4LPD 0604GB

March 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

!

!

!

!

!

!

If the pumps operating temperature ex-

ceeds 60°C let the pump cool off before any

service, maintenance or dismantling work

is commenced to avoid burn injury.

All work carried out on the pump has to be

performed in such a manner that risks for

personal injury are observed!

When handling liquids that may harm skin

use gloves and/or protective clothing.

When handling liquids which may involve

fire hazards appropriate precautions to

avoid danger are to be taken.

In case of failure for a system with elevated

pressure, fluid jets may cause injury and/or

damage.

Oil leakage may make the floor slippery

and cause personal injury.

Service intervals

The intervals for inspection and replacement of wear

parts vary greatly with the properties of the pumped

liquid and can only be determined by experience.

All internal parts of the LPD-pump are lubricated by

the pumped liquid. Pumping liquid which contains

abrasive materials, or liquid that is corrosive, will

significantly reduce service life and call for shorter

service intervals.

Wear in the pump may be indicated by:

• Vibration

• Noise

• Loss of capacity

• Reduction in flow/pressure

• Leakage

In installations where unplanned shut downs must

be avoided, it is advisable to have a complete pump

available for replacement, should any malfunction

occur. Furthermore we recommend planned inspec-

tion and overhaul at regular intervals, not exceeding

3 years.

It is recommended always to have the spares in-

cluded in minor spare part kit available.

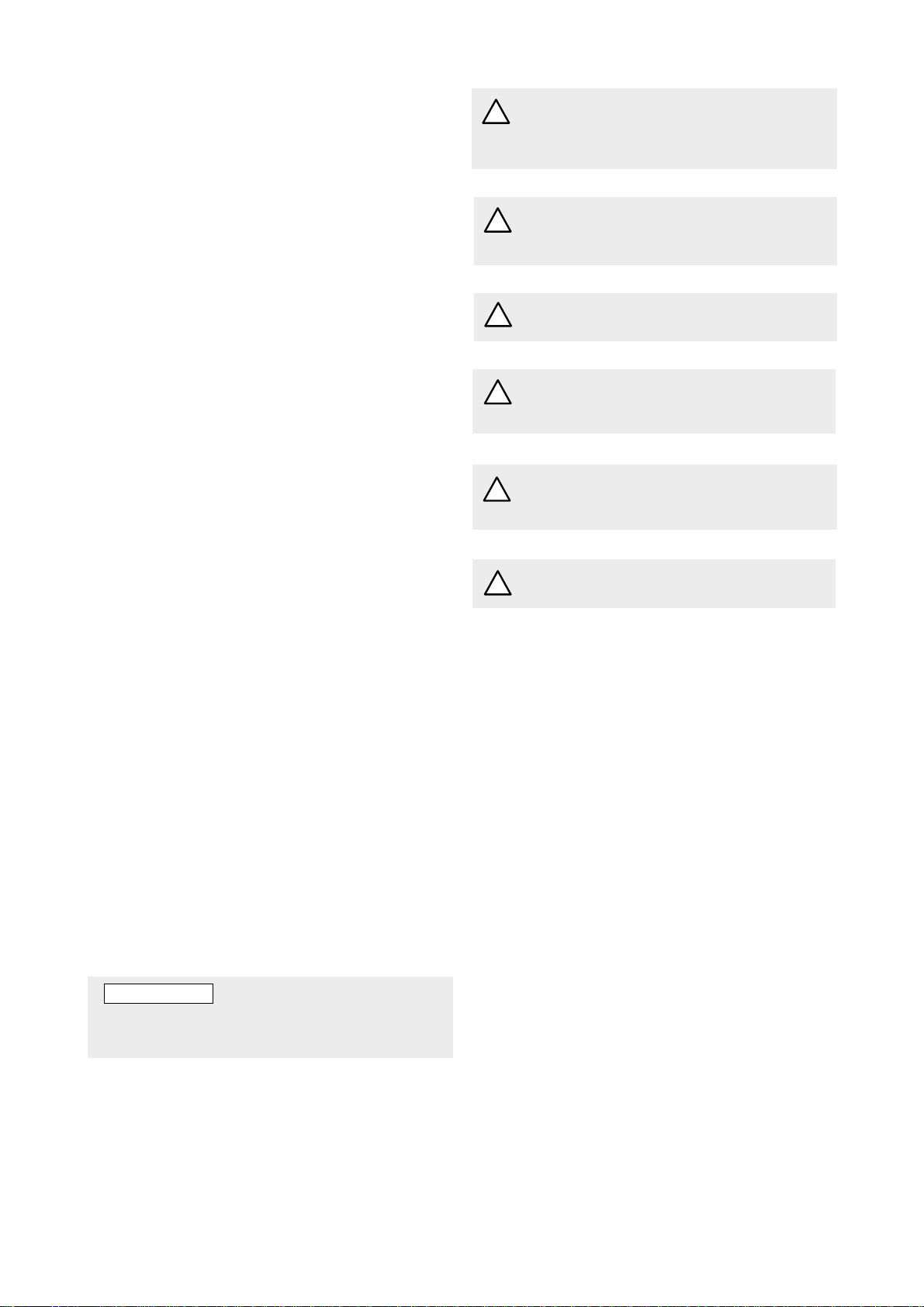

Inspection of shaft seal

As the seal faces of a mechanical shaft seal are

lubricated by the fluid a certain leakage will always

be present. Ten drops per hour can be considered as

acceptable.

