MIL'S 15SP1CB User manual

Specifications are subject to change without notice.

This document may not be forwarded or reproduced without authorisation from MIL’S SAS company.

Failure to respect this requirement may lead to prosecution.

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

520606-00 1

EN

CONTENTS

1GENERAL INFORMATION ............................................................................................................................ 2

2MAIN COMPONENTS .................................................................................................................................. 2

3MAINTENANCE OF THE AIR-END................................................................................................................. 3

3.1 Disassembly of the air-end ...................................................................................................................................................3

3.2 Disassembly of the tip seals ..................................................................................................................................................5

3.3 Supplying grease into the bearings.......................................................................................................................................5

3.4 Replacement of the brush [only for 52SP1CB / 42SP2CB] ....................................................................................................8

3.5 Assembly of the air-end ........................................................................................................................................................9

3.6 Cleaning the suction filter or replacement .........................................................................................................................12

3.7 Re-tightening discharge piping ...........................................................................................................................................12

4OTHERS .....................................................................................................................................................13

MEANING OF SYMBOLS USED IN THIS MANUAL

Symbols are used in this manual to help you understand them and to indicate particular points which you need to act upon or

consider. Those symbols are:

Reading symbol: to refer to the operator manual / instructions manual.

Warning symbol: This symbol means that failure to observe this point could lead to injury and possibly damage to

the machine. It serves as a special reminder about regulations and/or the correct implementation of certain

precautions.

Danger symbol: This symbol represents the DIN 4844 symbol (hazard warning); it warns of a hazard which could

result in death or injury, along with damage to the machine. This symbol must be observed by all personnel working

on this machine. Regulations on safety in the workplace must be observed.

Environmental protection symbol: This symbol serves as a reminder to sort waste during maintenance operations,

to store it in a safe place, and to dispose of it with due care for the environment.

Dustbin on wheels barred of a cross symbol: This symbol indicates that the equipment should not be thrown with

domestic waste and is subject to selective collection.

It is formally forbidden to take off the adhesive labels being on this machine.

The deteriorated adhesives or falling apart will have to be replaced.

General remark:

If they are used as the manufacturer intended, machines bearing marking comply with the requirements of the machines

directive 2006/42 EEC.

To ensure personal safety and to avoid any damage to equipment, it is essential to follow the instructions

contained in this document and any other documentation provided with the device, and particularly the

instructions on “Safe Practice”.

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

2 520606-00

EN

1GENERAL INFORMATION

Make sure to service and maintain a product indoor to prevent dust from damaging the product.

Make sure not to blow bearing directly.

Make sure not to put cloth gloves in servicing and maintaining a product to prevent clothing from entering into bearings.

Don’t hit any part of an scroll head in removing a fixed scroll from the scroll head.

Cleaning inside of auxiliary parts for dust and particle not to flow back to a Scroll head.

Make sure not to replace parts except face seal and tip seals.

Use metric tools when disassembling and/or assembling scroll head.

