PART

I1

ASSEMBLING

THE FREEZER

Once the parts have been washed, rinsed and sanitized, the

freezer is ready to be re-assembled. Prior to beginning the re-

assembly procedure,sanitize your hands by submerging in the

sanitizing solution. Begin to re-assemble as follows:

A)

Assembling the Beater/Augers

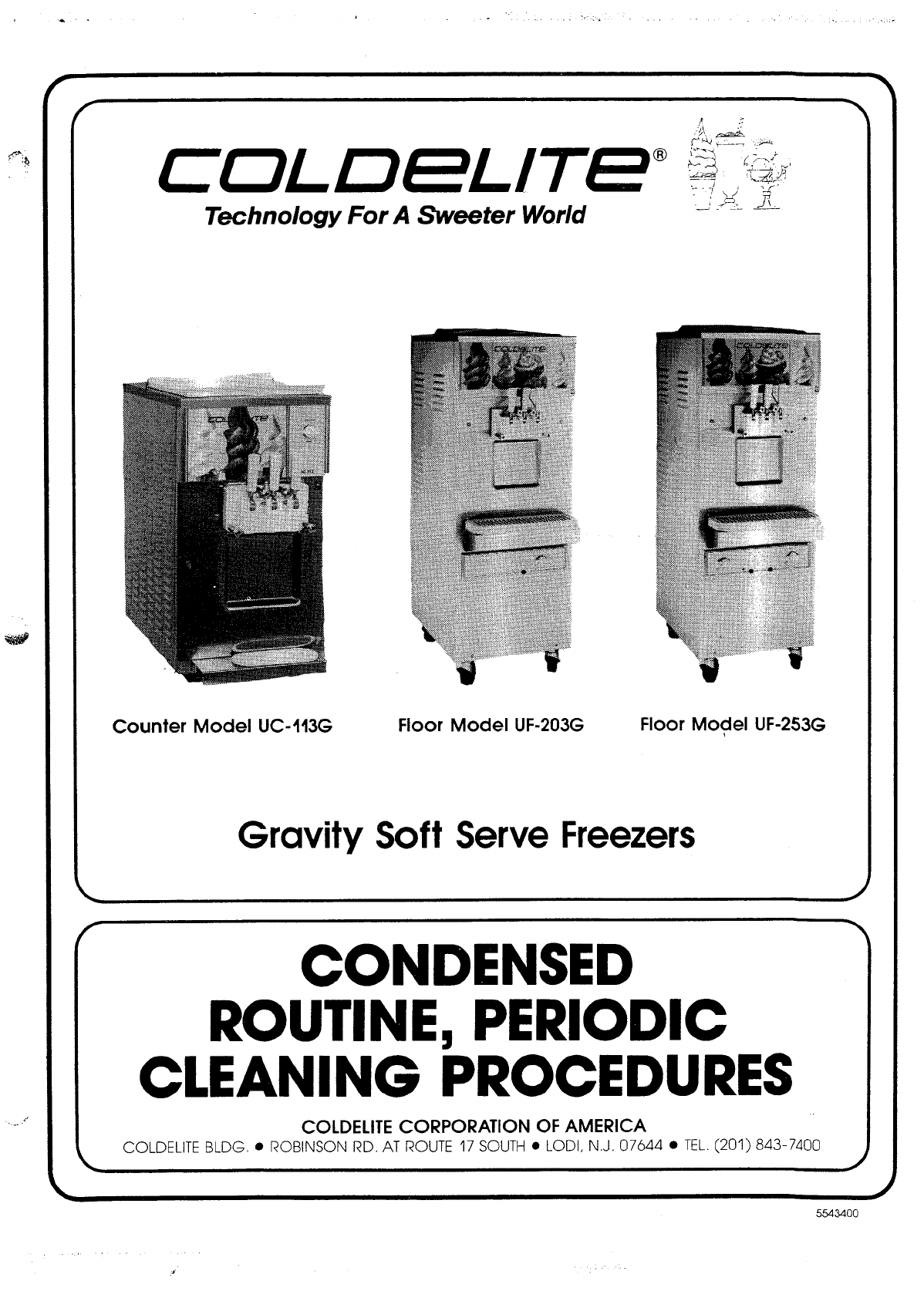

1)

First, re-assemblethe beater/auger assembly. Begin by

gathering the four parts needed to complete each assembly:

A) plastic "END PUSHER",

B)

BEATERIAUGER,

C)

IDLER,

D)

rubber, beater LIP SEAL.

