Cobolt 06-01 Series User manual

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

Plug and play modulatable CW

lasers

405 nm

515 nm

633 nm

445 nm

532 nm

638 nm

473 nm

553 nm

647 nm

488 nm

561 nm

660 nm

Cobolt 06-01

Series

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

2| 52

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

3| 52

CONTENTS

Introduction 5

Safety 6

General 6

Safety features 8

Equipment Safety 9

Quick Start Guide 10

06-MLD 10

06-DPL 12

Closedown operation 13

Overview 14

Model number 14

Configuration 15

Warning and Identification Labels 16

Laser head 18

Key control box 18

Thermal management 19

Power supply requirements 19

System Description 20

Specification 20

Mechanical Drawings 23

Remote Interlock Connector 25

Direct On/Off control 26

Pin assignment 27

Continuous wave operation 31

Modulation mode operation 31

06-MLD 31

06-DPL 34

Operation via data port 38

Data port connections 38

Handshaking 38

USB driver 38

Communication commands 41

Cobolt Monitor™ Software 43

Installation 43

Software instructions 43

Troubleshooting 49

Warranty and Maintenance 50

Service 50

Compliance (CDRH models only) 51

Disclaimer 51

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

4| 52

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

5| 52

Introduction

The Cobolt 06-01 Series offers a compact form factor and a wide wavelength span in a plug and play format. The

Cobolt 06-01 Series lasers consist of high performance fixed wavelength laser modules; modulated laser diodes (MLD)

and diode pumped lasers (DPL) cover a spectral range between 405 nm and 660 nm.

The lasers offer optimum beam quality and modulation performance in a compact package, manufactured using

Cobolt’s unique HTCure™ Technology ensures world-class quality and reliability, as well as unmatched robustness.

Cobolt 06-01 Series lasers add the feature of direct intensity modulation capability, allowing fast and deep modulation

from versatile input signals. Cobolt has designed an easy-to-integrate, compact laser with all control electronics fully

integrated in a laser head of industry standard size. The Cobolt 06-01 Series lasers are intended for stand-alone use in

laboratory environments or integration in analytical instruments for life science including fluorescence microscopy,

flow cytometry and DNA sequencing.

Cobolt 06-MLD lasers can be supplied with an ultra-compact and robust fiber delivery option. The fiber is permanently

aligned and fixed inside the laser sub-package, using Cobolt HTCure™Technology, ensuring stable optical output and

high polarization extinction ratio (PER > 100:1) over a large temperature range, as well as very high level of

insensitivity to transport conditions. The standard configuration is 1 m SM/PM fiber with 3 mm jacketing and FC/APC

output connector (non-collimated), but the design is intended for OEM use and type of fiber, connector and lengths

can be customized. See section 5.1.2 for available wavelength and power combinations.

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

6| 52

Safety

General

All Cobolt 06-01 Series lasers are Class IIIB (CDRH), Class 3B (IEC) laser products which emit less than 500 mW of laser

radiation within the visible spectrum. The residual emission does not exceed Laser Class 1.

Eye and skin exposure to direct or reflected laser light is hazardous and may be extremely harmful. Always wear eye

protection appropriate to the beam wavelength and intensity. Lasers may pose a risk of igniting flammable materials

and in event of ignition gasses and fumes may be generated. All equipment used in close proximity to the laser beam

should be suitably fire resistant and the facility should be properly ventilated. It is advised to perform a risk assessment

for the facility and equipment prior to using the laser. In the case of integration into a larger system, laser safety

compliance must be evaluated in the end product. The device must be handled by skilled personnel experienced with

lasers, in a laboratory environment and with access to adequate laser safety equipment.

The laser head clearly displays a yellow warning label that shows the location of the laser beam aperture. This label

must be visible unless the laser beam is totally enclosed.

If the laser does not function, do not attempt to open any of the units, or the warranty will be voided. Call or e-mail

your local Cobolt representative for consultancy and to request an RMA number (see back cover for contact

information).

CAUTION Use of controls or adjustments or performance of any procedures other than those

specified herein may result in exposure to hazardous radiation.

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

7| 52

Accessible Emission

The table below describes the irradiance in W/cm2and appropriate level of eye protection in terms of optical density

(OD) for each product line.

