Clinton D65-1000 User manual

(IWI{ER'S GUIDE

D65-1000

SUPER CHAINSAW

SPECIFIGATIONS

BEARINGS

BORT & SIROl(E 2th" Dto

OISPI.ACEMEN I

HON SEPOWER

ENGINE WEIGH]

IUEL IANK

CARBUREIOR: I

I

POWERHEAO I

Diophrogm wilh builrrn luel pump lor oll posltlon cuffing

TYPI Clinton one cy inder, two-cycle, oircooled

Consisls of hrgh quolity precis on die-co$ oluminum cyLnder blcck w th

inlegrol cosLrron liner plus seclonol d e-coil mogneslum $rut ond

hondles {or lo. cost replocemeni iI domoged.

3 Needle Beorlngs - I Boll Beoring

Push-Button type for oFErolor conirol lo 3uit vorious culling conditiont

lndustry opproved soinless seel spork oriester

Exhousl goses ond heot ore drected owoy {rom operoior

Chrome ploted steel tubulor hondle

Hond-sized lor eosy grip - permils Ilush cuting

Polented - csh os much os 20X foster reduces choin to guide bor

lrrclion ..extends life of guide bor, cho,n ond sprmket.

14".16".2a",26", ond 30" STElllTE-TIPPED induction hordened suide

Sors ond 16", 2A",26", and 30" boll beorins ROttER TlP.

Ako ovoiloble with 15" non-pinch, plunge{ype bowsow oliochment

h" pil.h, .058 gouge ttondord equipment.

l[" pitch, .063 gouge used on bowsows.

ASSEMBI.Y

CLINTON ENGINES CORPORATION

CHAINSAW.OUTBOARD DIVISION

CLINTON, MICHIGAN

MANUAL No. 403944

I

Oil ond gosoline mix - % pint to one gollon lor {r+ 5 houre -

I pinl per gollon thereo{ler.

PRINTED IN U.S.A.

a;a''

..:f r "

'-"t l'

- r t t\'...

'ttr'?

-..€!'r

' -.r,1'{i

FUEI-:

OPERATION OF THE TWO CYCLE ENGINE

ln q two cycle engine, intoke, compression, power

qnd exhqust ore completed in two strokes of the

piston. A power stroke results with every revolution

of the cronkshoft. On the upword stroke of the piston,

o portiol vocuum is creoted in the cronkcose. (See

Figure No. l)

First, the vocuum ond outside oir pressure couse lhe

reed volve between the cronkcqse ond the corburetor

to open. The qir-fuel mixture from the corburelor flows

in to the engine cronkcose. Then, the downword move-

ment of the piston couses the reed volve to close

while continued downword movement of the piston

compresses the fuel chorge in the cronkcose. Neor the

botlom of its stroke the piston uncovers the intoke

by-poss port, which connects the combustion chomber

ond the cronkcose.

As the piston moves upword on its stroke, it posses

the intoke port, closing the port opening. lts continued

upword movement couses the fuel mixture in the

cylinder to be compressed. At the some time o new

fuel chorge is drown into the cronkcose. As the

piston neors the top of the compression stroke, the

fuel mixture in the combustion chomber is ignited by

the spork. The explosion ond exponsion of goses

forces the piston down on its power stroke. Power

is not delivered for the full length of the stroke. Some

time is required to rid the cylinder of burned goses,

so thot it moy receive o fresh fuel chorge from lhe

cro nkcose.

As the piston neors the boltom of its stroke, it un-

covers the exhoust port opening slightly qheod of the

intoke port. This permits toking odvontoge of the

pressure of the exhqust goses in the cylinder, which

ore still comporotively high, ond ollows them to

stort escoping. Further downword trovel of the piston

uncovers the intoke by-poss port. The incoming chorge

ossists in forcing the exhoust gqses out of the cylinder,

to complete the cycle.

The chief ottributes of the two cycle engine ore its

lightweight, low cost ond powerful but simple opero-

tion. With only three bosic moving ports (cronkshoft,

piston ond rod), mointenonce costs qre ot o minimum

while efficiency is ot o moximum.

COMPRESSION

POWER

EXHAUST

Figure No. I

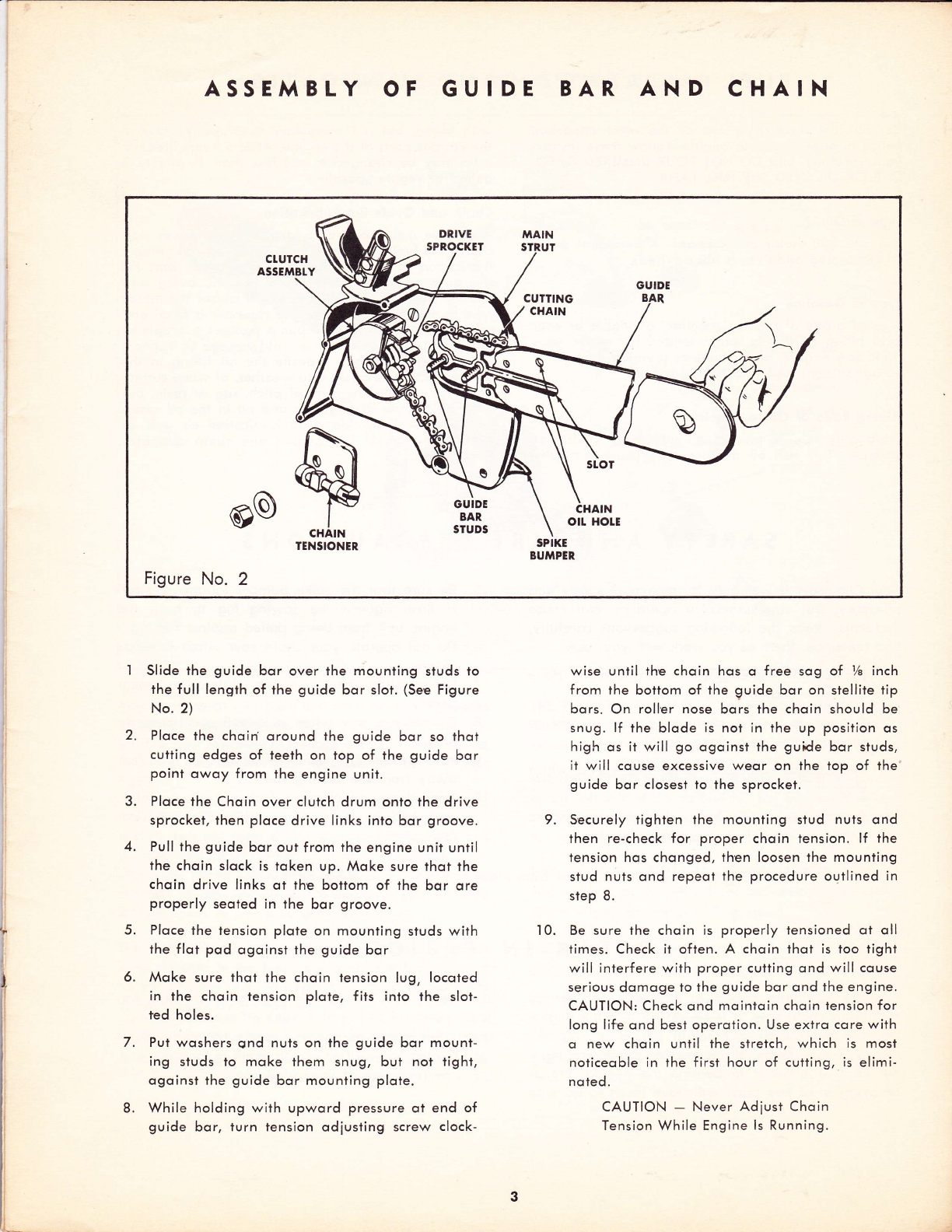

ASSEMBLY OF GUIDE BAR AND CHAIN

SPIKE

BUIYIPER

CIUTCH

ASSEfrTBTY

&

P

CHAIN

TENSIONER

@o

Figure No. 2

9.

2.

3.

4.

Slide the guide bor over the mounting studs to

rhe f ull lengih of the guide bor slot. (See Figure

No. 2)

Ploce the choin oround the guide bor so thot

cutting edges of teeth on top of the guide bor

point owoy from the engine unit.

Ploce the Choin over clutch drum onto the drive

sprocket, then ploce drive links into bor groove.

Pull the guide bor out from the engine unit until

the choin slock is token up. Moke sure thot the

choin drive links ot the bottom of the bor qre

properly seoted in the bor groove.

Ploce the tension plote on mounting studs with

the flot pod ogoinst the guide bor

Moke sure thot the choin tension lug, locoted

in the choin tension plote, fits into the slot-

ted holes.

Pul woshers qnd nuts on lhe guide bor mount-

ing studs to moke them snug, but not tight,

ogoinst the guide bor mounting plote.

While holding with upword pressure ot end of

guide bor, turn tension odiusting screw clock-

wise until the choin hos o free sog of I/e inch

from the botiom of the guide bor on stellite tip

bors. On roller nose bors the choin should be

snug. lf the blode is nol in the up position os

high os it will go ogoinst the guide bqr studs,

it will couse excessive weor on the top of the

guide bor closest to the sprocket.

Securely tighten the mounting stud nuts ond

lhen re-check for proper choin tension. lf the

tension hos chonged, then loosen the mouniing

siud nuts ond repeot the procedure outlined in

step 8.

Be sure the choin is properly iensioned ot oll

times. Check it often. A choin thot is too tight

will interfere with proper cutting ond will couse

serious domoge to the guide bor ond the engine.

