1/2

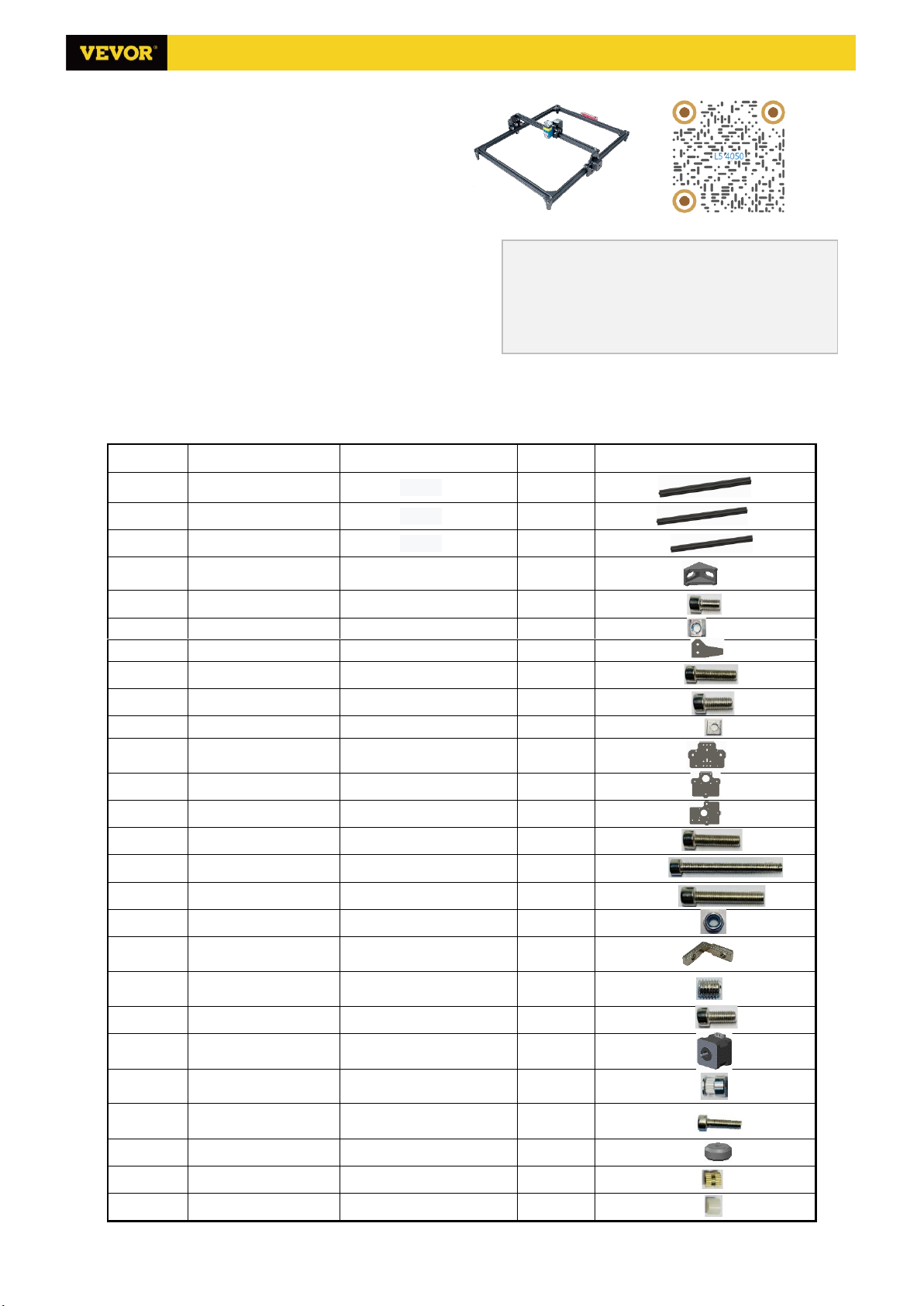

VG-L5 (4050) User Guide

Welcome to use VG-L5 laser engraving machine. Please follow the

steps below to get started or scan the right QR code to watch videos and

browse related content to understand the installation and basic use of

the VG-L5 engraving machine.

