8

DIANA

COLA ceramic tiles are hand-crafted products and therefore may have minor surface imperfections such as tiny

dots or slight colour variations.

We recommend using a soft dry cloth to clean the ceramic tiles; the use of detergents could highlight any

imperfections.

2.4 Instructions for safe installation

The successful operation of the cooker depends greatly on correct installation, which must be carried out by a

qualified person in accordance with the applicable safety regulations.

A cooker that has been installed incorrectly could cause very serious accidents (fires in the chimney,

insulating material, etc.).

There must be more than 20 cm clearance between the back and sides of the cooker and any combustible

materials. If the floor is made from a combustible material (wood, carpet, etc.), a protective steel sheet with a

recommended minimum thickness of 2-3 mm must be installed.

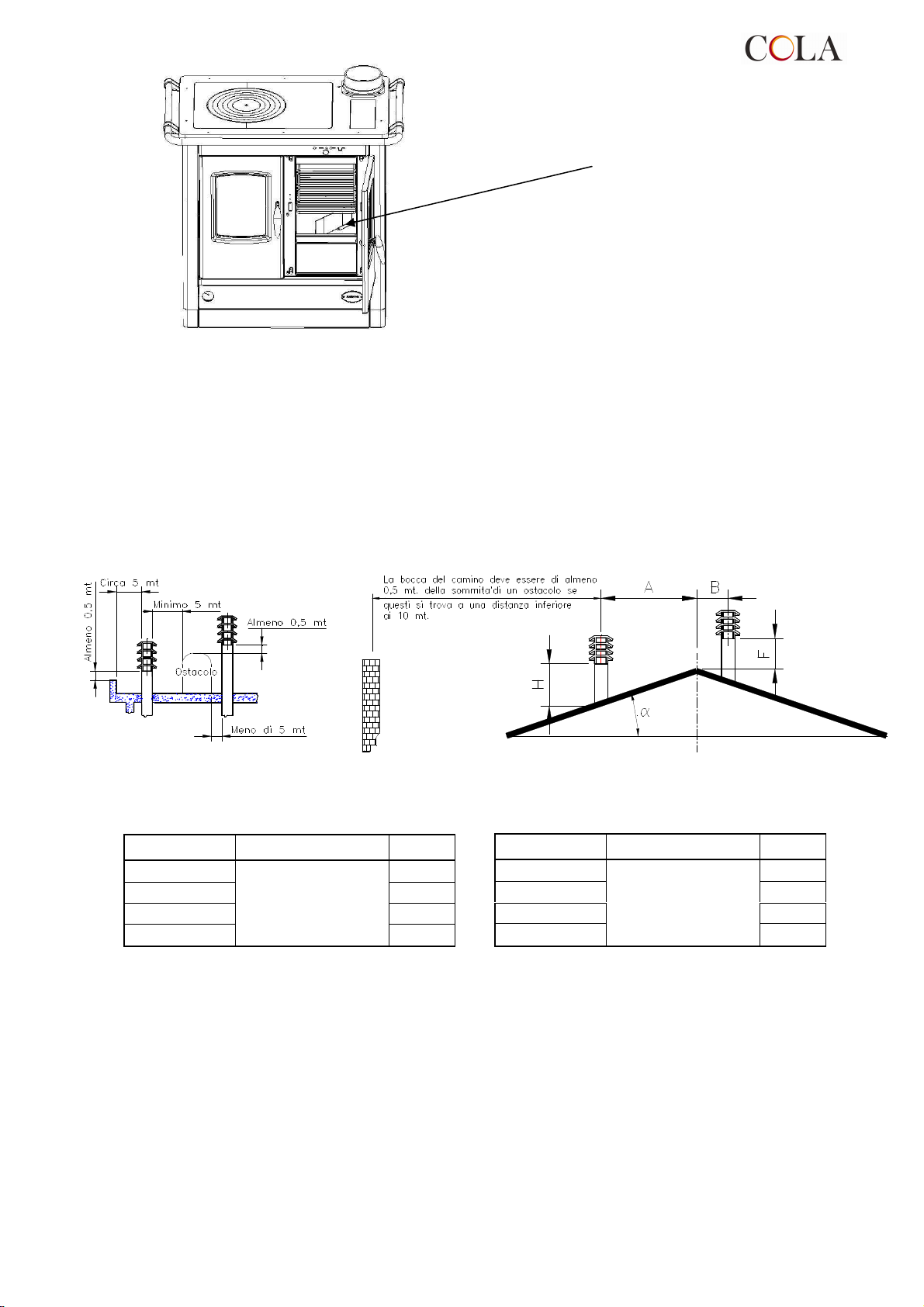

2.5 Connection to the flue

The DIANA cooker is to be connected to a chimney by way of the flue collar on the hotplate and commercially-

available flue pipes. Connection to the chimney must be made using strong, stable pipes, with a recommended

minimum wall thickness of 1.2-2 mm. The flue pipe connecting the cooker to the chimney should be as straight

and as direct as possible to prevent loss of draught. There must be effective seals at both ends of the flue gas

vent pipe.