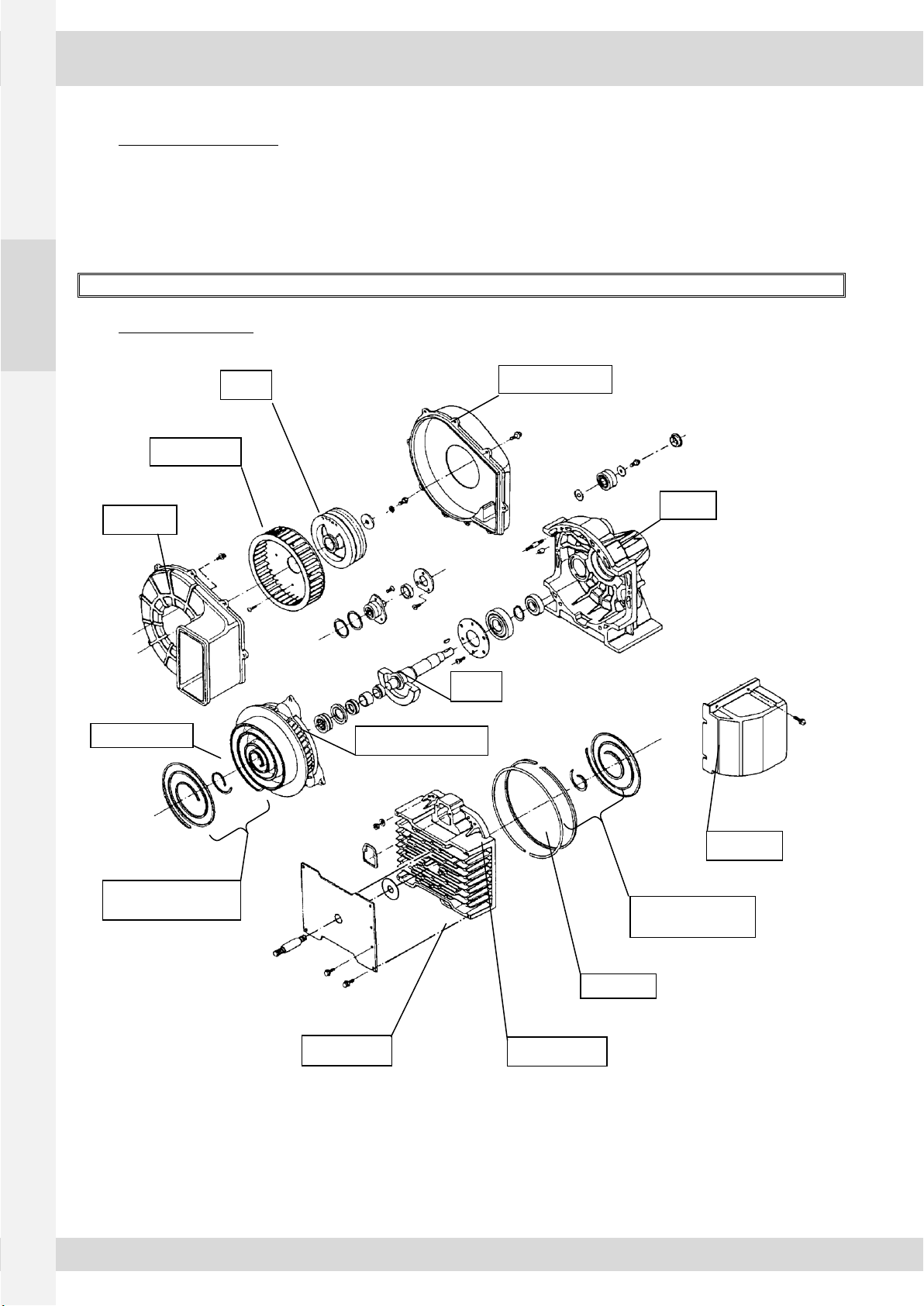

2MAIN COMPONENTS

Shaft

Fan Duct Guard

Pulley

Cooling Fan

Fan Duct

Tip Seal for Orbiting

Scroll

Orbiting Scroll

Casing

Side Duct

Tip Seal for Fixed

Scroll

Face Seal

Fixed Scroll

Main Shaft Bearing

Back-up tube

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

520606-00 3

EN

3MAINTENANCE OF THE AIR-END

3.1 Disassembly of the air-end

1) Remove the side duct

2) Remove the fan duct cover

①15SP1CB / 13SP2CB: Take off 8 screws (6mm).

②35SP1CB / 29SP2CB - 52SP1CB / 42SP2CB: Take off 9 screws (6mm).

3) Clean the cooling fan

①Blow off dust of the cooling fan by air blow.

②Blow off dust of the fixed and orbiting scroll fin.

Clean the cooling fan before disassembling the fixed scroll to prevent dust entering into compression area.

