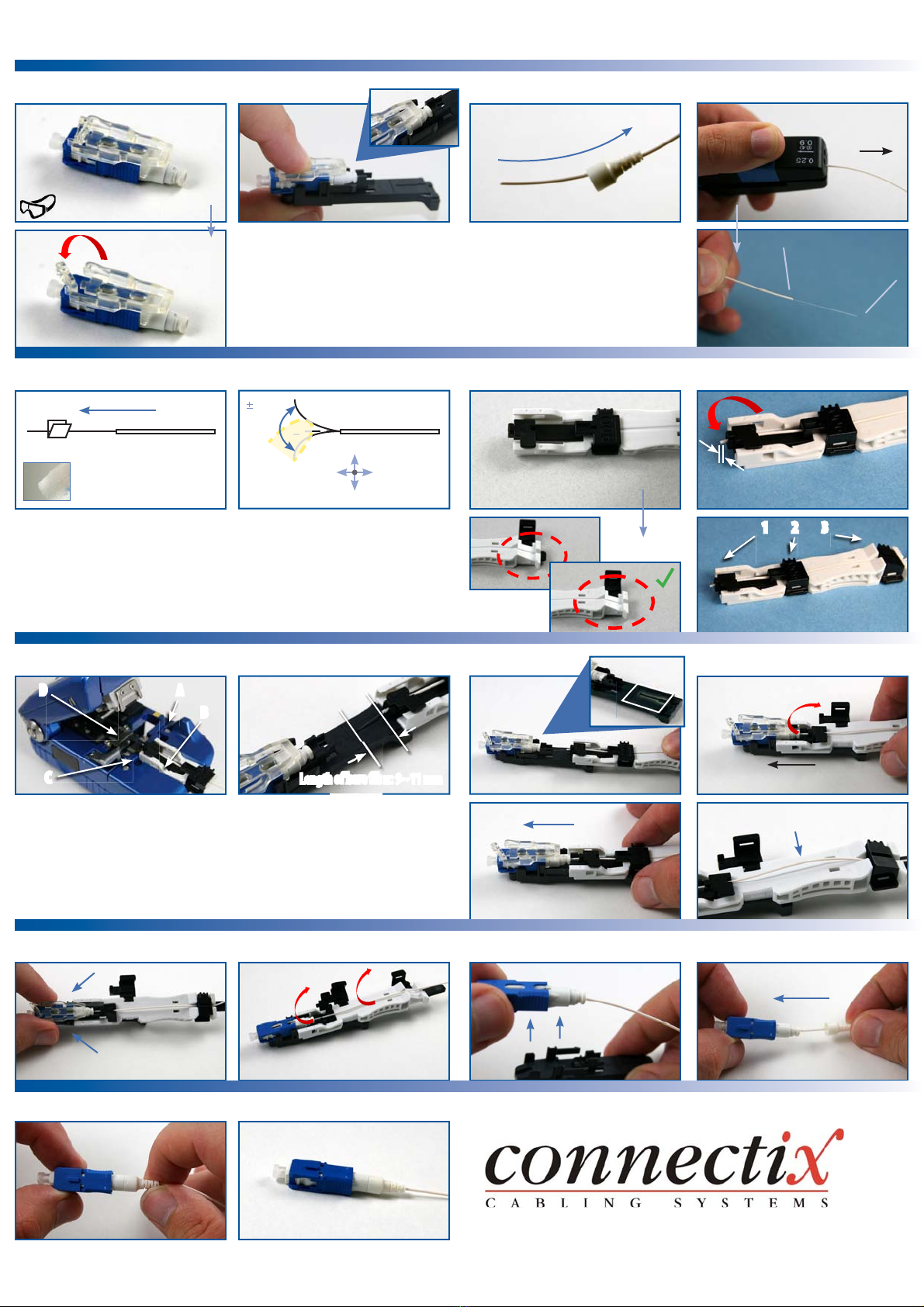

7- Setting Fiber on the Fiber Holder

A C

Close the front cover

B D

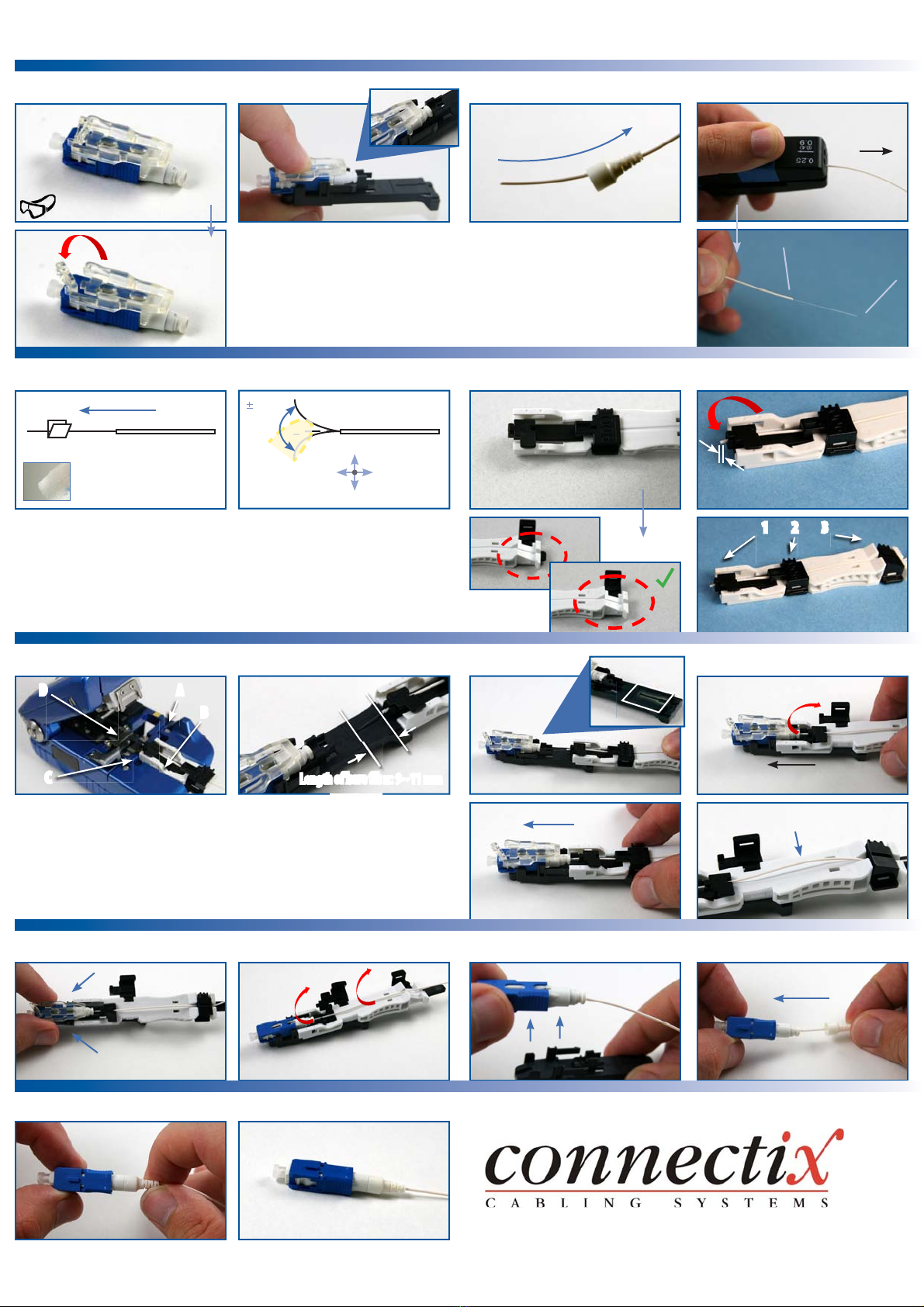

11 - Remove the Wedge 12 - Open the Front and Back Cover 13 - Take out Connector 14 - Fitting Boot

8- The Fiber Cleaver 9- Checking Cut Dimension

5- Cleaning Bare Fiber 6- Screening Fiber

2- Setting Connector 3- Install boot onto ber as shown 4- Removing 0.9 Wire Coating

AGrip

B

15 - Completion

1- Preparing Connector

A

B Open the lock lever

10 - Inserting Fiber

A C 1. Open the middle cover

B D

Small amount of bending is normal

Be sure to wear Safety Glasses

2 - Set circular groove of connector

tightly onto semicircular ridge “U”

shaped shelf of Jig.

Make sure there is no space between the

wedge and the connector, if there is, re-

align the products before proceeding.

Approximately 30 mm

4 A - Remove 0.25 mm or 0.9 mm ber

jacket remover. coating, using

appropriate ber jacket remover.

4 B - Removing appropriate length of

the ber jacket

Pull

5 - DO NO T USE DIRTY GAUZE!

6 Bend ber several times by moving it

