1. Benets

SM1 Series

• Electromagnetic holding of doors/casings of dangerous machines

• ACOTOM magnetic eld coding closure detection

• Version E: sticking with power o [security access control]

• Version R: sticking with power on [re door, public access]

• EOP version: sticking with power o acc. ISO 14119 [safety machine]

• ROP version: sticking with power on and compatible with ISO 14119 [safety machine]

• OX version: stainless steel 316L body and stainless steel suction cup : force up to 50 kg

• PL version: PA6 body, steel suction cup: force up to 30 kg, stainless steel suction cup: force up to

50 kg

• Automatic compatible lock/unlock command

• Two safety contacts

• An auxiliary output that indicates an open door or a default

• LED which indicates the closing of the door and that the decoding of the transmitter is complete

• Overheating protection with self-resetting device

• Optional RFID pairing version: contact us for information

SM2 Series

• Electromagnetic holding of doors/casings of dangerous machines

• Version E: sticking with power o [access]

• Version R: sticking with power on [re]

• EOP version: sticking with power o and compatible with ISO 14119 [machine]

• ROP version: sticking with power on and compatible with ISO 14119 [machine]

• Stainless steel 316L body and stainless steel suction cup: force up to 100 kg

• ACOTOMtamper-proof closure detection via coding

• Automatic compatible lock/unlock command

• Two safety contacts

• An auxiliary output that indicates an open door or a default

• Overheating protection with self-resetting device

• Optional antibacterial door handle (EPB)

