3

Yellow

spring is standard,

but

to increase engagement A.P.M. you

c

ould

install

a green spring

which

is stronger.

Part

Number

Color S

pr

ing

Compress

ion

Rate

050760 Y

ellow

50 Ibs. @in.

050786 Green 64 Ibs. @in.

NOTE : New

springs

will

have a

higher

ten

sion

than a used

spr

ing.

Norm

ally

, a

spring

will

"se

at"

afte

r approx

imate

ly 50

mil

es. Be sure to install a used

spring

when

adju

sting

your

drive

system

s

ince

spring

change

s

could

later alter y

our

ad-

ju

stments

.

TRACK CLEAR

SLOW-MAINTA

IN RACE OVER

POSITION

TJ2

Figure 2

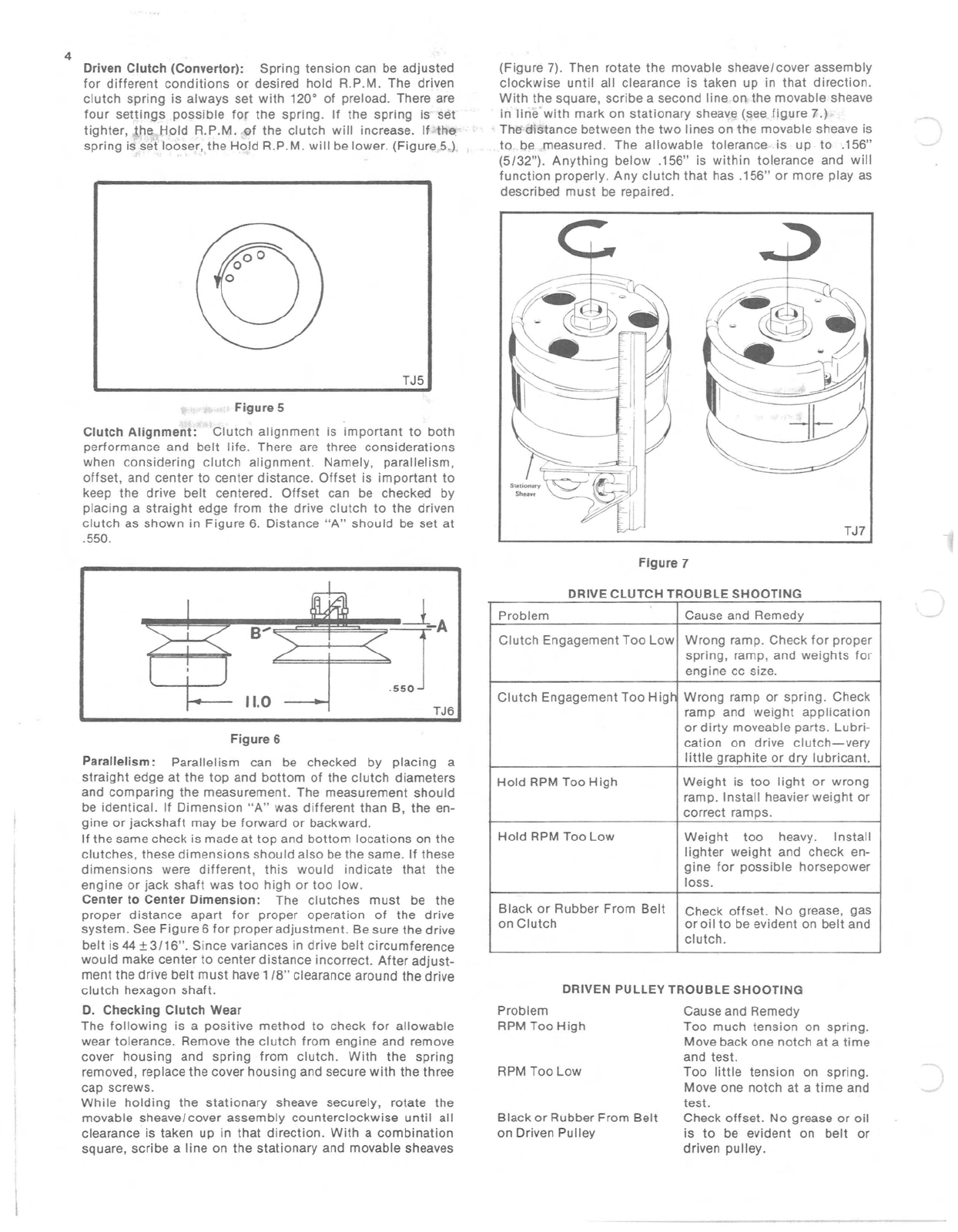

DRIVE SYSTEM

Weights: The

roller

arm

weights

primari

ly

control

the

hold

A.P.M. The

weight

will

also

have a

slight

effect

on the en-

gagements and

shift

pattern. 8000 A.P.M. must be

main

-

t

aine

d

for

best

efficiency.

Below

is a

weight

chart

li

sting

heavier and

lighter

weights.

Lighter

wei

ghts

would

incr

ease

the

hold

A

.P.M

. and a heavier

weight

would

decrease the

A.P.M .

WEIGHT

CHART

CAUTI

ON:

All six

weights

must

be the same. Never

mix

lighter

or heavier

weights

.

HIGHER HOLD R.P.M.

LOWER HOLD R.P.M.

NOTE: Some ra

cing

as

sociations

may not allow changing

clutch wei

ght

s

from

standard in stock classes.

Ramps:

Engagement, shift p

att

ern, and Hold A.P.M. are all

affected by the r

amp

angl

e. We do

not

re

com

mend

mod

ifi-

cation of the ramp

since

this

must be accurately matched to

the torque curve of the

engi

ne. Below is a chart which

indi

cates e

ffe

ct of ramp angle on the shift pattern. (

Fig

ure 4)

Part Number 1.0.

Num

ber

Out

side

Dia. Wei

ght

in

Grams

050780 175 .437 3.725 li

ght

er

050779 135 .471 4.479

ligh

ter

050777 107 .491 4.958

light

er

050776 106 .530 5.958 standard

050778 123 .568 6.992 heavier

'.'."

:

,

--

,\

,,\

,-,

,,,

,,,

:

,/

,

,,

,\

,\

."

\

.'

--r\.