Scan for videos and more guides

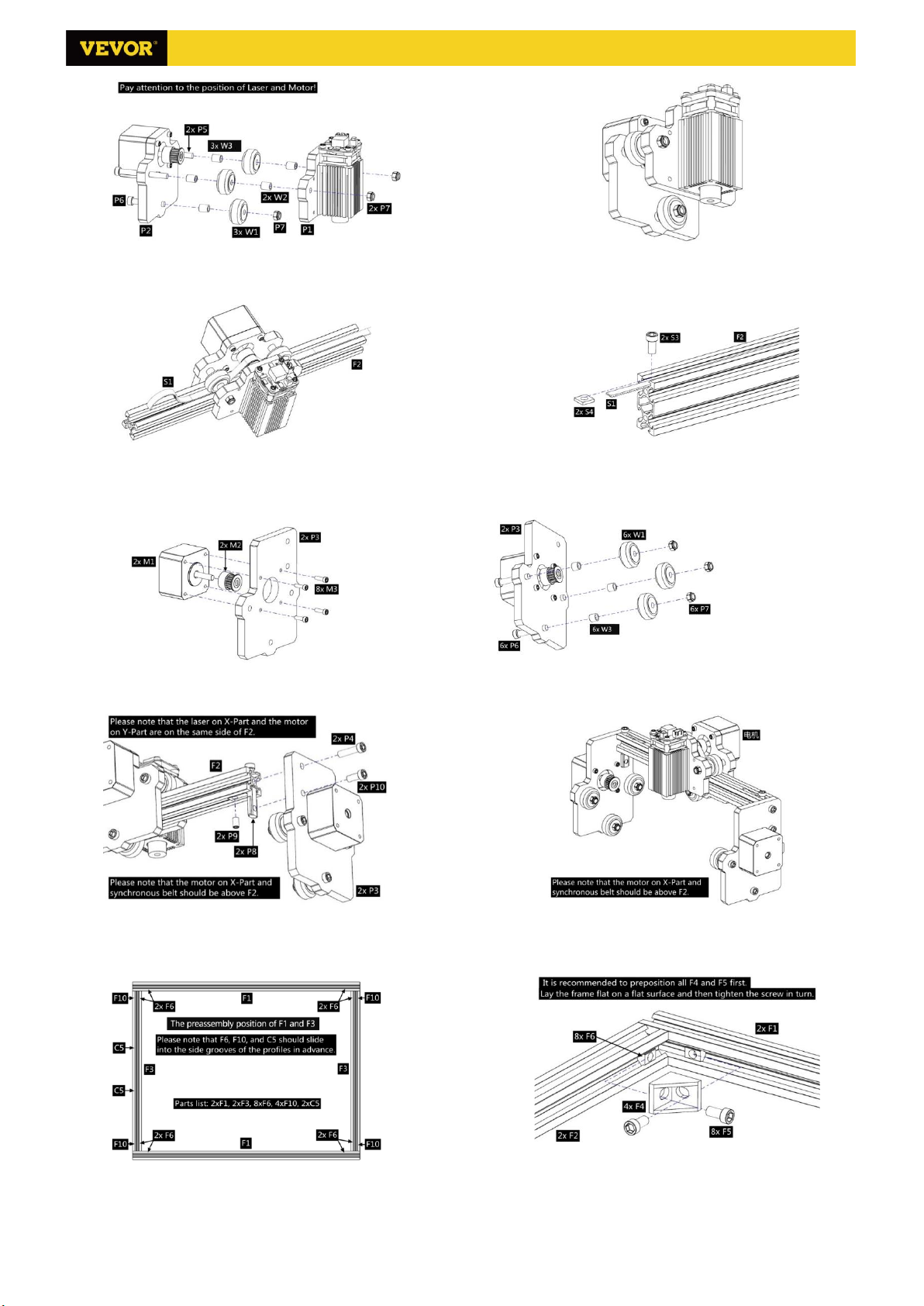

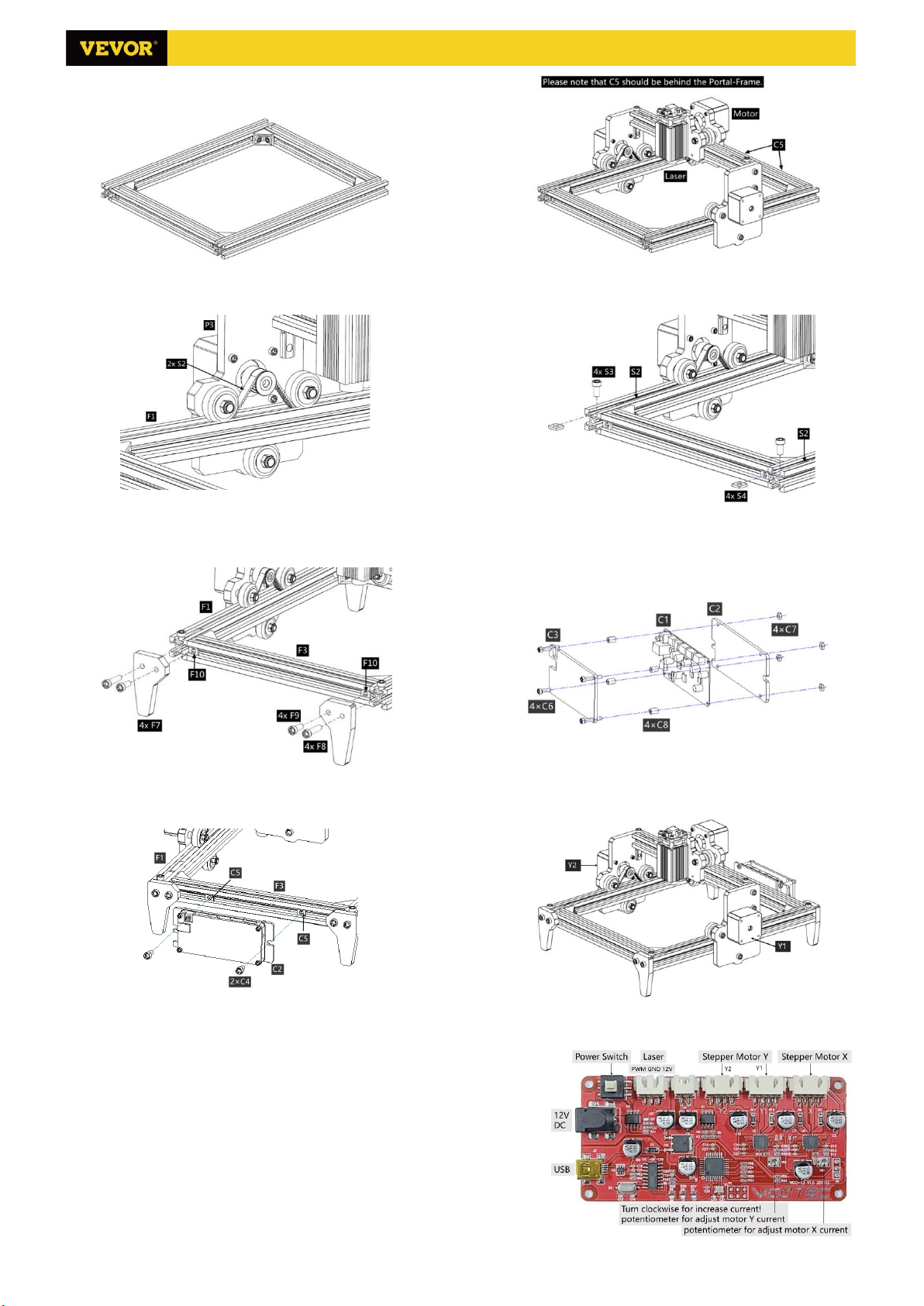

1. Assemble the machine

Please refer to the hardware manual for hardware assembly, which is ignored here.

Please go to the second step after the assembly is completed.

2. Download and run the software “VevorWorks”

Open our website www.VevorEngraver.com

Find the control software VevorWorks of VG-L5, then click to download to your computer.

Green software doesn't need to be installed. Decompress the file you downloaded just now. The software running

OS is Win7 Win8 and Win10.

Open the fold and double-click the VigoWorks.exe file to run the engraving software. The OS may prompt that the

software will use the network, please click OK (some computer systems do not prompt, if the software cannot use

the network, please allow it manually in the firewall).

This machine also supports other engraving software like Laser Grbl, Light Burn and so on.

3. Connect Engraving software and laser engraving machine

After turning on the machine by pressing the power key on the engraving machine board, connect the engraving

software and laser engraving machine by following methods.

USB-Serial Connection

Connect the USB-Serial cable to both control board and computer. In general, Win10 can automatically identify

the device While Win7 or other OS may need to install driver manually. Double click CH341SER.exe to install the

driver if necessary. Click Connect on top left corner of VevorWorks. The color of title bar will change to blue,

indicating that the connection between software and machine is successful.

