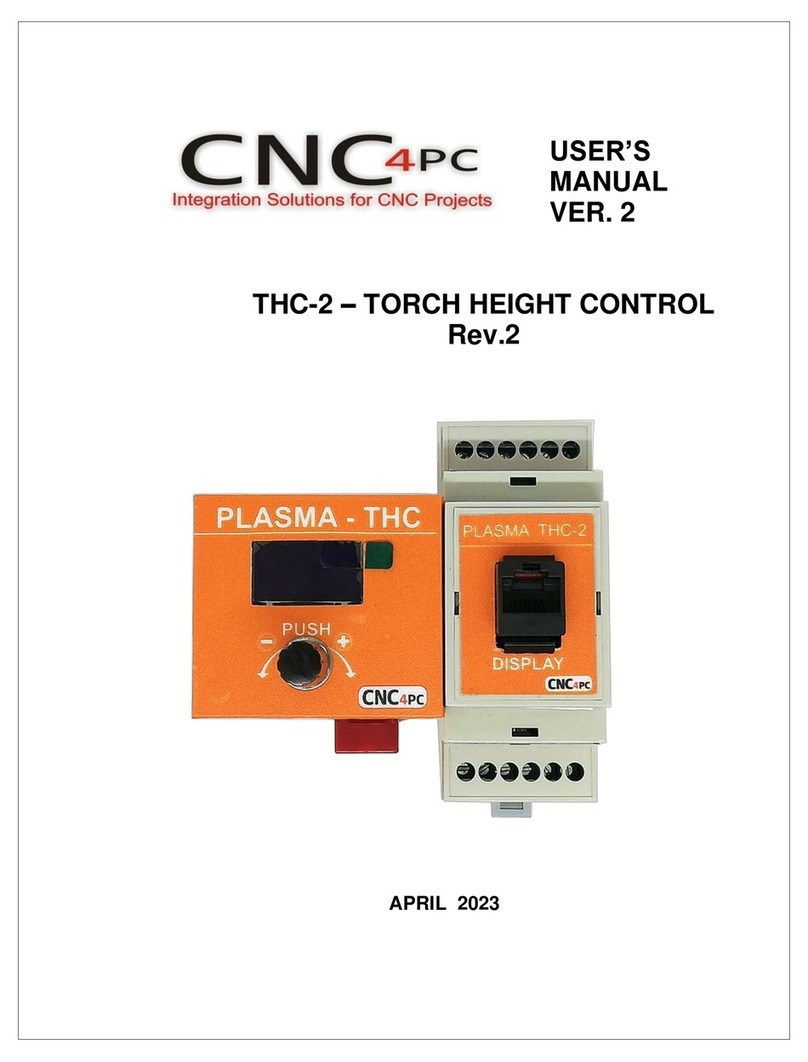

CNC4PC THC-1 User manual

USER’S

MANUAL

VER. 2

THC-1 –TORCH HEIGHT CONTROL

Rev.2

APRIL 2023

USER'S MANUAL

TABLE OF CONTENTS

Contents Page #

1.0 OVERVIEW..........................................................................................................................1

2.0 FEATURES..........................................................................................................................1

3.0 DESCRIPTION ....................................................................................................................2

4.0 TERMINAL BOARD............................................................................................................3

4.1 POWER....................................................................................................................................3

4.2 DIVIDED INPUT.......................................................................................................................3

4.3 TORCH VOLTAGE ..................................................................................................................4

4.4 OUTPUT SIGNALS..................................................................................................................4

5.0 CONFIGURE MENU............................................................................................................5

6.0 DESCRIPTION SCREEN ....................................................................................................6

6.1 SET POINT (SP)......................................................................................................................6

6.2 VOLTAGE ARC (ARC).............................................................................................................6

6.3 HYSTERESIS (HYS)................................................................................................................6

6.4 DELAY TIME (DT)....................................................................................................................6

6.5 TEST MODE (TEST)................................................................................................................7

6.6 DIVIDED VOLTAGE CONFIGURATION.................................................................................7

6.6 ANALOG SMOOTING..............................................................................................................7

6.7 ANTI-DIVE................................................................................................................................7

6.7 AUTO_SETPOINT...................................................................................................................8

7.0 WIRING SAMPLE................................................................................................................9

User’s Manual Page 1

1.0 OVERVIEW

This module allows controlling the height the plasma torch head relative to work piece during

plasma CNC operation, it supports either raw torch head voltage or an input of 0-10VDC, the ARC

OK, UP and DOWN outputs are isolated.

2.0 FEATURES

•Open collector to optoisolated output working at 5 to 24VDC.

•Built-in Voltage Divider for connecting to the voltage on the torch or can use the 0-10VDC

from a voltage divider from the plasma.

•LCD Screen.

•10 to 30VDC Power Terminal (+24 Typical).

•Isolated Power Connection.