,-\

-,,

-

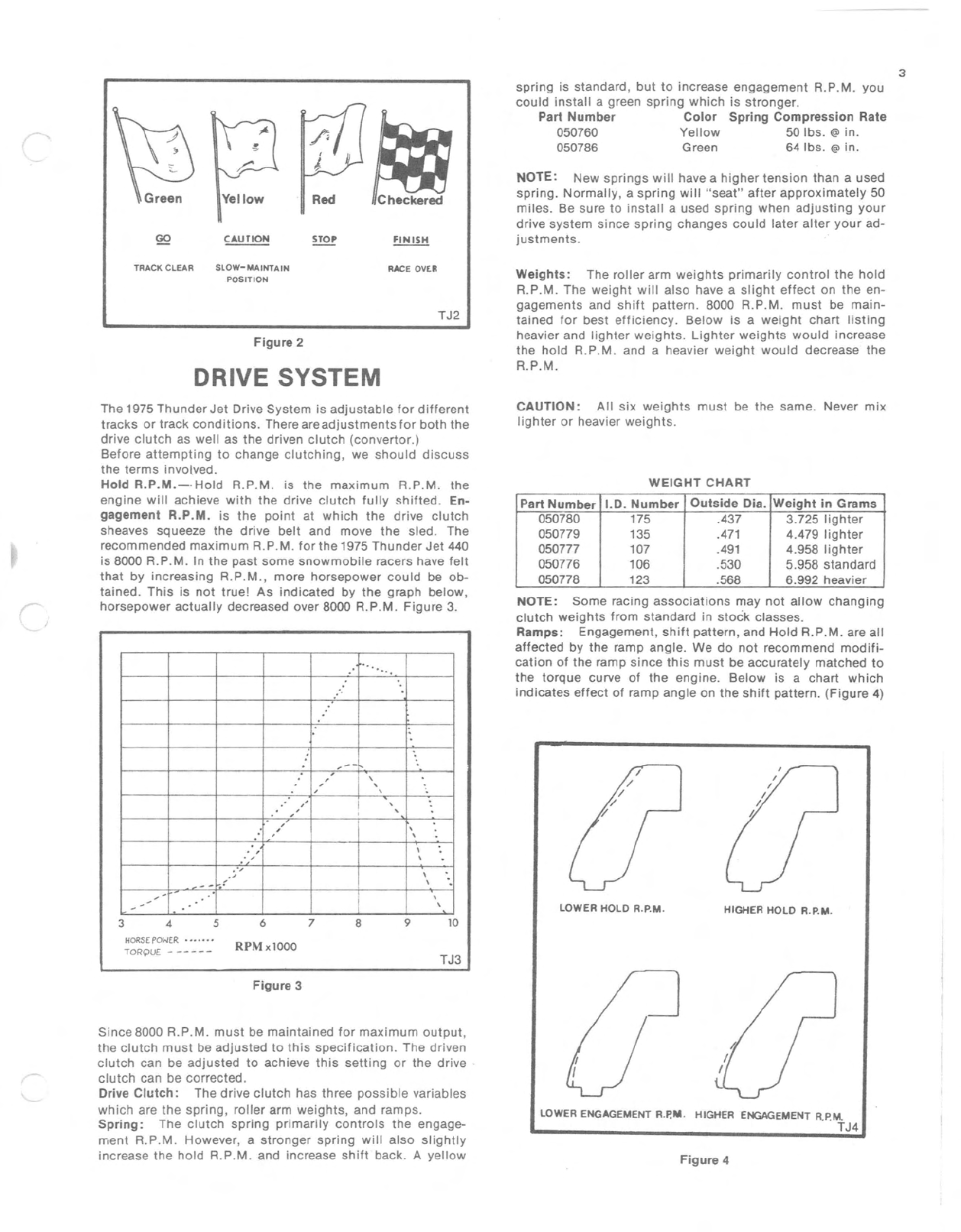

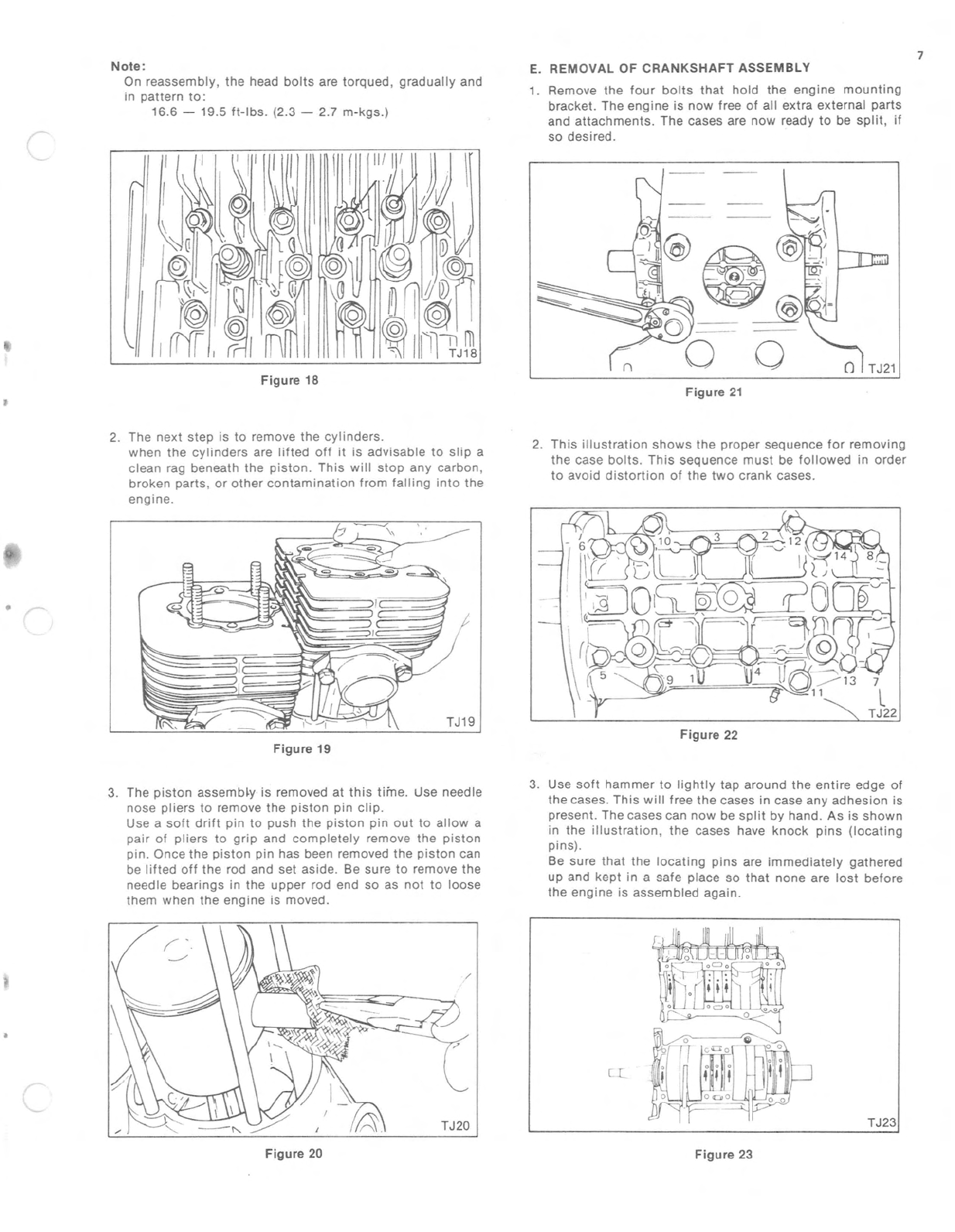

The 1975

Thunder

Jet

Drive

System

is ad

justable

for

different

tracks

or track cond

itions

. There are

adjustments

for

both

the

drive c

lutch

as well as the driven

clutch

(convertor.)

Before

attempt

ing to

change

clutch

ing , we

should

d

iscuss

the

terms

involved.

Hold

R.P.M.-

·Hold

A.P

.M.

is the

maximum

A.P.M . the

eng ine

will

achieve

with

the drive

clutch

fully

shifted

. En-

gagement

R.P.M

. is the po

int

at

which

the

drive

clutch

sheaves squeeze the

drive

b

elt

and move the sled . The

recommended

maximum

A.P.M.

for

the 1975

Thunder

Jet

440

is 8000 A.P

.M.

In the

past

some

snowmobile racers have

felt

that

by increa

sing

A.P.M ., more

hors

epow

er

could

be ob-

tained. This is not tru e! As

indic

ated by the graph

below

,

hors

epower

a

ctually

d

ecr

eased over 8000 A.P.M .

Figure

3.

345678910

HoRSE

POWER

....

.

..

RPMxl000

TORQ

UE -

--

---

TJ3

Figure 3

Since

8000 A.P.M.

must

be

maintained

for

maximum

output

,

the

clutch

must

be

adjusted

to th is

specification

. The driven

clutch

can be

adjusted

to achieve

this

setting

or the drive ·

clutch

can be corrected.

