of

ihe choin.

8. lf you notice symptoms of trouble but connot find

the couse, check with your outhorizgd Clinton

Service Stotion, ond be sure your sow is in good

running order.

r-

tt

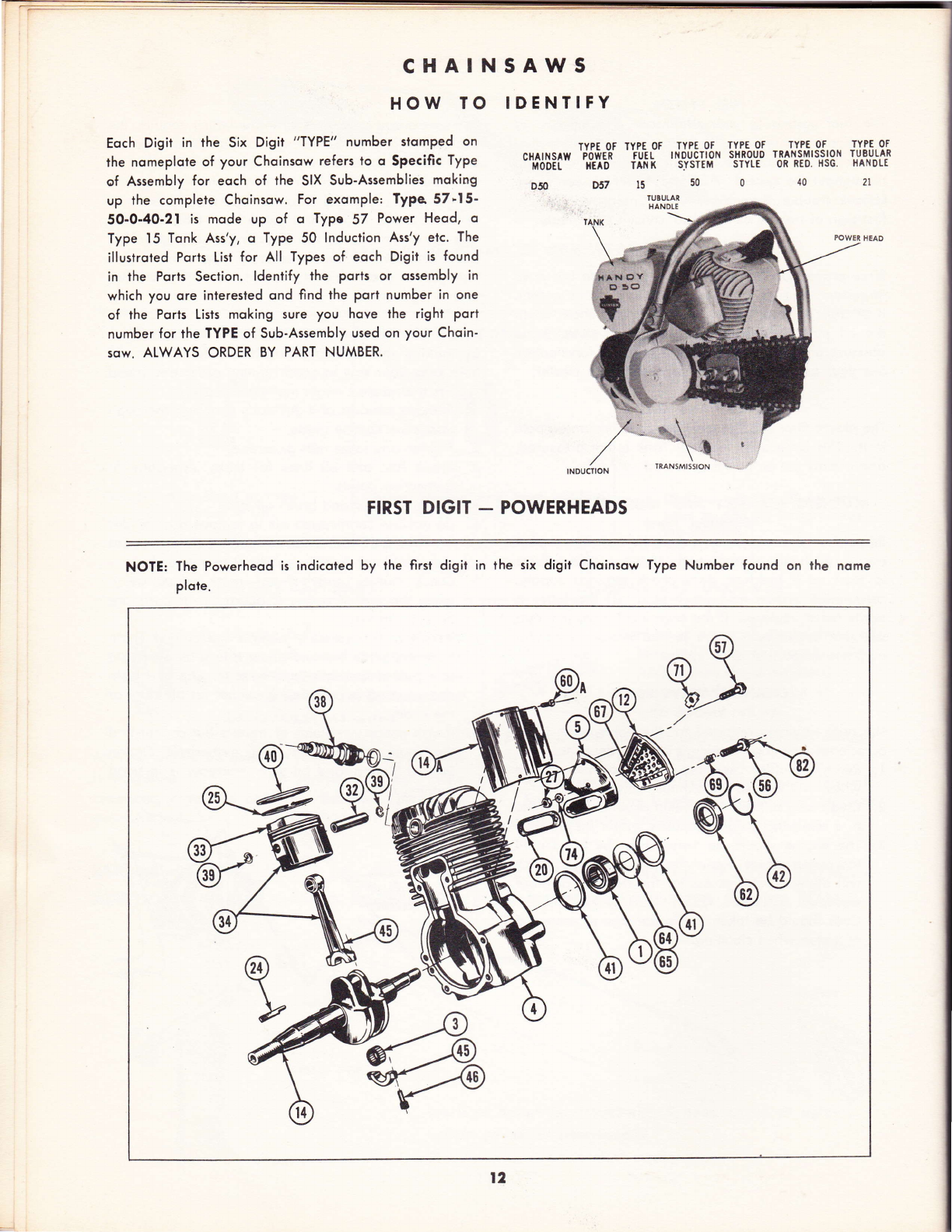

CHAINSAWS

HOW TO IDENTIFY

Eoch Digit in the Six Digit "TYPE" number stomped on

the nomeplote of your Choinsow refers to o Specific Type

of Assembly for eoch of the SIX Sub-Assemblies moking

up the complete Choinsow. For exomple: Type 57,15'