•Din Rail Mountable.

•Divider input.

User’s Manual Page 2

3.0 DESCRIPTION

User’s Manual Page 3

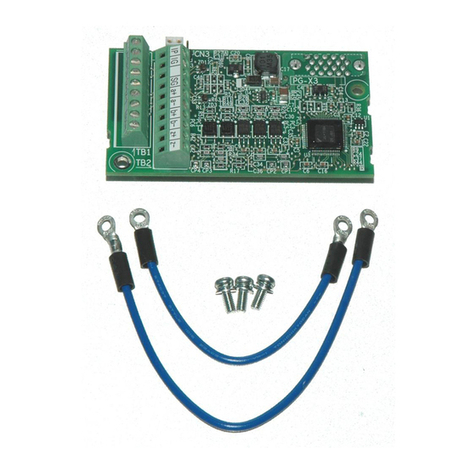

4.0 TERMINAL BOARD

4.1 POWER

Requires a 10 to 30VDC at 100mA Power Supply, “This board is electrically isolated through a

DC-DC converter.”

WARNING: Check the polarity and voltage of the external power source and connect

the 10VDC to 30VDC and GND. Overvoltage or reverse-polarity power applied to these terminals

can cause damage to the board, and/or the power source.

4.2 DIVIDED INPUT

NOTE:

Divided input is adjustable according to the plasma splitter.

User’s Manual Page 4

4.3 TORCH VOLTAGE

NOTE:

It is preferable to use the divided voltage instead of the torch voltage. The Torch voltage can be very

high and there could be many safety implications in wiring this to the controller. The high voltage could

also be a possible source of noise. Use it as a last resource.

4.4 OUTPUT SIGNALS

Voltage applied can be from 5 to 80VDC@50mA, outputs signal optoisolated Open Collector.

NOTE:

It is recommended to capture and send to the controller the ARC OK signal coming directly from

the plasma machine itself. If wiring is difficult, then use the terminals of the THC unit.

User’s Manual Page 5

5.0 CONFIGURE MENU

•Push the knob to enter configuration mode.

•Navigate through the configuration menu by pressing the knob.

•Turn the knob to adjust the value.

•Push the knob to set the value and navigate to the next parameter or until you reach the run

mode.

User’s Manual Page 6

6.0 DESCRIPTION SCREEN

6.1 SET POINT (SP)

SP is the target voltage to be achieved.

NOTE: If auto_SetPoint is activated the knob it's disabled

6.2 VOLTAGE ARC (ARC)

Limit from 40 to 400VDC, True Voltage measured at the terminals or the voltage divider.

6.3 HYSTERESIS (HYS)

Is the tolerance or (+/-) voltage range used to generate an adjustment. The torch height is not

commanded to adjust if the true voltage is inside the specified range. It can be between 2 to

32VDC.

6.4 DELAY TIME (DT)

Torch motion starts the number of seconds you set as DT after the ARC signal is determined.

This can be a value between 0.1 to 9.9 seconds.

User’s Manual Page 7

6.5 TEST MODE (TEST)

•Press the knob three times to enter test mode.

•Turn the knob up or down to make the spindle move.

•To exit test mode, press the knob once.

6.6DIVIDED VOLTAGE CONFIGURATION

•Press the knob three times to enter the setting mode

•Turn the knob to adjust the value.

•Press the knob to set the split voltage

6.6 ANALOG SMOOTING

This data smoothest the voltage reading. This can be a value between 0 to 3.

6.7 ANTI-DIVE

If the plasma torch moves over empty space, the THC will see it as a voltage spike. Setting a

max voltage value will allow the THC to ignore the voltage spike and prevent the torch from

diving. This can be a value between 50 and 300V.

User’s Manual Page 8

6.7 AUTO_SETPOINT

Automatically establishes the SetPoint based on the cutting height that is set.

ACTVATE DISABLE

If auto_SetPoint is activated the knob it's disabled and the word Auto is displayed on the screen

User’s Manual Page 9

7.0 WIRING SAMPLE

Disclaimer:

Use caution. CNC machines can be dangerous machines. Neither DUNCAN USA, LLC

nor Arturo Duncan is liable for any accidents resulting from the improper use of these

devices. This product is not a fail-safe device and it should not be used in life support

systems or in other devices where its failure or possible erratic operation could cause

property damage, bodily injury or loss of life.

Table of contents

Other CNC4PC Controllers manuals

Popular Controllers manuals by other brands

DLC

DLC OMNI CONTROL installation guide

Interactive Furniture

Interactive Furniture Advanced 4020 manual

Mesto

Mesto QUADRA-POWR X Installation maintenance and operating instructions

Habasit

Habasit PMR-06 General manual use and maintenance

Lenze

Lenze ETCHC Series, ETCHM Series Mounting instructions

motortronics

motortronics VCM series quick start guide