CNC CAT ST-PMC1 User manual

1/ 17

ST-PMC1single-axis motion controller operatingmanual

2/ 17

.Features.............................................................................................................................. 3

Ⅱ.Frontpanel diagram............................................................................................................ 3

Ⅲ.Back panel diagram and signaldescriptions....................................................................... 4

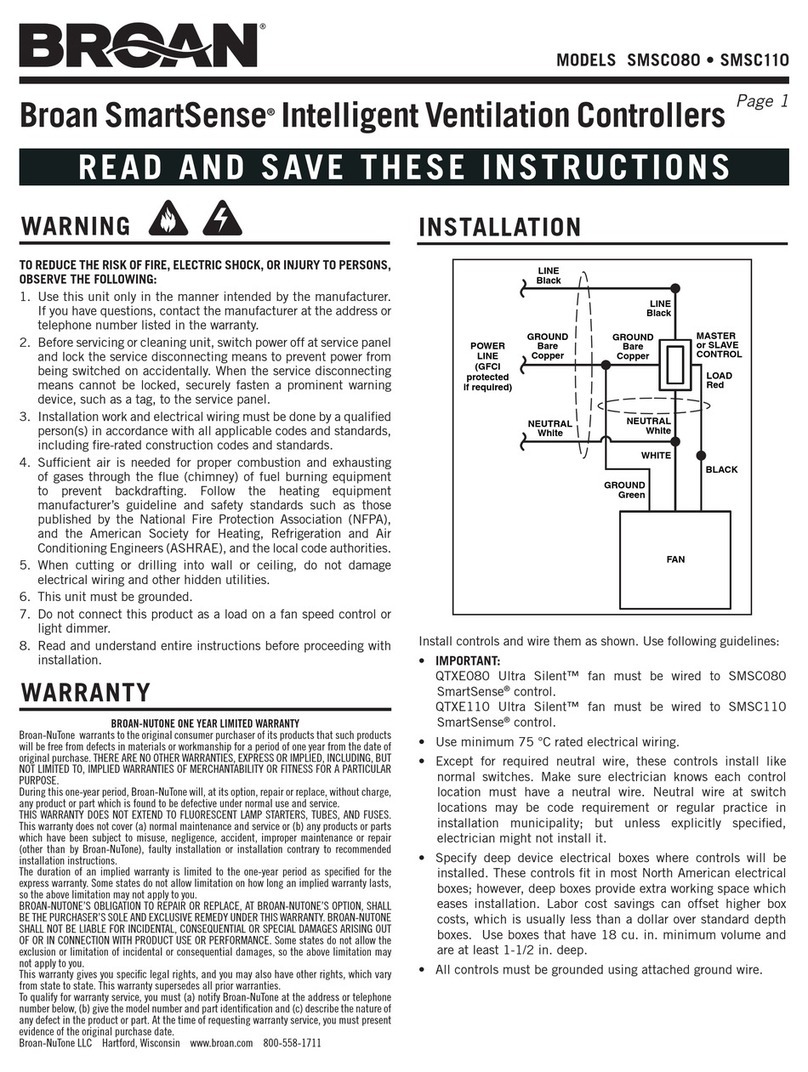

Ⅳ.Thecontroller connectiondiagram:................................................................................... 5

Ⅴ.Theoperationflow chart................................................................................................... 5

Ⅵ.parameter setting:............................................................................................................ 7

Ⅶ.program editing and Detailed instructions:...................................................................... 8

Ⅷ.Themanualoperationmode:........................................................................................... 10

Ⅸ.Automatic operationmode............................................................................................. 10

Ⅹ.Installationdimensions.................................................................................................... 11

Ⅺ.Editingand applicationexamples:................................................................................... 12

Ⅻ.directive searchform....................................................................................................... 14

ⅩⅢ.Parameters searchform............................................................................................... 15

ⅩⅣ.Buttonsearchform...................................................................................................... 16

3/ 17

.Features

•Numberof controlledaxis: Singleaxis;canachieveavariety ofcomplexoperation: positioning

control and non-positioning control;

•Themaximum outputfrequency:40KHZ;

•Outputfrequency resolution:1Hz;

•Programmable maximum numberof rows: 99;

•Signalinput:6(opticalisolation);

•Signaloutput:3(opticalisolation);

•Acontinuous displacementrange:-7,999,999 ~ 7,999,999;

•Operatingstate:Autorun mode, manualoperation,theprogramedit mode,parametersetting

status;

•Liftingspeedcurve:2 (optimization);

•Displaydigits: 8digitaldisplay,manual/automatic status display,run/stopstatus display,the

numberofsteps/counts/proceduresdisplay,edittheprogram,parameterdisplay,input /

outputstatus display, pulseanddirectiondisplay;

•Autorun feature:Youcanedit, you cancontrol thestart and stop automatically run through the

panelbuttons andprocessingand otheroperations attheterminallevel;