CAUTION: Check ond mointoin choin iension for

long life ond besi operoiion. Use extro core with

o new choin until the stretch, which is most

noticeoble in the first hour of cutting, is elimi-

noted.

CAUTION - Never Adiust Choin

Tension While Engine ls Running.

10.

5.

6.

7.

8.

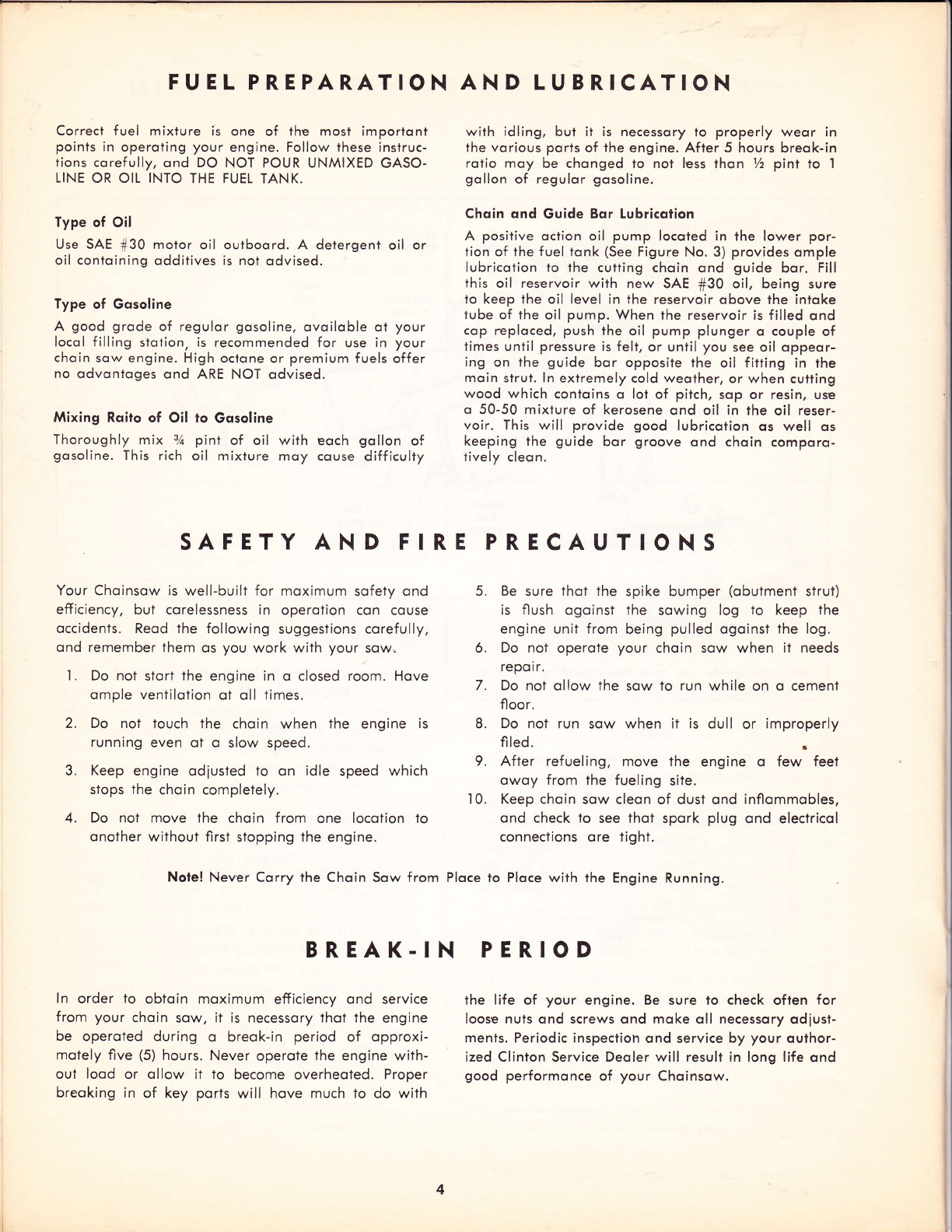

FUEL PREPARATION

Correct fuel mixture is one of the mosl importont

points in operoting your engine. Follow these instruc-

tions corefully, ond DO NOT POUR UNMIXED GASO-

LINE OR OIL INTO THE FUEL TANK.

Iype of Oil

Use SAE #30 motor oil outboord. A detergent oil or

oil contoining odditives is not odvised.

Type of Gosoline

A good grode of regulor gosoline, ovoiloble ot your

locol f illing stotion, is recommended for use in your

choin sow engine. High octone or premium f uels offer

no odvontoges ond ARE NOT odvised.

Mixing Roito of Oil lo Gssoline

Thoroughly mix 3/t pint of oil with eoch gollon of

gosoline. This rich oil mixture moy couse difficulty

AND LUBRICATION

with idling, but it is necessory to properly weor in

the vorious ports of the engine. After 5 hours breok-in

rotio moy be chonged to not less thon Vz pinl lo 1

gollon of regulor gosoline.

Choin qnd Guide Bor lubricqtion

A positive oction oil pump locoted in the lower por-

tion of the fuel tonk (See Figure No.3) provides omple

lubricotion to ihe cutting choin ond guide bor. Fill

this oil reservoir with new SAE #30 oil, being sure

to keep the oil level in the reservoir obove the intoke

tube of the oil pump.When the reservoir is filled ond

cop reploced, push the oil pump plunger o couple of

times until pressure is felt, or until you see oil oppeor-

ing on the guide bor opposite the oil fitting in the

moin strui. ln extremely cold weother, or when cutting

wood which contoins o lot of pitch, sop or resin, use

o 50-50 mixture of kerosene ond oil in ihe oil reser-

voir. This will provide good lubricotion os well os

keeping the guide bor groove ond choin comporo-

tively cleo n.

SAFETY AND FIRE PRECAUTIONS

Your Choinsow is well-built for moximum sofety ond

efficiency, but corelessness in operotion con couse

occidents. Reod the following suggestions corefully,

ond remember them os you work with your sow.

1. Do not stort the engine in o closed room. Hove

omple ventilotion ot oll times.

2. Do not touch the choin when the engine is

running even ot o slow speed.

3. Keep engine odiusted to on idle speed which

stops the choin completely.

4. Do not move the choin from one locotion to

onother without first stopping the engine.

ln order to obtqin moximum efficiency ond service

from your choin sow, it is necessory thot the engine

be operoted during o breok-in period of opproxi-

motely five (5) hours. Never operote the engine with-

oui lood or ollow it to become overheoted. Proper

breoking in of key ports will hove much to do with

Be sure thot the spike bumper (qbutment strut)

is flush ogoinst the sowing log to keep the

engine unit from being pulled ogoinst the log.

Do not operote your chqin sow when it needs

repoir.

Do not ollow the sow to run while on o cement

floor.

Do not run sow when it is dull or improperly

filed. .

After refueling, move ihe engine o few feet

owoy from the fueling site.

Keep choin sow cleon of dust ond inflommobles,

ond check to see thot spork plug ond electricol

connections ore light.

the life of your engine. Be sure to check often for

loose nuls ond screws ond moke oll necessory odlust-

menis. Periodic inspection ond service by your outhor-

ized Clinton Service Deoler will result in long life ond

good performonce of your Choinsow.

6.

7.

Note! Never Corry the Choin Sow from Ploce to Ploce with the Engine Running.

BREAK.IN PERIOD

8.

9.

10.

5.

4

CHAIN SAW CONTR,OLS

BLOWER

HOUSING

FUEI TANK

CAP

RECOIt

STARTER

INDUCTION

SYSTEM

FIG. 3

Moior conlrols on your choin sow ore conveniently grouped

oround the hond grip ossembly for finger tip oction. You

will find your sow eosy to monoge once you ossociole the

following conlrols wiih their locotions on the sow. (See

Figure 3.)

THE RECOII STARTER-Locoled on the left side of the unit.

A slight pull will engoge the siorler with the engine ond

o spring disengoges it when lhe tension is relieved. CAU-

TION: The ilorler coble when pulled out, should not be

releosed obruptly ond ollowed lo snop bock into its socket.

Releose slowly to permit compleie re-winding.

THE CHAIN O|tER-Monuolly operoied, plunger lype oil

pump, locoted in the lower portion of the fuel lonk iust

obove lhe hond grip. This system forces oil to the guide

bor ond choin for positive lubricotion.

FUEL SHUT-OFF VATVE-On the bottom of the fuel tonk

qt lhe lower right. To open, iurn counter-clockwise until

o slight lension ic noticed.

THE THROTTLE CONTROL - Trigger-type, locoled on ihe

hondle grip. The engine speed, or lhrofile opening, is

increosed by squeezing the lrigger upword igto the hondle.

THE HIGH SPEED MIXTURE ADJUSTMENT SCREw-Locoted

on the left side of the corburetor. The odiuslment is used

lo obtoin proper fuel ond oir mixture, moke the engine

run smoolhly ond ochieve moximum power.

THE IDLE FUEL MIXTURE ADJUSTMENT SCREW - Thls de-

vice is found on the left side of corburelor. lt ii used to

obtoin smoolh ond proper idling speed.

THE CHOKE LEVER - Locoted on the left side of tlre

corburetor iust obove the odiustment screws,

THE FUEL PUMP - Locoted in lower section of cor-

buretor moinioins proper f uel supply to the corburetor.

THE IGNITION SWITCH - Toggle-type, locoted directly

under fuel tonk.

