4HMD IO&M B51242-002

4. Compare the supplied voltage,

hertz, and phase with the unit

and motor’s nameplate infor-

mation.

5. Open the blower access door

and run the blower momentarily

to determine the rotation. Ar-

rows are placed on the blower

scroll to indicate the proper di-

rection.

NOTICE! If the blower is rotating in the wrong direc-

tion, the unit will move some air, but will not perform

as designed. Be sure to perform a visual inspection to

guarantee the correct blower rotation.

• To reverse the rotation on three phase units,

disconnect and lock-out the power, then interchange

any two power leads.

• To reverse the rotation on single phase units,

disconnect and lock-out the power, then rewire the

motor per the motor manufacturer’s instructions.

6. Check for unusual noise, vibration or overheating of

the bearings. Reference the Troubleshooting sec-

tion for corrective actions. Excessive vibration may

be experienced during the initial start-up. Left un-

checked, it can cause a multitude of problems in-

cluding structural and/or component failure. Gener-

ally, fan vibration and noise is transmitted to other

parts of the building by the ductwork. To minimize

this undesirable eect, the use of heavy canvas duct

connectors is recommended.

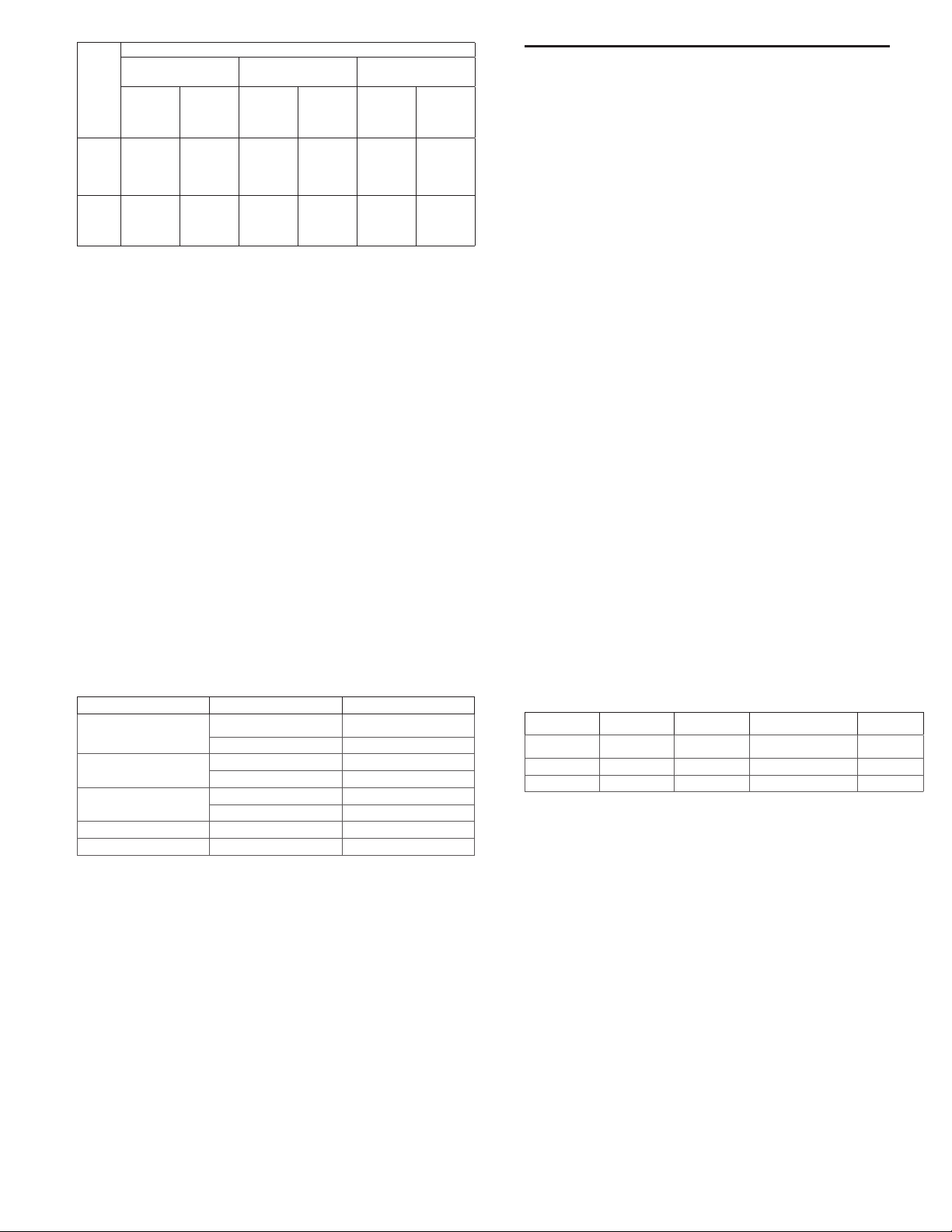

7. Measure the motor’s voltage, amps and RPM.

Compare to the specications. Motor amps can be

reduced by lowering the motor RPM or increasing

system static pressure. Additional starters and over-

loads may be provided in the make-up air control

center for optional exhaust blowers. Any additional

overloads must be checked for proper voltage and

amps.

