7

Termo Regina 4

1.7 Dataplate

The dataplate is located on the back of the stove. It contains the following data:

-

model;

-

serial number;

-

type of fuel;

-

max. heat output;

-

max. fuel consumption;

-

min. flue draught;

-

flue gas temperature ;

-

min. – max. efficiency;

-

flue pipe size;

-

stove external dimensions;

-

minimum safety distance;

-

weight.

1.8 Ordering replacement parts

For the end-user:

Contact the service centre and/or your dealer to order replacement parts.

For the dealer:

To request any replacement parts contact the Cola s.r.l. service centre and/or send a fax clearly

specifying the following:

-

stove model;

-

serial number;

-

date of purchase;

-

list of replacement parts;

-

details of faults encountered.

-Operations on parts must be carried out by authorised and/or qualified personnel.

-Only use original Cola replacement parts.

1.9 Stove decommissioning

For disposal, the stove must be sealed inside strong packing; contact the local authority in charge of

such operations in order to proceed according to the current local regulations.

2 – TRANSPORT AND INSTALLATION

2.1 Packing, handling, shipment and transport

The stove can be lifted using a lift truck, inserting the forks (of suitable length) in the special spaces in

the wooden packing.

Make sure the equipment used for lifting and transport can take the weight of the stove, specified on

the dataplate and in this manual.

Avoid taking the load in areas where it could be a danger if dropped.

Set the stove down on the floor carefully without bumping, and position it in the required place; make

sure the floor can take the weight of the stove, otherwise consult a specialised technician.

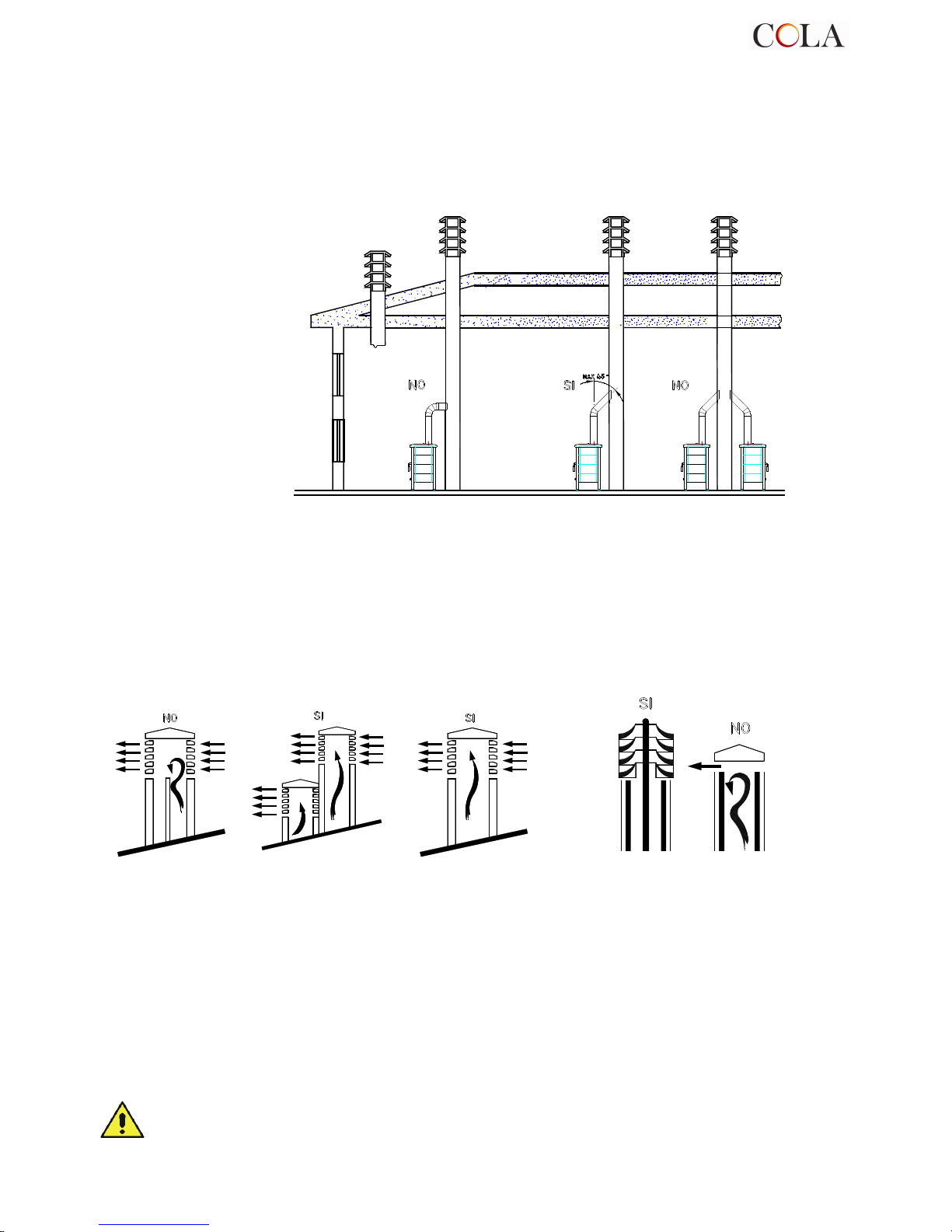

2.2 Instructions for safe installation

The stove must be installed by a technician, taking into account the local, national and European

regulations. The stove must be placed on a floor able to support .

its weight; otherwise corrective measures can be taken by consulting specialised technicians.

Flammable parts or those sensitive to heat must not be kept near the glass, as this zone becomes hot.

The minimum front distance for the protection of flammable objects is 80 cm. The minimum side

distance and that of the rear wall from flammable parts or those sensitive to heat is 20 cm. If the

support base is made of flammable material (wood, cork, etc.) a protection base in 2-3 mm thick steel

plate or a sheet of toughened glass must be provided.