TUBULAR

HANDTE

/

CHAIN

5

STARTING PROCEDURE

ADJUSTMENT INSTRUCTIONS throttle trigger. Do not roce engine, groduolly de-

To properly odiust corburetor for best performonce creose the choke to full open position os engine

To stort o new engine: First, corefully close by turning of the Moin Adiustment Screw (Ref. l9).

clockwise, both ldle ond Moin Ad justment Screws F!NAt ADJUSTMENTS

(Ref.7 & I9)"--locoted either below oir intoke opening Now close throttle ond reodiust ldle Speed Reguloting

or ot left side of corburetor. Now open Moin Adlust- Screw so engine idle speed is ot opproxim0tely 1800

menl Screw (Ref. l9) counterclockwise opproximotely lo 220O RPM ond without choin turning or throttle

one ond one-quorter turns (l%). Open ldle Adjuslment trigger being depressed. Then, slowly reodiust ldle

Screw (Ref. 7) three-quorters (3/r) turn. Bock ldle Speed Adiustment Screw (Ref. 7) to obtoin smooth ond

Regulotor Screw off its contoct wilh Throttle Stop Lever even engine performonce, ofter which enrichen the

then turn it inwqrd obout one (l) full turn so os to mixture slightly obove ihis setting to provide sufficient

slightly open Throttle Shutler (Ref. I l). fuel for quick occelerotion. Finolly, with sow function-

Open fuel shut ofi volve, choke corburetor, put igni- ing under o cutting lood, slowly reodlust Moin Ad-

tion switch to "ON" position, squeeze ihrottle trigger iustment Screw (Ref. l9) to obtoin even cutting speed.

ond give firm quick pull on storting cord. When engine This setting will vory between one (l) to one ond

fires, decreose the choke slightly ond eose off the one-holf (l7z) turns open.

the engine must be thoroughly worm.

INITIAI. ADJUSTTTAENTS

l. Fuel lnlet

2. Fuel Pump Body

3. Fuel Pump Diophrogm

3A Fuel lnlet Check Vqlve

38 Fuel Outlet Check Volve

4. Fuel Pump Gqsket

5. Diophrogm Cover Gqsket

6. Diophrogm Chqmber

7, ldle Adiusrmenl Screw

8. lmpulse Chqnnel

9. ldle Fuel Adiustment Orifice

l0A Primory ldle Dischqrge Port

l0B Secondory ldle Dischorge Port

I I. Throttle Shutter

12. Moin Fuel Adiustment Orifice

13. Body

14. Venturi

15. Moin Fuel Dischorge Port

16. Choke Shutler

17, Fuel lnlet Supply Chqnnel

18. lnlet Needle & Seot

t9. Moin Adiuslment Screw

20. lnlet Tension Spring

2l . lnlet Control Lever

22. Fulcrum Pin

23. Atmospheric Vent Hole

24. Diophrogm Cover

25, Diophrogm

26, Stroiner Gqsket

27. Fuel Inlet Screen

28. Strqiner Cover Retqining Screw

29, Strqiner Cover

worms. Then mqke severol test cuts ond if necessory,

to keep engine from stolling, slightly increose opening

FIG. 4

6

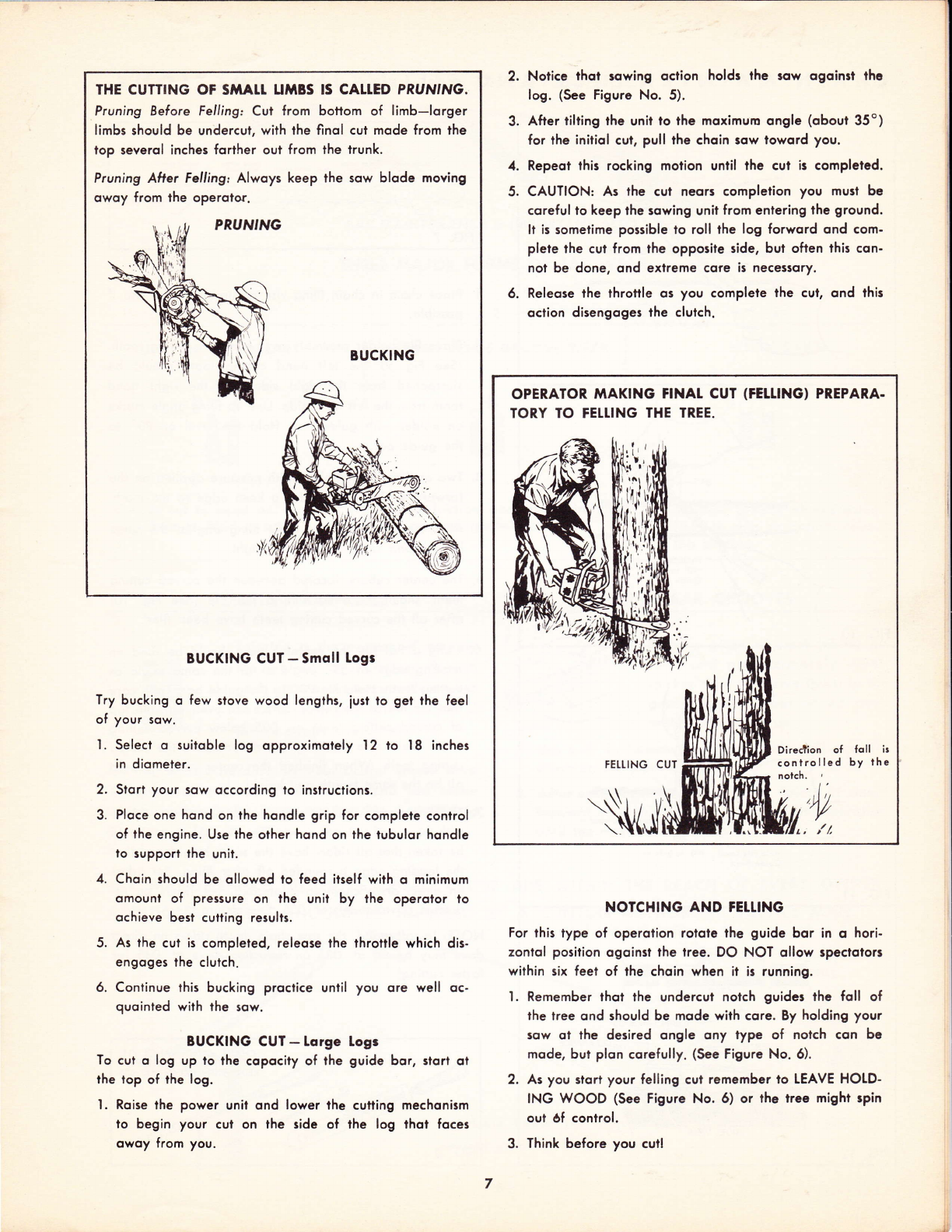

THE CUTTING OF SiIALt U}IBS IS CALTED PRUN'NG.

Pruning Before Felling: Cut from bottom of limb-lorger

limbs should be undercut, with the finol cut mode from ihe

lop severol inches foilher oul from the trunk.

Pruning Aller Felling: Alwoys keep the sow blode moving

owoy from ihe operotor.

BUCKING

BUCKING CUT-Smoll Logr

Try bucking o few slove wood lengths, iust io get the feel

of your sow.

l. Select o suitoble log opproximoiely I2 to l8 inches

in diometer.

2. Stort your sow occording to instruclions.

3. Ploce one hond on the hondle grip for complete control

of the engine. Use the other hond on the tubulor hondle

to support the unii.

4. Choin should be ollowed to feed itself with o minimum

omount of pressure on lhe unit by lhe operolor lo

ochieve best cutting results.

5. As ihe cui is completed, releose the throttle which dis-

engoges the clutch.

6. Continue this bucking proctice until you ore well oc-

quoinled with the sow.

BUCKING CUT - Lorge Logr

To cui o log up to the copocity of the guide bor, siorl ol

the top of the log.

l. Roise the power unit ond lower lhe cutling mechonism

to begin your cut on the side of the log thot foces

owoy from you.

Notice thot rowing oction holds lhe row qgointt thc

log. (See Figure No. 5).

After tilting the unit to the moximum ongle (obout 35o)

for the iniiiol cul, pull the choin sow loword you.

Repeot this rocking molion unril the cut is completed.

CAUTION: As the cul neors completion you mu3t be

coreful to keep lhe sowing unit from enlering the ground.

ll is somelime possible to roll the log forword ond com-

plete the cul from the opposite side, but oflen lhis con-

nol be done, ond extreme core ii neces3qry,

Releose the throttle os you compleie lhe cul, ond this

oction disengoges the clutch.

NOTCHING AND FEIIING

For this type of operolion rolote the guide bor in o hori-

zontol position ogoinsl the tree. DO NOT ollow specloloru

within six feel of the choin when it is running.

l. Remember thot the undercul notch guides the foll of

the tree ond should be mode with core. By holding your

eow ot the desired ongle ony type of nolch con be

mode, but plon corefully. (See Figure No. 6).

2. As you slort your felling cut remember io LEAVE HO[D-

ING WOOD (See Figure No. 6) or lhe ire6 might spin

out 6f control.

3. Think before you cutl

1.

5.

OPERATOR MAKING FINAT CUT (FELLING) PREPARA.

