Columbia EMERALD EM-85 EE Setup guide

Other Columbia Boiler manuals

Columbia

Columbia CSC SERIES Instruction manual

Columbia

Columbia MPH SERIES User manual

Columbia

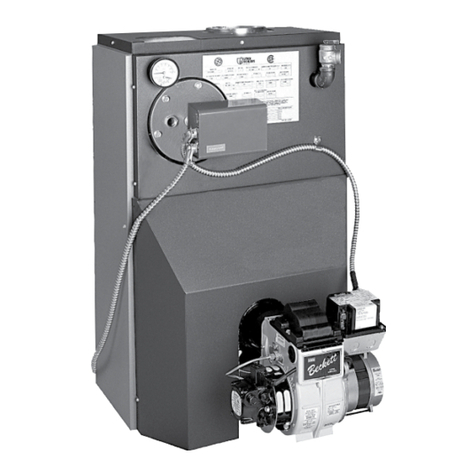

Columbia CSFE-3090S Instruction manual

Columbia

Columbia CEG-C Technical Document

Columbia

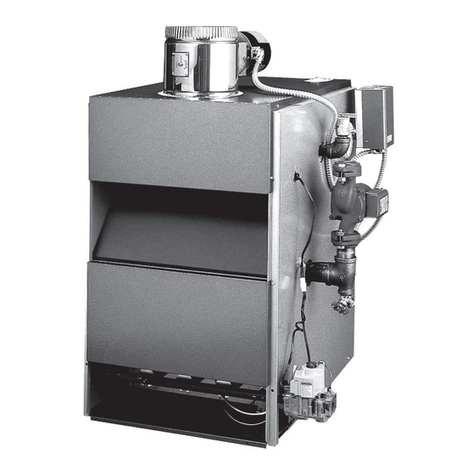

Columbia LV Series Instruction manual

Columbia

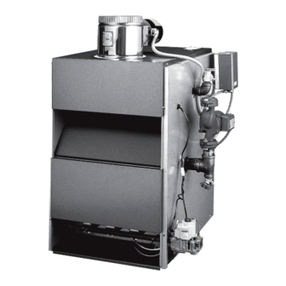

Columbia CT Series User manual

Columbia

Columbia MCB50 Instruction manual

Columbia

Columbia CEG E Series Instruction manual

Columbia

Columbia CSFE0365 Instruction manual

Columbia

Columbia CDVB SERIES Owner's manual

Columbia

Columbia CSVB-2 Instruction manual

Columbia

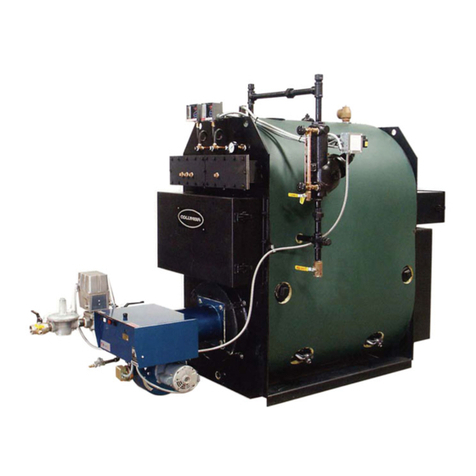

Columbia CEGDID075D Instruction manual

Columbia

Columbia CT-10 User manual

Columbia

Columbia MCB50 Owner's manual

Columbia

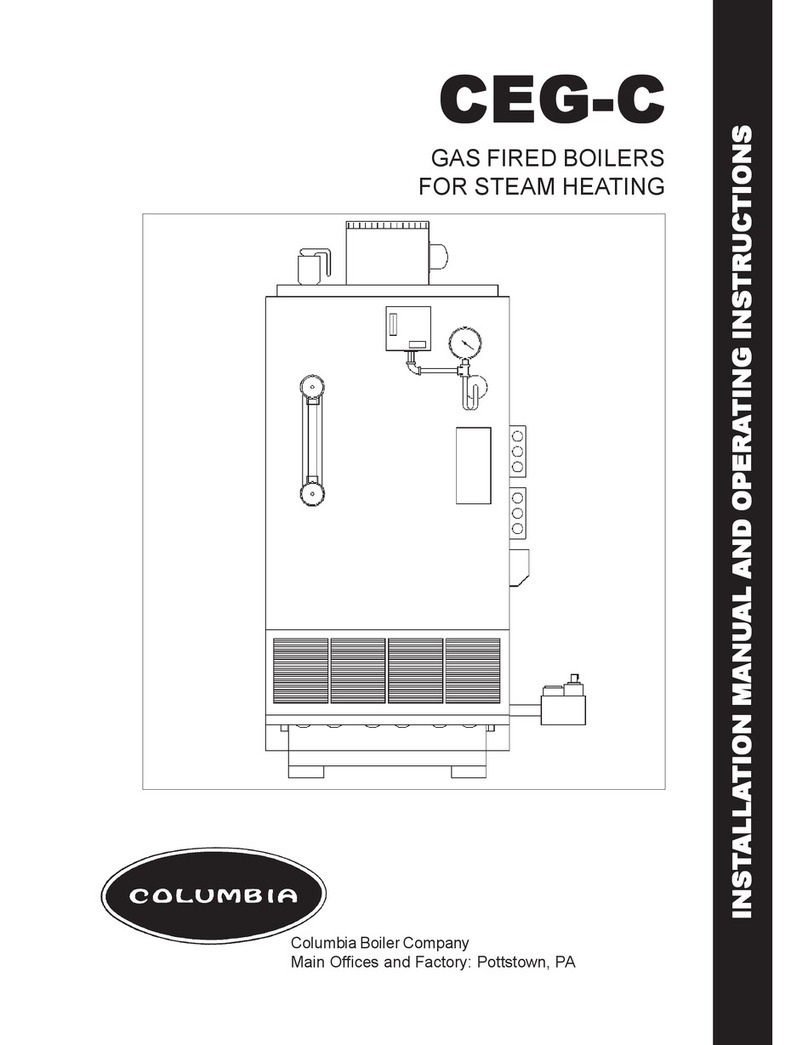

Columbia CEG-C Instruction manual

Columbia

Columbia CSFE0365 User manual

Columbia

Columbia MPH 40 User manual

Columbia

Columbia L series User manual

Columbia

Columbia EMG-31 120 User manual

Columbia

Columbia HERITAGE series Service manual

Popular Boiler manuals by other brands

Vaillant

Vaillant uniSTOR VIH SW GB 500 BES operating instructions

Radijator

Radijator BIO max 23.1 instruction manual

Brunner

Brunner BSV 20 Instructions for use

Buderus

Buderus Logamax GB062-24 KDE H V2 Service manual

Potterton

Potterton 50e Installation and Servicing Manual

UTICA BOILERS

UTICA BOILERS TriFire Assembly instructions

Joannes

Joannes LADY Series Installation and maintenance manual

ECR International

ECR International UB90-125 Installation, operation & maintenance manual

Froling

Froling P4 Pellet 8 - 105 installation instructions

Froling

Froling FHG Turbo 3000 operating instructions

U.S. Boiler Company

U.S. Boiler Company K2 operating instructions

Henrad

Henrad C95 FF user guide

NeOvo

NeOvo EcoNox EF 36 user guide

Potterton

Potterton PROMAX SL 12 user guide

Eco Hometec

Eco Hometec EC 25 COMPACT Technical manual

Viessmann

Viessmann VITODENS 200 Operating instructions and user's information manual

Baxi

Baxi Prime 1.24 installation manual

REXNOVA

REXNOVA ISA 20 BITHERMAL Installation, use and maintenance manual