50-0-40-2I is mode up of o Typc 57 Power Heod, o

Type 15 Tonk Ass'y, o Type 50 lnduction Ass'y etc. The

illustroted Ports List for All Types of eoch Digit is found

in the Ports Seclion. ldentify the ports or ossembly in

which you ore inlerested ond find the port number in one

of the Ports Lists moking sure you hove the righi port

number for the TYPE of Sub-Assembly used on your Choin-

sow. ALWAYS ORDER BY PART NUMBER.

TYPI OF TYPE OF TYPE OF TYP€ Of TYPE OF TYPE OF

'po*r-C iult- ltioucTl0N sHR0u0 TRAN!Mlss!qN TU.BUtAR

'x1,ro fANt sYSTEtrt sTYIE 0R ntD. HsG. HANoLE

10 2l

CHAINSAW

MODEL

D50

NOTE: The Powerheod is indicoted by the first digit in the six digit Choinsow Type Number found on lhe nome

plote.

l2

x"*i

/-- *\t 'i

,"or.(o* rurusmrsiroN

FIRST DTGIT _ POWERHEADS

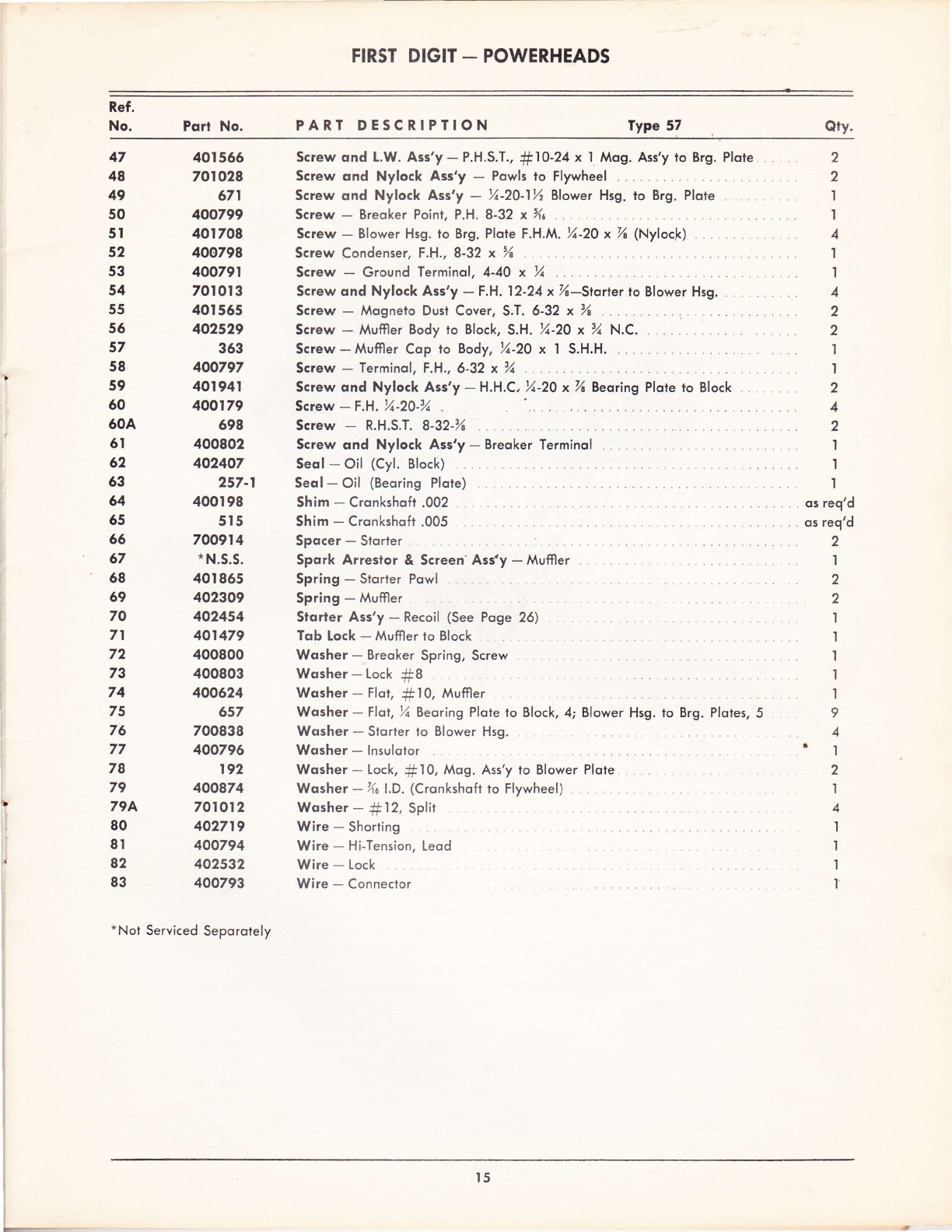

FIRST DIGIT - POWERHEADS

NOTE: The Powerheod is indicoted by the first digit in the six digit Choinsow Type Number found on ihc nome

plote.

t3

T

FIRST DIGIT - POWERHEADS

NOfE: The Powerheod is indicoted by the first digii in the six digit Choinsow Type Number found on the nome

plote.

Ref.

No. Port No. PART DESCRIPTION Type 57 Qry'

I

2

3

4

5

6

7

8

9

IO

II

t2

I3

t4

r4A

I5

l6

l7

t8

l9

20

2t

22

23

24

25

26

27

28

29

30

32

33

34

35

36

37

38

39

40

4t

42

43

44

45

46

233

820

401o27

402699

40t774

400792

400682

402533

400789

400777

401567

402476

401679

402384

402727

40t 68r

40r 680

400609

700743

401987

700038

40I 568

401677

400795

9s8

402701

401761

402235

838

40080r

7009t5

402673

4p2806

49a!O8