Product

Nominal Output Power

(mW)

Irradiance

(W/cm2)*

Eye protection

Requirement**

Cobolt 06-MLD 405 nm

120

47

4

300

117

4

Cobolt 06-MLD 445 nm

100

39

4

Cobolt 06-MLD 473 nm

100

39

4

300

117

4

Cobolt 06-MLD 488 nm

60

23

3

200

78

4

Cobolt 06-MLD 515 nm

80

31

3

Cobolt 06-DPL 532 nm

200

71

3

Cobolt 06-DPL 553 nm

50

18

3

Cobolt 06-DPL 561 nm

100

35

3

Cobolt 06-MLD 633 nm

80

31

3

Cobolt 06-MLD 638 nm

180

70

3

Cobolt 06-MLD 647 nm

130

51

3

Cobolt 06-MLD 660 nm

100

39

3

* Irradiance (W/cm2) = 110% of Nominal Power (W) Beam Area at bottom tolerance (cm2)

** Eye protection (OD) = Log10( Max Power (W) 60825-1 Emission Limit : Class 1 (W) ) , rounded up to the next integer.

CAUTION Always wear the appropriate eye protection for all of the specified emitted wavelengths.

Verify the accessible emission wavelengths and power levels on the warning label before operating.

Fiber Pigtailed Option

All safety recommendations in section 2.1 are also valid for the Cobolt 06-01 series fiber pigtailed laser heads.

Additionally, heat generated from absorption of laser radiation by particles on the fiber end may increase the

probability of ignition hazards in certain environments. Always clean the fiber end before turning on the laser. In

systems where the beam is exposed, fiber end must be mounted < 2 m from the emission warning LED on the key

control box. It is advised to perform a risk assessment for the facility and equipment prior to using the laser. In the

case of integration into a larger system, laser safety compliance must be evaluated in the end product.

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

8| 52

Safety features

The laser is equipped with all required safety features as described in the laser safety standard IEC 60825-1. If any part

of the delivered equipment is replaced with a part not supplied by Cobolt or if the equipment is not properly grounded

system may not conform to CE / CDRH compliance standards listed in section Fel! Hittar inte referenskälla..

Disabling any of the safety features nullifies the CE marking and violates the laser safety standard.

Remote Interlock Connector

The remote interlock connector is a connector which permits the connection of external controls placed apart from

other components of the laser product. When the terminals of the connector are open-circuited, emission is

interrupted and no radiation will be accessible. The remote interlock connector permits easy addition of an external

interlock in laser installation. See section 5.3 for a detailed description of the remote interlock circuit and operation.

Manual Shutter (Beam Stop)

The laser head is equipped with a manual shutter, which functions as the beam stop, capable of preventing human

access to laser radiation. The aperture location and the open and close positions of the shutter are indicated on the

top surface of the laser head. For 06-03 fiber pigtailed lasers, the fiber end cap is considered the ‘manual shutter’

Key Control

The CDRH compliant model comes with a key control box which must be connected for the laser to operate. When

the key is in the OFF position, the diode is prevented from emitting. The key must be actively turned to the ON

position each time the laser is powered on. When the key is removed from the system laser radiation is not accessible.

Laser Radiation Emission Warning

The key control box, which is part of the CDRH compliant models, incorporates LEDs which indicate the status of the

Laser. The “ON” LED is illuminated whenever the device is emitting or could emit light. See section 4.3 for details on

the key control box. The emission warning indicators are also visible in the Cobolt Monitor™ software, see section 9

for details on the control software.

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

9| 52

Equipment Safety

Back Reflection Sensitivity

Laser light reflected directly back into the laser head causes damage to the laser diode and results in a dramatic

decrease in product lifetime. 06-MLD lasers with a wavelength greater than 600 nm are particularly sensitive, exercise

extreme caution.

Electrostatic discharge

Always install the laser system to a properly grounded power outlet. Cobolt lasers contain a laser diode which is

sensitive to electrostatic discharge (ESD).

Fiber care

It is important to always make sure the fiber end-face is clean before turning the laser on and before connecting the

fiber connector in physical contact with another connector. Failure to do so may lead to irreparable damage of the

fiber end-face. Do not clean the fiber when the laser is on. We recommend using appropriate equipment for fiber

cleaning and inspection.

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

10 | 52

Quick Start Guide

06-MLD

1. Mount the laser on a heat sink or suitable flat surface that provides adequate heat dissipation and connection

to ground. Use the four holes on the laser’s base plate to secure it.

2. Attach the 15-pin D-SUB cable to the laser head.

3. Attach the 15-pin D-SUB cable to the Control Box.

4. Insert the interlock plug into the connector on the laser head.

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

11 | 52

5. Connect the supplied 5V power supply unit to the socket on the laser head, and plug it in to the mains.

6. To start the laser, turn the key on the Control Box clockwise to the ON position. If it is already in the ON

position, turn it to OFF and then ON again. Light will be emitted as soon as the key is turned.