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

4 520606-00

EN

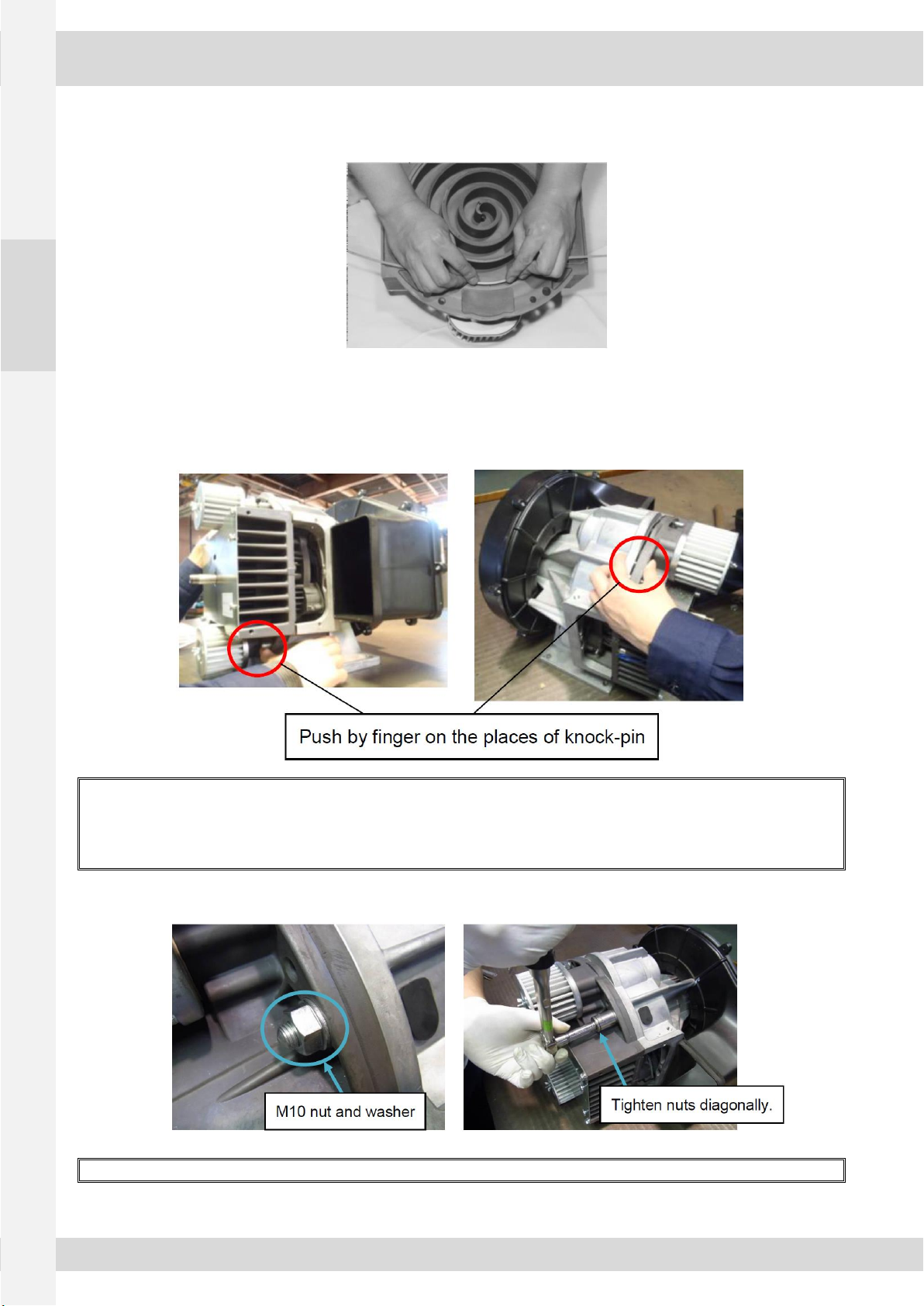

4) Disassembly the fixed scroll

Disassemble the fixed scroll after cooling enough to prevent difference of knock-pins pitch by thermal expansion

Note: It is easy to disassemble to put lubricant to knock-pin in advance

①Loose the 4 of nuts(M10) for 1 revolution.

It should be marked on the nut to count revolution.

②Disassemble the fixed scroll keeping parallel with the fixed scroll and frange surface of casing using plastic hammer.

