CNC 3018 User manual

3018/2418/1610

CNC Engraving Machine

12

Laser on Machine

Machine Assemble

13

How to connect

13

Package

14

Candle software

19

LaserGRBL

24

Offline instructions

25

FAQ

Attention

3018/2418/1610 has same assemble steps just size different,

please refer to the form below. Here is the assemble manual for 3018:

Name Serial

number Type 3018 2418 1610 Number

Work aera

Weight 8kg 8kg 6kg

001 15180 1

002 2020 360mm 330mm 240mm 5

(1610 4 pcs)

003 2020 330mm 300mm 220mm 2

004 2020 220mm 220mm 200mm 2

300*180mm 240*180mm 160*100mm

300*180mm 250*180mm 180*100mm

/ /

/ /

2020*220mm

M3*6

Optical axis

Optical axis

Z-Axis

Lead screw

Lead screw

Stepper Motor

3.0 Controller

USB Cable

775 Motor Cable

Stepper Motor Cable

Hexagon Socket Screw

Hexagon Socket Screw

Hexagon Socket Screw

Hexagon Socket Screw

M5*8

M5*10

T nut

Slide nut

M6*12

15180*300mm

2020*360mm

2020*330mm

Z-axis

Φ10*400mm

Φ10*330mm

T8*400mm

T8*320mm

42HS34-13D

GRBL 1.1

1500mm

500mm

600mm

M6

M5

1

5

2

2

1

2

2

1

1

2

1

1

1

3

8

4

59

10

63

10

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Root

Root

Root

Root

Root

Root

Root

Root

Root

Root

Set

017

1

Copper nut 2

Corner piece 2028

Pitch 2 Lead 4

16

Support

Nut seat

SK10

T8

8

1

Linear Bearings LM10UU 10*19*29

power supply

ABS isolation column

Drill Bit

Optional

500mw

15000w

1600mw 2500mw

1 Inch Offline 1.8 Inch Offline

3500mw

Motor mounting plate

ER11

X-bearing

Y-bearing

DC24V5A

11*5.2*5

3.175*30°0.1

C16-ER11-35L 5mm

/

/

/

/

/

/

/

1

Word support 2

1

1

1

Pressure plate

Flash Memory Disk

Package

2/2.5/3/4/5 1

Socket wrenches

026 Coupling

027

028

029

030

031

032

033

034

035

036

037

038

039

Gasket

5*8

M5 36

2

1

4

1

1

2

1

4

025

Pair

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Pc

Set

Set

Set

Set

Box

2

3018 Machine Assemble

022: Corner pieces*1 pc

019:T-nut M5*2 pcs

027:Gasket M5*2 pcs

017:M5-10*2 pcs screw

003: Aluminum Profile330mm*2 root

002: Aluminum Profile360mm*3 root

56mm

1

3

035: Y-bearing*1 pc

017:M5-10*2 pcs screw

019:T nut*2 pcs

Note: Place the center of the profile

026:Coupling*1 pc

021:Copper nut*1 pair

Spring*1

024:Nut seat*1 pc

009:Lead screw320mm*1 pc

2

3

4

4

033: Motor mounting plate*1pc

010: Stepper Motor*1 pc

015:M3-6*4pcs Screw

5

019:T nut*2 pc

017: M5-10*2 pcs screw

027:M5 Gasket*2 pcs

5

017: M5-10*8 pcs screw

019: T nut*8 pcs

025: Linear Bearings*2 pcs

023: Support*1 pc

007: Optical axis 330mm*1 root

Y axis assemble belt

018:M6-12*10 pcs screw

020:Slide nut*10 pcs

8

7

6

6

9

10

11

001:Aluminum Profile*1 root

7

017: M5-10*2 pcs screw

027: M5 Gasket*2 pcs

019: T nut*2pcs

019: T nut*2pcs

022: Corner piece*1pc

016: M5-8*2 pcs screw

Flat bracket*1 pc

002:2020-360mm*2 root

004:2020-220mm*2 root

56mm

12

13

8