with your nger back and fourth.

IF FIBER BRAKES, START WITH A

NEW FIBER FROM THE BEGINNING.

7B - When fully pushed forward guide

member should not be visible from the

back end of the ber holder

7D- SETTHE FIBER ALONG THE GROOVE

TIGHTLY BEFORE CLOSING THE BACK COVER.

8 - A - Insert slider

B - Set the ber holder to the Cleaver

C - Set the ber holder tightly

D - Push the cover of the Cleaver

SET THE FIBER HOLDERTIGHTLY!

A

B

C

D

10A -

Set the ber holder to the guiding rail

10 B - Slide holder slowly until it is stopped.

BE CAREFUL NOTTO HIT THE EDGE OF FIBER!

10C See diagram

10D CHECKING WHETHERTHE FIBER IS

BENDING OR NOT IMPORTANT!

Guiding Rail

Length of bare ber: 9~11 mm

CLICK!

Push the arm to remove the wedge PULL OUT WEDGE AND OPEN COVER.

CLICK!

IF OUT OF TOLERANCE,

REWORK FROM

PROCEDURE4!

Close the cover in the order of above

LENGTH OF 0.9 BUFFER IS WITHIN 2 MM!

<2mm

1 2 3

X

Clean bare ber with a lint-

free Gauze Pad moistened

with pure Alcohol

X

up

down

left right

30o

degree

GUIDE MEMBER MUST BE PUSHED AS

FAR FORWARD AS POSSIBLE.

2. Insert until sounding click