Knock the fixed scroll gently when using plastic hammer.

③Repeat ①through ③until taking off the fixed scroll from casing.(7 times)

Do not damage scroll wrap during and after removing the fixed scroll.

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

520606-00 5

EN

3.2 Disassembly of the tip seals

Do not damage scroll wrap when disassembling the tip seals and face seal, back-up tube.

3.3 Supplying grease into the bearings

Supply grease into the main shaft bearing and 3 of support bearings.

①Take off the rubber plug.

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

6 520606-00

EN

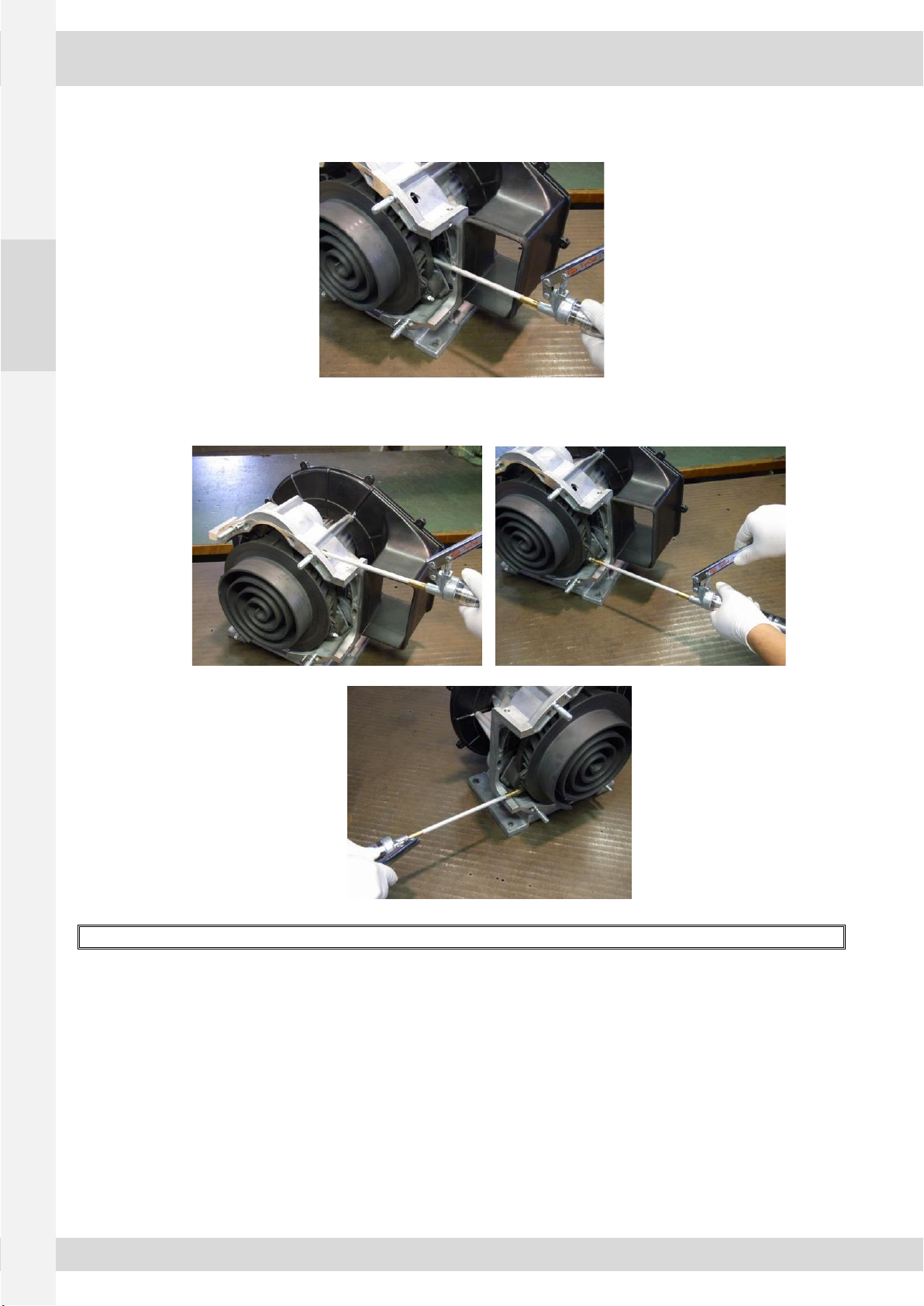

②Supply grease into the main shaft bearing using specified grease gun.