7. The laser will now start up in continuous-wave, constant current mode at its nominal maximum power level.

The power and wavelength may continue to drift for up to 3 minutes while the temperature of the platform

stabilizes.

NOTE If the power does not match the power as stated on the test sheet see Section12: Service for more

information.

Modulation quick-start

There are three ways of modulating the 06-MLD (digital, analog, and on/off modulation), the simplest of which is the

on/off modulation feature, which requires no data connection to the laser. Here is a quick guide to getting on/off

modulation up and running. For a detailed guide to operating the laser in modulation modes see section 6.3.

1. Set your signal generator to give a square-wave with an amplitude of 5V peak-to-peak.

2. Connect the input from the signal generator to the socket labelled “ON/OFF MOD” on the Control Box via a

3.5 mm stereo plug (section 6.3 contains details on wiring the plug).

3. When the system is connected to a signal generator it will automatically enter on/off modulation mode.

4. When an input signal is received the laser will begin modulating (5 V = on, 0 V = off). The peak power is set by

default to the laser’s nominal maximum power.

5. To return to continuous-wave mode, disconnect the connector from the “ON/OFF MOD” socket, then restart

the laser by turning the key off and on again.

!

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

12 | 52

06-DPL

When delivered the lasers are, by default, set to continuous-wave, constant power mode. As soon as power is supplied

to the laser head the auto-start procedure will begin. Light will be emitted once the remote interlock connector is

connected, the shutter is open and when the key is turned to the ON position (CDRH model).

1. Mount the laser on a heat sink or suitable flat surface that provides adequate heat dissipation and connection to

ground. Use the four holes on the laser’s base plate to secure it.

2. Attach the 6-pin Molex cable to the laser head. Be sure the orange arrow is facing the top (labelled) side of the

laser head.

3. Attach the 15-ping Sub-d end of the cable to the key control box.

4. Insert the remote interlock plug into the connector on the key control box.

5. Connect the supplied 5 V power supply unit to the socket on the laser head, and plug it in to the mains.

6. To start the laser, turn the key on the control box clockwise to the ON position. If it is already in the ON position,

turn it to OFF and then ON again.

7. The laser now goes through the following auto-start sequence:

•Temperature stabilization (1-2 min).

•Turn the key switch to start the laser. Status LEDs: ON goes on. (CDRH model only)

•The laser light is emitted in a constant warm-up current for 60 sec.

8. The laser will now start up in continuous-wave, constant power mode at its nominal maximum power level. The

power and wavelength may continue to drift for up to 3 minutes while the thermoelectric cooler (TEC) stabilizes.

NOTE If the power does not match the power as stated on the test sheet see Section12: Service for more

information.

!

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

13 | 52

Modulation Quick start guide

The 06-DPL can be modulated with digital modulation, analog modulation or a combination of the two. The simplest

of which is the digital modulation. Here is a quick guide to getting digital modulation up and running. For a detailed

guide to operating the laser in modulation modes see section 6.3.

1. Set your signal generator to give a square-wave, 0-5 V.

2. Connect the input from the signal generator to the SMA connector on the back of the laser head.

3. Choose digital modulation mode in the Cobolt Monitor™ software (see section 9 for software installation

instructions).

4. When an input signal is received the laser will begin modulating (5 V = high, 0 V = low). The peak power is set

by High current setting in the software.

Closedown operation

1. Turn the key switch to OFF first (CDRH models only).

2. Disconnect PSU from mains outlet.

3. Disconnect laser from PSU.

4. Disconnect laser head from Key control box (only required for shipping).

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

14 | 52

Overview

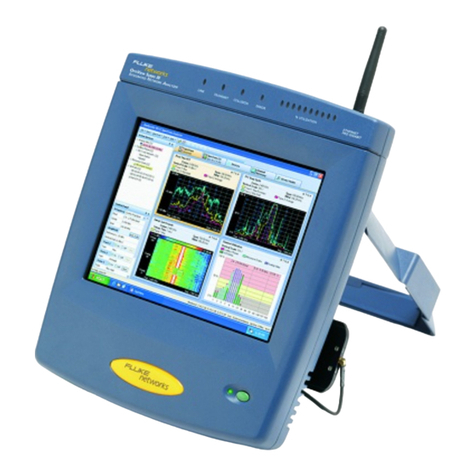

Cobolt 06-01 Series laser systems consist of four main parts: the laser head, key control box, cable between laser head

and key control box, and the power Supply (not shown). Always install the laser system to a properly grounded power

outlet.

Cobolt 06-MLD with CDRH compliant key control box

Model number

Cobolt 06-01 Series lasers are sold in two configurations; CE/CDRH compliant and OEM, described in section 4.2.

