3

Operation

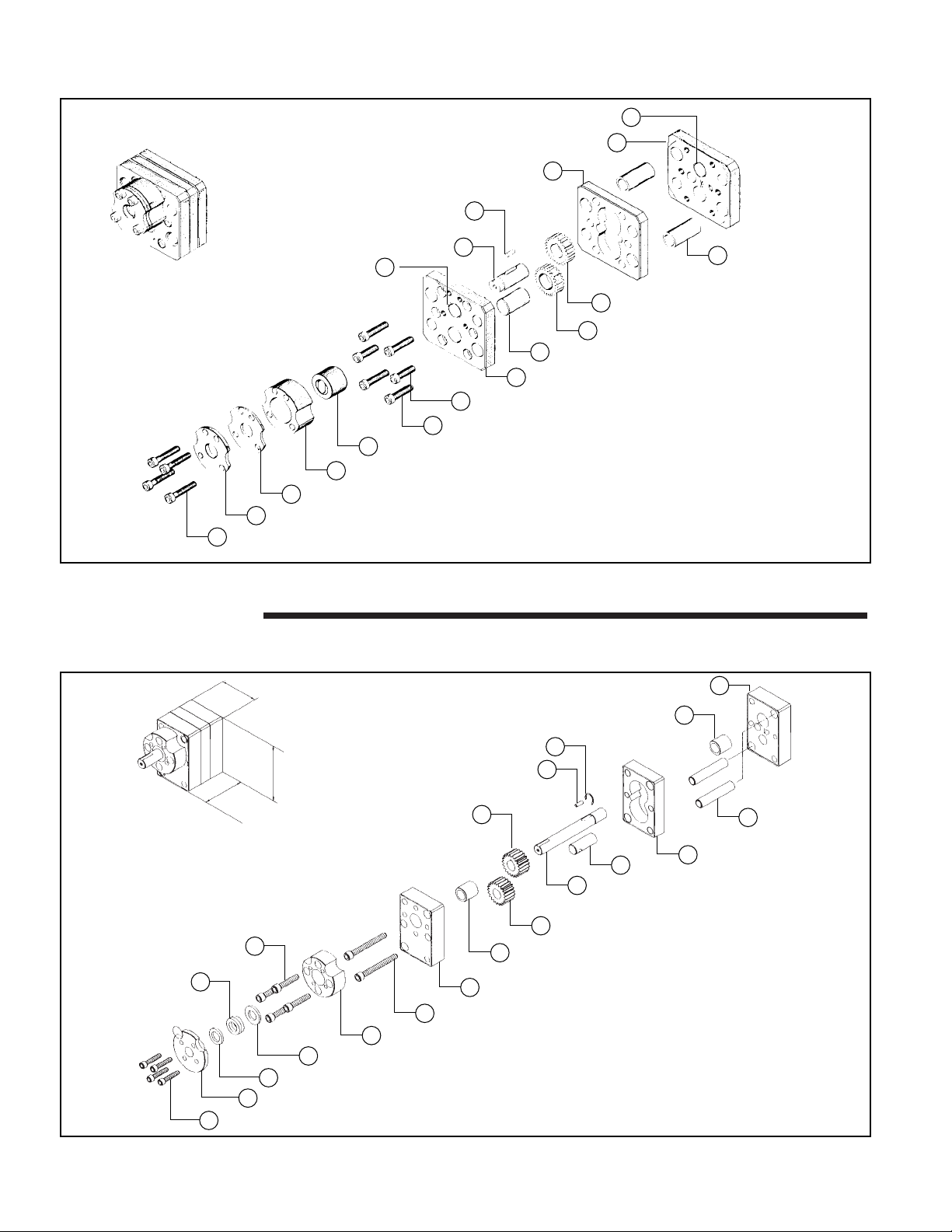

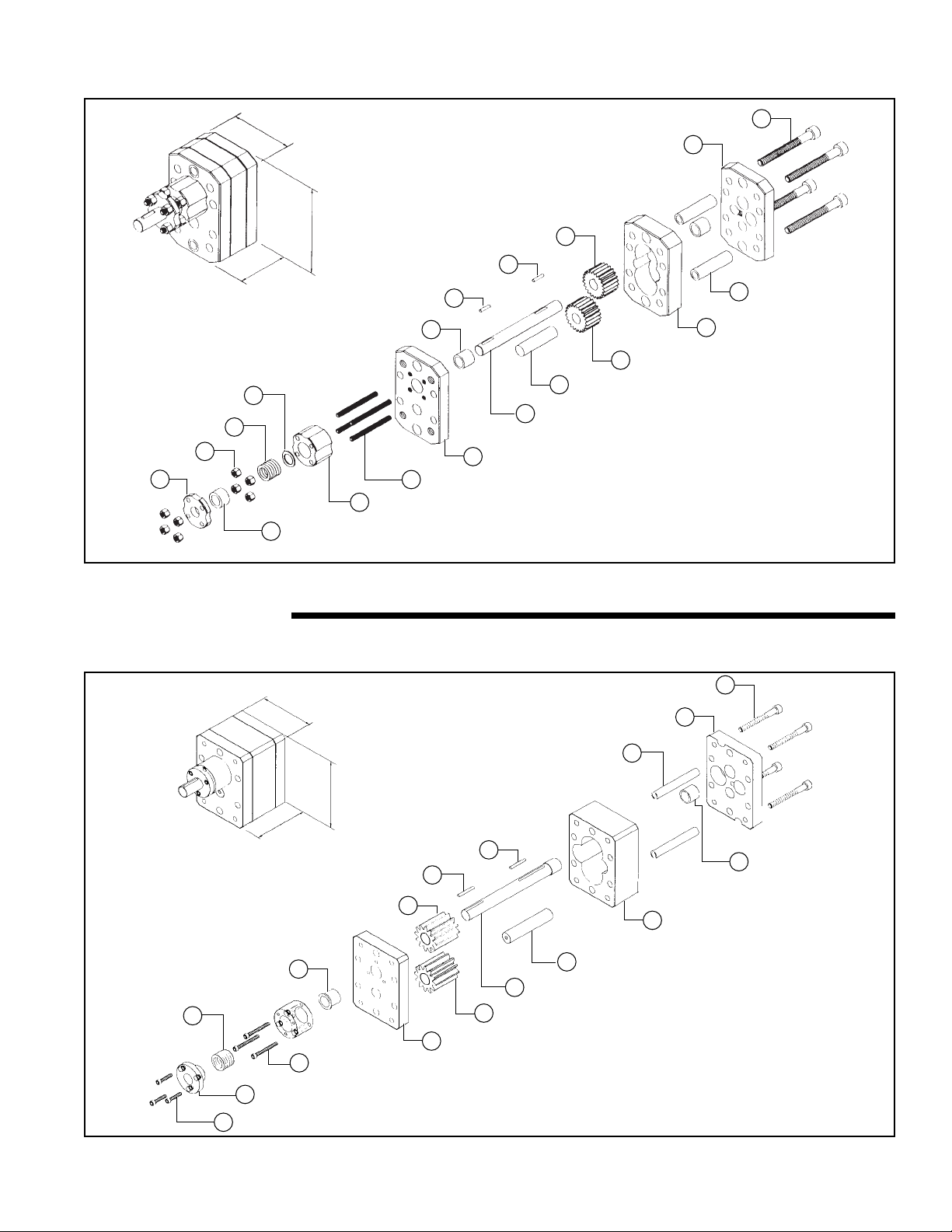

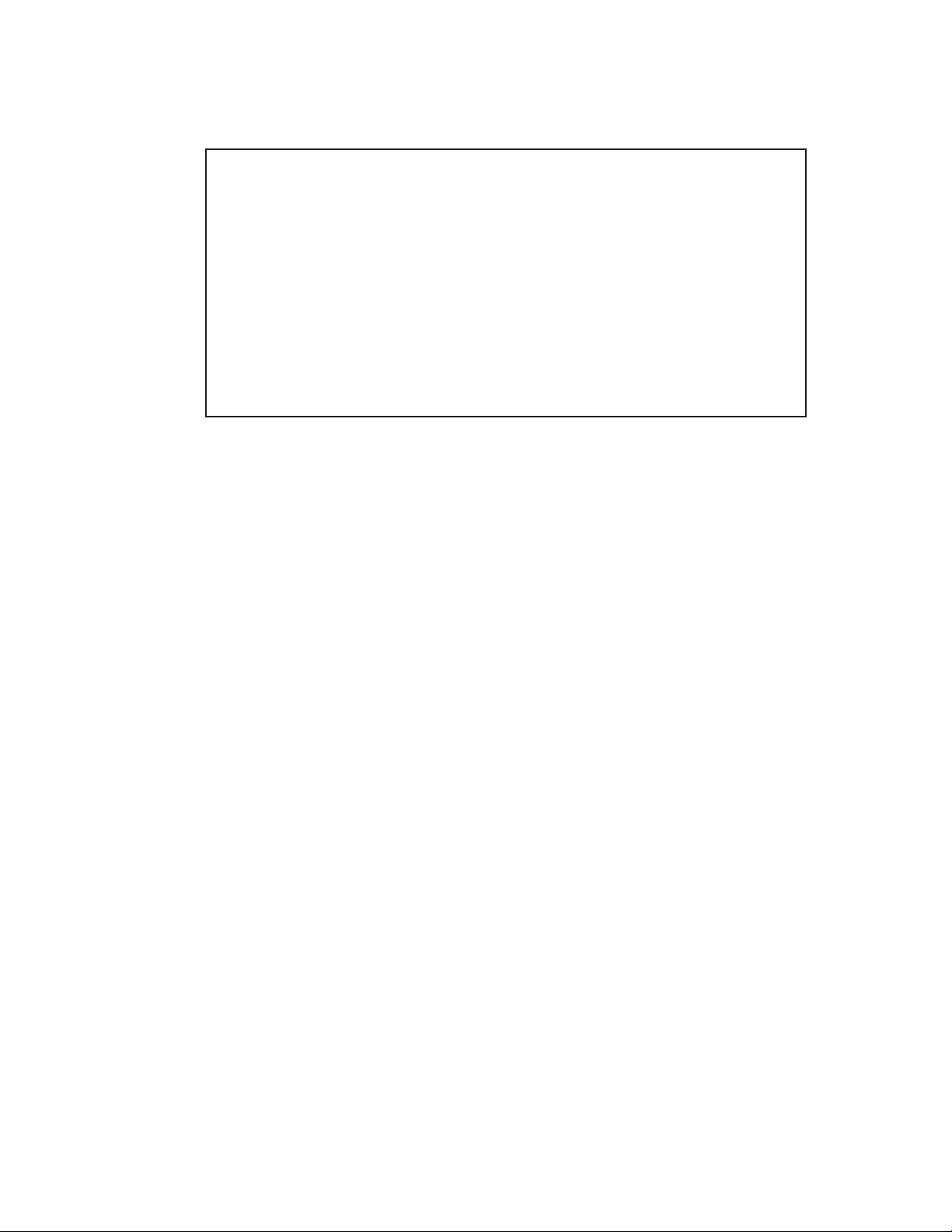

Design Zenith H-Series metering pumps consist

of two gears rotating in mesh within a

closely fitted housing that is comprised of

three plates. The center gear plate fits

closely around the outside diameter of the

metering gears. The front and rear plates

sand-wich the center plate and restrict

axial movement of the gears. Power is

transmitted to the gears by the drive shaft

which is either a through shaft, as in the

packing gland type pump, or a shaft with

a tang that engages a universal seal cou-

pling. The coupling is both a connection

to external power and the rotating mem-

ber of a mechanical seal.

The two seal designs, mechanical

face seal and packing seal, have different

operating requirements. As mentioned

above, the mechanical face seal design

consists of a rotating universal seal cou-

pling that seals against a fixed seal plate.

The all-metal seal design is dependent

upon sufficient inlet pressure (usually 25 -

50 psi) to force the inner rotating coupling

against the outer stationary anchor. This

design is commonly used in abrasive fluid

or high temperature applications.

Since the metal seal requires sufficient

inlet or working pressure to be effective, a

packing seal design is also available.

Pumps with this type of seal can have two

to four packing rings. Common available

materials are Grafoil and Teflon. To seal

effectively, fluid must be able to travel

axially along the shaft. Weepage in these