•Manualoperation functions: position adjustments(manualjog speedand jog thenumberof

stepscan be set);

•Parametersettingfunction:Starting frequency,accelerationanddeceleration curve,reverse

clearance, manually runlength,manualspeed,backtozerospeedand interrupt jumptheline

all canbe set;

•Programediting functions: Youcaninsert,delete, modifythe program. Thecontrollercan

identify the error Instruction;

•Return toZerofeatures:It canbefrom thepositiveand negativedirections,automatic return

tozero

•Thenumberof programming instructions:14 instruction;

•Outside theoperating functions: interruptoperationthroughparametersettingandswitch

connectedtotheterminals Aand B;

•Powersupply:DC24V;

Ⅱ.Front panel diagram

1.8digitalledSegmentdisplays;

2.6inputstatus indicator;

3.3output status indicator;

4.CPpulse signalindicator;

5.CW direction signalindicator;

6 Keys: 10keystotal, and mostofthecompositekeys,

theyrepresentdifferentfunctionsin differentstates,

in

thefollowingdescription, wejusttake one ofthe

functionsrepresents a key.

Figure I:operation panel

4/ 17

Ⅲ. Backpanel diagram and signal descriptions

1. CP,CW, OPTO for steppermotordrive signal;

CP: pulse signal

CW: direction signal

0PT0: Publicmale end beforethetwosignals

2. RUN: Start runningtheprogram,Thesamefunction as

Run”of the operationpanel;

3. STOP: Pauseprogramis run automatically,Thesame

functionas Pause”of theoperation panel,Afterstarting

again, theprogramcontinuestorun;

4. A: Aoperation

B: Boperation

Aoperation”and Boperation”this isamajor feature ofthe controller:

For steppermotors,wegenerally quantitativepositioning control,such ascontrollingthe

displacementof themotor mustberunning ataconstantspeed ,Inthis wayitis easytosolve,

justputthe amountandspeedof displacementofthe programming canbe.

But therearequitealot of control isnotpositioningin advance, such ascontrollingthe

steppermotor inonedirectionfromthe starting pointtostartrunninguntilhe hit aswitchafter

strokestop,thenreversedirectionbacktothestartingpoint. Anotherexamplerequiresthe

steppermotor runningbackandforth betweenthetwolimit switchseveraltimes,andso on. In

theseoperations,wedo not knowin advancethespecificvalueof thesteppermotor

displacement,andhow theyshould beprogrammedit?Thecontrolleruses: tointerruptthe

operation,which wecall "AOperation" and "B operation”,for example,"Aoperations",workers

workflowis:whenthe programisrunning. If"Aoperation" signalinput,motor deceleratesto

stop,Programinterruption,the controllerremembersinterruptedcoordinate values, theprogram

jumpstothe "Aoperation" entry address specifiedprograms runtheprogram;

5. IN1 and IN2 Switchingsignalinput terminal

6.OUT1,OUT2 and OUT3 Switching signaloutputterminal,

7.COM+, COM- :thepowersupply of externalinput and outputdevices,thispowersupply is

DC24V, COM+ is thepositive terminalof thepowersupply,COM- negative side;

8. +24V: The positivepowersupply,GND: Negative powersupply;

Thesignal RUN,STOP,A , B , IN1, IN2 calledtheinput signal,theyhavethesameinput interface

circuit. OUT1, OUT2,0UT3 calledtheoutputsignal. Theyhavethesameoutput interfacecircuit.

Both inputand outputopticalisolation circuittoensurethattheinternaland externalcontrollers

do not interferewitheach other;

Thestateoftheinput signaland outputsignal,corresponding indicator on the panel. For input,

inputlow(switchisclosed) Indicator light;For outputsignal,theoutput 0islow,thelightisoff,

theopposite willlight.

Figure II:Back paneldiagram

5/ 17

Figure Ⅲswitchinputcircuit

Whentheswitchis turnedon,Input levelis low,on thefrontpanelindicator lights,theprogram

is definedas0.

Figure Ⅳswitchoutput circuit

Outputoflowoutput, loadconduction, frontpanelindicator lights,theprogramis definedas1.

Ⅳ.The controllerconnectiondiagram:

Figure Ⅴcontrollerconnection diagram

Ⅴ.The operation flow chart

Controlleralwaysoperateinoneoffour states:automatic mode, manualmode,theprogramedit

mode, parametersetting state.Poweror pressthe Reset,Controllertoberun inautomatic mode,

thecursorcoordinates0, thenyou can start the programtorunautomatically orswitch to

manualmode,programeditingstateand parametersetting statuscanonlyswitchinmanual

mode.Editing completedor parametersetting procedureiscompleted,pressthe Quit toreturn

tomanualmode(theprogramwill besaved) ,inmanualmode, if you switch toprogramedit

mode,simply pressthe Edit button,ifyou switchtotheparametersetting state,press Set more

than2 seconds.