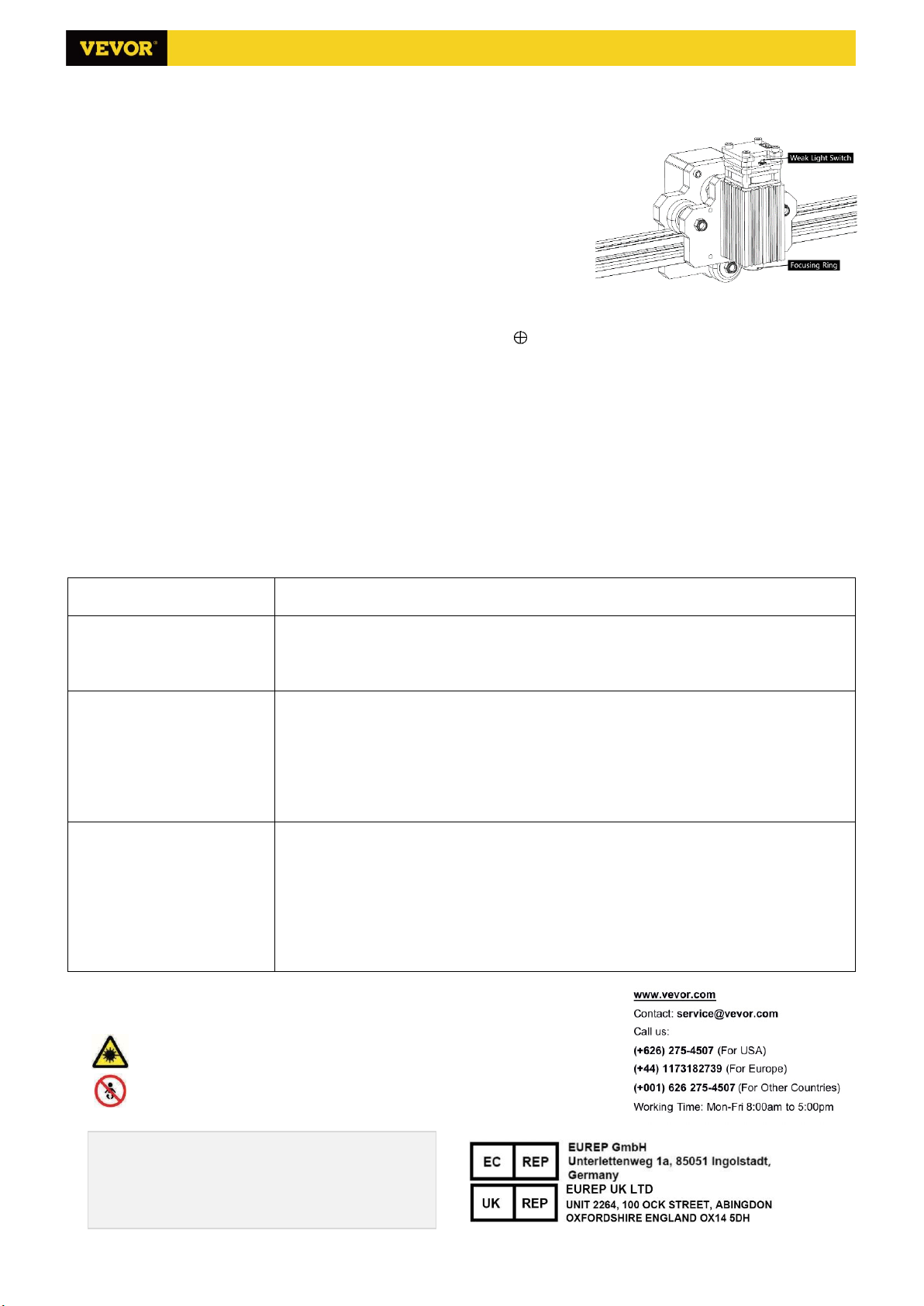

4. Adjust focus

Place the object to be engraved on the lower part of the laser module, the recommended distance is 3-10cm. Click

the weak light button in the upper right corner of the software to turn on the weak light of the laser, then turn

forward and back the focusing ring of the laser module head until the light spot on the surface of the object become

smallest and clearest.

