1

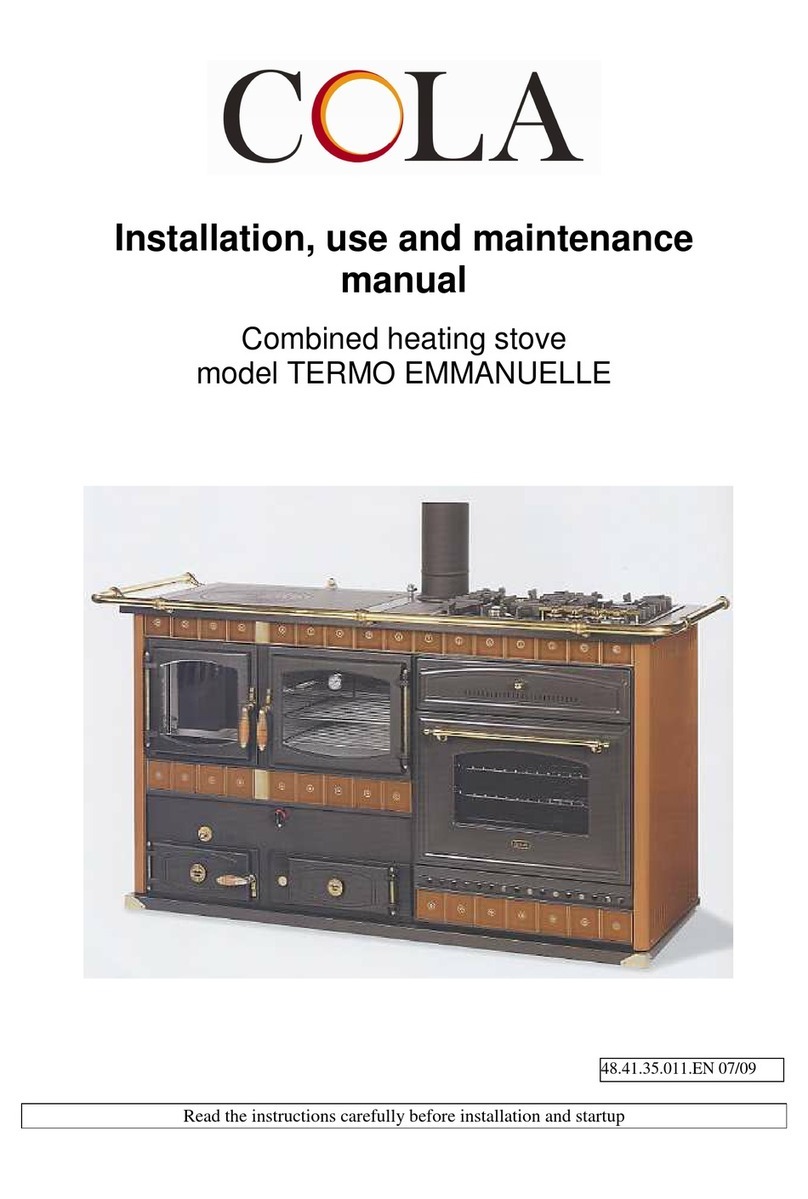

GENERAL INFORMATION................................................................................................................3

1.1 Introduction ......................................................................................................................................3

1.2 Using the manual .............................................................................................................................3

1.3 Safety rules......................................................................................................................................3

1.4 Technical description........................................................................................................................4

1.5 Permissible and non-permissible fuels.............................................................................................6

1.6 Accessories supplied........................................................................................................................6

1.7 Reference standards........................................................................................................................6

1.8 Dataplate..........................................................................................................................................6

1.9 Instructions for requesting assistance and replacement parts...........................................................6

1.10 Stove decommissioning..................................................................................................................6

2

TRANSPORT AND INSTALLATION...................................................................................................7

2.1 Packing, handling, shipment and transport.......................................................................................7

2.2 Instructions for safe installation ........................................................................................................7

2.3 Connection to the flue ......................................................................................................................7

2.4 Room ventilation...............................................................................................................................7

2.5 Electrical connection ........................................................................................................................7

2.6 Gas connection................................................................................................................................7

2.7 Advice on flues and connections......................................................................................................8

3

STOVE USE.......................................................................................................................................9

3.1 Introduction ......................................................................................................................................9

3.2 Startup .............................................................................................................................................9

3.3 Lighting and controlling the fire.........................................................................................................9

3.4 Adjusting the combustion air ..........................................................................................................10

3.5 Normal operation............................................................................................................................10

3.6 Operation with slow combustion.....................................................................................................10

3.7 Operation in off season ..................................................................................................................10

3.8 Wood-fired oven operation.............................................................................................................10

3.9 Multifunction oven operation...........................................................................................................10

3.9.1 Multifunction knob....................................................................................................................10

3.9.2 Temperature knob...................................................................................................................11

3.9.3 Wiring diagram........................................................................................................................11

3.10 Idle period and summer................................................................................................................11

4

ROUTINE STOVE CLEANING AND MAINTENANCE......................................................................12

4.11 Removing ash..............................................................................................................................12

4.12 Cleaning the glass........................................................................................................................12

4.13 Stove cladding maintenance.........................................................................................................12

4.14 Cleaning the cast iron hotplate.....................................................................................................12

4.15 Cleaning the oven ........................................................................................................................12

4.16 Cleaning the flue and baffle..........................................................................................................12

5

TROUBLESHOOTING .....................................................................................................................13

5.17 The stove does not work ..............................................................................................................13

5.18 Difficult lighting.............................................................................................................................13

5.19 Smoke leaks.................................................................................................................................13

5.20 The glass gets dirty quickly ..........................................................................................................13

5.21 Condensate in the heating chamber.............................................................................................13

5.22 The oven does not heat................................................................................................................13

5.23 The electric fan oven does not work.............................................................................................13

5.24 The gas hob does not work ..........................................................................................................13

6

ENCLOSURES………………………………………………………………………………………………….13

6.1 Warranty certificate…………………………………………………………………………………………13