70091 3

401675

400790

400692

402237

563

402698

234

700893

401952

40r 866

400093

400585

Beoring - Boll

Beoring - Needle (Beoring Plote) .

Beoring - (Connecling Rod) .

Block Ass'y -l% Bore, lncl. Ref. Nos. I, 41 , 42,62, 64, 65

Body - Muffler

Breqker - Point Assembly

Cqm - Breoker :

Ctomp - Drow Pull

Coi! - Mogneto

Condenser - Mogneto

Cover - Breoker Point, Dusl

Cover & Screen Ass'y - Muffler incl. Ref. No. 67

Cover - Spork Plug

Crqnkshqft

Defleclor

Ftywheel

Flywheel Ass'y - lncl. Ref. Nos. 15,30,35, 48,66,68 . .

Gosket - Dust Cover :

Gosket - Beoring Ploie to Cylinder Block .

Gosket - Spork Plug Cover

Gqsket - Muffler to Block

Grommel - Dusl Cop (Rubber) .

Housing - Blower, lncl. Ref. Nos. 8, .l3, .l9, 44 . . .

lnsulqlor - Terminol

Key - Flywheel

Lock - Pision Ring

Muffler Ass'y - lncl. Ref. Nos. 5, 12,27, 56, 67,71,74

Nut-Muffler,%x10x32 .

Nut - Storter Cup, X, x 20 Hex.

Nut - Terminol, #6-32

Powl - Storler

Pin-Wrist..

Piston

Piston & Rod Ass'y - lncl. Ref. Nos. 25, 32,33, 39, 40, 45

Plole - Bose Powl, Storter

Plole Ass'y - Beoring, lncl. Ref. Nos. 2, 63

Plote - Stotor

Plote - Stotor, Ref . Nos. 6, 9, 10, 29, 37 , 49, 50, 52, 53, 58, 6.l , 72, 73, 77, 83

Plug - Spork

Reloiner - Wrist Pin

Ring - Piston, Compression

Ring - Reloiner

Ring - Retoiner (Cyl. Block)

Rivet-O.H.%x%

Rivel - % x %0, LG. Flot Heod (Spork Plug Cover)

Rod ond Cop Ass'y - Connecting, lncl. Ref. No. 46

Screw - Cop to Rod ..

t4

-

I

I

2

I

I

I

I

I

I

'I

I

I

I

2

3

2

I

2

2

I

2

I

I

I

I

3

I

I

I

I

2

I

I

I

I

I

r

FIRSI DIGIT _ POWERHEADS

Ref.