TORY TO FELTING THE TREE.

rEt[ING CUT

tuvt

foll ir

by rhe

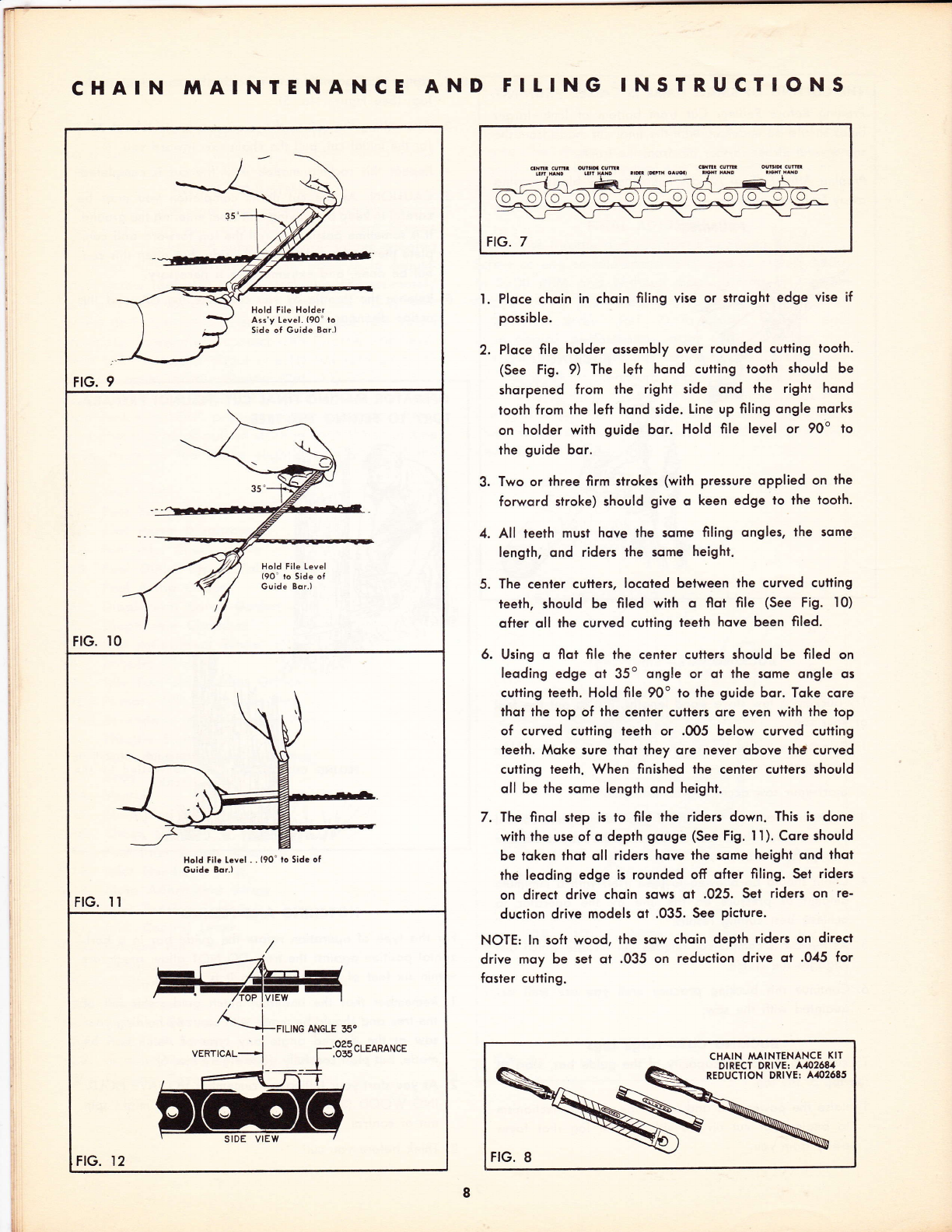

CHAIN TIAINTENANCE AND FITING INSTR.UCTIONS

Hold File Holder

Ass'y Level. (90'to

Side of Guide Bor.)

FIG.

FIG. l0

Hold File Level

(90- to Side of

Guide Bor.l

Hold Filc Lcvel.. l9o'to Side of

Guidc Bor.)

FIG. 'il

FILING ANGLE 35O

.t

VERTICAL+

--_r.3'f

CLEARANCE

FIG. I2

ilG.7

'I . Ploce choin in choin filing vise or stroight edge vise if

possible.

2. Ploce file holder ossembly over rounded cutling toolh.

(See Fig. 9) The left hond cutting tooth should be

shorpened from the right side ond the right hond

tooth from the left hond side. Line up filing ongle morks

on holder with guide bor. Hold file level or 90o lo

the guide bor.

3. Two or lhree firm slrokes (with pressure oPPlied on the

forword stroke) should give o keen edge to lhe tooth.

4. All teeth musi hove the some filing ongles, the some

length, ond riders the some height.

5. The cenler cutlers, locoled belween lhe curved cutling

ieeth, should be filed with o flot file (See Fig. l0)

ofter oll the curved cufiing teeih hove been filed.

6. Using o flot file the center cutters should be filed on

leoding edge ot 35o ongle or ol lhe some ongle os

cutiing teeih. Hold file 90o to the guide bor. Toke core

thot the top of the center culters ore even with the top

of curved cutting teeth or .0O5 below curved cutting

teeih. Moke sure thoi they ore never obove th0 curved

cutling teeth. When finished lhe center cutlers should

oll be the some length ond height.

7. The finol siep is to file lhe riders down. This is done

with the use of o depth gouge (See Fig. I I). Core should

be token lhot oll riders hove the some height ond thot

the leoding edge is rounded ofi ofter filing. Set riders

on direct drive choin sows ot .025. Set riders on re-

duclion drive models oi .035. See Picture'

NOTE: ln soft wood, lhe sow choin depih riders on direct

drive moy be set ot .035 on reduclion drive ot .045 for

fosler cutting.

CHAIN MAINIENANCE KIT

DIRECT DRIYET A10268/

REDUCTION DRIVET A.102685

BAR 'NAINTENANCE

BAR MAINTENANCE IS IMPORIANT ATSO.

UNEVEN INSIDE GROOVE WEAR

Cquses friction qnd heot binding

ond generol inefficiency.

THREE MAJOR FORMS OF BAR WEAR

UNEVEN RAII. WEAR

Couses cul lo bend or "tvn"

. . . chqin to bind in cul.

JOINTING BAR RAITS

Jointing is lhe process of moking

the two roils level ond squore with

eoch olher so qr lo provide proper

beoring surfqces for lhe bottoms of

the tie slrops qnd cullers.

tointing should be done by your dealer whose shop

is equipped lo render lhis service. You con moke

lemporqry repoir by using the flot file A40I906 fo

even lhe roils.

BAR MAINTENANCE

ADDITIONAL DUTIES

Shqllow groove qllows drive

links to ride on bollom cous-

ing chotter.

CTOSING BAR GROOVES

I. PIqce q piece of steel (obout d'

long ond opproximotely .0O4"

thicker thon the drive links) in the

groove ond loy bqr on qn onvil

with the thin roi! up.

2. Use o 3 lb. hqmmer qnd close rhin rqil rnuggly

down on the piece of steel.

3. After eoch section is closed, drive "piece of sleel"

forword ils enlire length ond repeol the operotion

until the enlire bqr is completed.

OF EVERY OWNER.

SERVICE MAN.

t

%e

WORN

..t.

AJ

A402555 TtP

SHOUTD

-{

s/

DUTIES DESCRIBED ABOVE ARE WITHIN THE REACH

BE HANDLED BY A CTINTON AUTHORIZED

[ubricote Rotler Tip frequently. A

weight greose is recommended.