The model numbers are composed as described below:

Wavelength Indicator

Laser Head

Model

Power

Configuration:

100 = CE / CDRH Compliant

200 = OEM

xxx = OEM customization

XXXX –06 –XX –XXXX –XXX

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

15 | 52

Configuration

CE/CDRH Compliant

The CE/CDRH compliant system is supplied with a key control box, which must be connected, along with a remote

interlock connector. Once power is supplied, laser emission starts when the key is turned from the OFF position to the

ON position. The status of operation can be monitored via LEDs on the key control box. Setting the key to its OFF

position puts the laser in stand-by mode.

The standard CDRH model consists of:

•Laser head

•Key control box

•Keys

•5 V power supply unit

•Remote interlock plug (for short circuiting the remote interlock connector)

•USB communication cable

•(06-MLD) 15-pin D-SUB male-male cable between the laser head and key control box

•(06-DPL) 6 pin Molex to 15-pin D-SUB cable between laser head and key control box

OEM

The laser head is supplied without the key control box. Connecting a 5 VDC power supply to the laser head initiates

an automatic start-up sequence. If the remote interlock is connected, laser emission will start automatically as soon

as power is supplied and internal temperatures are stabilized.

The OEM model consists of:

•Laser head

•5 V power supply unit

•USB communication cable

•Remote interlock plug (for short circuiting the remote interlock connector)

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

16 | 52

Warning and Identification Labels

The upper face of the laser head contains a yellow label with laser safety warning and classification information, the

wavelength and maximum power of the unit. It also shows the location of the laser beam aperture and indicates the

open and closed positions of the manual shutter. This label must be visible unless the laser beam is totally enclosed.

A silver label showing information about the laser model, manufacturer date and location, and the power supply

voltage and current, is located on the laser head. Lasers shipped to customers in the USA also contain a label of CDRH

compliance.

Free beam laser head

Laser Notice No. 50 Label

CDRH models shipped to USA

CE /CDRH compliant label

OEM label

Aperture Warning Labels

Manufacturer Identification Labels

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

17 | 52

Fiber pigtailed laser head

Laser Notice No. 50 Label

CDRH models shipped to USA

CE / CDRH compliant label

OEM Label

Aperture Warning Labels

Manufacturer Identification Labels

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

18 | 52

Laser head

The laser head contains the laser cavity, beam shaping optics, thermoelectric coolers (TEC) for temperature control

and, in 06-DPLs, an optical feed-back loop which ensures long-term power stability of the emitted laser beam. The

laser head also features a manual mechanical shutter, a laser hazard label and a laser classification label. When power

is supplied to the laser head, regardless of direct on/off or key-switch state, the temperature control element will be

active to reach its set point values.

06-01 Free beam 06-MLD

Cobolt model 06-01 are 06-MLD free beam lasers. See section 5.1.1 for available wavelengths and power levels. The

laser head can take electrical power from either the power jack or the 15-pin D-SUB connector. The D-SUB (OEM

model only) and the mini-USB can each be used to communicate with the laser. In addition, the laser head features

an SMA connector for the digital modulation input and a 2.5mm socket for the interlock.

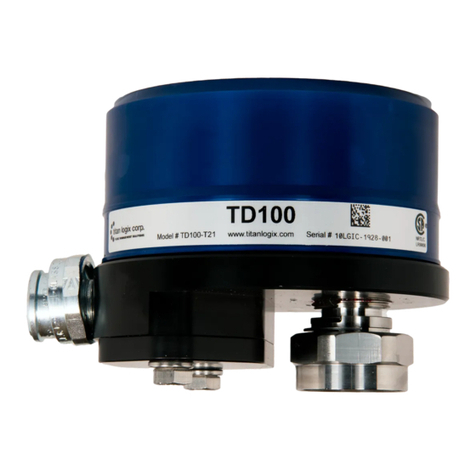

06-03 Fiber pigtailed 06-MLD

Cobolt version 06-03 lasers are 06-MLD models delivered with a permanently aligned fiber pigtail. The fiber is

equipped with a removable end-cap for protection of the fiber end-face. The fiber end-cap serves as the mechanical

shutter of the laser system. See section 5.1.2 for available wavelengths and power levels.

06-91 Free beam 06-DPL

Cobolt model 06-91 are 06-DPL free beam lasers. See section 5.1.1 for available wavelengths and power levels. The

mini-USB is used to communicate with the laser. In addition, the laser head supplies a Molex 6-pin connection, of

which the pin 1 and pin 2 are used for the remote interlock function.

