CONTENT

1. BASIC PARAMETERS.......................................................................................................................................3

2. COOLING CAPACITY CURVE........................................................................................................................4

3. FACTORY LIST.................................................................................................................................................. 4

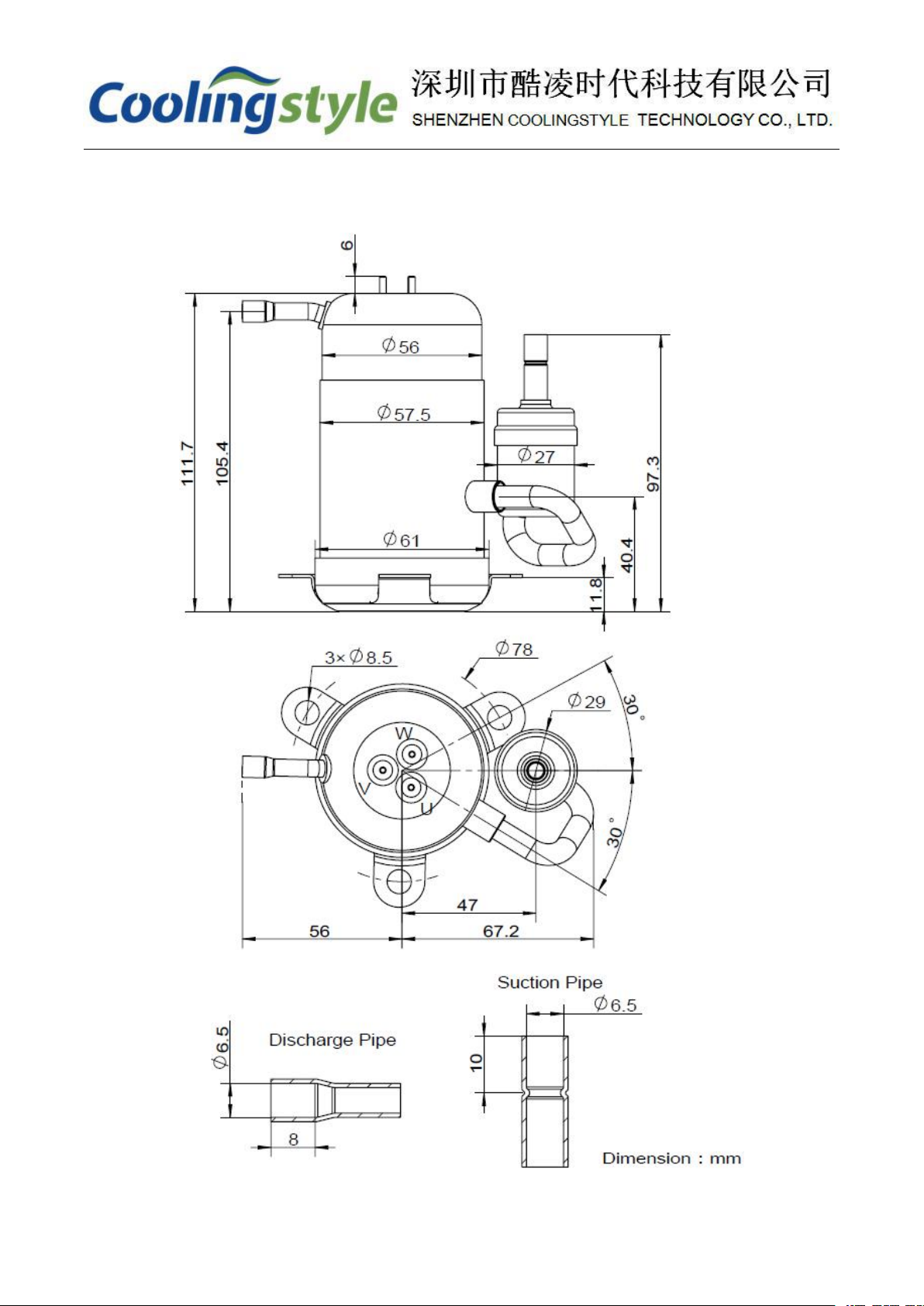

4. SIZE...................................................................................................................................................................... 5

4.1 COMPRESSOR SIZE....................................................................................................................................... 5

4.2 DRIVE BOARD SIZE...................................................................................................................................... 6

4.3 SIZE OF CUSHION.........................................................................................................................................6

4.4 INSTALLATION............................................................................................................................................. 7

5. DRIVER WIRING INSTRUCTIONS................................................................................................................ 8

5.1 POWER INPUT PORT(TB1, TB2)............................................................................................................. 8

5.2 WIRING PORT OF DRIVER AND COMPRESSOR(TB3, TB4, TB5)..............................................................8

5.3 CONDENSING FAN POWER SUPPLY PORT(TB6, TB7)..............................................................................9

5.4 INDICATOR...................................................................................................................................................9

5.5 5V VOLTAGE OUTPUT PORT (TB8).............................................................................................................10

5.6 COMPRESSOR SPEED SIGNAL INPUT PORT (TB9)....................................................................................... 10

5.7 COMPRESSOR ENABLE SIGNAL INPUT PORT (TB10).................................................................................. 10

5.8 GND(TB11).........................................................................................................................................10

5.9 STATUS SIGNAL OUTPUT PORT (TB12)...................................................................................................... 10

5.10 POWER SIGNAL OUTPUT PORT(TB13)...................................................................................................11

5.11 RESERVED EMERGENCY STOP SWITCH SIGNAL (TB14, TB15)................................................................... 11

5.12 RESERVED COMMUNICATION PORTS (TB16, TB17, TB18, TB19).............................................................11

6. TYPICAL WIRING EXAMPLE.......................................................................................................................12

6.1 EXAMPLE 1................................................................................................................................................12

6.2 EXAMPLE 2................................................................................................................................................13

6.3 EXAMPLE 3................................................................................................................................................14

7. NOTICE..............................................................................................................................................................15

8. TROUBLE SHOOTING....................................................................................................................................17