(Note:Theabovementioned Edit, Set, Quit,isthesamebutton,weintroduceafeature,the

button'sname onlychoose one, the samebelow)

OUT1-3

CP CW OPTO

Inputdevices: External

Startbutton、Limit switch 、

Photoelectric switch

Outputsignalcontrol relay、

indicator light

Powersupply:DC24V

ST

-

PMC1

Stepper

Motor Controller

steppermotor drive

r

steppermotor

6/ 17

Press Enter enter data

editing 00400

Press

RUN

Automatically run the program

and displaysthe current status:

the coordinate values,count or

program lines

Press

STOP

Program pauses

Press

Home

Motor back tozero

in accordance with

a pre-set speed

Aoperationor

B

operation

Motor interrupt the current operation,

for deceleration stop, remember the

current coordinate value, then the

program pointer operations into Aor B

operation specified by the entrance to

the program.

Power on or Rest

A:After power on or Rest, Coordinates

to reset, As the coordinate zero, In

standby mode;

B: Memory is not cleared, the data

transferred to the last stored

memory(Please refer tothe "Program

Edit")

Auto ModeL000000

This step is step number

display,You can switch

the display mode for the

count or program

Motor run in accordance

with the appropriate amount

of displacement in the

direction and speedof

preset

Press < or >

Program edit state

00 speed

Press Move the cursor

00

speed

press∧∨edit number

10400

Press Enter Go to the next

line editing

01 end

Press Insert the new

program line

01 PRUSE

Until all programs are modified

or completed entry

Press Edit/Quit

more than 2 seconds

Press Enter edit

parameter

J

f

00

400

Press Enter save parameter

Return to previous menu

press∧∨to set another

parameter

CP

------

Parameter setting status

Jf ------

Press ﹤or ﹥Selectthe

number

J

f

00

400

press ∧∨edit

number

J

f

01

400

Press Edit/Quit

more than 2 seconds

Press Edit/Quit

Manual mode

-11- 000000

Press

Auto/Jog

Press

STOP

Pause manually run

Press RUN

Press

Home

Motor back tozero in accordance

with a pre

-

set speed

7/ 17

Ⅵ.parametersetting:

Out of thewayof parametersetting statusis: In manualmode, press Edit and holdthe

buttonfor 2secondsor more,entertheparametersetting state.Afterparametersetting is

complete,pressthe Quit buttontoreturn tomanualmode(parameterswillbe saved).

Parametersdisplayedintworows,thefirstrowshowsthenameoftheparameter,thesecond

lineshowstheparameterdata.

Parameterchanges: Afterenteringtheparametersetting state, thefirstlineof thedisplay:

jf------.Formertwoparameternameinflashing: press∧∨,Willdisplaythenextor previous

parametername, pressEnter,Will entertheedit state(nextrow) parameterdata,whenthefirst

bit of dataflashing display,press∧∨,datawill bechanged.press <>,Willmovetothenext

onetobemodified,afterthe datamodification,press Enter Savechanges,press Cancel discard

changesandexit.

In short,the setparametersthrough ∧∨<> "Enter", "Cancel" sixbuttons tocomplete thesix:

bymoving leftandrightkeystomovethecursortotheappropriateposition, thenthe digital

displaywillbeat,and thenthroughtheupperand lowerkeystochangethevalue:usetheEnter

keytoenterthedatamodification status,afterthedatamodification iscompleted,confirmwith

theEnterkeytoexitor discardthechangeswith Cancelbutton.Pleaserefertothe"Listof

operational processes."

N

O

Name

parameter

displayform

Data range

(unit)

ParameterDescription

1

Offfrequency

JF- -----

JF XXXXXX

400-3999

(Hz) If thesetvalueisless than400Hz, thesystemwillalarm;

Users cansetdifferentofffrequenciesaccording totheir actualsituation

2

Rising and

fallingcurve rS- -----

rS X L、H

(stripe Thecontrollerhastwo internaloptimization risingand fallingspeedcurve,Lis

aslow curve;Hto afastercurve, to selectadifferent rateof riseand fallcurve

basedon theactualloadsituation.

3

Backlash

compensation CC- -----

CC XXXX 0-9999

(pulses

number

Mainlyusedto compensatetherotationmechanism(suchasa

screw,gear,etc.)Theamountofdisplacement causedbythebacklash

error

compensation is not displayedon thecontroller.

4

Manual

increment HL------

HLXXXX

XX

1-999999

(pulses

number)

In manualmode,themanualoperationis adisplacement ofthe

steppermotor; Ifthesetvalueis equalto 0, thesystemwill alarm.

5

Manualspeed

HF- -----

HF XXXXX

X

1-39999

(Hz) In manualmode,manualoperation is running speedsteppermotor; If theset

valueis equalto0, the systemwillalarm.