Push the idler back, inserting its shaft into the hole of the

beaterlauaer shaft.

When installed correctly, the idler (whenturned) should rotate

freely. If the idler does not rotate,it is incorrectly installed

and must not be installed into the machine. Repeat the

above instructions.

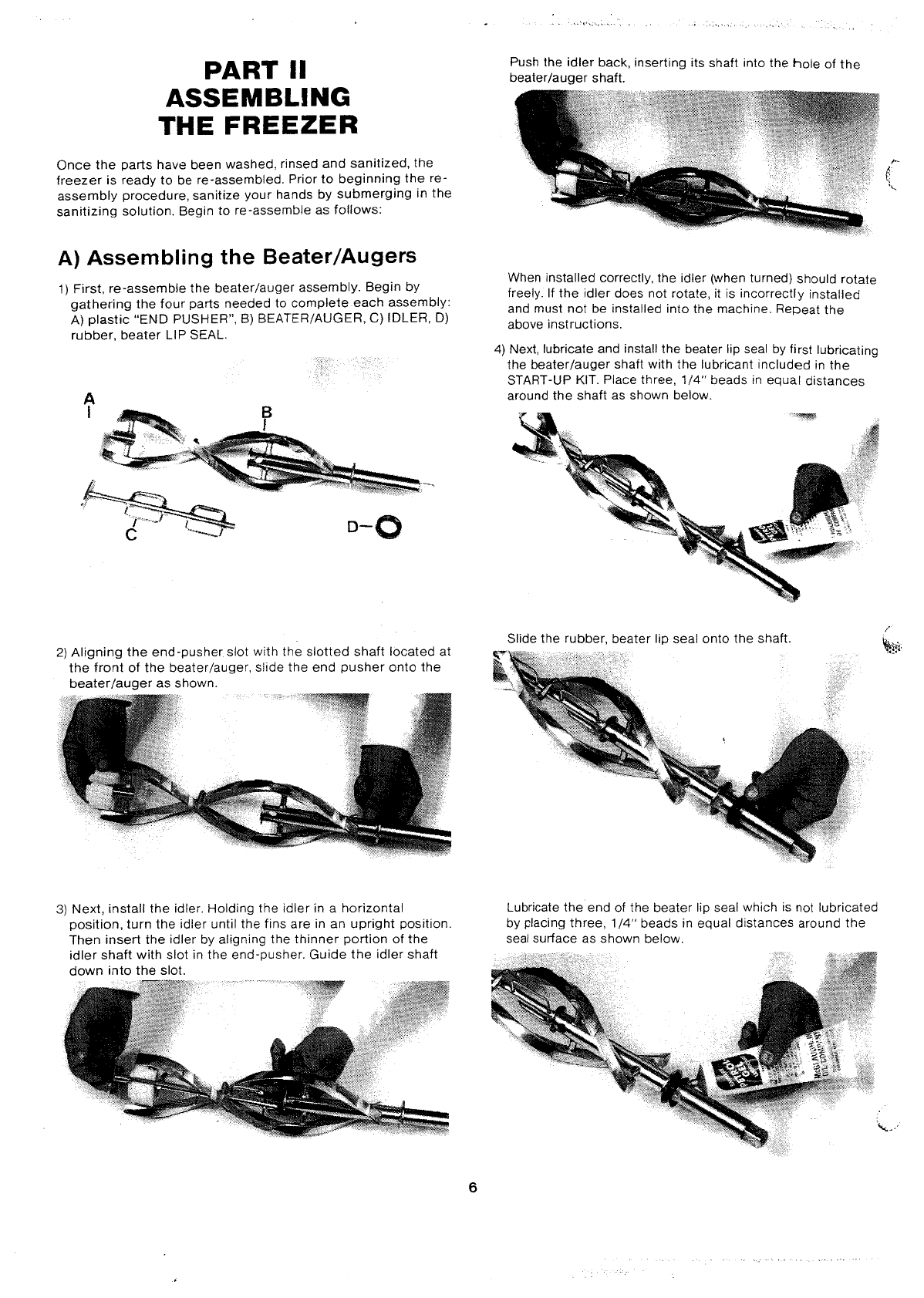

4)

Next,lubricate and install the beater lip seal by first lubricating

the beaterlauger shaft with the lubricant included in the

START-UP KIT. Place three, 114" beads in equal distances

around the shaft as shown below.