Refer to fig 4/5 for the grease gun and amount of supplying grease.

③Supply grease into the support bearings. (3 places)

Refer to fig 4/5 for the grease gun and amount of supplying grease.

Clean Up the head of grease nipples in case of dirty before supplying grease

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

520606-00 7

EN

Table 1.

Amount of supplying grease

[0.83MPa use for 15SP1CB; 35SP1CB; 0.8MPa use for 52SP1CB]

Item

Amount of supplying grease

0h

2,500h

2,501h

5,000h

5,001h

7,500h

7,501h

10,000h

15SP1CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

9 strokes

(5.0±0.5 g)

13 strokes

(7.3±0.6 g)

15 strokes

(8.4±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

4 strokes

(2.2±0.2 g)

35SP1CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

9 strokes

(5.0±0.5 g)

13 strokes

(7.3±0.6 g)

15 strokes

(8.4±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

4 strokes

(2.2±0.2 g)

52SP1CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

11 strokes

(6.2±0.4 g)

16 strokes

(9.0±0.5 g)

22 strokes

(12.3±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

5 strokes

(2.8±0.2 g)

Table 2.

Amount of supplying grease

[1.0MPa use for all models]

Item

Amount of supplying grease

0h

1,250h

1,251h

2,500h

2,501h

3,750h

3,751h

5,000h

13SP2CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

9 strokes

(5.0±0.5 g)

13 strokes

(7.3±0.6 g)

15 strokes

(8.4±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

4 strokes

(2.2±0.2 g)

29SP2CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

9 strokes

(5.0±0.5 g)

13 strokes

(7.3±0.6 g)

15 strokes

(8.4±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

4 strokes

(2.2±0.2 g)

42SP2CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

11 strokes

(6.2±0.4 g)

16 strokes

(9.0±0.5 g)

22 strokes

(12.3±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

5 strokes

(2.8±0.2 g)