6

Backto zero

speed bF- -----

bF XXXXXX

1-39999

(Hz) Whenzeroingoperation,steppermotor speed;Ifthesetvalueisequalto0,the

systemwillalarm

7

AOperation"

entryaddress Na------

NAXX 00-99

(Linenumber

Whenthe program is running, if the "AOperation"signalinput port, the motor

for thedeceleration stop theprogramatthis interruption,theapplication

remembers interruptedcoordinatevalues,theprogramwilljumptothisline

numberspecified

bytheprogram atrun theprogram.

8

BOperation"

entryaddress nB- -----

nB XX 00-99

(Linenumber

Whentheprogram is running,suchasGao"B Operation" end signalinput,the

motor will slowdown to stoptheprogramatthis interruption,theapplication

remembers interruptedcoordinatevalues,theprogramwilljumptothisline

numberspecifiedbythe program run theprogram.

9

Pulse mode

CP- -----

CPX 0、1 CP=Orepresentedasasingle pulseoutput,CP-siderearpaneloutput step

pulse, CW-endedoutput direction level; CP=Iexpressedasasinglepulse

output,CP-endedoutputontherearpanelforward steppulse,CW-ended

output inversion steppulse.

8/ 17

Ⅶ.program editing and Detailed instructions:

Out ofthewaytheprogrameditor is:Inmanualmode, pressthe "Edit" button. Toenterthe

programedit state.Aftertheprogramediting is complete,pressthe "Quit" button backto

manualmode (parametersareautomatically saved)

Programareaof thecontrollercaneditupto99instructions,each instructionintheprogram

thereisalinenumber,linenumberfor automatic numbering startsfrom OOarrangedinorder,

you caninsertor delete arowin theprogram, but the line number will bereassigned.

Theprogramformatis: Each programis dividedintotwo-linedisplay(except no parameter

program),thefirstline displaysthelinenumberandcommand name,andthesecondlineshows

theinstruction data.The lastinstruction of theprogramis fixedto"END",

In short,modifytheprogramby "∧“V""< “>" “insert “delete "Enter""Cancel" eight

buttonstocomplete:by moving left and rightkeystomovethecursor totheappropriateposition,

thenbeatthedigital displaywillthenchangethevalueviathearrowkeys:UsetheEnterkey

enterdatamodification status,afterthedatamodification iscompleted,confirmwiththeEnter

keytoexitor discardthe changes with Cancelbutton. Please refertotheoperation flowchart.

Program editing instructions

Program edit Operate procedure

Enter edit mode

In manual mode, press the Edit”button

Exit edit mode Under the state program editing line numbers flashing state, press the Quit”key

to return to the manual mode, the program will automatically save

Clear the

program When the program editingline numbers flashing,press and hold " Clear "button

for 2 seconds or more, until the first 00-line instructions for END time.

entry anew

program

First clear the program area, then only one program, 00 row END command,

and then press the "Insert"button, Directive00 line program into aPAUSE, and

flashing display; press the"∧""∨"command name was changed; until you find

the desired command, and then press the" Enter "to enterthe command data

area (no parameters for command, enter the program after the completion of this

section entry), press ∧∨<>to modify,After thechanges are complete press

the "Enter" button, enter this line program is completed, you can see the nextline

becomes END command, then press the "Insert"key entry programwith the

same way until all program entry is completed.

Special Note: When you enter anew program obviously is thecorrect procedure,

but the alarm controllererror,thishappens inabranch instruction: like JUMP

instruction, J-BIT directive, J-CNT ifthese threedirectiveSkip the linenumber

where this instruction isgreater thanthe currentline number,due to the jump

target has not been entered, the controller will misjudge entry line number is

wrong, in order to avoid this, we require anew program at the time of entry,these

three instructions Jump inthe line number that appears temporarily replaced with

00, after the program is completed entry,Change the line number 00 to the

correct line number.

Modify program

Reference above, " entrya new program " approach, modify the current program

Insert program When the program edit state line number is flashing, press the "Insert"button to

insert anew row abovethe current program, the program modification operations.

Delete program

When the flashing line number in theprogram editor,press the "Delete"key,the

program is deleted, the following program automatically move up.

9/ 17

Detailed instructions for directive(HH-linenumber, XXXXXX-- data)

Browse

program When the program editorline numbersflashing, press "∧""∨", you canbrowse

command name of each line of theprogram, but you wantaquick look at the

instruction parameters, how to do it, you just click the "<"key,the parameters will

flashing a second.

No.

Directive

Name Directive to display

the form Description

1Pause

directive HH 一PAUSE

No arguments Program pause and waitfor the panel start buttonor terminal

operation start signal or A, B operation signal.