Sl~dethe rubber, beater Ilp seal onto the shaft.

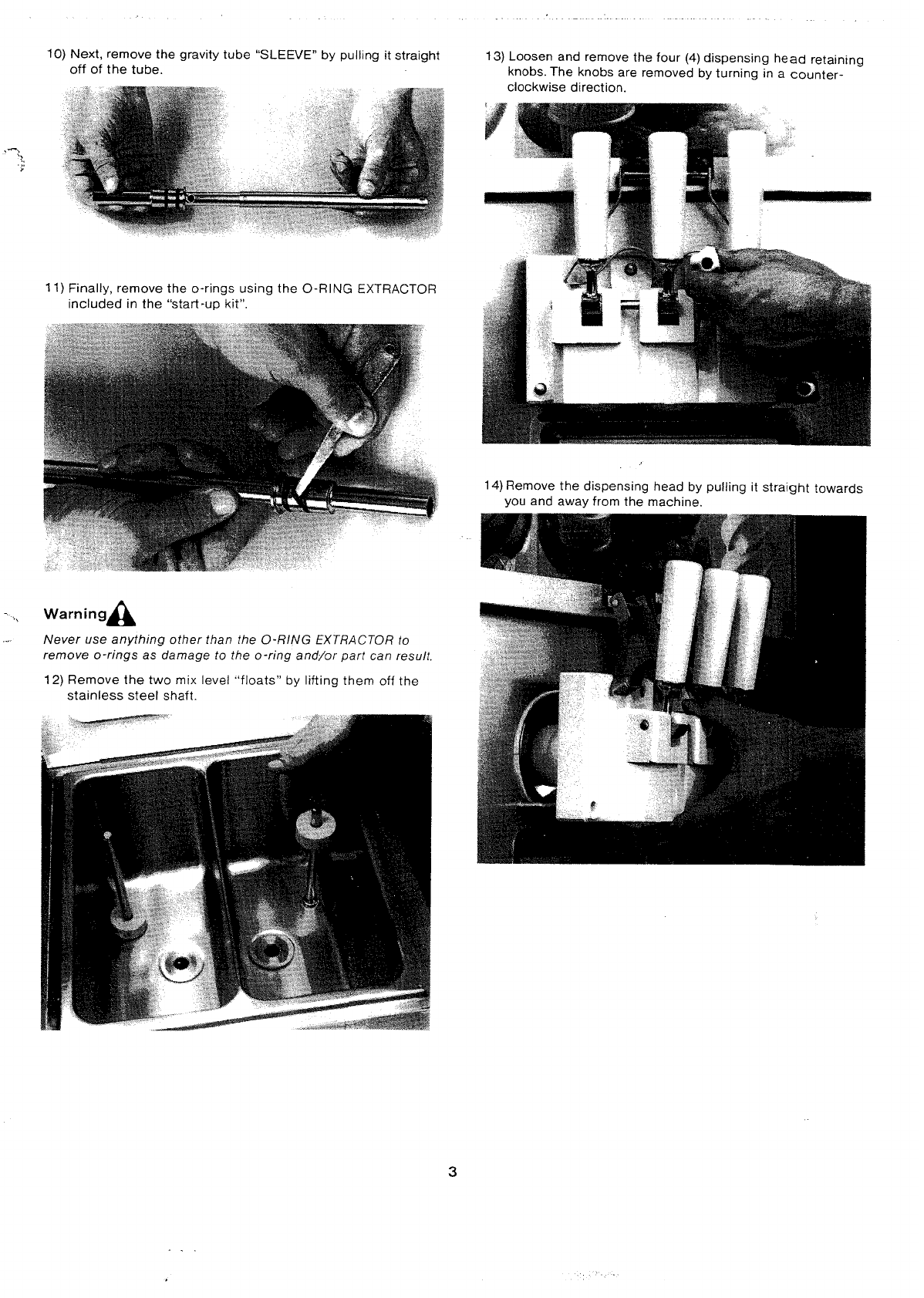

2)