TIP ASSEMBTY

ONtY

A101976

good grodc of lisht-

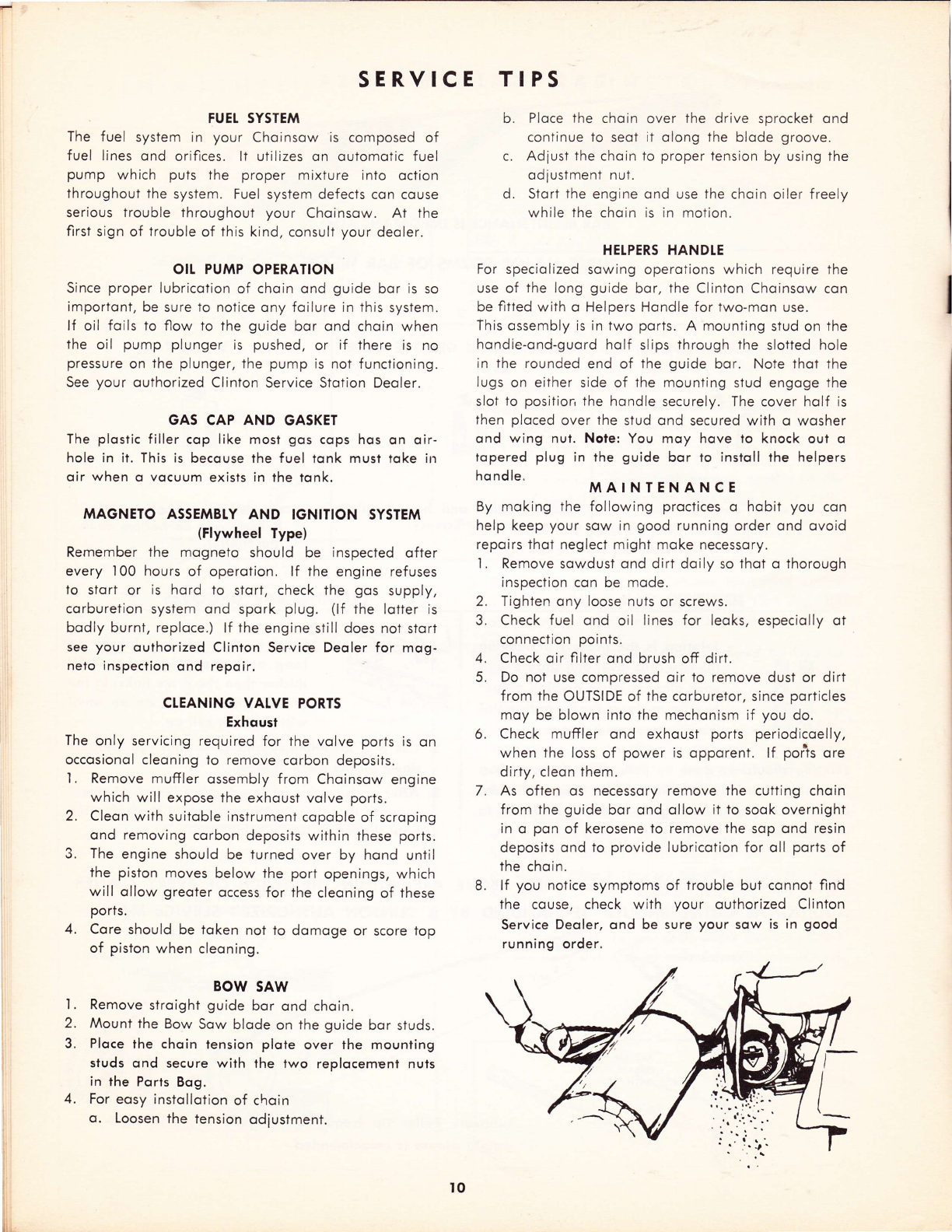

SERVICE TIPS

FUEI SYSTEM

The fuel system in your Choinsow is composed of

fuel lines ond orifices. lt utilizes on outomotic fuel

pump which puts the proper mixture into oction

throughout the system. Fuel system defects con couse

serious trouble throughout your Choinsow. At the

first sign of trouble of this kind, consult your deoler.

OII PUMP OPERATION

Since proper lubricotion of choin ond guide bor is so

importont, be sure to notice ony foilure in this system.

lf oil foils to flow to the guide bor ond choin when

the oil pump plunger is pushed, or if there is no

pressure on the plunger, the pump is not functioning.

See your outhorized Clinton Service Stotion Deoler.

GAS CAP AND GASKET

The plostic filler cop like most gos cops hos on oir-

hole in it. This is becouse the fuel ionk must toke in

oir when o vocuum exists in the tonk.

MAGNETO ASSEMBTY AND IGNITION SYSTEM

(Flywheel Type)

Remember the mogneto should be inspected ofter

every 100 hours of operotion. lf the engine refuses

to stort or is hord to stort, check the gos supply,

corburetion system ond spork plug. (lf the lotter is

bodly burnt, reploce.) lf the engine still does not stort

see your outhorized Clinton Service Deoler for mog-

neto inspection ond repoir.

CTEANING VALVE PORTS

Exhoust

The only servicing required for the volve ports is on

occosionol cleoning to remove corbon deposits.

'I . Remove muffler ossembly from Choinsow engine

which will expose the exhoust volve ports.

Cleon with suitoble instrument copoble of scroping

ond removing corbon deposits within these ports.

The engine should be turned over by hond until

the piston moves below the port openings, which

will ollow greoter occess for the cleoning of these

ports.

Core should be token not to domoge or score lop

of piston when cleoning.

BOW SAW

Remove stroight guide bor ond choin.

Mount the Bow Sow blode on the guide bor studs.

Ploce the choin tension plote over the mounting

studs ond secure with the two replocement nuis

in the Ports Bog.

For eosy instqllotion of choin

o. Loosen the tension odiustment.

b. Ploce the choin over the drive sprocket ond

continue to seot ii olong the blode groove.

c. Adiust the choin io proper tension by using the

odjustment nut.

d. Stort the engine ond use the choin oiler f reely

while the choin is in motion.

HETPERS HANDTE

For speciolized sowing operotions which require the

use o{ the long guide bor, the Clinton Choinsow con

be fitted with o Helpers Hondle for two-mon use.

This ossembly is in two ports. A mounting stud on the

hondie-ond-guord holf slips through the slotted hole

in the rounded end of the guide bor. Note thot the

lugs on either side of the mounting stud engoge the

slot to position the hondle securely. The cover holf is

then ploced over the stud ond secured with o wosher

ond wing nut. Nole: You moy hove to knock out o

topered plug in the guide bor io instoll the helpers

ho ndle. MAINTENANCE

By moking the following proctices o hobit you con

help keep your sow in good running order ond ovoid

repoirs thot neglect might moke necessory.

1. Remove sowdust ond dirt doily so thot o thorough

inspection con be mode.

2. Tighten ony loose nuts or screws.

3. Check fuel ond oil lines for leoks, especiolly ot

connection points.

Check oir {llter ond brush off dirt.

Do not use compressed oir to remove dust or dirt

from the OUTSIDE of the corburetor, since porticles

moy be blown into the mechonism if you do.

Check muffler ond exhoust ports periodicoelly,

when the loss of power is opporent. lf porls ore

dirty, cleon them.

As often os necessory remove the cutting choin

from the guide bor ond ollow it to sook overnight

in o pon of kerosene to remove the sop ond resin

deposits ond io provide lubricotion for oll ports of

the choin.

lf you notice symptoms of trouble bui cqnnot find

the couse, check with your outhorized Clinton

Service Deoler, ond be sure your sow is in good

running order.

4.

5.

2.

.).

t.

2.

3,

t].

4.

4.

t0

BASIC PARTS BREAKDOWN

It

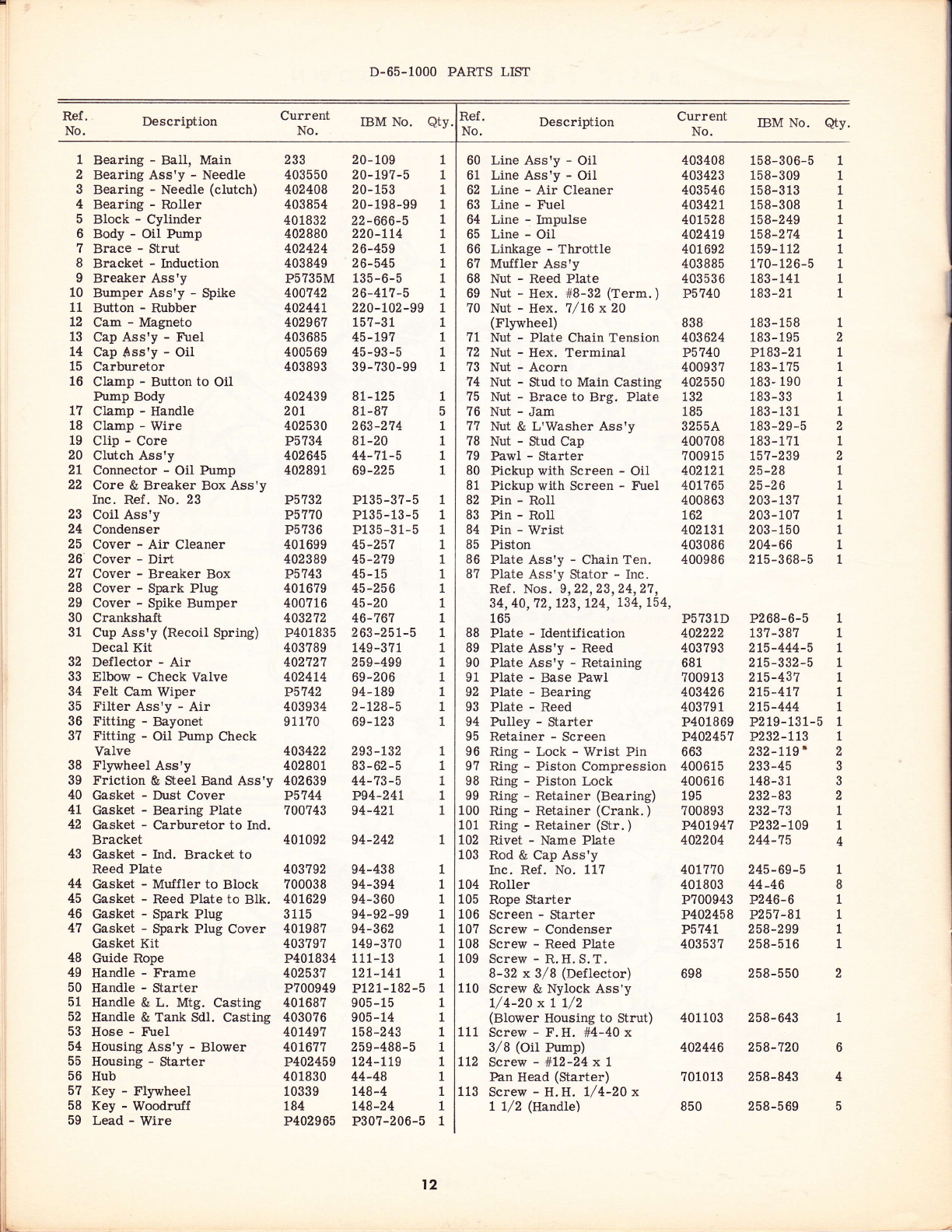

D-65-1OOO PARTS LIST

Ref .

No. Description

Bearing - BalI, Main

Bearing Ass'y - Needle

Bearing - Needle (clutch)

Bearing - Roller

Block - Cylinder

Body - Oil Pump

Brace - Strut

Bracket - Induction

Breaker Ass'y

Bumper Ass'y - Spike

Button - Rubber

Cam - Magneto

Cap Ass'y - Fuel

cap Sss'y - oil

Carburetor

Clamp - Button to Oil

Current IBM No,

233

403550

402408

403854

401832

402880

402424

403849

P5?35M

400742

40244t

402967

403685

4005 69

403893

Description

Plate - IdentiJication

Plate Ass'y - Reed

Plate Ass'y - Retaining

Plate - Base Pawl

Plate - Bearing

Plate - Reed

Pulley - Starter

Retainer - Screen

Ring - Lock - Wrist Pin

Ring - Piston Compression

fung - Piston Lock

Ring - Retainer (Bearing)

Ring - Retainer (Crank. )

Ring - Retainer (Str.)