2

Displacement

directive

HH_G-LEN

±XXXXXX When executing this directive, the controller will beconferred the

latest SPEED assignment, displacement volume parameter

settings specified in thisdirectiveset offfrequency,acceleration

and deceleration curve, backlash compensation,and control the

motor running; If this instruction is not SPEED assignment, place

start frequency for runningspeed; Parameters of the first oneis

the sign bit, 0for positivedisplacement, -for negative

displacement; Parameters: -7999999-+7999999 Unit: pulse

number if the argument is 0, it will alarm

3

Speed

assignment

directive

HH_SPEED

XXXXX All run this program following this directivewill set the speedto

run until the next occurrence rate assignment directive;

Range of parameters: I a 39,999 unit:pulses / sec (Hz)

If the parameter is 0, it will alarm.

4

Delay

directive HH_DELAY

XXXXXXX Delay time; parameters: Ia7,999,999Unit: milliseconds; suchas

Gao parameter set to 0, the system will alarm.

5

Uncondition

jump directive HH 一JUMP

XX Unconditional jump directive,parameter XX represents the

program to jump to theline number; XX line numbers when more

than END directive line numbers, alert prompts.

6

Cycle

directive HH 一LOOP

XXXXXXX From the current line to the specified line through the loop; first

two digits of the line number (requires less than thecurrent line),

after fiveof cycles (0 defined as infinite). When the line number

than the current line number, the system will alarm.

7

Move to

a position HH_G0T0

±xxxxxxx Run to thespecified location, in practical applications, this

general location as areference point in the system; first

parameter isthe sign bit, apositivenumber indicates that the

zero point lies in thepositivedirection, negative,negative

direction indicates that this point is zero;

If the parameter value =0, which returns zero;

Parameter Range: -7,999,999 + 7999999 Unit: pulse number

8

Output

directive HH 一OUT

XXXX The first three parameters from leftto right correspond to the

output terminals 0UT1-0UT3; while the corresponding front panel

LEDs 1-3 every three output has three options: O,I, N:.

0- corresponding output terminal is high, the load is not

conducting, panel lights off.

I- corresponding output terminal is low,the load is turned on, the

panel lights.

N- Maintain previous working state

The last oneparameter, control buzzer

When 0- execute this command, ashort buzzer sound; (Note: in

order to execute the program after the end of the next sound)

When 1- execute this command, along buzzer sound; Note:in

order to execute the program after the end of the next sound)

When N- execute this command, the buzzer doesnot sound.

10 / 17

Ⅷ.The manualoperation mode:

In automatic mode,press "Auto/Manual" will enterthemanual mode,theformertwo-bit

digital tubewillbedisplayedasto ,indicatethatthemanualstates. Press“<or “>,the

motor will run manually in differentdirections,Speedand displacementof therunning,as

determined byHFandHL of theparametersset,pleasereferto"Figure6:Controlleroperation

flowchart .

Ⅸ.Automatic operation mode

Poweron thecontrollerorpress theresetbutton,automatically makesthecoordinatescleared,

and redefinesthis coordinates of thenew coordinate zero,reads the counter value, the controller

is instandby mode,press "Run "buttonor enterastart signalfromtheterminal,thecontroller

from thefirstrow00 programstartstorununtiltheruntothelastprogramEND,then

automatically run ended,thecontrollerreturnstostandbymode.Pleasereferto"Figure6:

Controller Operation Flowchart"

In automaticmode, therearethree kindsof differentsub-states:

1.Standbymode:indicatesthatthecontrolleris readytorun theprogram,simplypressthe Run

buttonor the inputsignaltostart theprogram,afterthe run,also inthis state.

9

Positioning

Jump HH_J-BIT

XXXX The first two jumps for the line number indicating the position, the

fifth bit input port IN1-IN2 is one of them; eighth to jump condition

(0 or 1); measured when the input port is set Jump to the

directivelinewhen the state number,otherwise, the order of

execution. END command line number line number is exceeded,

will alarm.

10 Counting

Jump HH_J-CNT

XXXXXXX counter directive, The first two digits is the line number,specify

the location of the jump program; after fiveof theset value. When

the counter counts to or greater thanthe set value, then jump to

aspecific line number,otherwise the order of execution. END

command line number line number is exceeded, it will clarm.

11 Variable

displacement HH_60-AB

±x This directive is the displacement instruction, run mode like

HH-G-LEN±XXXXXXX,different isrunning displacement can't

know aheadof time, thisis avariable displacement, generated

by the interrupt operation, the controller receives an interrupt

signal, the motor slows down to stop, at this point coordinates, is

the variable

12 Counter

is

incremented1

directive

HH 一CNT-1

No arguments This directive counter instruction, the internal controller has a

counter unitwith acapacity of 999,999, the counter value can

display real-time status display counter; counter values are not

automatically saved when power is off, unless you manually click

counter storage key ﹥”.After poweron, it willautomatically be

transferred tothe storedvalue of the latest counter,this counter

incremented1 by this directive.

13 counter clear

directive HH_CNT-0

No arguments This instruction to counter reset; This directive can alsobe

invoked withthe button (in automatic mode),press: V”to clear

counter.