Al~qninsthe end-pusher slot w~ththe slotted shaft located at

the-froit of the beater/auger, slide the end pusher onto the

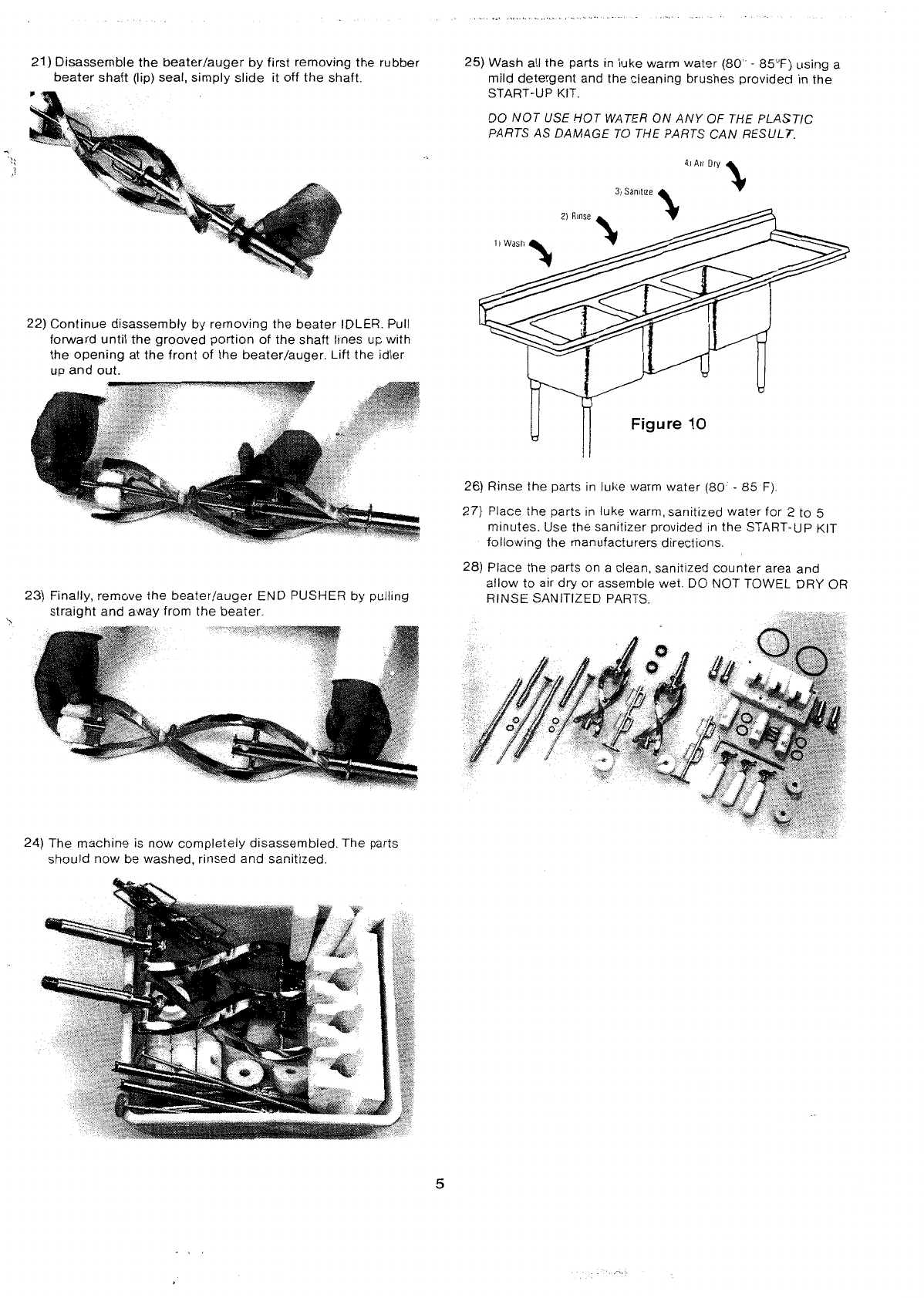

3)

Next, install the idler. Holding the idler in

a

horizontal Lubricate the end of the beater lip seal which is not lubricated

position, turn the idler until the fins are in an upright position. by placing three, 114" beads in equal distances around the

Then insert the idler by aligning the thinner portion of the seal surface as shown below.