MN-35947 •Rev 12 •11/16 •Combitherm® CT PROformance™ and CT Classic Series Installation Manual •5

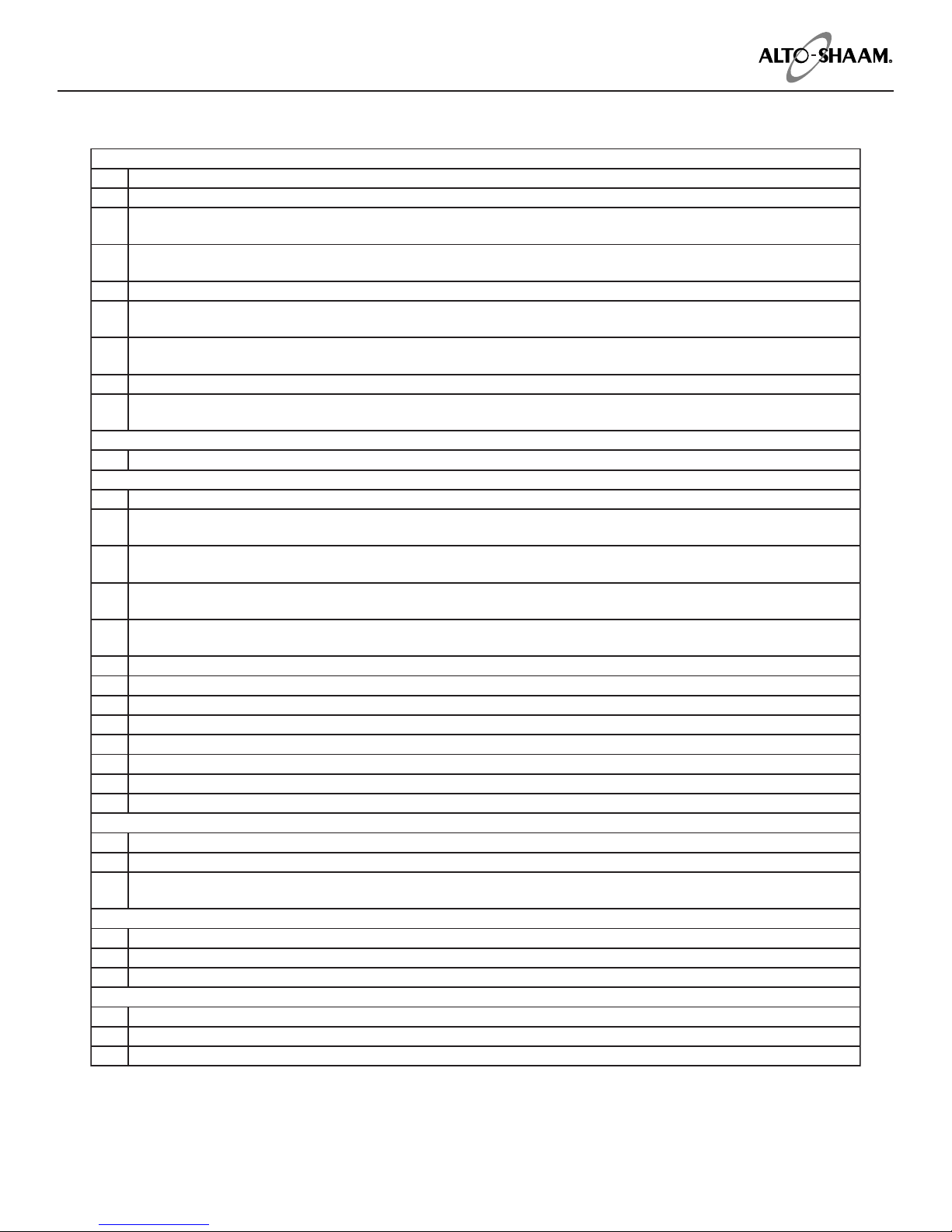

Table of Contents

Transportation Damage and Claims .............2

Delivery ......................................3

Safety Procedures and Precautions .............6

Installation...................................8

Site Installation..................................8

Installation Codes and Standards .................8

Ventilation Requirements .......................8

Sound Pressure Measurements ...................8

Installation Duties & Responsibilities –

New Construction .............................9

Installation Duties & Responsibilities –

Retrot/Existing Kitchen .......................10

Factory Authorized Installation Program

Pre-Installation Checklist.......................11

CTP6-10E Spec Sheet ..........................14

CTC6-10E Spec Sheet ..........................15

CTP6-10G Spec Sheet ..........................16

CTC6-10G Spec Sheet ..........................17

CTP10-10E Spec Sheet .........................18

CTC10-10E Spec Sheet .........................19

CTP10-10G Spec Sheet .........................20

CTC10-10G Spec Sheet .........................21

CTP7-20E Spec Sheet ..........................22

CTC7-20E Spec Sheet ..........................23

CTP7-20G Spec Sheet ..........................24

CTC7-20G Spec Sheet ..........................25

CTP10-20E Spec Sheet .........................26

CTC10-20E Spec Sheet .........................27

CTP10-20G Spec Sheet .........................28

CTC10-20G Spec Sheet .........................29

CTP20-10E Spec Sheet .........................30

CTC20-10E Spec Sheet .........................31

CTP20-10G Spec Sheet .........................32

CTC20-10G Spec Sheet .........................33

CTP20-20E Spec Sheet .........................34

CTC20-20E Spec Sheet .........................35

CTP20-20G Spec Sheet .........................36

CTC20-20G Spec Sheet .........................37

Installation ..................................38

Liing Instructions ...........................38

Positioning on Site – Countertop .................39

Positioning on Site – 20-10 & 20-20 Models .........40

Electrical Safety ReguLations......................41

Electrical Connection for Gas Models ...............42

Electrical Connection for Electric Models ............42

Electrical Kit Installation – 50 Hz...................43

Electrical Kit Installation – 60 Hz...................44

Ventilation Requirements for Gas Models ............45

Gas Supply & Installation .........................46

Water Quality Requirements ......................51

Water Supply & Installation .......................52

Water Drainage – For Single Oven ..................53

Water Drainage – For Stacked Ovena ................54

Mobile Equipment Restraint ......................55

For Gas Models...............................55

For Electric Models ...........................55

CombiHood PLUS™ Ventless Hood Option ...........56

Grease Collection Installation

(If Equipped With This Option) ....................57

Liquid Cleaner Hook-Up

(If Equipped with this Option) .....................58

CT PROformance™ Start-Up Procedures ...........59

How To Turn On the Appliance ..................59

How To Start a Manual Calibration ...............59

How To Calibrate the Touch Screen...............59

How To Turn Off the Appliance ..................59

How To Run a Cycle Test of the Appliance............60

CT Classic™ Start-Up Procedures ............. 61

How To Turn On the Appliance ....................61

How To Preheat the Appliance .....................61

Factory Authorized Installation Program

Post-Installation Checklist ................... 62

Factory Authorized Installation Program

Function Test Checklist ...................... 64

Daily Inspection Checklist ................... 66

Weekly Inspection Checklist ................. 67

Monthly Inspection Checklist ................ 68

Twelve-Month Inspection Checklist ........... 69

Troubleshooting ............................ 72

Error Codes ....................................72

Touch Motor Control Error Codes ..................78

Original Equipment Limited Warranty. . . . . . . . . 79