pumps is a common occurrence and

should be expected.

H-Series pumps are precision

instruments requiring skilled and careful

maintenance. Constructed of high-quality

tool and die steels such as AISI D2, M2, M4

and CPM-M4, or other high-performance

alloys, they are tempered after heat treat-

ment to hardnesses ranging from HRc 58

to HRc 64. Since the thermal expansion

rates for all three steels are almost identical

and are otherwise entirely compatible, it is

possible to combine them so as to take

advantage of their best qualities in the

most economical way.The Type D2 tool

steel is often selected for the side and

center plates as it offers good abrasion

resistance, and it is the most economical

of the three steels we most commonly

use. Type D2 will also provide a higher

degree of corrosion resistance than M2

or M4.

The portion of the side plate subject

to the most wear is the shaft bearing

hole, which has an easily replaceable,

inexpensive sleeve bearing that can be

made of the extremely wear resistant

Type M4 tool steel. Types M2 and CPM-M4

steels are commonly used for the metering

gears, drive shaft, and universal seal

coupling, due to their superior torsional

strength and abrasion resistance for these

items that are the most critical to proper

metering performance.

All H-Series pumps are rear ported. Fluid

enters the pump through a port drilled into

the rear side plate (the side opposite the

drive shaft). The fluid fills the exposed gear

tooth volumes and is transported around