026:Coupling*1 pc

006:Optical axis 400mm*1 root

017: M5-10*8 pcs screw

019: T nut*8pcs

023:Support*4 pcs

005: Z-Axis*1set

Spring*1

008:T8-400mm*1 pc

021:Copper nut*1 pair

15

16

17

14

9

033: Motor mounting plate*1pc

010: Stepper Motor*1 pc

017:M5-10*2 pcs screw

027: Gasket*2 pcs

015:M3-6*4 pcs screw

019: T nut*2 pcs

017:M5-10*1 pc screw

019: T nut*1 pc

034: X-bearing*1 pc

18

19

10

017:M5-10*4 pcs screw

011:Controller*1 pc

019: T nut*4 pcs

030:ABS isolation column*4 pcs

20

11

2cm

12

Package

How to connect

13

User manual

1.Overview

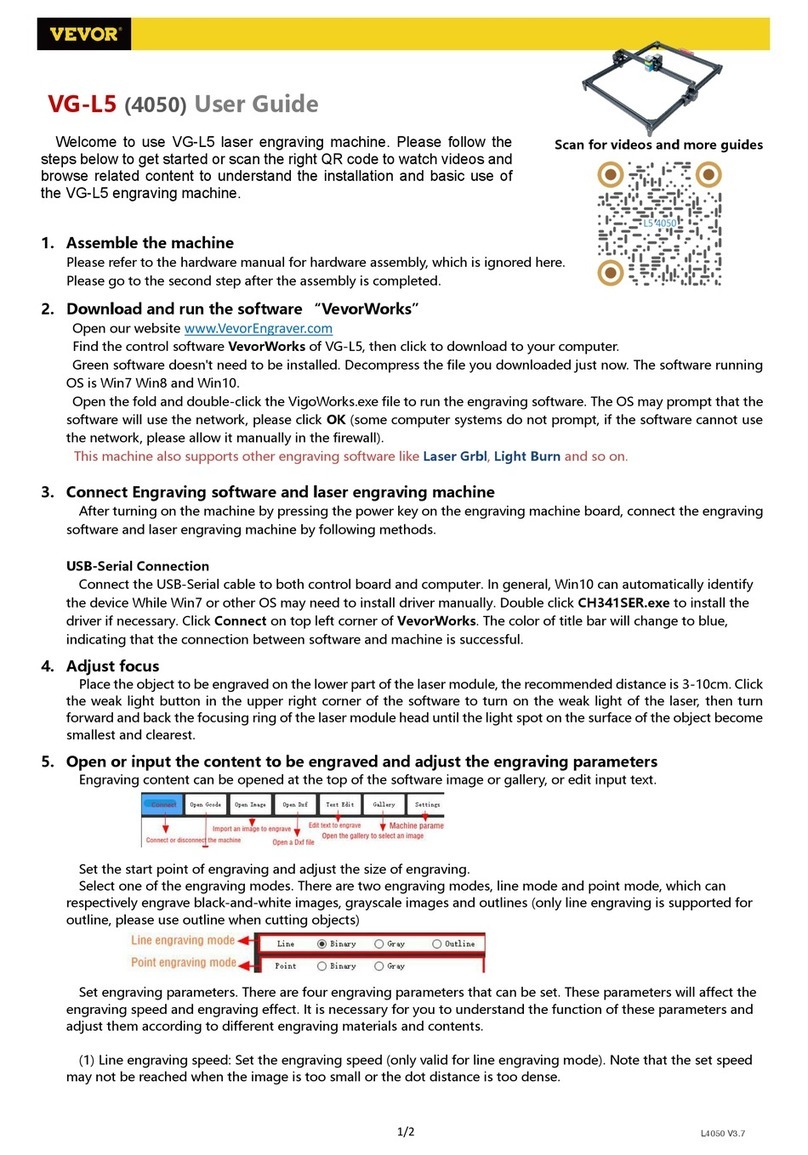

Candle is an open source software suitable for CNC machine tool processing. It supports G code file processing and

visual display.

2.Install the driver

For the first time use, please connect the device to the computer via USB cable, and click the CH340-Driver.exe file

in the driver folder to install the driver. Under normal circumstances, the Win10 system will automatically identify

and install the driver. For Win7 and Win8 systems, please install it manually.

Driver install(X64)

Driver install/remove

Choose INF file:

Install

Remove

Help

3. Set the port

After installing the driver, open the device manager of the computer and click on the port option to see the content

inside the red box on the screen shown in the figure below (the port information is in brackets).

Remember the port information queried above, switch to the Candle software interface and click the "Settings" option

in the upper left corner. Selecting the setting will bring up the interface. Under "Connection", select the port name you

queried, select the baud rate 115200, and then click below The icon "Finish" ends the setting

Candle software

14

4. Connection is complete

After setting the port and baud rate, click Finish. The status bar at the top right of the Candle interface will show Idle,

and at the same time, the console at the bottom right will display the information shown below, indicating that the

connection has been successfully established.

15

5. Processing documents

The "File" option at the top, click "New" to create a G code in the command bar at the bottom of the interface, and

click "Open" to select a G code file that has been made, and then you can import the file. After importing, the middle

of the interface will display a visual graph composed of tool paths (the position of the pen-shaped graph in the graph

is the current tool position). In the visualization window, hold down the left mouse button to move to rotate the graph,

and hold down the right button to move. Graphics, scrolling the middle wheel can zoom in and out of the graphics.

At the same time, the content of the G code will be displayed in the lower command bar. During processing, the

machine will run one by one according to the G code commands.

16

This manual suits for next models

2

Table of contents