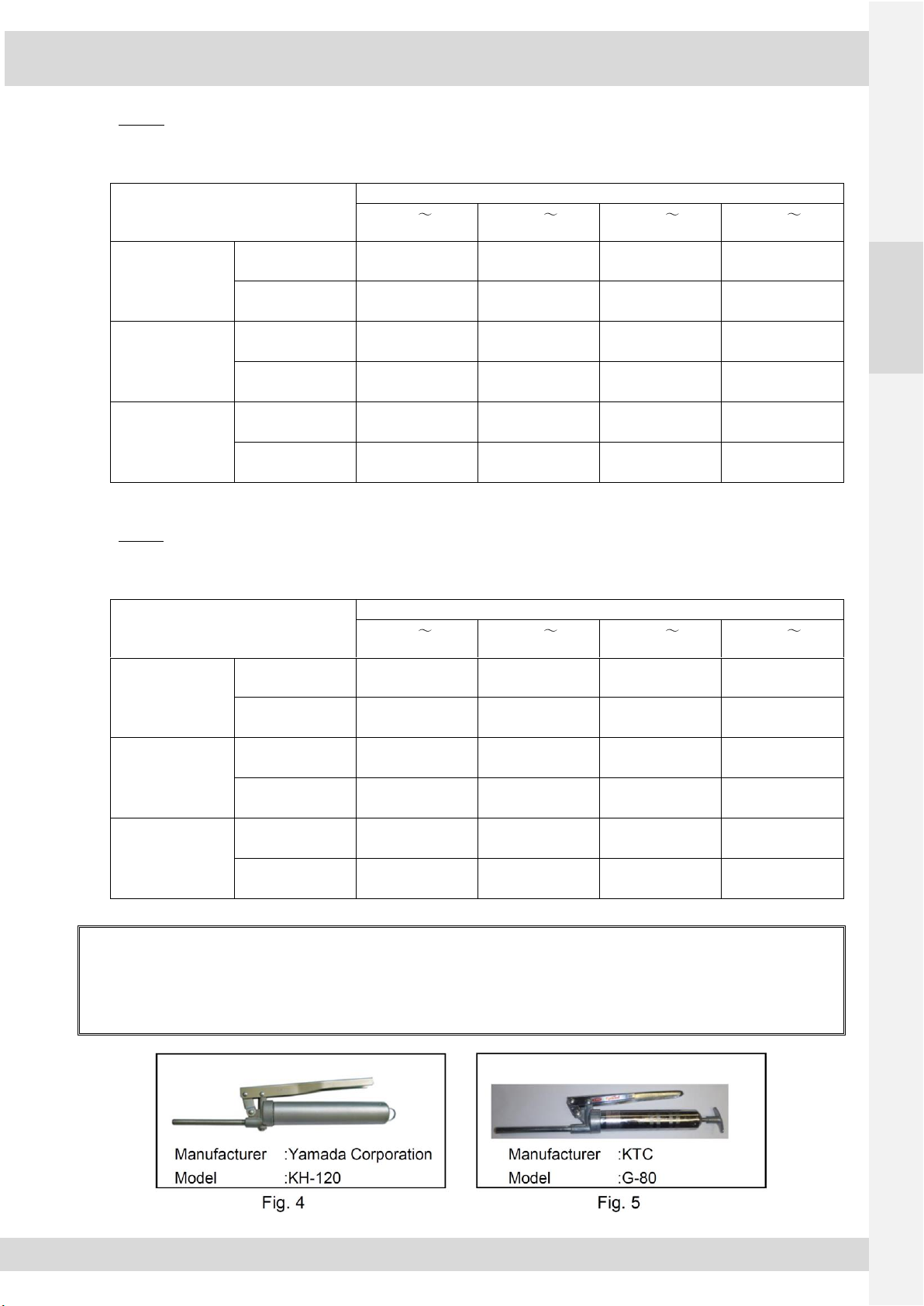

Note:

1) Use grease gun as shown in Fig 4 or 5 when supplying grease into each bearings.

2) Do not supply grease into each bearings beyond specified number show in above table, otherwise the bearings are damaged.

3) The amount of supplying grease should be determined based on operating time mentioned below.

