t

D4 ø max 0.3 mm

D6 ø max 0.4 mm

E4 ø max 0.4 mm

max

0.1°

D

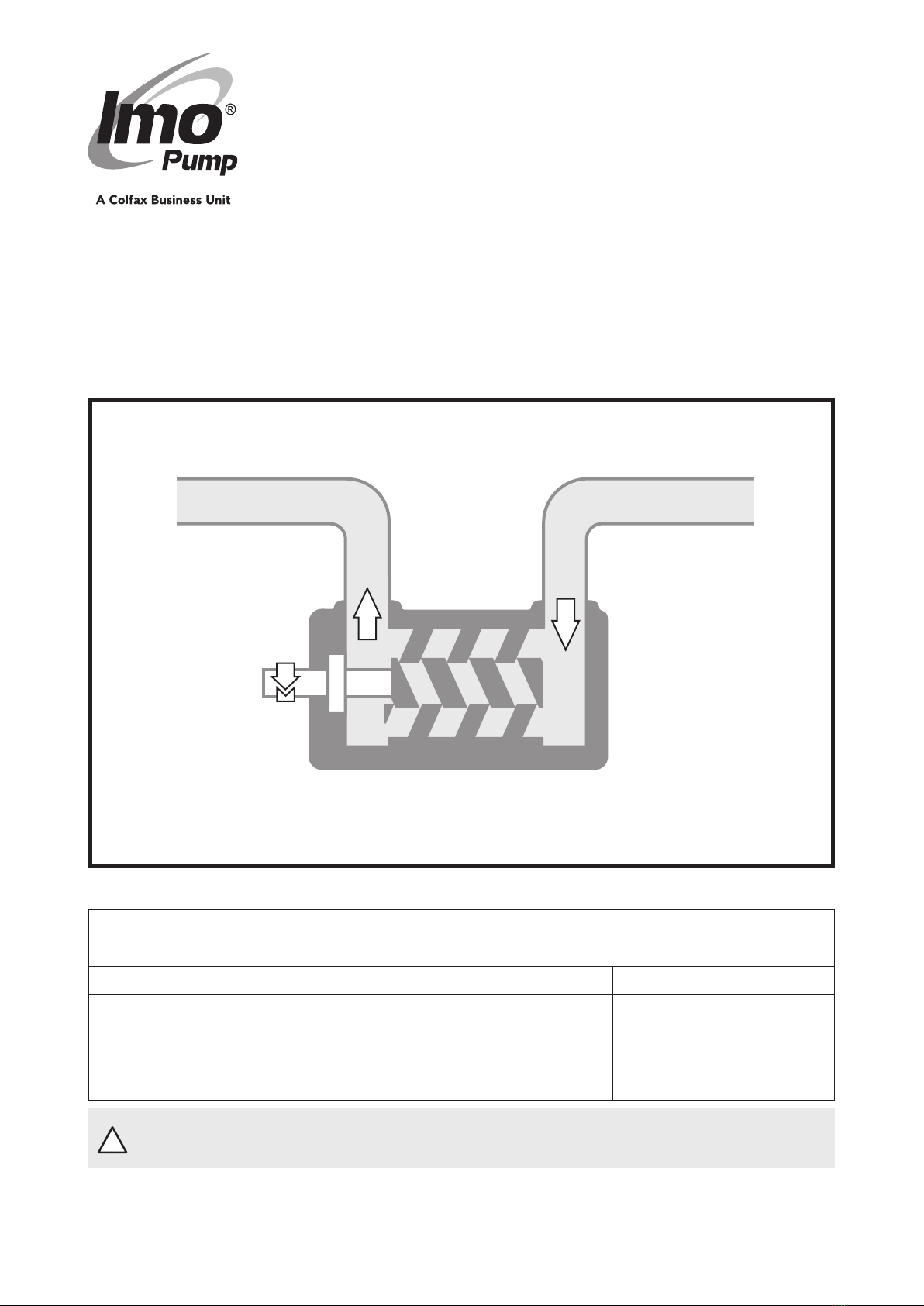

Fig. 3 Alignment of the IMO AB standard coupling

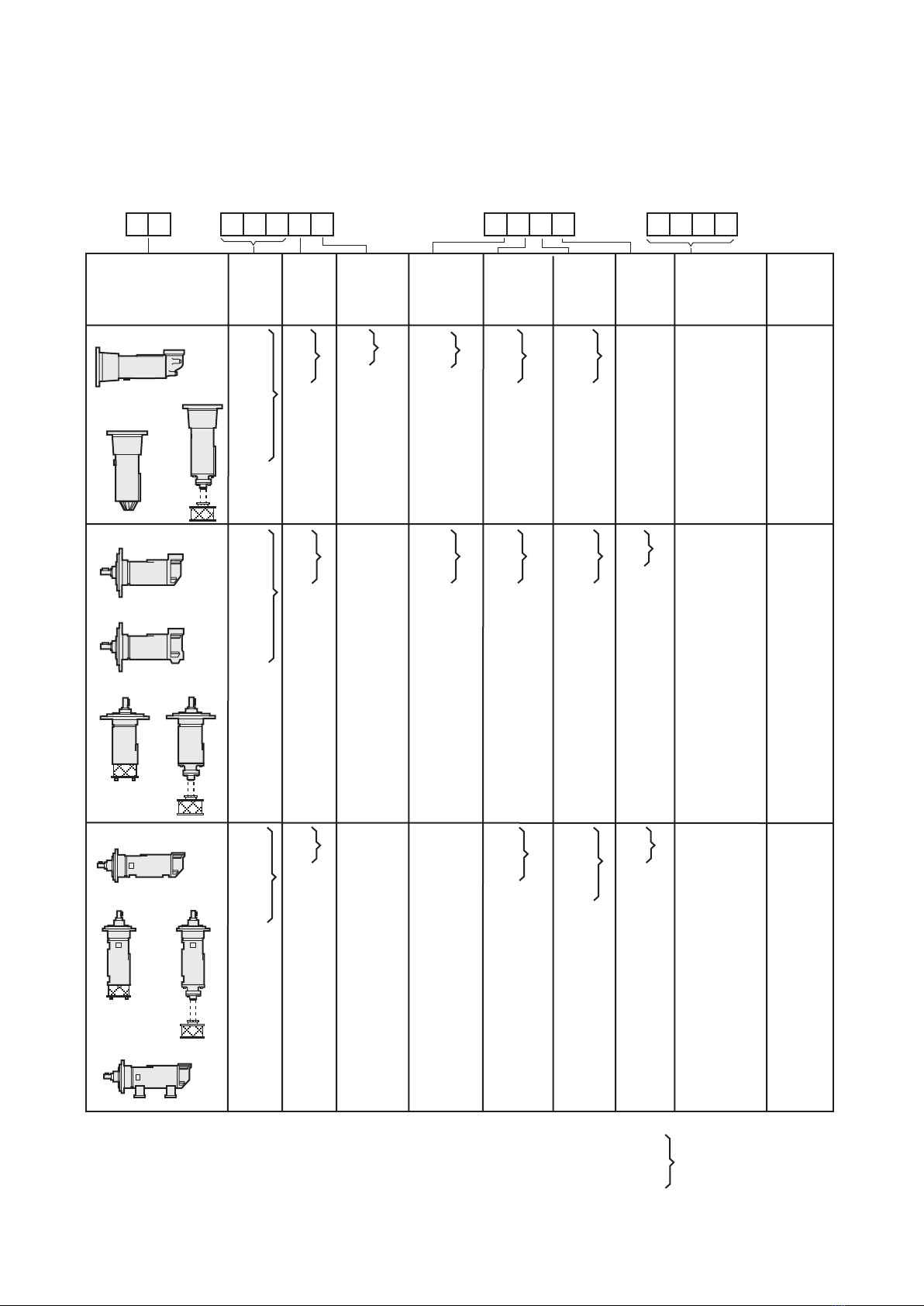

Fig. 4 Distance between coupling halves

(IMO AB standard coupling)

Outer diameter

of coupling

(mm)

Distance between

coupling halves

(mm)

Outer diameter

of coupling

(mm)

Distance between

coupling halves

(mm)

50

67

82

97

112

128

2.0

2.5

3.0

3.0

3.5

3.5

148

168

194

214

240

3.5

3.5

3.5

4.0

4.0

Mounting

The pump must be securely mounted on a rm

stable foundation and positioned so that it is easily

accessible for inspection and servicing.

Provisions for collecting oil spillage when servicing

the pump are to be installed.

ATTENTION

The installation must always be designed to

minimise damage should an operational or

functional failure occur.

Provisions should be installed to collect oil

spillage if a functional failure results in a

broken pipe or pump housing.

The pump installation should be provided

with an emergency shutdown to avoid dam-

ages due to overheating or if the oil volume

is below a minimum tank level.

Alignment and shaft couplings

The pump shall be connected to its driver via a ex-

ible sha coupling. The pump may also be driven

via gears or pulleys as specied in the Product De-

scription, provided the radial forces are kept within