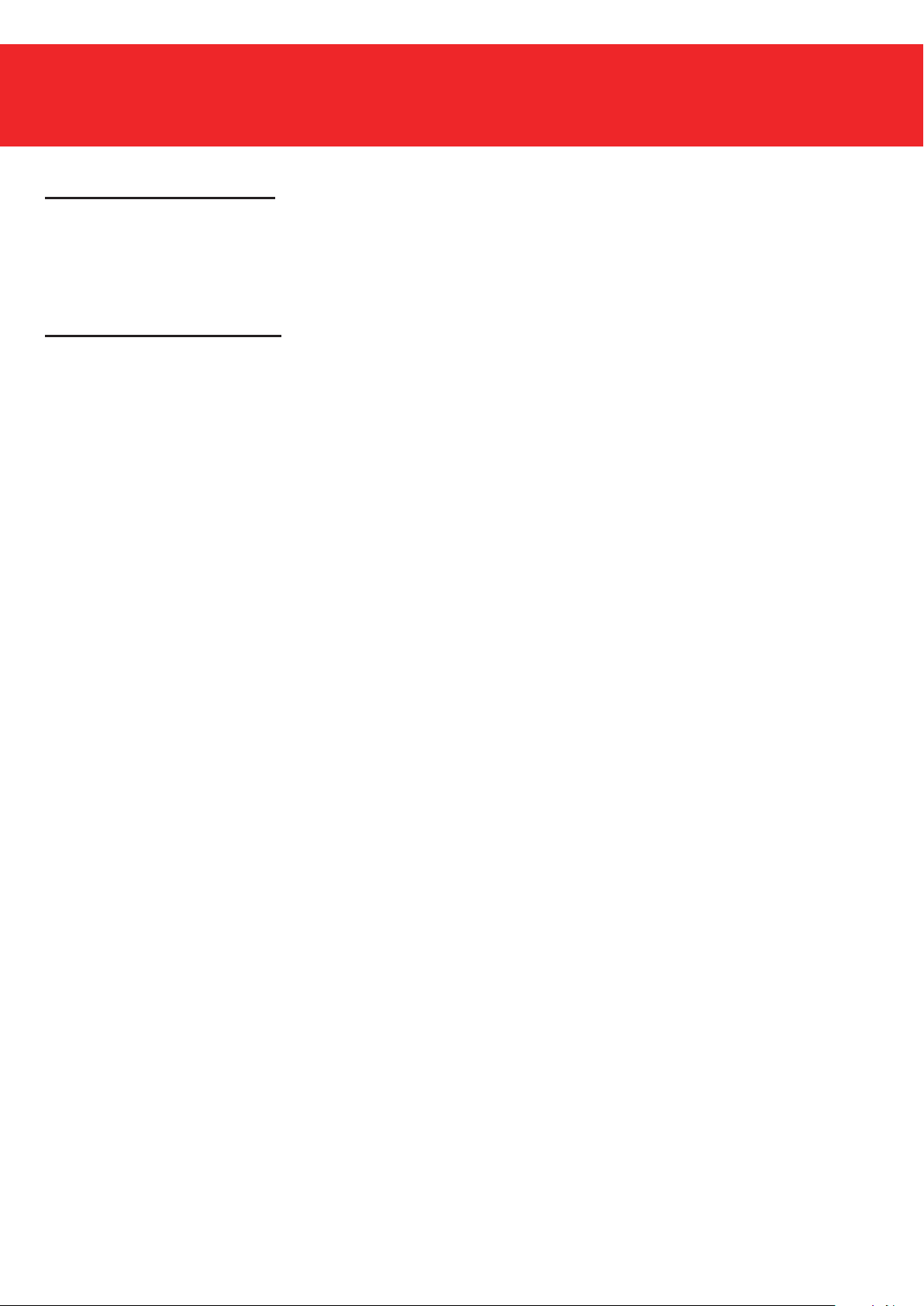

2. Cautions for Use

The polar plate of the transmitter and the suction cup of the receiver must be kept clean and must not

be damaged. For the version "sticking in o", the maximum duration of power is 10 min, we advise pla-

cing a control button near the door to limit the duration. The B22-CV-1OL-RGO-D3T10-BU-MKT touch

button performs the "open" function and limits the duration to 10 min:

- 1st support = delayed opening at 10 min

- 2nd support = closing (even if the duration has not elapsed)

