Introduction 1

1. INTRODUCTION

The Model 220i Level Monitor is a microprocessor based instrument

which accepts a 4-20mA input and displays level and contents. It is

powered entirely from the 4-20mA loop and, therefore, does not require

an external power source.

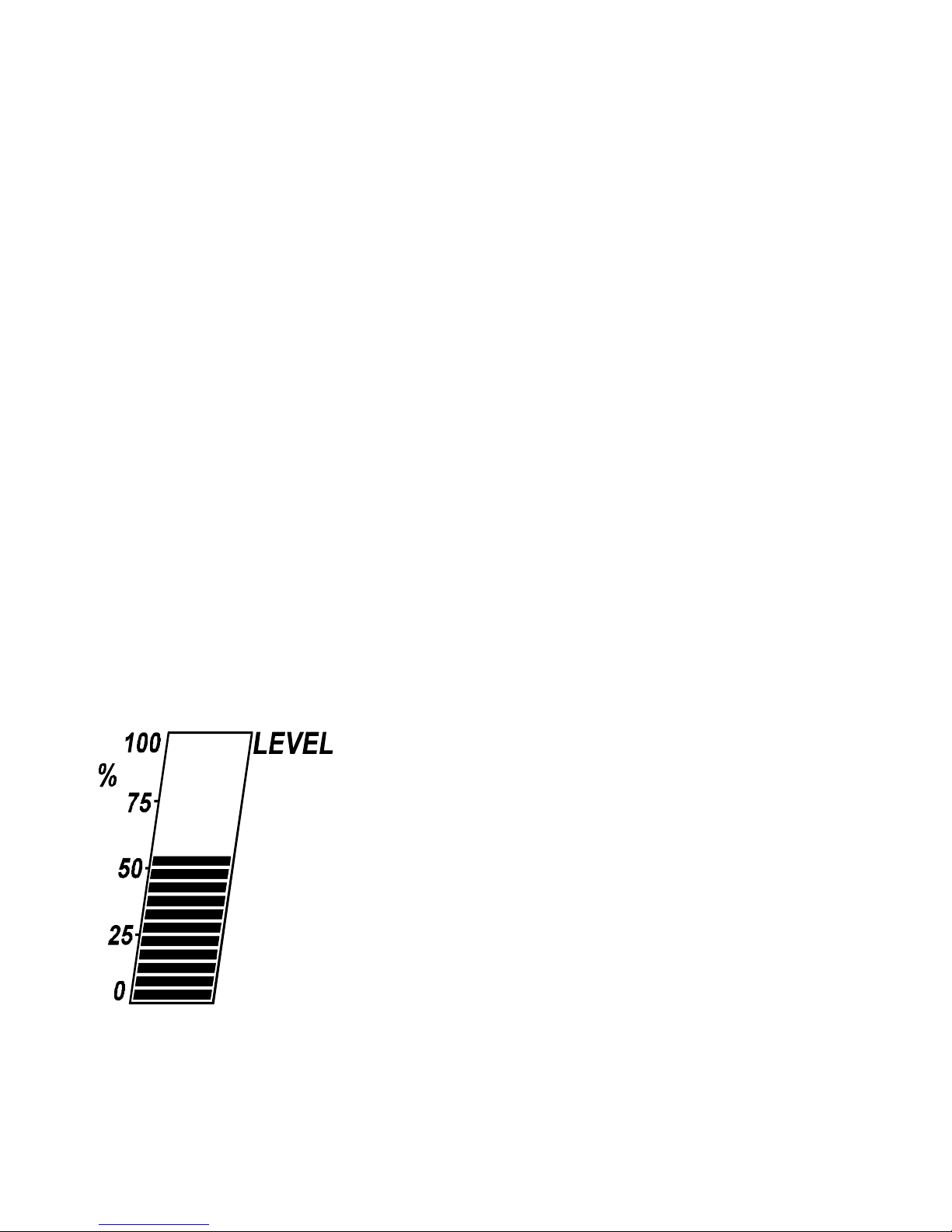

Level is displayed in a bar graph as 0...100%. The contents are a 7 digit

numeric display which can be spanned in any engineering units.

The instrument is fully programmable; the user can program alarm settings,

span & zero levels and non-linear correction points. Calculation constants are

also set from the front panel and are stored in a non-volatile memory which

retains data indefinitely.

The Model 220i Rate Totaliser conforms to the EMC-Directive of the Council of

European Communities 2004/108/EC, the LVD directive 2006/95/EC and the

following standards:

EN61326:2013 Electrical equipment for measurement, control

and laboratory use – EMC requirements :

Residential, Commercial & Light Industry

Environment & Industrial Environment.

EN61010:2010 Safety requirements for electrical equipment

for measurement, control, and laboratory use.

In order to comply with these standards, the wiring instructions in Section 7.5

must be adhered to.