1st time: Operating time from start operation

2nd time: Operating time from the last time maintenance

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

8 520606-00

EN

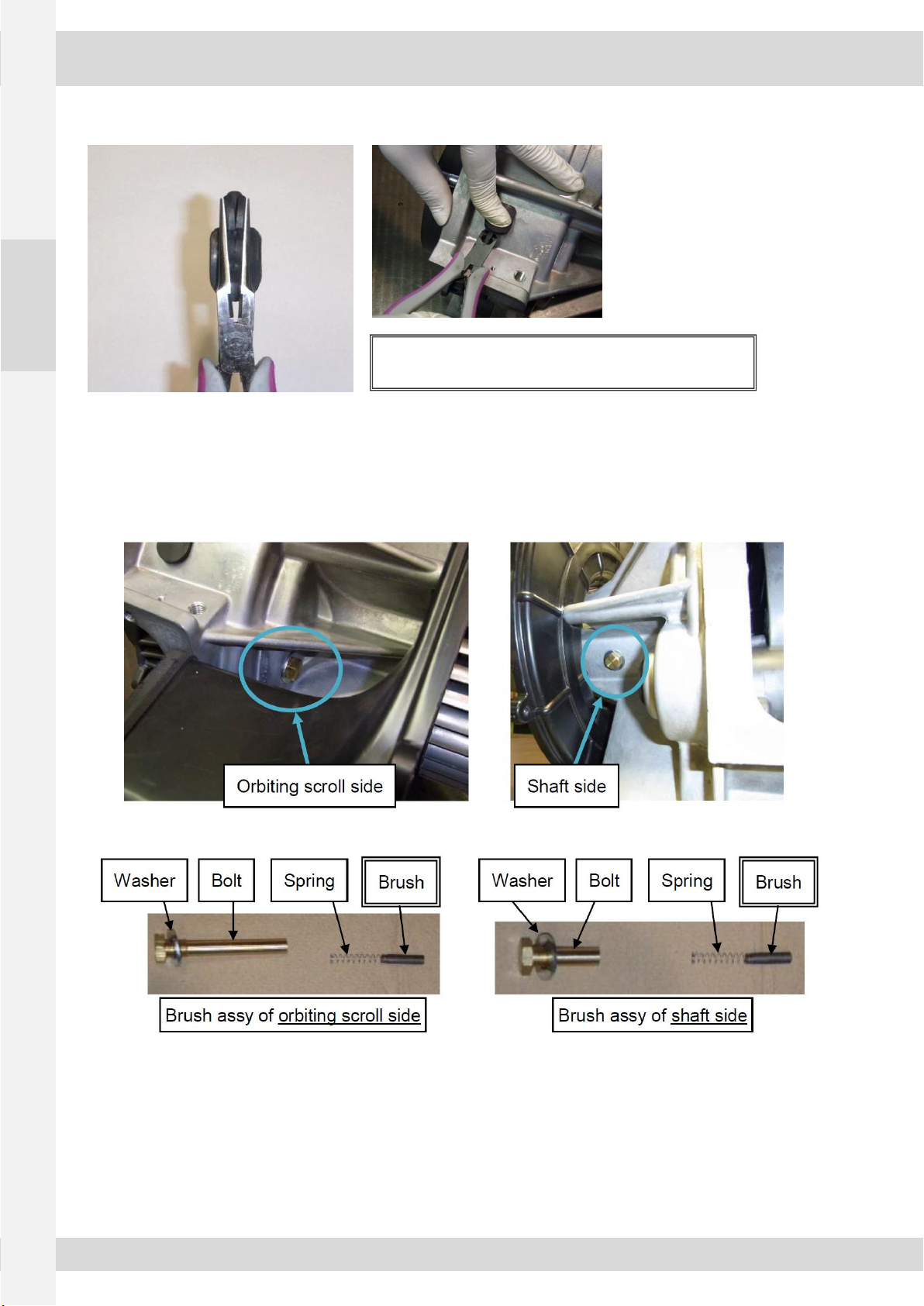

④Assemble the rubber plug using a plier.

3.4 Replacement of the brush [only for 52SP1CB / 42SP2CB]

①Remove brushes each of orbiting scroll side and shaft side.

②After that, replace brushes and re-assemble.

③Do not lose a washer.

④Tighten torque of the bolt: 15 N-m

Pull out the plier pressing the rubber plug by finger.