When the cooker is operating at the rated output, the flue draught should be between 10 and 14 Pa.

For maximum cooker efficiency, a draught restrictor or damper should be installed in the flue or chimney.

Each appliance must vent its combustion gases through its own flue; two or more appliances must never share

the same flue.

2.6 Room ventilation

It is absolutely essential that the room in which a cooker with natural draught flue is installed receives an

adequate supply of air for combustion, i.e. at least 25 m³ per hour. Vents must be installed to ensure a sufficient

supply of external air; the cross-sectional area of the vents must comply with applicable local regulations. These

vents must be protected by grilles and must not be obstructed.

If the air supply is insufficient, even the operation of an extractor fan in the room could impair operation of the

cooker.

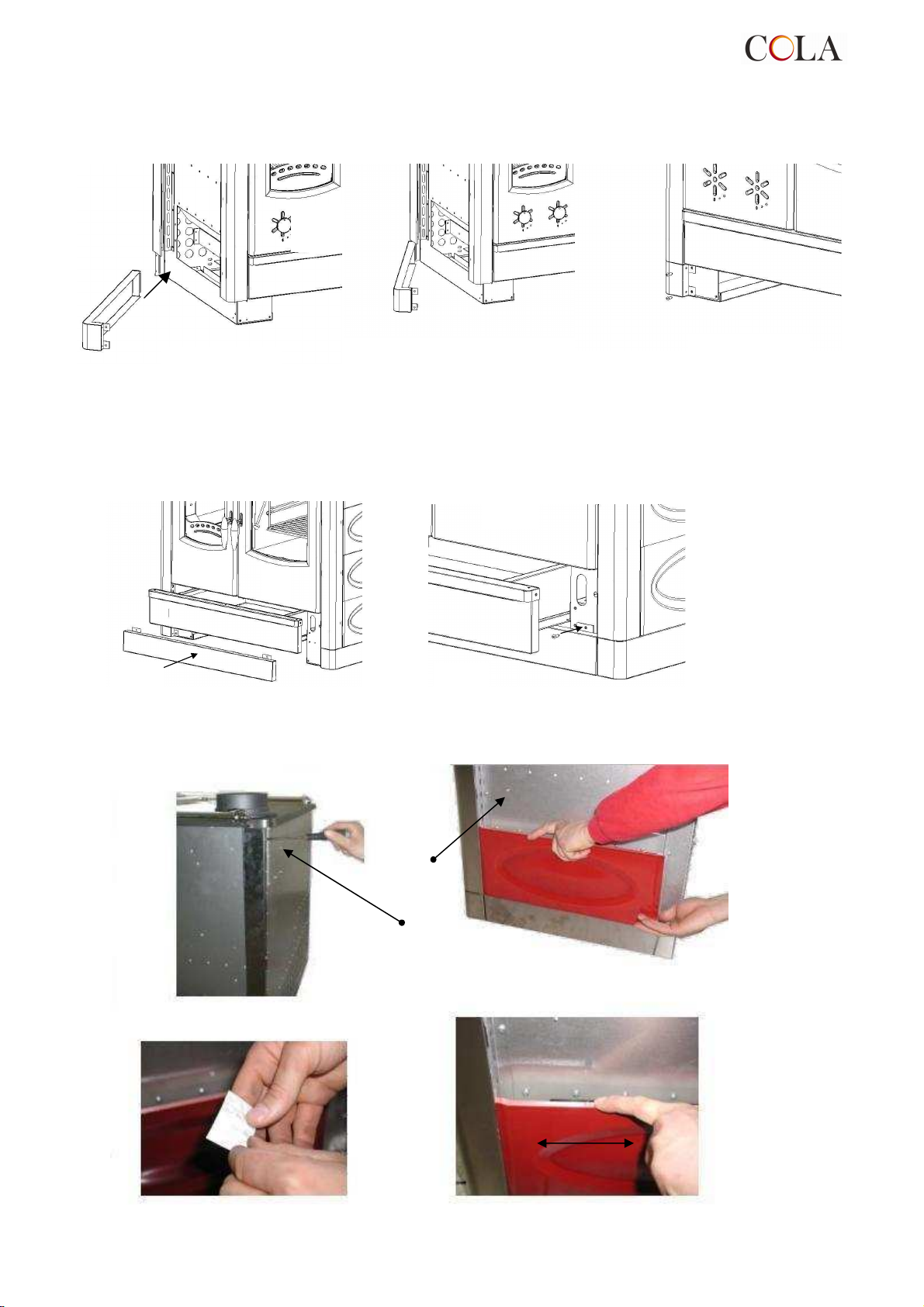

2.7 Bottom baffle

Before operating the cooker, make sure that the bottom baffle, located underneath the removable stainless steel

base plate of the oven, is in the correct position (as shown in the figure).