the specied range. We recommend that the pump

is connected via our standard connecting frame and

IMO AB standard coupling.

The coupling and alignment shall be selected not to

exert any axial or radial loads on the sha ends.

IMO AB standard couplings shall have a distance

between the coupling halves as per table, g. 4 the

coupling halves shall be secured by lock screws.

For other types of couplings, please refer to respec-

tive maker’s instructions.

For direct driven pumps the alignment between

pump and motor shas must be kept within the

limits according to g. 3 and 4.

Measures shall be provided to avoid acci-

dentalcontactwiththerotatingshacou-

pling. Any installed coupling guard

shallpermiteasyaccesstothepumpsha

for maintenance and inspection of the

pump bearing and seal housing.

When handling liquids that may harm skin

use gloves and/or protective clothing.

When handling liquids which may involve

rehazardsappropriateprecautionstoavoid

danger are to be taken.

In case of failure for a system with elevating

pressureuidjetsmaycauseinjuryand/or

damage.

See table below An angular

misalignment of

0.1° corresponds

to approx. 0.2 mm

deviation/100 mm.

Angular

alignment

Distance

between

coupling halves

Circular

run-out

Outer diameter Distance between Outer diameter Distance between

of coupling coupling halves of coupling coupling halves

(D mm) (t mm) (D mm) (t mm)