14 Coordinate

cleared HH-CLR Executethisdirective, the current coordinates and display are

cleared, The controllerredefines this coordinates of the new

coordinate zero ..

15 End

of directive HH 一END

No arguments End the program ,When the program is running this directive,

the controller automatically run ends

The directive, can’tbe edited, and always at thelast line ofthe

program.

11 / 17

2.Autorunprogramstatus: indicating thatthecontrollerisrunningthe program.

3.Theautomatic operation stopstate:thecontrolleris running theprogramis thestopbutton or

inputfrom theterminalstopsignalinterruption.Runtheprogramwill waittobe startedagain at

thebreakpoint.

In autorun programstatus:therearethree differentways:( displaybypressing thesamekey

“step “count “∧toshift)

1.Stepnumberdisplay:controllerdisplaysthe currentcoordinatevalues, unit:pulsenumber:

2.Countdisplaymode:Thecontrollerdisplaysthecountervalueof the counterunit:asingle

currentnumber:

3.Programdisplay:controllerdisplaysthe currentprogramlineandinwhichtheprogramname.

Tobeable todistinguish betweenagoodthreesub-stateautomaton statesandthreedisplay

modeon thedisplay,weuseadifferentdisplaymodetodisplaythedifferencebetweenthefirst

two:( seetable below)

Ⅹ.Installation dimensions

Thecontrollerusesthe embeddedinstrumentshell,smallsizeandlightweight(500g),recitethe

frontpanelis 71mm*71mm, lengthof 105mm, specific dimensions shown below:

Display Corresponding state Description

Step number (coordinates)

display,

To be run in automatic mode

When theactualcoordinatevalues

displayed over six digits (including the

sign bit),onlyShowthelastsix

digits

Counter display,

To be run in automatic mode When the value ofthe counter more

than sixdigits,only

Showthelastsixdigits

Program display,

To be run in automatic mode The lastsixdigitsofthe display,in

order toexpress simplecurrent

program withsix-figure line,weused

3,4-bitdisplay the currentline

number:Bit 5Empty:The first

instruction isreferredtoas6,7,8-bit

display (refer to" directivesearch

form "directiveabbreviation)

Steps number,counting,

program three display mode

automatic operation

When the three display mode inthe

automaticoperation display the first

twoare thesame,scilicet

means theprogram under way.

Steps number,counting,

program three display mode

Automatic stop state

When thecurrenttwodigitsflashing,

itmeansthatthe programis

interrupted,the breakpointis

waiting.

12 / 17

Figure Ⅶ:installation dimensions

Ⅺ.Editing andapplication examples:

Example1:

Parameterrequirements: offfrequency 2.5KHz, lifting speedfaster,backlash compensationis 0;

Operational requirements: tospeed2.9KHzrun 98,765steps,thenrun 8765 stepsin the

oppositedirection ata speedof15KHz, stop.

Parameterlist:( Entertheparameterlistparametersetting statuschanges) JF=02500,rS=H,CC

=OOOO.

ProgramListing:00SPEED02900;assignmenttorunbelowthespeed2.9KHz

01 G-LEN0009876 ;motor running98,765 steps forward

02 SPEED15000;assignmenttorun belowthe speedof15KHz

03 G-LEN-0008765 ;8765 stepmotor is runningin theopposite direction

04 END ;End ofprogram;

Example2:

Parameterrequirements: Whenthestarting frequency is2.5KHz,theLiftingspeedisSlowand

Backlash compensationis 12;

OperatingRequirements:Whenrunning,Requirefor thatafterthebuzzertweetfor ashort

time,run1234567stepasthespeedof39KHZ,Making threeoutputsfor 101state,afterdelaying

thetimefor 55.9seconds,letthelasttwooutputs stateis11,Programpausehere,Untilrun

again, letthe motor return tothe startingpointatthesame rateon the otherside thatis

the888steppositions,Afterreaching apredeterminedposition,thebuzzerwilltweetfor along

time,thentheprogram ends!

ParameterList:(Entertheparametersetting mode tomodify) JF =02500,rS=L, CC = 0012.

13 / 17

Program Listing:(enterthe programeditstate)

00 OUTnnn0 ;Letthe buzzertweetfor ashort time

01 SPEED39000 ;Assign thespeedas39KHz

02 G-LEN01234567;Motor runsforward1234567 step

03 OUT101n;Makingthreeoutputsfor 101 state

04 DELAY0055900 ;delayingthe time for 55.9 seconds

05 OUTn11n;letthe lasttwooutputsstate is11

06 PAUSE;Programpausehere

07 GOTO-0000888;letthemotor return tothestartingpointon theothersidethatis the888

steppositions

08 OUTnnn1 ;Letthe buzzertweetfor a longtime

09 END ;theprogramends!

Example3:

OperatingRequirements: (Ignoretheparametersetting) Oneobject,from zerothatrun for

2.9KHz speedtorunforward100 step(this pointasthereferencepointof theobject); Afterthe

referencepointstopped,theoutput is010;Detecttheinput,ifINI =0,themotor willreturn to

zeroatthesamespeed.IfINI ≠0,the motor willrunforward10,000stepsataspeedof15KHz

and letbuzzeralarm for ashort time;And thenwill return tothereferencepointataspeedof

35KHz. If INI =0, thenreturn tozero,Otherwise,continuetofollowthewayof thefirstto

run.Afterreturntozero,Thebuzzerwillalarm for along time.