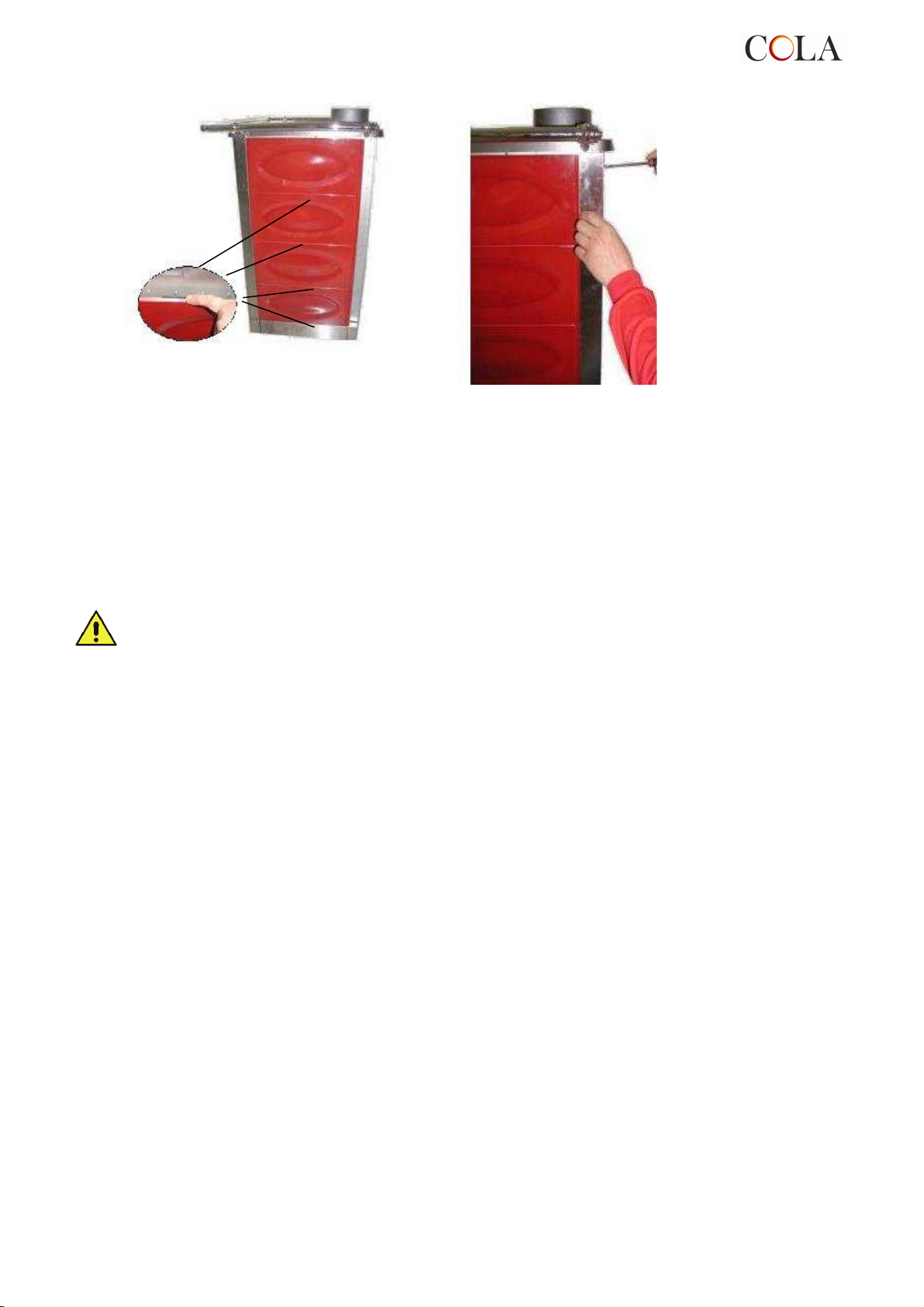

(fig.12) refit the rear tile trim,

taking care not to drop the tiles

and making sure they are fully

inserted in groove of the front

trim (b)

(fig.11) position two rubber buffers on each

tile as shown