Operating Instructions

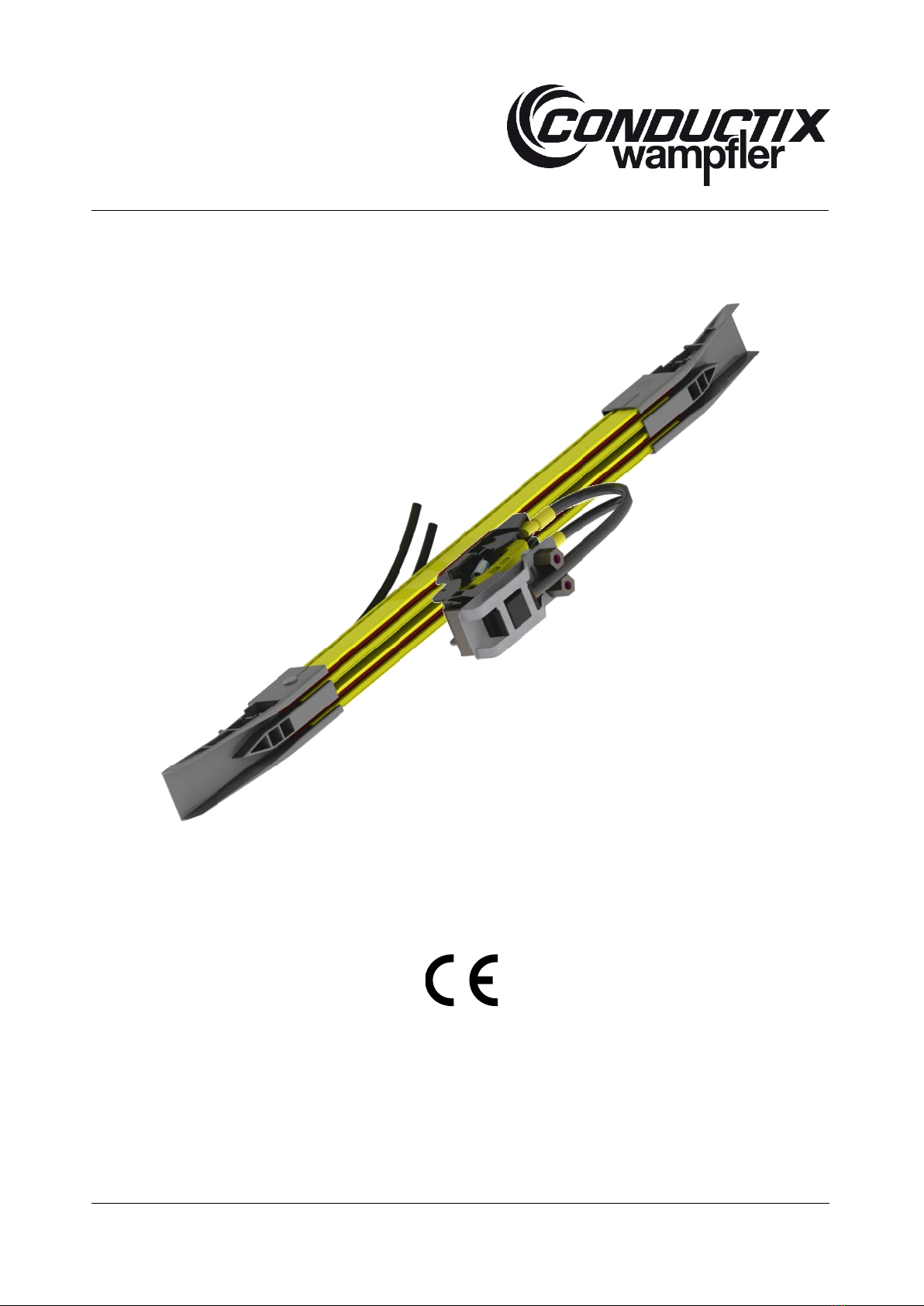

Conductor Rail System

BAL0865-0001-EN

www.conductix.com Translated from: BAL0865-0001-DE page 2 of 51

Contents

1General Information ....................................................................................................................................................................4

1.1 Information about these operating instructions...............................................................................................................4

1.2 Limitation of liability ........................................................................................................................................................4

1.3 Copyright ........................................................................................................................................................................5

1.4 Replacement parts .........................................................................................................................................................5

1.5 Material defects ..............................................................................................................................................................5

1.6 Technical support ...........................................................................................................................................................5

2Safety Information.......................................................................................................................................................................6

2.1 Explanation of symbols...................................................................................................................................................6

2.2 Personnel requirements .................................................................................................................................................7

2.3 Personal protective equipment .......................................................................................................................................8

2.4 Intended use...................................................................................................................................................................9

2.5 5 Safety Rules for working on electrical systems ...........................................................................................................9

2.6 Special dangers..............................................................................................................................................................9

3Technical Data ..........................................................................................................................................................................15

3.1 Electrical .......................................................................................................................................................................15

3.2 Mechanical ...................................................................................................................................................................15

3.3 Operating conditions.....................................................................................................................................................17

4Description andFunctional Principle..........................................................................................................................................18

4.1 Brief description............................................................................................................................................................18

4.2 Description of assemblies.............................................................................................................................................19

5Transport, Packaging and Storage ...........................................................................................................................................23

5.1 Transport ......................................................................................................................................................................23

5.2 Storage of packaged parts ...........................................................................................................................................23

6Installation.................................................................................................................................................................................25

6.1 Safety ...........................................................................................................................................................................25

6.2 Procedure .....................................................................................................................................................................27

7Commissioning .........................................................................................................................................................................38

8Operation ..................................................................................................................................................................................40