Rivet - Name Plate

Rod & Cap Ass'y

Inc. Ref. No. 117

RolIer

Rope Starter

Screen - Starter

Screw - Condenser

Screw - Reed Plate

Screw - R, H. S. T.

8-32 x 3/8 (Deflector)

Screw & Nylock Ass'y

L/4-20 x | 7/2

(Blower Housing to Strut)

Screw - F.H. #4-40 x

3/8 (oil Pump)

Screw - #L2-24x1

Pan Head (Starter)

Screw - H.H. l/4-20 x

1 1/2 (Handte)

IBM No. Qty.

Current

No.

1

2

3

4

5

6

7

B

I

10

11

L2

13

L4

15

16

t7

18

19

20

21

22 P5732

P57?0

P5736

401699

402389

P5743

401679

400716

403272

P401835

403789

402721

402414

P5742

403934

91 170

403422

402801

402639

P5744

700?43

401092

403792

700038

401629

3115

401987

403797

P401834

402537

P?00949

401687

403076

401497

40L677

P402459

401830

10339

184

P402965

81-125

81 -87

263-274

81-20

44-7L-5

69-225

P135-3?-5

P135- 13-5

P135-3 1-5

45-251

45-219

45- 15

45-256

45-20

46-767

263-251-5

t49-377

259-499

69-206

94- 189

2-L28-5

69- 123

293 - 132

83-62-5

44-73-5

P94-24L

94-42L

94-242

94-438

94-394

94-360

94-92 -99

94-362

149-370

111- 13

12L-L4L

PtzL-182-5

905-15

905-14

t58-243

259-488-5

L24-LLg

44-48

t48-4

L48-24

P307-206-5

183- 158

183 - 195

P183-2 1

183- 1?5

183- 190

1 83 -33

183-131

183-29-5

183-171

15 7-2 39

25-28

25-26

203 - 137

203 - 10?

203 - 150

204-66

2 15 -3 68-5

P2 68- 6-5

137-387

215-444-5

215-332-5

2L5-437

2t5-4L7

2t5-444

P2 19-131-5

P232-LL1

232-119'

233-45

148 -3 1

232-83

232-13

P232-L09

244-75

20-109 1

20-L97-5 1

20-153 1

20-198-99 1

22-666-5 1

220-tt4 1

26-459 1

26-545 1

135-6-5 1

26-4t1-5 1

220-t02-99 1

157-31 1

45-tS7 1

45-93-5 1

39-730-99 1

403408

403423

403546

40342t

40152 B

4024t9

401692

403885

403536

P5740

B3B

403624

P5?40

400937

402550

132

185

3255A

400?08

?009 1 5

402121

401 ?65

400863

162

402t31

403086

400986

P5731D

402222

403793

681

700913

403426

40379 1

P401869

P402457

663

400615

400616

195

700893

P40t947

402204

40t770

401803

P700943

P402458

P5741

40353?

698

401 103

402446

7010 13

850

158-306-5

158-309

158-3 13

158-308

L5B-249

L58-274

159-112

170- 12 6-5

183 - 141

183 -2 1

60 Line Ass'y - Oil

61 Line Ass'y - OiI

62 Line - Air Cleaner

63 Line - Fuel

64 Line - Impulse

65 Line - OiI

66 Linkage - Throttle

67 Muffler Ass'y

68 Nut - Reed Plate

69 Nut - Hex. #8-32 (rerm. )

?0 Nut - Hex. 7/L6x20

(FlywheeI)

?1 Nut - Plate Chain Tension

72 Nut - Hex. Terminal

73 Nut - Acorn

74 Nut - Stud to Main Casting

?5 Nut - Brace to Brg. Plate

76 Nut - Jam

77 Nut & L'Washer Ass'y

?B Nut - Stud Cap

?9 Pawl - Starter

80 Pickup with Screen - OiI

81 Pickup with Screen - Fuel

82 Pin - Roll

83 Pin - RoII

84 Pin - Wrist

B5 Piston

86 Plate Ass'y - Chain Ten.

87 Plate Ass'y Stator - Inc.

Ref . Nos. 9,22,23,24,27,

34, 40, 72, 123, L24, 134, 154,

165

1

2

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

Pump Body 402439

Clamp - Handle 20t

Clamp - Wire 402530

Clip - Core P5734

Clutch Ass'y 402645

Conneetor - Oil Pump 402891

Core & Breaker Box Ass'y

Inc. Ref. No. 23

Coil Ass'y

Condenser

Cover - Air Cleaner

Cover - Dirt

Cover - Breaker Box

Cover - Spark Plug

Cover - Spike Bumper

Crankshaft

Cup Ass'y (Recoil Spring)

Decal Kit

Deflector - Air

Elbow - Check Valve

Felt Cam Wiper

Filter Ass'y - Air

Fitting - Bayonet

Fitting - Oil Pump Check

Valve

Flywheel Ass'y

Friction & Steel Band Ass'y

Gasket - Dust Cover

Gasket - Bearing Plate

Gasket - Carburetor to Ind.

Bracket

Gasket - Ind. Bracket to

Reed Plate

Gasket - Muffler to Block

Gasket - Reed Plate to BIk.

Gasket - Spark Plug

Gasket - fuark Plug Cover

Gasket Kit

Guide Rope

Handle - Frame

Handle - Starter

Handle & L. Mtg. Casting

Handle & Tank Sdl. Casting

Hose - tr\rel

Housing Ass'y - Blower

Housing - Starter

Hub

Key - Flywheel

Key - Woodrulf

Lead - Wire

1

5

1

1

1

1

23

24

25

26

27

28

29

30

31

32

33

34

35

36

3?

38

39

40

4t

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

88

89

90

91

92

93

94

95

96

97

98

99

100

101

toz

103

104

105

106

107

108

109

110

2

3

3

2

1

1

4

245-69-5 1

44-46 B

P246-6 1

P257-8L 1

258-299 1

258-516 1

258-550 2

258-643 1

258-720 6

258-843 4

111

LL2

113

t2

258-569

Ref .

No.

1

1

1

1

1

Ref .

No. Description

114 Screw & Nylock Ass'y

(Induction Bracket)

115 Screw & L'Washer Ass'y

(Ta-nk Strap)

current IBM No. Description

Screw - Spike Cover to

Spike Bumper

SeaI - Oil (Cylinder Block)

Seal - Oil (Bearing Plate)

Shorting Ass'y - Ignition

Spacer (Starter)

Spacer - Clutch Cover

Spark Plug

Spring - Starter Pawl

Spring - Oil Pump

Spring - Breaker Box Cvr.

Sprocket - Clutch Cup&Brg.

Starter Ass'y

Stop - Reed

Strap - Tank Retainer

Strut - Main

Stud - Guide Bar

Stud - Muffler to Block

Tank Ass'y - Fuel

Terminal - Jamtite

Trigger - Throttle

Valve - Fuel Shutoff

Valve - Reed

Washer - Internal Lock

Washer - Brg. Plate to Bk.

Washer - Lock (Flywheel)

iYasher - Shorting Switch

Washer - Chain Guide

trVasher - Lock (Starter)

Washer - Lock (Handle)

Washer - Terminal

Washer - 2 Plate Chain Ten.

2 Spike Bumper to 1\{. Cast.

Washer - Lock, Bump. Cvr.

Washer - #10 Lock (Str. )

Washer - Plain (Str.)

Washer - Retaining (Str.)

Washer - Wave (Str. )

Washer - Lead (Str. Rope)

Qty.

2

2

2

2

4

4

2

2

1

,

3

1

2

1

2

Current

No. IBM No. Qty.

400177 258-586-5

400189 258-592

258-741

94-301 -99

94-251

266-41-5

304-524

304-373

K2 6?-66-5

263-L7t

263-269

P263-10

106-2 39- 5

265-160-5

293-9?

26-446

26-477

24-70

24-Lt

277 -323-5

P307-230

15 7-296

293-t22

293-96

304-3

304 -35 1

304-3?5

304-368

304-430

304-532

304-451

304-290

5682A

P402493

701028

401708

403478

40r704

401733

403071

258-845

2 58-61 5

258-?10

258-520

258-678-5

258-588-5

258-692-5

2 58- 108- 5

P25B-723-5

258-851-5

258-678-5

258-?50

258-677-5

258-681-5

258-737

258-75L

258-549-5

258-680

258-297

258-622

403 15 1

402407

257-t

403638

700914

400540

I.'403923

401865

402443

P5745

403405

402454

403544

401700

403206

403 189

5 659

4034t7

P5738

40 169 1

401878

403543

114

657

4008?4

400323

402388

701012

403 150

P5?39

r;C7

403950

Pi92

P400624

P401946

P401945

P700964

403396

6

2

136

13?

138

139

140

L4L

t42

143

t44

145

t46

147

148

149

150

151

t52

153

t54

155

156

L57

158

159

160

161

162

163

164

I T,D

166

167

168

169

1?0

1?1

172

116

tL7

118

119

120

t2t

Screw - #L0-24x1/2

(PuII Guide) 701016

Screw - Cap to Rod 400585

Screw - Clamp to Carb. 402126

Screw - l/4-20 x1/8

(Carb. to Ind. Bracket) 365

Screw - Handle to Ind. Brlrt. 401?08

Screw & Nylock Ass'y

Bearing Plate to Block 400179

Screw - Brg. Plate to Block 401941

122

t23

t24

L25

126

127

t28

1,29

130

131

732

133

134

135

Screw - IViagneto to Bearing

Plate

Screw & Oil C::p Ass'y

Screw & Nylock Ass'y

Pawl Plate to Flywheel

Screw & Nylock Ass'y

Blower Hsg. to Brg. Plate

Screw - H.H. 5/16-18 x

?/8 (Iliain Cast. to Block)

Screw & Nylock Ass'y

Tank Saddle to L, Handle

Screw & Nylock Ass'y

Tank Saddle to L, Handle

Screw - S.H.C. l/4-2Ox

1 1/2 (Blower Hsg. to Brg.