8. Measure the unit’s air volume (cfm) and compare it

with its rated air volume. If the measured air volume

is wrong, adjust the fan’s RPM by changing/adjust-

ing the drive. The most accurate way to measure

the air volume is by using a Pitot traverse method

downstream of the blower. Changing the air volume

can signicantly increase the motor’s amps. If the

air volume is changed, the motor’s amps must be

checked to prevent overloading the motor. To ensure

accuracy, the dampers are to be open when measur-

ing the air volume.

9. Adjust the settings on the optional components. See

the Control Center Layout in the Reference section

for location of optional components.

• Heating Inlet Air Sensor:

Typical setting: 60-70ºF

• Building Freeze Protection:

Typical setting: 45ºF

• Dirty Filter Gauge:

Typical setting: Settings vary greatly for each unit.

Do not connect the unit to gas types other than what

is specied and do not connect the unit to gas pres-

sures that are outside of the pressure range shown on

the label.

When connecting the gas supply, the length

of the run must be considered in determining

the pipe size to avoid excessive pressure drop.

Refer to a Gas Engineer’s Handbook for gas

pipe capacities.

Refer to the heater rating plate for determining

the minimum gas supply pressure for obtain-

ing the maximum gas capacity for which this

heater is specied.

1. Determine the supply gas requirements by looking

at the unit’s nameplate on the outside of the unit on

the control center side.

2. When the supply gas pressure exceeds the maxi-

mum gas pressure shown on the nameplate, an ad-

ditional regulator (by others) is required to reduce

the pressure. The regulator must have a listed leak

limiting device or it must be vented to the outdoors.

The regulator located inside the unit is used to adjust

the unit’s maximum output temperature.

3. If an optional vent line is located between the safety

shuto valves it must be piped to the outdoors.

Reference the National Fuel Gas Code for

additional vent line requirements.