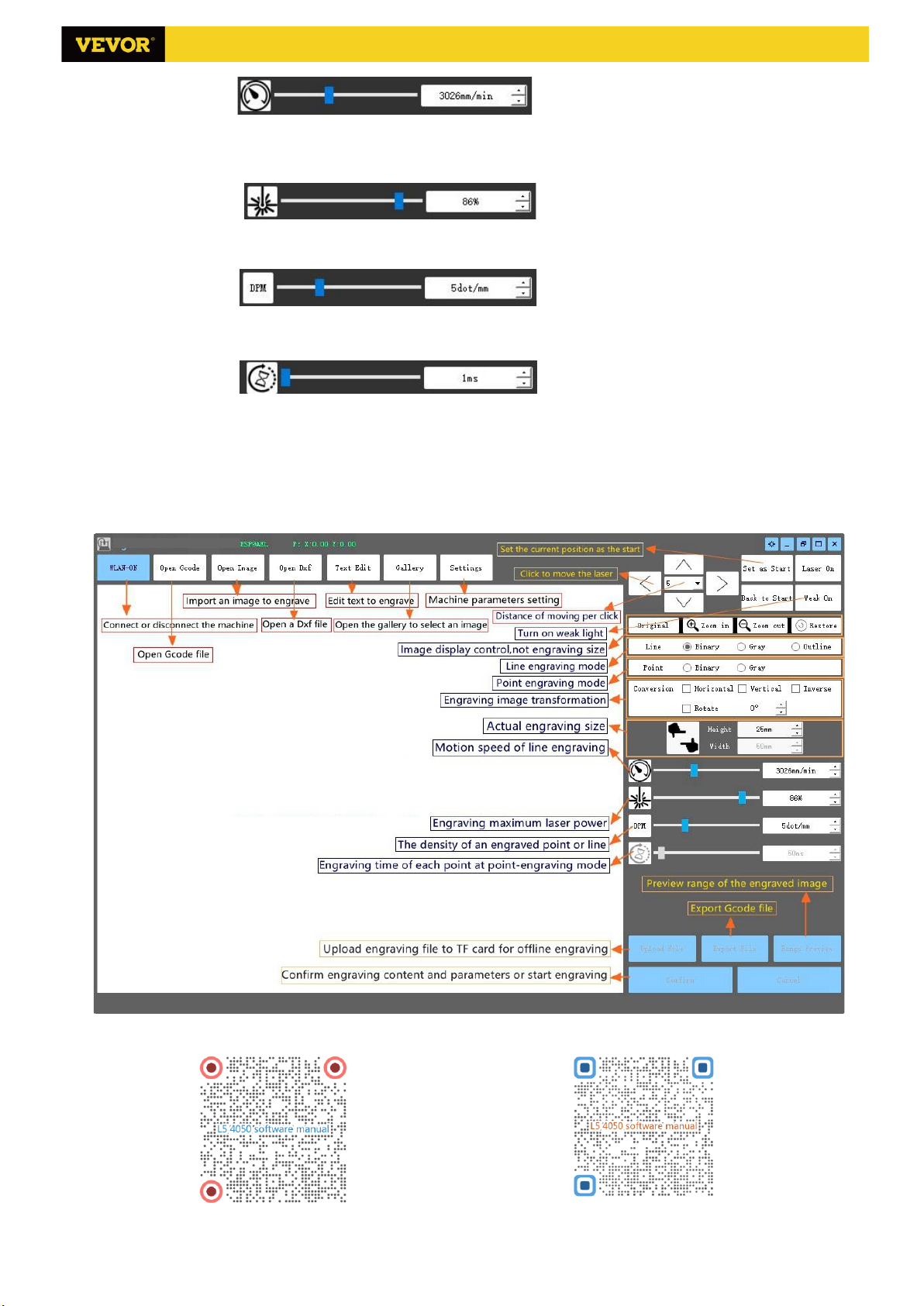

5. Open or input the content to be engraved and adjust the engraving parameters

Engraving content can be opened at the top of the software image or gallery, or edit input text.

Set the start point of engraving and adjust the size of engraving.

Select one of the engraving modes. There are two engraving modes, line mode and point mode, which can

respectively engrave black-and-white images, grayscale images and outlines (only line engraving is supported for

outline, please use outline when cutting objects)

Set engraving parameters. There are four engraving parameters that can be set. These parameters will affect the

engraving speed and engraving effect. It is necessary for you to understand the function of these parameters and

adjust them according to different engraving materials and contents.

(1) Line engraving speed: Set the engraving speed (only valid for line engraving mode). Note that the set speed

may not be reached when the image is too small or the dot distance is too dense.