Plate to Saddle)

Screw - H.H. 5/16-18 x

L 1/4 - (ivlain Cast. to Sdl. ) 403479

Screw & Nylock Ass'y

Tank Sdl. to l\lain Casting 671

Screw - Switch Cover to

Saddle Casting 401732

Screw & L'Washer Ass'y

Breaker P573?

Screw - Spike Bumper to

Main Casting 400?09

D-65-1000: No Variation. Use Basic Parts List.

D-65-1100: Note l, 2, 3.

D-65-1101: Note 9, 11,

D-65-1102: Note 1, 2, 9, 10:

D-65-1103: Note 4.

1

1

1

2

2

1

4

2

1

1

2304-337 4

304-451 2

P304-318 2

P304-3?7 2

P304-4L2 1

P304-411 1

P304-525 1

3C7 -265-5 1

Not Illust.

173 Wire - Shorting

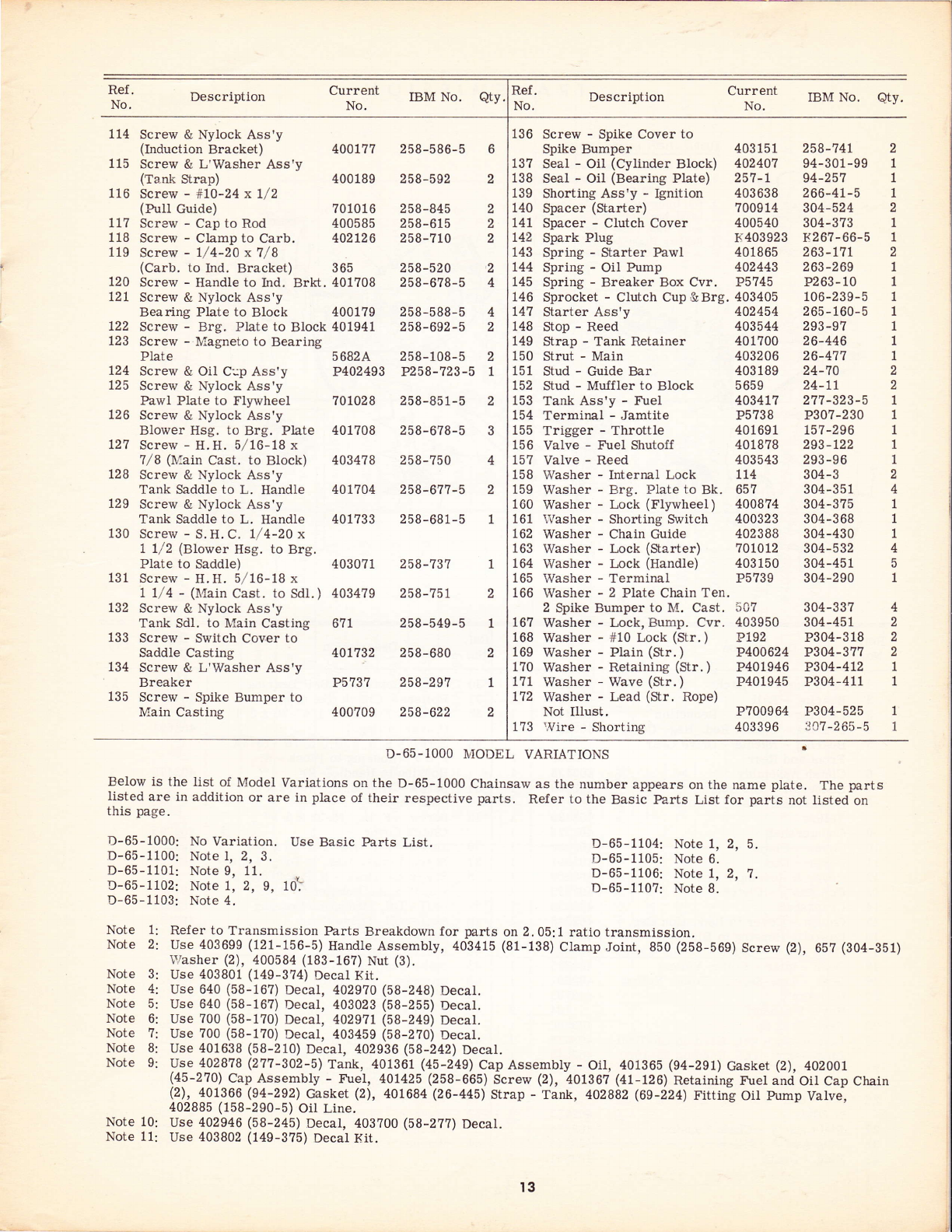

D.65-1OOO NIODEL VARIATIONS

Below is the list of Model Variations on the D-65-1000 Chainsaw as the number appears on the name plate, The parts

listed are in addition or are in place of their respective parts. Refer to the Basic Parts List for parls not listed on

this page.

D-65-1104: Note 1, 2, 5.

D-65-1105: Note 6.

D-65-1106: Note 1, 2, 7.

D-65-1107: Note 8.

Note 1:

Note 2:

Note 3:

Note 4:

Note 5:

Note 6:

Note 7:

Note 8:

Note 9:

Refer to Transmission Parts Breakdown for pa.rts on 2.05:1 ratio transmission,

Use 403699 (121-156-5) Handle Assembly, 403415 (81-138) Clamp Joint, 850 (258-569) Screw (2), 65? (304-351)

V,'asher (2), 400584 (183-16?) Nut (3).

Use 403801 (149-374) Decal Kit.

Use 640 (58-16?) Decal, 402970 (58-248) Decal.

Use 640 (58-167) Decal, 403023 (58-255) Decal.

Use 700 (58-170) Decal, 402971 (58-249) Decal.

Use ?00 (58-170) Decal, 403459 (58-270) Decal.

Use 401638 (58-210) Decal, 402936 (58-242) Decal.

Use 402878 (277-302-5) Tank, 401361 (45-249) Cap Assembly - Oil, 401365 (94-291) Gasket (2), 4O2OO|

(45-270) Cap Assembly - Fuel, 401425 (258-665) Screw (2), 40136? (41-126) Retaining Fuel and Oil Cap Chain

(2), 401366 (94-292) Gasket (2), 401684 (26-445) Strap - Tank, 402882 (69-224) ritting Oil Pump Valve,

402885 (158-290-5) Oil Line.

Use 402946 (58-245) Decal, 403700 (58-27?) Decat.

Use 403802 (149-375) Decal Kit.

Note 10:

Note 11:

I3

No.

I

TRANSMISSION

IUBRICATION INSTRUCTIONS:

l. Remove Droin Plug (Front of Cover).

2. Remove .Filler Plug (Top of Cover).

- lJse lF90 Oil -

3. Fill Tronsmission ro Oil LevEl - Oil

level hos been reqched when oil

spills from Droin Plug.

4. Reploce Droin ond Filler Plug.

- Check Oil Level frequently -#uuu

INTERMEDIATE

Ref.

No. Description

Band Ass'y - Clutch

Bearing - Ball

Bearing - Needle - Reduction

Bearing - Needle Red. Hsg. Cover

Bearing - Needle - Drive Gear

Front and Rear

Clutch Assembly

Connector - Oil Line

CountershaJt Ass'y - Color:

Yellow

Countershaft

Cover - Clutch

Cover - Dirt

Cover & Housing Ass'y

Cup Ass'y - Clutch

CrankshaJt

Gasket - Cover to Reduction Hsg.

Gasket - Housing to Block

Gear Ass'y - Drive - Color: Yellow

Gear - Idler - Color: Yellow

Gear - Low-Speed - Color: Ye1low

Hub Ass'y

Key - Woodruff

Key - 5/32 Sp.