No. Pqrl No. PARI DESCRIPTION Type 57 Qrv.

47

48

49

50

5I

52

53

54

55

56

57

58

59

60

60A

6t

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

794

80

8I

82

83

40t556

70to28

671

400799

401708

400795

400791

70t 0I 3

40I 565

402529

353

400797

401941

400179

698

400802

402407

257-l

400r98

5t5

700914

* N.S.S.

40r 865

402309

402454

401479

400800

400803

400624

657

700838

400796

192

400874

701012

402719

400794

402532

400793

Screw qnd L.W. Ass'y - P.H.S.T., #10-24 x I Mog. Ass'y to Brg. Plote

Screw ond Nylock Ass'y - %-20-1% Blower Hsg. lo Brg. Plote . . .

Screw - Breoker Point, P.H. 8-32 x Xc . .

Screw - Blower Hsg. ro Brg. Plote F.H.M. %-20 x % (Nylock)

Screw Condenser, F.H., 8-32 x % . . . .

Screw - Ground Terminol, 4-4O x % . . .

Screw ond Nylock Ass'y - F.H. 12-24 x %-Storter to Blower Hsg.

Screw - Mogneto Dusl Cover, S.T. 6-32 x %

Screw - Muffler Body to Block, S.H. %-20 x % N.C.

Screw - Muftler Cop to Body, %-20 x I S.H.H.

Screw - Terminol, F.H., 6-32 x % . .

Screw ond Nylock Ass'y - H,H.C, %-20 x'A Beoring Plote to Block . .

Screw-f.H.%-20-%

Screw - R.H.S.T. 8-32-%

Screw qnd Nylock Ass'y - Breoker Terminol

Seql- Oil (Cyl. Block)

Seol- Oil (Beoring Plore)

Shim - Cronkshoft .002

Shim - Cronkshoft .005

Spocer - Slorter

Spork Arresior & Screen' Ass'y - Muffler

Spring - Storter Powl

Spring - Muffler

Slorler Ass'y - Recoil (See Poge 26)

Tob lock - Muffler to Block

Wqsher -.Breoker Spring, Screw

Wosher-Lock f8

Wosher - Flot, f 10, Muffler

Wosher - Flot, % Beoring Plote to Block, 4; Blower Hsg. to Brg. Plotes,

Wosher - Storter to Blower Hsg.

Wosher - lnsulotor

Wosher - Lock, Sl0, Mog. Ass'y to Blower Plote

Wosher -%e l.D. (Cronkshoft to Flywheel)