the outer diameter of the gear pocket. As

the gears mesh together, the fluid is dis-

placed in a very precise amount out

through the discharge port that is drilled

alongside the inlet port in the rear plate.

Since Zenith pumps are not self-prim-

ing, a flooded suction is usually the mini-

mum inlet pressure required. However,

when high-viscosity fluids are used, more

time is required to fill the tooth volumes.

As a result, the inlet pressure must be

increased, or the gears must rotate at a

slower speed to ensure complete volume

filling and to prevent cavitation.

Zenith pumps rely on the metered

fluid for lubrication of internal bearing

areas. The pump should never be

allowed to run dry or be allowed to run

with non-lubricating fluids such as water.

Because of the close clearances in the

bearing areas, lack of sufficient lubrication

can cause pump seizure or some other

catastrophic failure.

Slip can occur across the faces of the

gears from the high-pressure side to the

low-pressure side. The amount of slip

depends on four factors: fluid viscosity,

speed, differential pressure, and pump

clearances. Under reasonably stable

operating conditions, slip is repeatable

and predictable,and pump operation can

be adjusted to compensate.

The Zenith H-Series are designed

for high-temperature and high-pressure

operation. As such, operating tempera-

tures to 950° F can be achieved. When

operating at temperatures above ambient,

heat jackets should be used and pumps

should be heated slowly and uniformly to

avoid warpage and internal component

interference.