Line Ass'y - OiL, Used on G5-1000

Line Ass'y - Oil, Used on 55-1000

Nut - Grip, 3/8"-24

Nut - Hex. , 7/16,,-20 x3/8,,

Nut - Std. 3/8,'-24, Guide Bar End

of Studs

Plate Ass'y - Chain Tension

Plug Ass'y - Filler

PIug - Drain

?J: erv'

402639 1

196 1

402343 1

403433 2

No. Description

Ring - Retaining, Bail Bearing

Rollers - Clutch (Set of 8)

Dust Shield

Screw - F. H., #8-32 x 5/8,,

Clutch Cover

Screw - Soc. Hd. l/4-20 x 3/4

Screw Blower Hsg. to Brg. Plate

Screw & Nylock - H. H 3/8,,- 24

x3/4" Spike Bumper "o Strut

Seal - Oil, Reduction Housing

Seal - Oil, Drive Gear

Shield - Dust

Spacer - Sprocket

Spike Bumper

Sprocket - (T-tooth)

Studs - Guide Bar

Washer - Flat, 12/32,, x 13/32,,

x l/16

Washer - Chain Guide

Washer - Thrust, Drive Gear

Washer - Thrust, Idler Gear

'\ilasher - #8, Clutch Cover

Washer - FIat

Washer - Slinger

Washer - Lock

Washer - Thrust

?J: etv

1

2

3

4

5

30

31

32

33

195 2

401803 1

Screw - Fil. Hd. , L/4,,-20 x3/4,,

(Cover to Hsg. ) 402691 11

6

I

8

402332

403435

402688

403429

403326

402338

403391

403689

402335

403339

402345

403689

402696

403325

402 69 1

403 182

184

403390

403436

403043

402550

400642

40252L

402324

402346

40235t

2

1

1

Screw - S.H.F.H., 5/16"-18-34

x1/8" (Housing to Block - 4;

Housing to Handle - 2) 403478

Screw - R.H.S.T., #B-32 x3/8,,

34

35

36

31

38

39

40

41

42

43

44

45

46

48

49

50

51

EO

53

54

698

400798

403393

401708

401403 1

40234t 1

402333 1

402339 1

403338 1

402742 1

40022t 1

402535 2

507

4028t7

402334

402328

110

402

402323

403392

402899

6

1

4

1

1

I

10

11

L2

13

t4

15

16

t7

18

19

20

2t

22

23

1

2

1

1

1

2

1

5

2

1

2

4

24

25

26

27

28

29

2

1

1

1

14

i

_)

flE

37 53

(,l

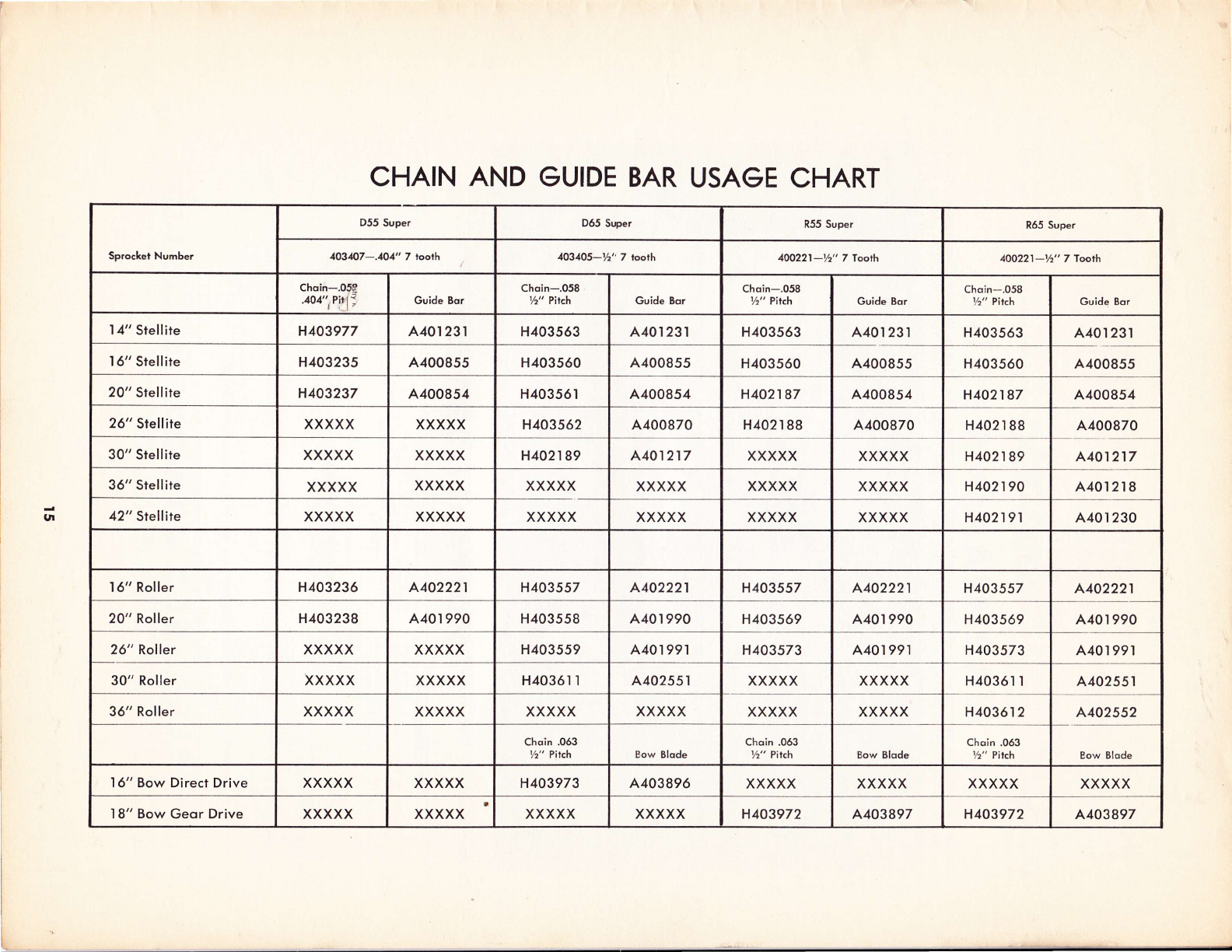

CHAIN AND GUIDE BAR USAGE CHART

Sprocket Number

D55 Super D55 Super R55 Super R65 Super

403&7-.101" 7 tooth 4O31O5-b" 7 tooth 100221-Yz" 7 Tooth 4oO22l-lz" 7Trcth

Choin-.05!

.404" Pi|-

t' Guide Bor Choin-.058

Yz" Pitch Guide Bqr Chqin-.058

Yz" Pirch Guide Bqr Choin-.058

Vz" Pitch Guide Bor

'I 4" Stellire H403977 A40r 231 H403563 A40l 23 tH403563 A40t 231 H403563 A40r23l

16" srellire H403235 A400855 H403560 A400855 H403560 A400855 H403560 A400855

20" Srellire H403237 A400854 H40356 IA400854 H402187 A400854 H402187 4400854

26" Stelliie XXXXX XXXXX H403562 A.400870 H402 r 88 A400870 H402r 88 A400870

30" stellire XXXXX XXXXX H402 r 89 A.401217 XXXXX XXXXX H402r89 A401217

36" Srellire XXXXX xxxxx XXXXX XXXXX XXXXX XXXXX H402190 A40l 2l 8

42" Stellire XXXXX XXXXX XXXXX xxxxx XXXXX XXXXX H402191 A40r 230

16" Roller H403236 4402221 H403557 4402221 H403557 4,402221 H403557 A.402221

20" Roller H403238 A40r 990 H403558 A401 990 H403569 A40 t 990 H403569 A40 t 990

26" Roller XXXXX XXXXX H403559 440199'l H403573 A40r 99.l H403573 A40r 991

30" Roller XXXXX XXXXX H4036l lA402551 XXXXX XXXXX H4036 r r4402551

36" Roller XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX H403612 A.402552

Choin .063

t/z" Pitch Bow Blode Choin .063

Yz" Pitch Bow Blode Choin .063

1/z" Pilch Bow Blode

I6" Bow Direct Drive XXXXX xxxxx H403973 A403896 XXXXX XXXXX XXXXX XXXXX

'I 8" Bow Geor Drive XXXXX xxxxx XXXXX XXXXX H403972 4403897 H403972 A.403897

CLINTON CHAINSAW WARRANTY REGISTRATION

CLINTON ENGINES CORPORATION

Maquoketa, Iowa Clinton, Michigan

You have purchased a Clinton-built Chainsaw, world famous for quality and performance. This Chainsaw is manufac-

tured by Clinton Engines Corporation, builder of the most complete line of Air-Cooled Engines in the world. The Clin-

ton Engines Corporation "Arrowhead" trademark is your guarantee of top performance and long service liJe. This

Chainsaw carries the following warranty.

WA.R,RANTY

This Chainsaw Unit is warranted for 45 days from the date of purchase. The Clinton Engines Corporation will replace

at no charge to the original purchaser (end user), any part or parts found to be def ective in material and/ or workman-

ship when inspected by an Authorized Clinton Service Outlet or Clinton Engines Corporation. (Normal maintenance on

the cutting chain, guide bar, sprocket, and clutch is the responsibility of the owner and,/or user, These parts are war-

ranted for defective pa.rts and/or workmanship for a period of 45 days from date of purchase. No part replacement

labor allowance, )

All transportation charges on warranty material submitted for replacement is to be paid by the purchaser.

Warranty repa.irs are to be made by an Authorized Clinton Service Outlet only, There is no other warranty expressed

or implied. Clinton Engines Corporation shall in no event be liable for consequential damages.

Clinton Engines Corporation appreciates any opportunity to be of service to you.

HOW TO SECURE SERVICE

Mr. Salesman or Mr. Dealer: Please fill out this warranty form to insure that your customer will receive warranty

service if needed.

Mr, Customer: Please retain this warranty form along with your Chainsaw Operation and Maintenance Manual. If war-

ranty service is required, present this completed warranty form to your Authorized Clinton Service

Center along with the Chainsaw.

CAUIION: Please read the Operation and Maintenance instructions prior to starting the Chainsaw.

Owner's Name City

Street Address or R. F.D. No. County

Chainsaw Ser'-l No,

Irdte t,trrt'Ildseo t urcnaseo .rrolu

City County

WARRANTY PROCEDURE

State

If warranty is required:

1, Do not attempt to disassemble or repa.ir Chainsaw or have repairs made other than by an Authorized Clinton Servic-

ing Account.

2. Show the Authorized Clinton Service Account this warranty registration form.

3. Fill out warranty claim completely with Service Account and sign.

4. If a Clinton Service Account is in doubt whether the repairs necessary are warranty, he is within his rights to charge

for the repair and fill out a wamanty claim for refund which is submitted to his source of supply and is then subject

to the source of supply or factory inspection, review, and decision,

l6

Table of contents

Other Clinton Chainsaw manuals