4. Test the system for leaks.

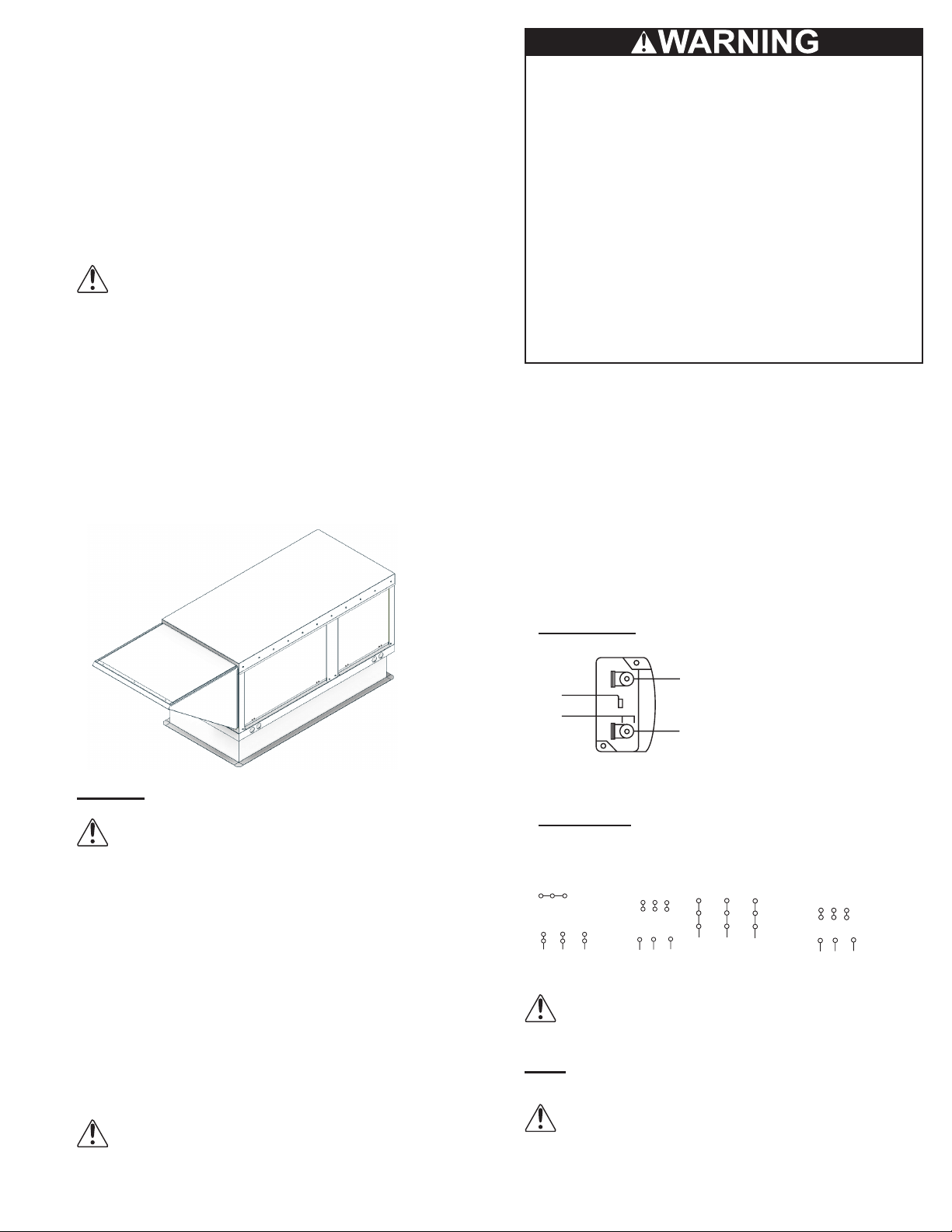

Operation

Pre Start-Up

Follow the pre start-up list before proceeding. Follow

the procedure in the exact order that it is presented.

Failure to do so could result in serious injury or death

and damage to equipment.

Pre Start-Up

General

1. Get voltage & amperage meter, thermometer, micro amp

meter, u-tube manometer and tachometer.

2. Perform a gas leak check during heater start-up, to verify

the gas tightness of the heater’s components and piping

under normal operating conditions.