Program Listing:(enterthe programeditstate)

00 SPEED02900 ;Assign thespeedas2.9KHz

01 G-LEN00000100 ;Motor runs forward100steps

02 OUT010n ;Letoutputstateis 010

03 J-BIT11 1 0;

04 SPEED15000 ;IN1 ≠0,thenassignthe newspeedas15KHz

05 G-LEN00010000;Motor runsforward10000 stepsagain

06 OUTnnn0 ;Letbuzzeralarm for ashorttime

07SPEED35000;Assign the speedas35KHz,Forsettingthespeedof returningtothe

referencepoint

08 GOTO00000100 ;Motor returntothereferencepointatthespeedof15KHz

09 LOOP0300000 ;Motor willrunfor aninfinite loop,until IN1 = 0,it will returntozero

10 SPEED02900 ;Assign thespeedofreturning tozeroas2.9KHz

11 GOTO00000000 ;Motor returns tozeroatthe ofspeed2.9KHz

12 OUTnnn1 ;Afterreturntozero,Thebuzzerwill alarmfor alongtime

13 END ;theprogram ends!

Example4:

OperatingRequirements: (Ignoretheparametersetting)Oneobject,from zerothatrunfor a

high speedtorun forwardUntil itcametothefrontof thelimitswitch,Thenreturn tozeroatthe

samerate, theprogramends.(Assumethesystembeginningfrequency is 500Hz,thedistance

14 / 17

from thezerotoproximity switchisgreaterthan100000steps,lessthan100010steps).Design

analysis: thevariabledisplacementof thismovementdoesnotknowitsprecisevalue,but only

knowit'sageneralrange(belongtoaunknown variable). Weuseamethodfor interrupting

operation tosolvethisproblem. Weconnect thelimit switch totheAoperating port,Duethe

interrupt operation,themotor willslowdowntostop,Ifruntothelimit switch asahigh-speed

directly,will produceovershoot,In ordertoavoid theovershoot,weusethis method thatthefirst

run asahigh-speed,thenrunasa low-speed(low-speedisbelowthestarting frequency).

ParameterList:(Entertheparametersetting modetomodify) Setting A Operator address nA = 04,

otherparametersareignored.

Program Listing:(enterthe programeditstate)

00 SPEED39000 ;assign thespeedas39KHz

01 G-LEN0099000 ;First,high-speedclose to, butcan’thitthelimit switch

02 SPEED00400 ;low-speedfrequencymustbelowthe startingfrequency

03 G-LEN07999999;Theamountofdisplacementissettothemaximum,toreachthelimit

switch

04 SPEED39000 ;A Operator, assign thereturntozerospeedas39KHz

05 GO-AB-A ;In the oppositedirection,running thesame amountof displacement,back tozero

06 END; theprogram ends!

Ⅻ.directive search form

N

O.

Directive

Name Example Instructions, data range, unit Directive

full name Directive

abbreviati

on

1

pause

directive

00

PAUSE

Programpauses, waitingforthe startsignal

PAUSE

PAU

2

displacemen

tdirective

01 G

-

LEN

-1234567

According to the latestSPEED assignmentspeed,reverse

mobile 1234567 step;pulsesnumber

G

-

LEN

G-L

3

Speed

assignment

directive

02 SPEED

12345

Run this

directive

following assignmentspeed;12345Hz

1-39999,pulses /sec (Hz)

SPEED

SPD

4

Delay

directive

03 DELAY

1234567

Delaytime: 1234567 ms 1

-

7999999,ms

DELAY

OLY

5

Uncondition

al jump

directive

04

JUMP

12 Unconditional jump to the line XII program runs

00-99, line number

JUMP

JMP

6

Cycle

directive

05

LOOP

03 12345 Jump from the current line to the (05) to 03 lines

for 12,345 cycles 1-99999 (0 defined as infinite),

Times (only forward loop)

LOOP

LOP

7

Move to

a position

06

GOTO

-1234567 Control themotor running to coordinate the

position of -7999999- +is -1,234,567 7,999,999,

the number of pulses (0 equivalent return to zero)

GOTO

GOT

8

Output

directive

07

OUT

03 01N0 Switch output is: 0UT=(K 0UT2 =1,0UT3

unchanged internal buzzer ashort sound (a =

long beep, N= no sound)