3

SM1 AND SM2 SERIES

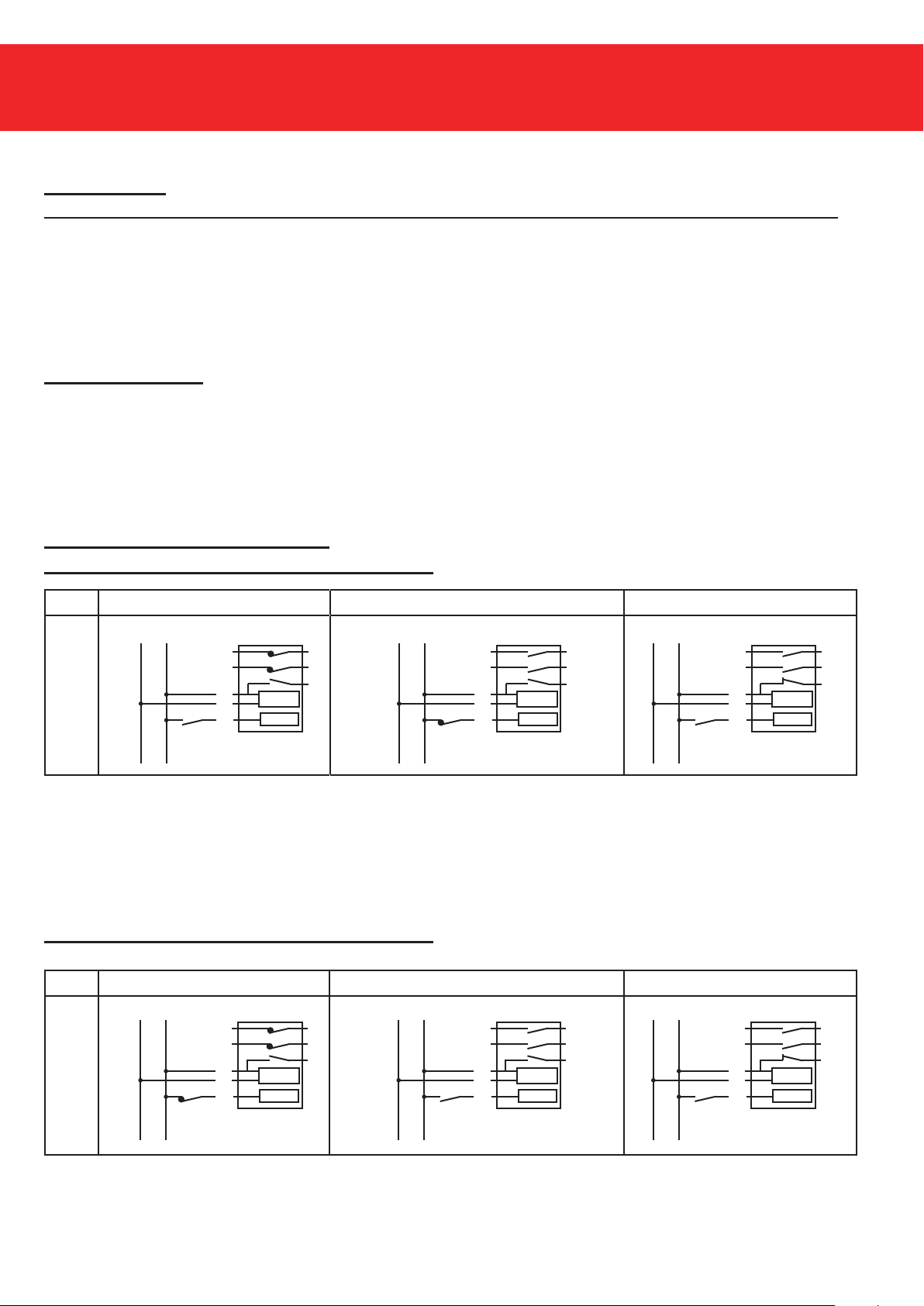

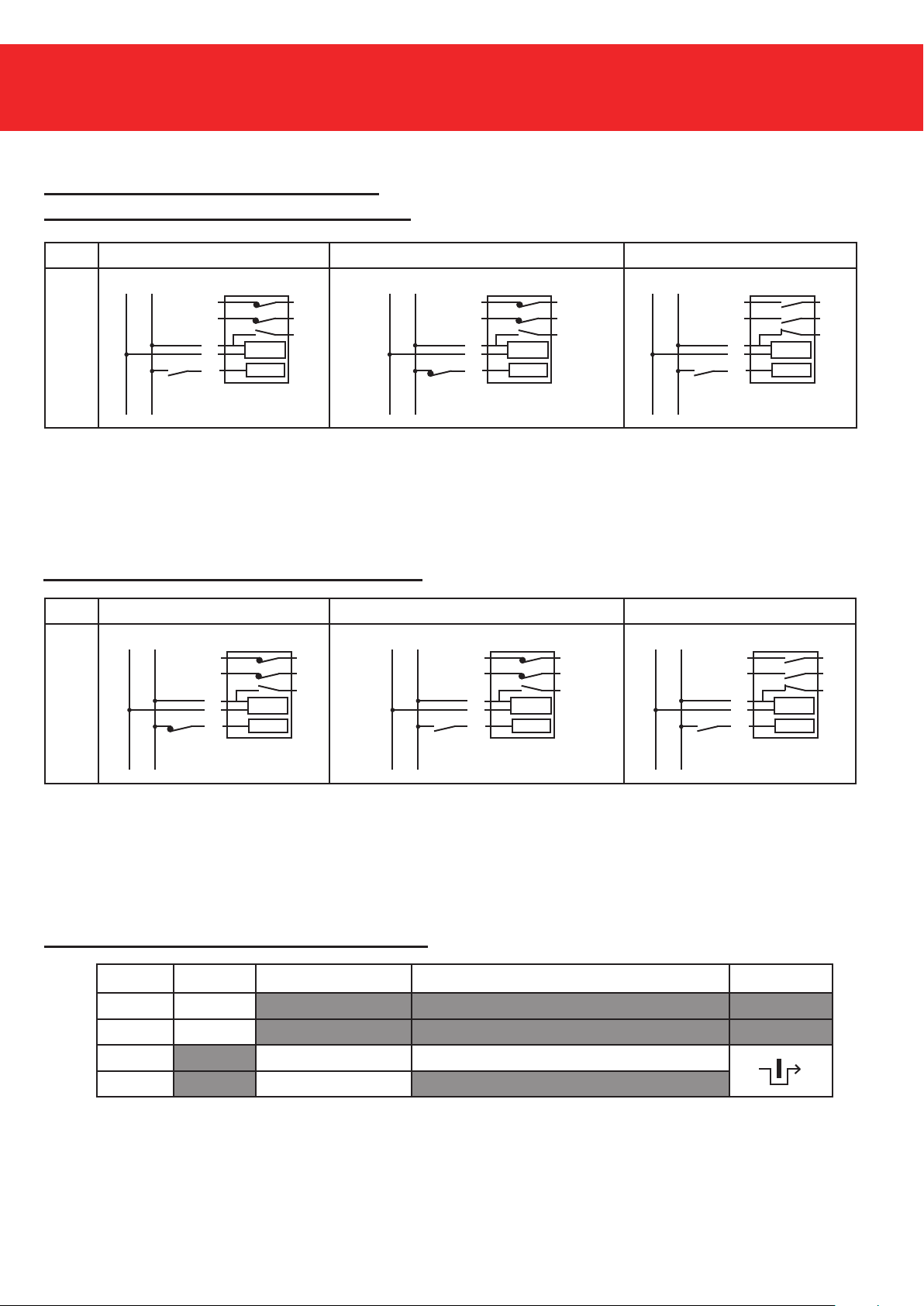

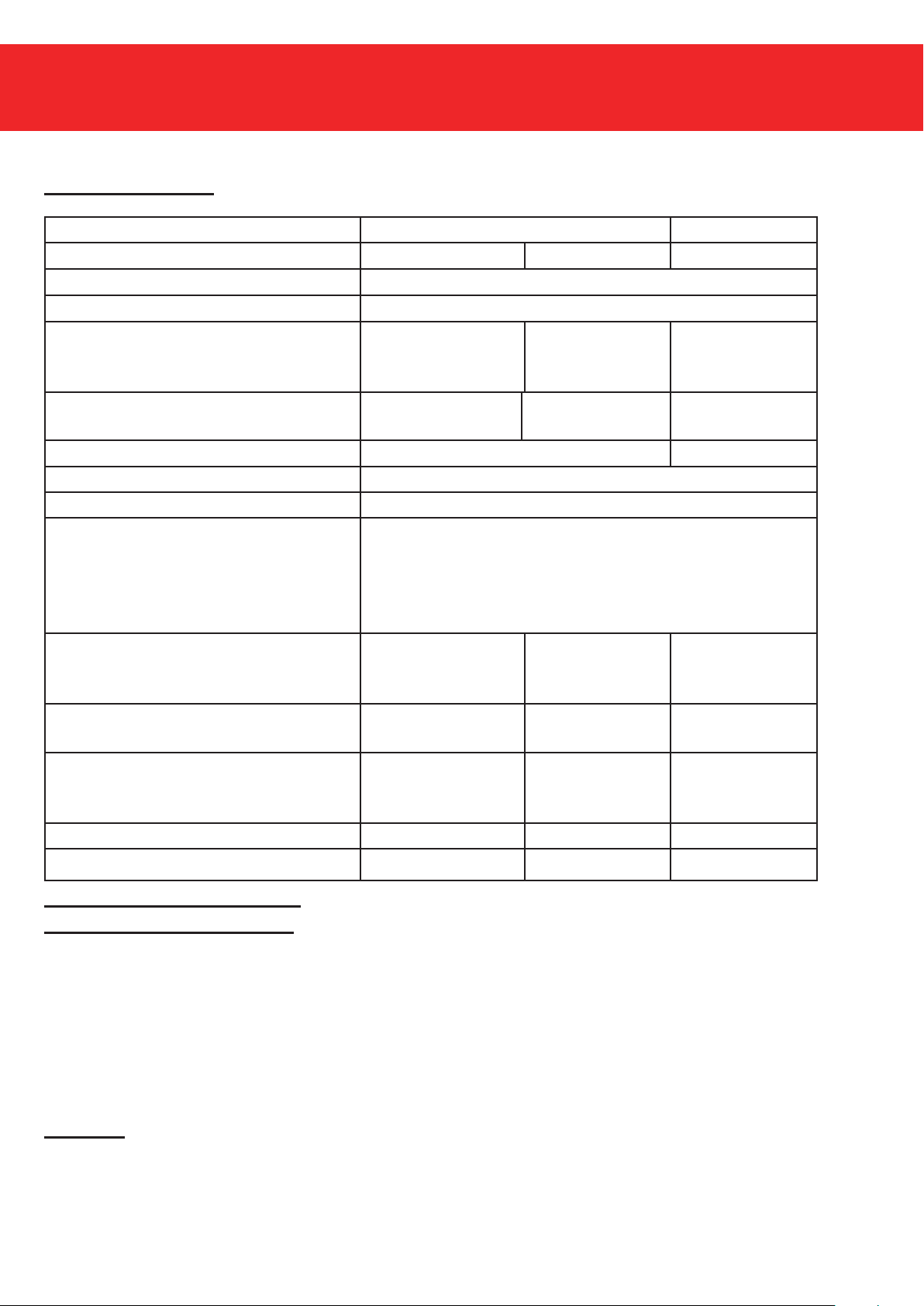

Hold and interlock

Transmitter

LED lighting

Connection

Receiver

Handle

antibacterial

(optional)

overheating

protection

polar spring plate

exible 360 °

connection

M12

output

diagnostic

redundant safety

contacts