3. Disconnect and lock-out all power and gas.

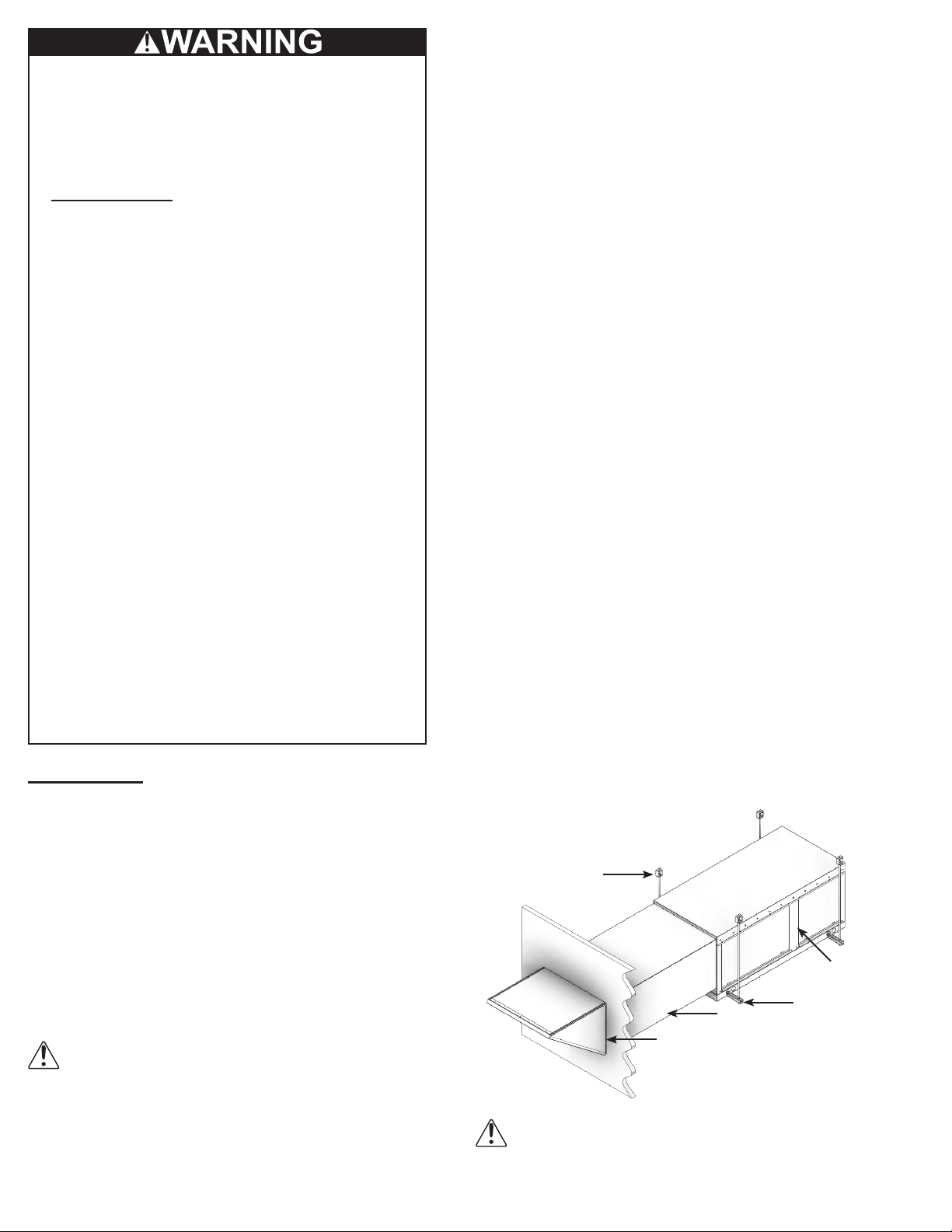

Blower

1. Check the housing, blower, and ductwork for any foreign

objects before running the blower.

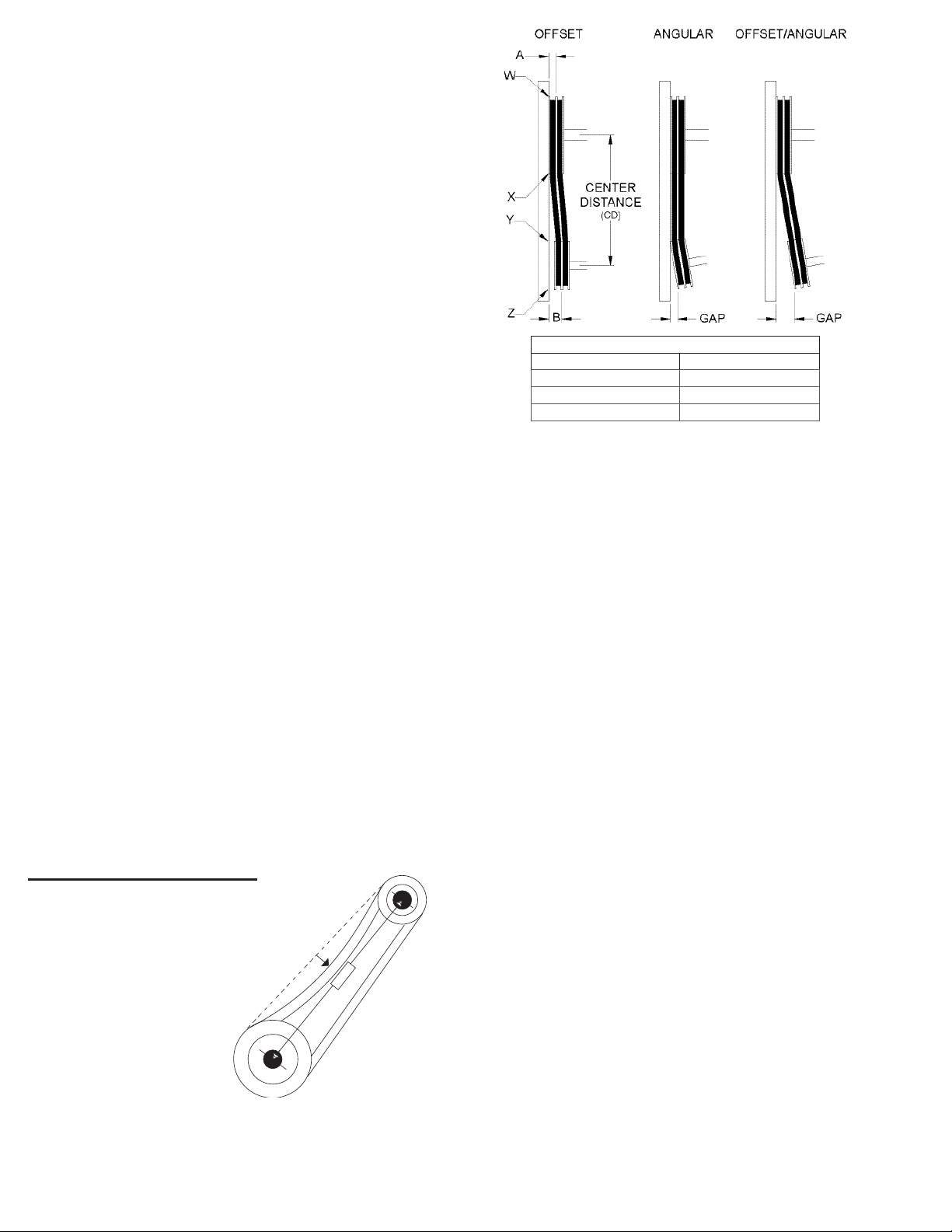

2. Rotate the fan wheel by hand and make sure no parts are

rubbing. Check the V-belt drive for proper alignment and

tension (a guide for proper belt tension and alignment is

provided in the Belt Maintenance section).

3. Check fasteners, set screws and locking collars on the

fan, bearings, drive, motor base, and accessories for tight-

ness.