Key control box

The optional key control box allows the user to operate the laser with a CE/CDRH compliant key-switch. It also

provides direct connections for analog modulation and (06-MLD) on/off modulation. The key control Box has LEDs to

indicate the laser status. When power is supplied to the laser head, regardless of direct on/off or key-switch state, the

temperature control elements will be active to reach set point values.

The status of the laser operation is given via LED indicators 06-MLD:

POWER

Green

Power is supplied.

ON

Orange

Laser emission is on. This light is on in modulation mode if laser emission is possible.

ERROR

Red

An error has occurred.

The status of the laser operation is given via LED indicators 06-DPL:

ON

Orange

Laser emission is on. This light is on in modulation mode if laser emission is possible.

ERROR

Red

An error has occurred.

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

19 | 52

Thermal management

To ensure operation within given specifications and for the warranty to be valid, the laser head must be mounted on

a suitable heat sink. The requirement on thermal resistance of the heat sink can be calculated by taking the difference

between the maximum allowed laser head base plate temperature (50 ºC) and the ambient temperature at the air-

heat sink interface (e.g. 40 ºC), divided by the maximum power dissipated from the laser; 12 W for 06-MLD and 20 W

for 06-DPL. The 06-MLD laser head must be attached to a heat sink providing a thermal resistance of < 0.8 K/W at

40°C ambient temperature and the 06-DPL requires a heat sink with a thermal resistance of < 0.5 K/W. The mounting

surface should be flat within 0.05 mm over mounting surface. Under normal circumstances thermal heat compound

is not required, however if the laser is operated in an area with a high ambient temperature it is recommended to use

a thermally conductive compound between the laser head and the heat sink to provide good thermal contact. For

assistance in thermal management and system integration, please contact Cobolt’s technical support.

Heat Sink Requirements for Cobolt 06-01 Series.

Power supply requirements

An appropriate Power Supply Unit (PSU) is supplied by Cobolt with the laser and can be plugged into a standard power

outlet. The power supply accepts 90-264 VAC and 47-63 Hz. Ripple and noise 1% peak-peak max, 20 MHz bandwidth.

Accepted voltage range for the laser head is (5.0 ± 0.4) VDC. Specification values are given at 5 VDC.

OWNERS MANUAL | Cobolt 06-01 Series | D0136-K DECEMBER 2018

201

20 | 52

System Description

The information presented here is believed to be accurate and is subject to change without notice. The specifications

contained herein cannot be guaranteed outside of normal operational conditions.

Specification

Optical Specifications Free Beam lasers

06-MLD

06-DPL

06-MLD

Center Wavelength (nm)

405

445

473

488

515

532.1

552.8

561.2

633

638

647

660

Wavelength precision 1 (nm)

5

± 0.3

± 5

Output power2(mW)

120

300

100

100

300

60

200

80

100

200

50

50

100

80

180

130

100

Beam divergence, full angle (mrad)

< 1.1

< 1. 2

< 1.3

< 1.2

< 1.7

Spatial mode (TEM00)

M2< 1.2

M2 < 1.1

M2 < 1.2

Beam diameter at aperture (µm)

700 100

700 70

700 100

Polarization extinction ratio

> 100:1, vertical

Beam symmetry

> 0.90:1

> 0.95:1

> 0.90:1

Noise 250 Hz - 2 MHz (%,rms)

< 0.2

< 0.3

< 0.25

< 0.2

Power stability over 8 hrs (%)

< 1

< 2

< 1

Spectral bandwidth (FWHM)

< 1.2 nm

< 1.5 nm

< 1 MHz

< 1.2 nm

Beam position accuracy (mm)

< 0.5

Beam angle accuracy (mrad)

< 5

1. The wavelength is fixed with this accuracy. The wavelength is specified in air.

2. Power in continuous wave operation mode.

Optical Specifications Fiber pigtailed lasers (MLD Only)

Product

405 nm

445 nm

473 nm

488 nm

515 nm

633 nm

638 nm

647 nm

660 nm

Maximum Power out of Fiber (mW)

50

150

50

50

30

100

30

40

75

60

50

Power stability over 8 hrs

< 2 %

Exit ferrule

End cap

No End cap

Fiber Output

FC/APC, 8°, non-collimated

Fiber Type

SM/PM

Standard fiber length / Jacket

1 (m) / 3mm stainless steel jacket

Polarization

PER > 100:1, vertical ± 2°

Mechanical Interfaces

MLD

DPL

Laser Head dimensions

100 x 40 x 40 mm

Fixation holes, Laser head

= 4 x 4.2 mm; 90 mm x 30 mm

Weight

< 0.2 kg

< 0.3 kg

This manual suits for next models

12

Table of contents

Other Cobolt Measuring Instrument manuals