OUT

OUT

15 / 17

ⅩⅢ.Parameters search form

9

Positioning

Jump

08

J

-

BiT

19 20 If IN2 =0, then 1.2 =Linenumber which jumps

to line 19 execution data,

5 = input port, 8 = Jump status

J

-

BIT

J

-

B

10

Counting

Jump

09

J

-

CNT 20

12345 If the countervalue> 12345, then jump to 20-line

program execution 0-59999, natural number

J

-

CNT

J

-

C

11

Variable

displacemen

t

09 GO

-

AB

-A If the motor is running: the absolute valueof the

displacementamount ofA, Aopposite to the

direction and the soil A, ±B, the number of

pulses (Note: A, B itself as a symbol number)

Go-rb GRB

12

Counter

Is

incremented

1

11

GNT

-

1

Value of thecounter is incrementedby 1(Max

count up to 999999)

CNE-I

CNI

13

Counter

iscleared

12

GNT

-

O

Counter iscleared

CNE-O

CNO

14

Coordinate

cleared

13

CLR

Current coordinates and displays are cleared, the

motor this location as a new zero

CLR

CLR

15

End of

directive

13

END

End of program lines, the directivecan’tbe

edited, it always located at the last line.

END

END

N

O.

Name example Data

range

unit Parameter Description

1 Off

frequency JF12345 400-3999

9 Hz According to motor size and load

inertia, etc. to choose parameters

JF

2 Risingand

falling curve rS H L,H Strip L slower; H faster (optimizeddesign)

RS

3 Backlash

compensatio

n

CC1234 0 -9999 Pluse

number Backlashcompensationtransmission

mechanism

CC

4 Manual

increment HH 23456 1-999999 Pluse

number Whenthemanualmode, theamountof

displacementof the stepper motor

HL

5 Manual

speed HF12345 1-39999 Hz Whenthemanualmode, thestepper

motor speed

HF

6 Back tozero

speed bF12345 1-39999 Hz When return to zero

operation ,running speed of the

stepping motor

BF

7 "A

Operation"

entry

nA18 00-99 Line

number Aoperationisinterrupted,theprogram's

entryaddress

NA

8 "B

Operation"

entry

nB18 00-99 Line

number Boperationisinterrupted,theprogram's

entryaddress

NB

9 Pulse mode CP 0 01 CP = O single pulse, CP = I doublepulse

CP

16 / 17

ⅩⅣ.Button search form

Button

Function

Instruction

U

seofstate

U

se

method

run Startthe program runs;

startup programcontinues

to run

Autowaitingtorun stat

us

;

run automaticallystopped state;

When executing directive pause

Click

enter

Confirm the modification of

the parametersarevalid;

Confirm thechangesor

enter the program effective

Parameter setting state;

program editstate

Click

Pause

Pauseprogramisrun

automatically;pausethe

program isbeing run

Automa

ticoperation;manual

operationstatus

Click

cancel

Cancelmodified

parameters;Cancelmodify

or entryprocess

Parameter setting state;program edit

status

Click

home

letmotorreturn tozero

(position whenpower is

on)

Autowaitingtorunstat

us

;The

automaticoperation stopstatus;

Click

Clear

Clear all entered

program;

Programedit

status;

Click for2

seconds or

more

delete

Deletethe currentline

program

Programedit

status;

Click

Auto Converted toautomatic

status: manualstatus;

Click

Jog Converted to manual

status: automatic status;

Click

Insert Position inthe program

abovethe currentrow

insert anewrowprogram

Programedit

status;

Click

Step Displays the status

switches tocoordinate

(steps) display

Autowaitingtorun stat

us

Click

count

Displays the statusswitch

tocountdisplay mode

Autowaitingtorun stat

us

Click

Program

Displays the statusswitch

toprogramdisplay mode

Auto

waitingtorun stat

us

Click

edit

Enter the program edit

status manualstatus;

Click

set

Enter theparameter setting

status manualstatus;

Click for2

seconds or

more

quit

From the programedit

stateorparametersetting

statereturn tomanual

mode,and savethe fileto

savethe modified program

or parameters

Programedit status;parameter

setting status

Click

Move

cursor

to left

Current positionmovetothe

left

Programedit status;parameter

setting status

Click

Quick

View Return afterbrowsing

program,onlytheline

number andprogram

name,as thisprogram to

see thedata,click this

Programedit status

Click

Move

cursor to

down

Currentpositionmovedown

one line

Programedit status;parameter

setting status

Click

17 / 17

Counter

iscleared

The currentcounter valueis

cleared

Autowaitingtorun stat

us

Move

cursor to

right

Current positionmovetothe

right

Programedit status;parameter

setting status

Click

Counter

save Savethe currentcounter

value

Autowaitingtorun stat

us

Click

reset

ResetController

Click

Table of contents