An external visual inspection of the pump is advis-

able at least every two days to assure that the shaft

seal is not leaking too much.

Excessively leaking shaft seals should be replaced

without delay, as the leakage normally will grow

worse and cause additional damage.

Follow the instructions in the dismantling/reassem-

bly session.

When working with a shaft seal, cleanliness is of

utmost importance. Avoid touching the seal faces. If

necessary, the seal faces should be cleaned immedi-

ately prior to assembly, using a dustfree cloth and

clean solvent.

Never use grease on the seal faces.

O-rings

All O-rings found to be hard or damaged shall be

replaced.

Inspection of rotors

If an indication of a worn pump is noticed (see

service intervals above), a brief inspection of the

idler rotors is recommended.

A quick inspection of the idler rotors can be made

simply by removing the rear cover. Note that the

driver must be deenergized and the pump hydrauli-

cally isolated before the rear cover is removed.

Internal clearances in the pump, which are vital for

its proper function, may have been affected by wear.

Acceptable wear can be determined only by experi-

ence of the actual application. As a rule of thumb the

following max clearance values may apply:

• Between rotor and bores or bushings: 0.2 mm

• Between rotor flanks: 0.4 mm

For light duties (low pressure, medium viscosity)

even bigger clearances may be acceptable but for

low visc./high pressure duties the limit will be

lower.

Also check if there are major scratches on these

parts.

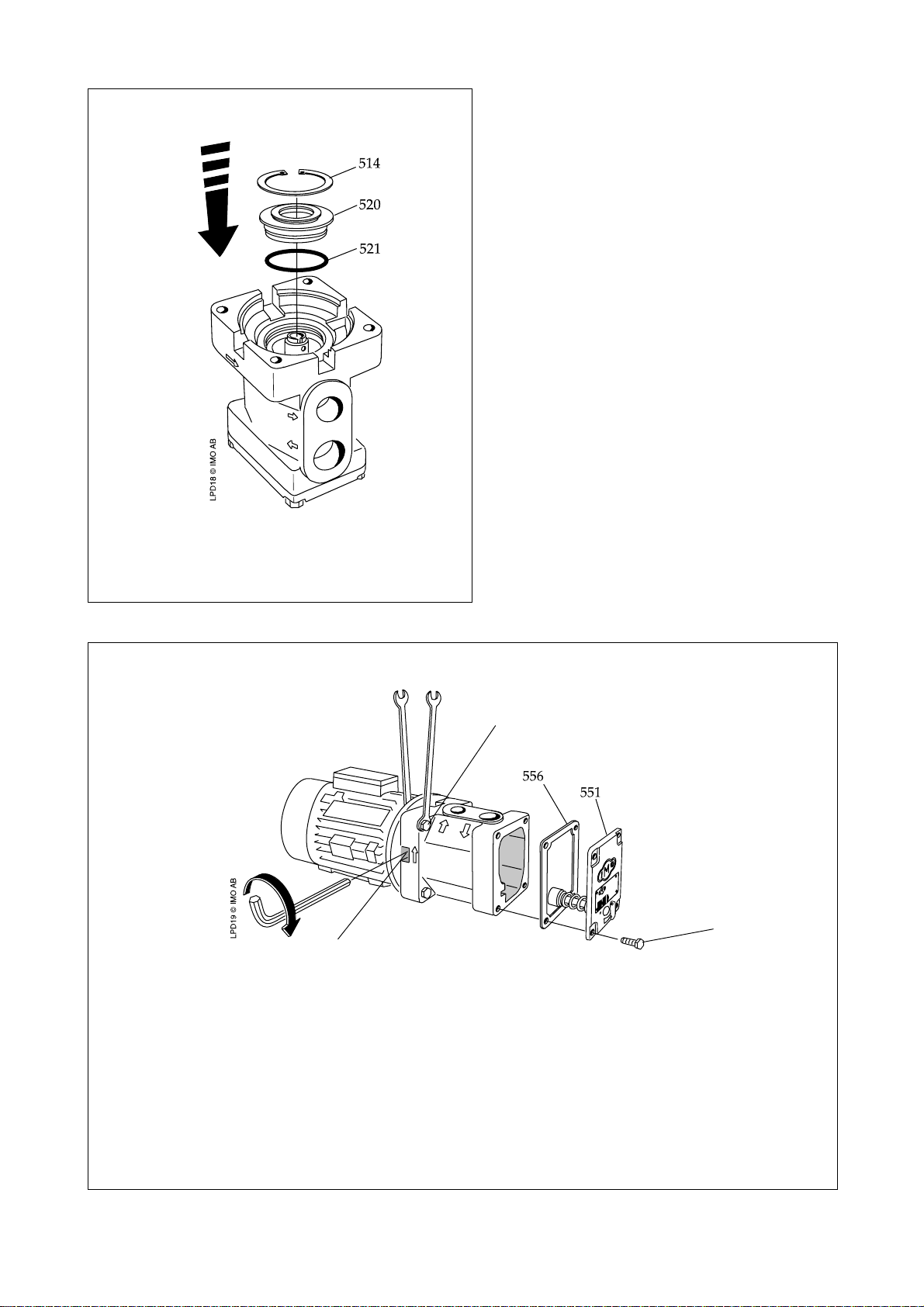

If a more thorough investigation is needed, proceed

as under ”Dismantling and reassembly”.

ATTENTION

Use appropriate vessels to collect oil spillage

when removing and opening the pump.