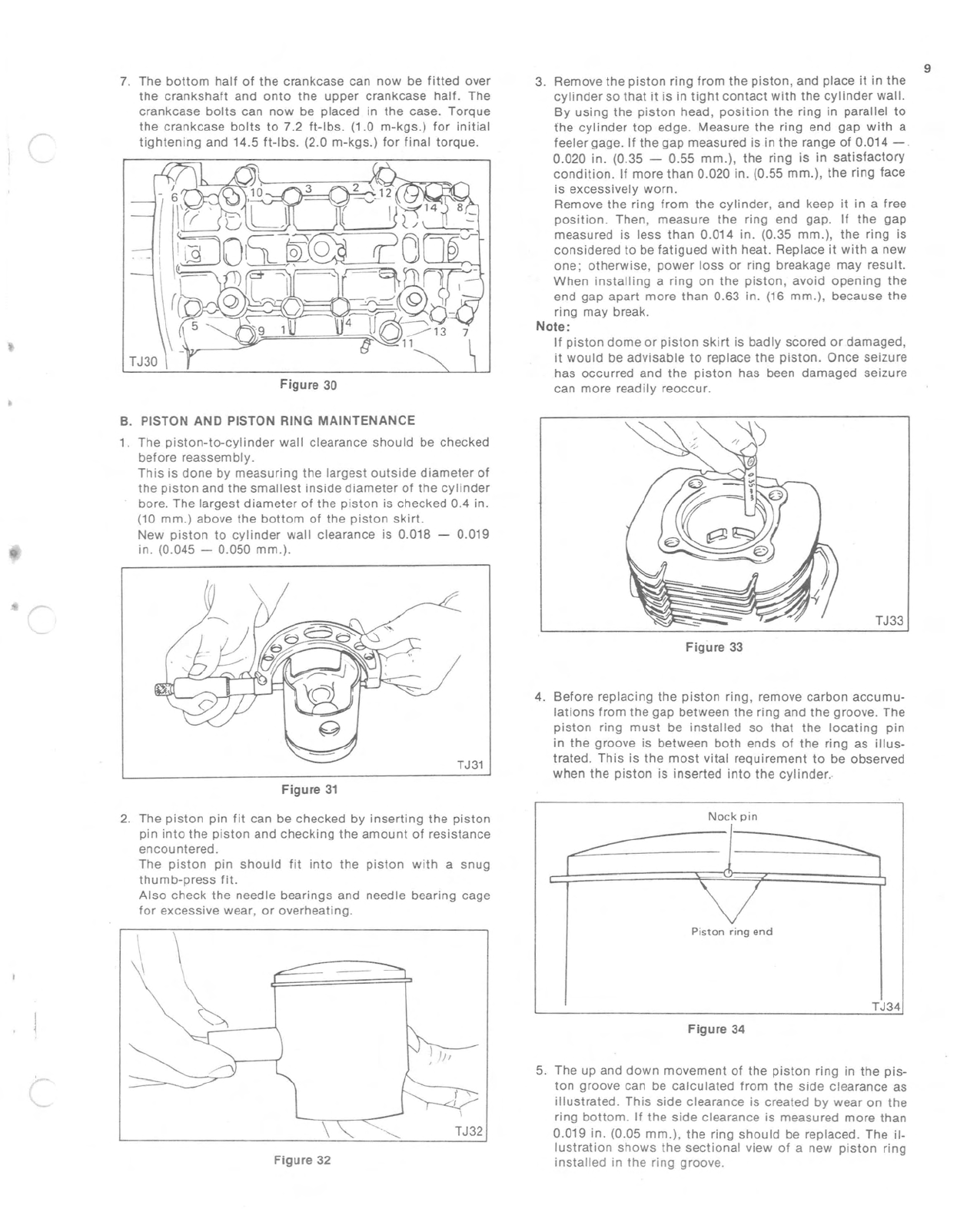

Drive

Clutch:

The drive

clutch

has three

possible

variables

which

are the

spring

,

roller

arm

weights,

and ramps.

Sprin

g:

The c

lutch

spr

ing

primarily

controls

the engage-

ment A

.P.M.

However, a

stronger

spring

will

also

slightly

increase the hold A.P.M. and increase shift back . A

yellow

LOWER ENGAGEMENT R.p,M. HIGHER ENGAGEMENT R.P.M.

TJ4

Figure

4