Wosher-fl2,Split

Wire - Shorting

Wire - Hi-Tension, Leod

Wire - Lock

Wire - Connector

2

.2 I

I

4

II

.4 2

2

I

I

2

.4

.2 I

'l

I

. os req'd

. os req'd

2

'I

2

2

'l

I

'|

'l

't

9

4

I

2

I

4

I

I

't

I

*Not Serviced Seporotely

I

I5

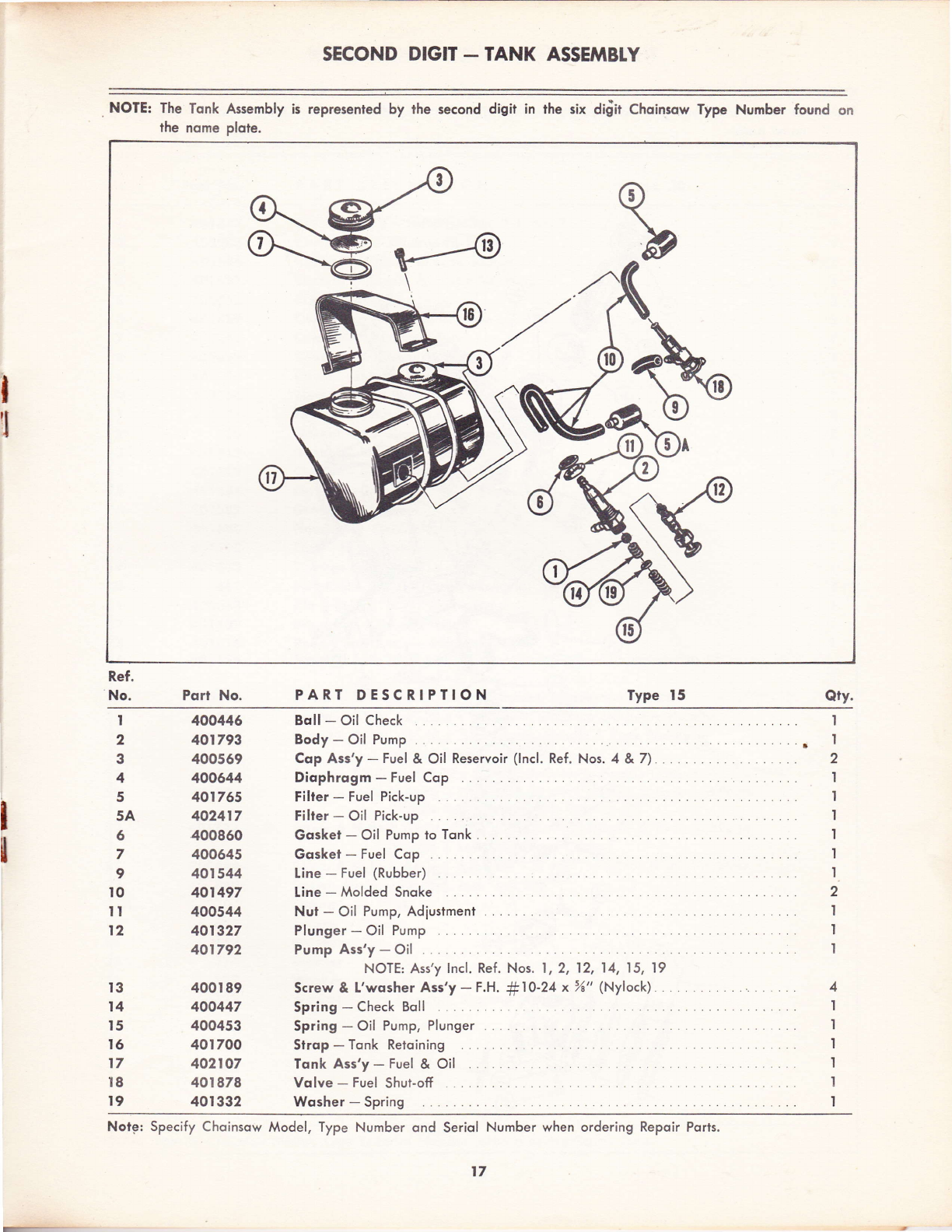

SECOND DIGIT - TANK ASSEMBTY

NOTE: The Tonk Assembly is represented by the second digir in ihe six diiit Choinso\y Type Number found on

the nome plote.

I

I

Ref.

No. Pqrt No. PART DESCRIPTION Type 15 Qtv.

I

l

I

2

3

4

5

5A

6

7

I

l0

II

t2

l3

14

l5

I6

t7

I8

t9

400446

401793

400569

400644

401755

402417

400860

400645

401544

401497

400544

401327

401792

400I 89

400447

400453

401700

402107

401878

40t332

Boll - Oil Check

Body - Oil Pump

Cop Ass'y - Fuel & Oil

Diophrogm - Fuel Cop

Filter - Fuel Pick-up

Filter - Oil Pick-up

Goskei - Oil Pump io T

Gosket - Fuel Cop

Line - Fuel (Rubber)

Line - Molded Snoke

Nur - Oil Pump, Adiustmenl . .

