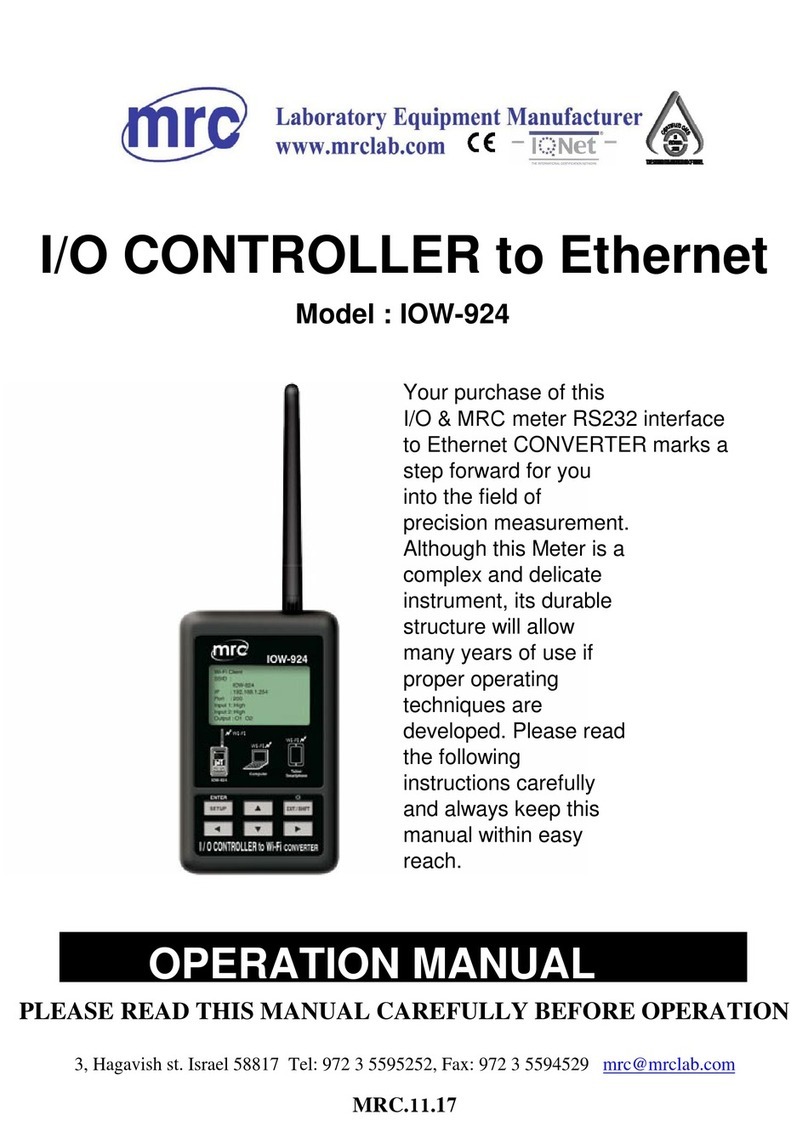

TABLE OF CONTENTS

1.FEATURES.................................................................1

2.SPECIFICATIONS.......................................................1

2-1 General Specifications..........................................

1

2-2 Electrical Specifications........................................

3

3.FRONT PANEL DESCRIPTION.....................................

4

3-1 Display................................................................4

3-2 PV ( process value ) indicator...............................

4

3-3 SV ( set value ) indicator......................................4

3-4 Set Button...........................................................4

3-5 Button............................................................

▼4

3-6 Button............................................................

▲4

3-7 Function Button................................................... 4

3-8 Control relay indicator..........................................4

3-9 Alarm relay indicator............................................4

3-10 RPM indicator....................................................

4

3-11 ft/min indicator..................................................4

3-12 m/min indicator................................................. 4

3-13 Wire terminals...................................................

4

3-14 Case holder ......................................................

4

3-15 RS232 terminal.................................................. 4

4.MEASURING PROCEDURE..........................................

5

4-1 Terminal connection.............................................5

4-2 RPM measurement...............................................6

4-3 Surface speed ( m/min., ft/min. )

measurement......................................................6

4-4 1st layer setting procedures.................................

8

4-5 2nd layer setting procedures................................

10

5. RS232 PC SERIAL INTERFACE....................................14

6. SYSTEM RESET.........................................................15

7. OPTIONAL PROXIMITY SENSOR, PX-01 .....................16

8.

HE ADDRESS OF AFTER SERVICE CENTER................

17