Plunger - Oil Pump

Pump Ass'y - Oil

NOTE: Ass'y lncl. Ref. Nos. l, 2, 12, 14, 15, 19

Screw & L'wosher Ass'y - F,H. #10-24 x %" (Nylock). .

Spring - Check Boll

Spring - Oil Pump, Plunger

Strop - Tonk Retoining

Tonk Ass'y - Fuel & Oil

Volve - Fuel Shut-off

Wosher - Spring

Reservoir (lncl. Ref. Nos. 4 & 7)

1

.l 2

I

I

I

I

I

I

2

I

I

I

4

I

I

t

1

I

I

Notg: Specify Choinsow Model, Type Number ond Seriol Number when ordering Repoir Ports.

r

t7

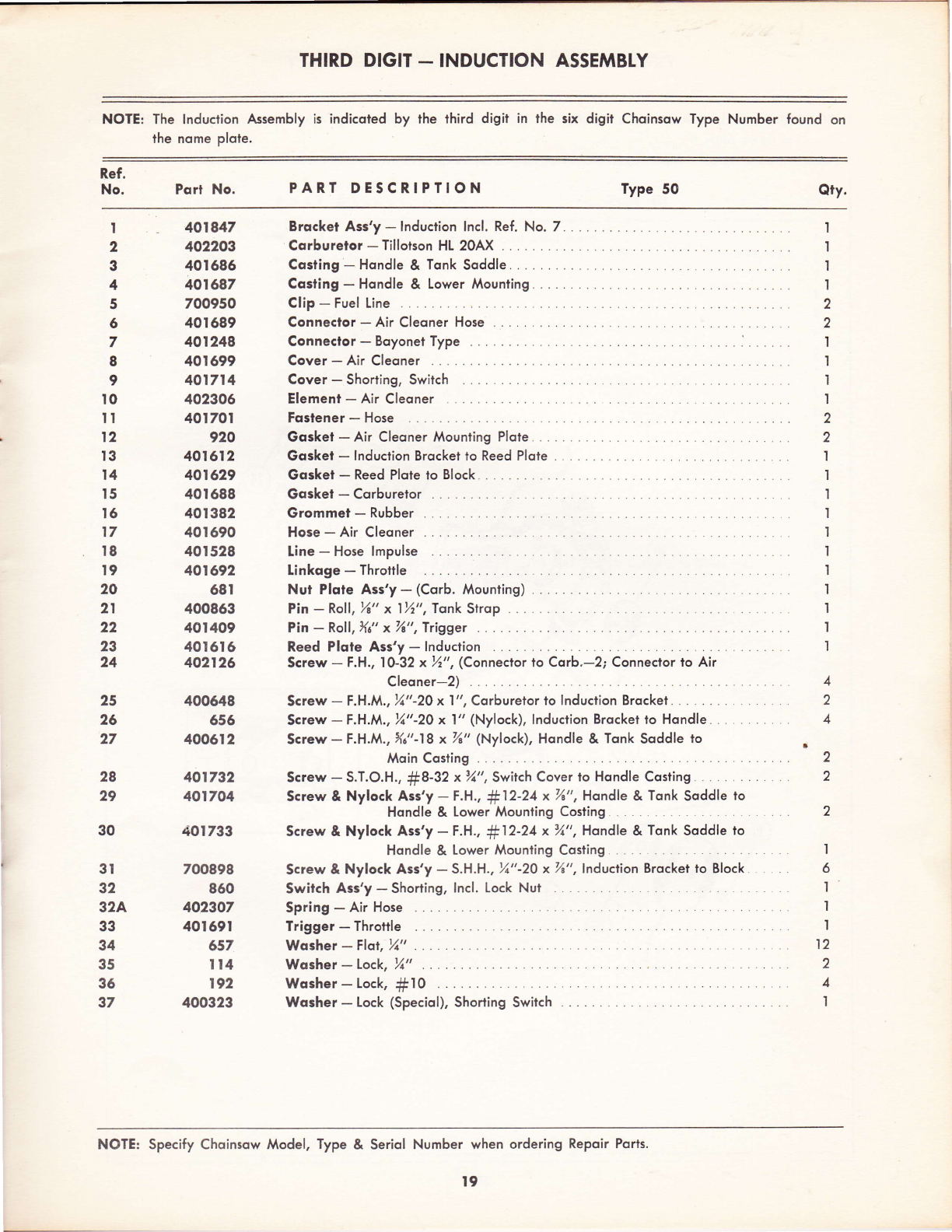

THIRD DIGIT - INDUCTION ASSEMBIY

Note: The lnduclion Assembly is indicoted by the rhird digir in the six digit Choinsow Type Number found on the

,r'

nome plote.

r8

THIRD DIGIT - INDUCTION ASSEMBTY

NOTE: The lnduction fusembly is indicoted by rhe rhird digir in lhe six digit Choinsow Type Number found on

the nome plole.

Ref.

No. Pqrt No. PART DESCRIPTION Type 50 Qry.

I

2

3

4

5

6

7

8

9

to

It

t2

I3

t4

t5

l6

t7

l8

t9

20

2l

22

23

24

25

25

27

3t

32

32A

33

34

35

36

37

401847

402203

40t 686

40t687

700950

40t689

401248

401699

401714

402306

40t70t

920

401612

401629

40t688

40I382

40t690

40t528

401692

68t

400863

40I409

40t6t6

402126

400648

556

400612

401792

401704

40t733

700898

860

402307

40169t

657

tt4

192

400323

Brqcket Ass'y-lnduction lncl. Ref. No.7.

Corburelor - Tillotson HL 20AX

Costing - Hondle & Tonk Soddle

Costing - Hondle & Lower Mounting

Clip - Fuel Line

Connector - Air Cleoner Hose

Conneclor-BoyonelType. ... .....

Cover - Air Cleoner

Cover - Shorting, Switch

Element-AirCleoner .... ..

Foslener - Hose

Gqsket - Air Cleoner Mounting Plote. .

Gosket - lnduction Brocket to Reed Plote .

Gqsket - Reed Plote to Block .

Goskei - Corburelor

Grommel - Rubber

Hose - Air Cleoner

Line - Hose lmpulse

Linkoge - Throttle

Nut Plqte Ass'y - (Corb. Mounting) .

Pin - Roll, %" x 1%", Tonk Strop

Pin - Roll, Xo" x%", Trigger

Reed Plqte Ass'y - lnduction

Screw - F.H., I0-32 x %." , (Conneclor lo Corb.-2; Conneclor io Air

Cleoner-2)

Screw - F.H.M., %"-20 x I ", Corburetor lo lnduclion Brockel

Screw-F.H.M., %"-20 x l" (Nylock), lnduction Brocket to Hondle... ,

Screw - F.H.M., Xa"-18 x %" (Nylock), Hondle & Tonk Soddle to

Moin Costing

Screw - S.T.O.H., #8-32 x%", Swilch Cover to Hondle Costing

Screw & Nylock Ass'y - F.H., #12-24 x %", Hondle & Tonk Soddle to

Hondle & Lower Mounling Costing

Screw & Nylock Ass'y - t.H., #12-24 x %", Hondle & Tonk Soddle to

Hondle & Lower Mounting Cosling

Screw & Nylock Ass'y - S.H.H., %"-20 x %", lnduclion Brocket to Block

Switch Ass'y - Shorting, lncl. Lock Nut

Spring - Air Hose

Trigger - Throttle

Wqsher-Flor,%"...

Wqsher-Lock, %" ...

Wqsher - Lock, #10

Wqsher - Lock (Speciol), Shorting Switch .

I

I

I

I

2

2

I

I

'l

't

2

2

1

I

I

I

1

I

I

I

I

I

I

2

'I

6

I

1

I

12

2

4

I

4

2

4

2

2

28

29

30

NOTE: Specify Choinsow Model, Type & Seriol Number when ordering Repoir Ports.

t9

FIFTH DIGIT _ TRANSMISSION ASSEMBTY

NOTE: The Tronsmission Assembry is represented by the fifth digit in the six digit.choinsow Type Number found on

the nome Plofe.

20

Other Clinton Chainsaw manuals