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

520606-00 9

EN

3.5 Assembly of the air-end

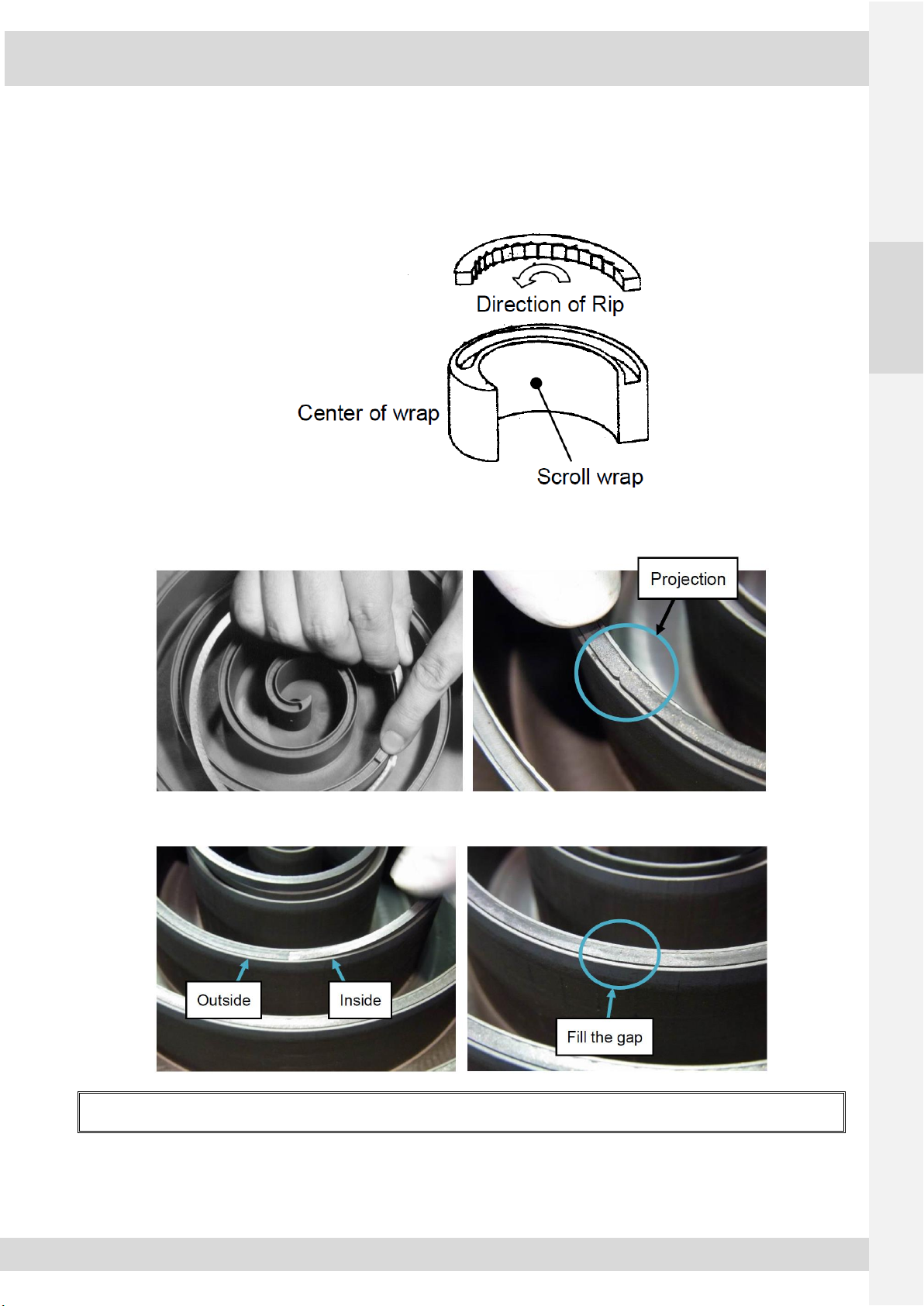

1) Install the tip seals and face seal

①Make sure to install tip seals in the right direction, because the orbiting scroll tip seals and the fixed scroll tip seals are

different.

②First, install outside tip seal.

Push the inner end of the outside tip seal to the outer end of the inside tip seal and then install the tip seal into the

groove.

Make sure that a stopper of the outside tip seal fits in a projection of the groove.

③Second, install inside tip seal filling the gap of outside and inside tip seals.

Do not push out the tip seals to bottom of groove.

Install tip seals to the groove by protruding 1mm from edge of groove

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

10 520606-00

EN

④Install back-up tube and face seal

Move the seam of each seal 180 degrees.

2) Assembly of the fixed scroll

①Assemble the fixed scroll on the basis of 2 places knock-pin.

Note for the direction of the fixed scroll.

②The gap of the fixed scroll and frange surface of casing should be below 2 mm.

If the gap between the fixed scroll and the casing is more than 2mm or is not parallel, there is a possibility that the tip seals or

face seal are not installed in the groove properly.

In this case, never tighten nuts and disassemble the fixed scroll and repeat the same

process to install the tip seals or seal properly.

③Tighten 4 of M10 nuts including washers.

First tighten nuts by hand and then tighten them at the equal torque of 30 N-m using a torque wrench.

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

520606-00 11

EN

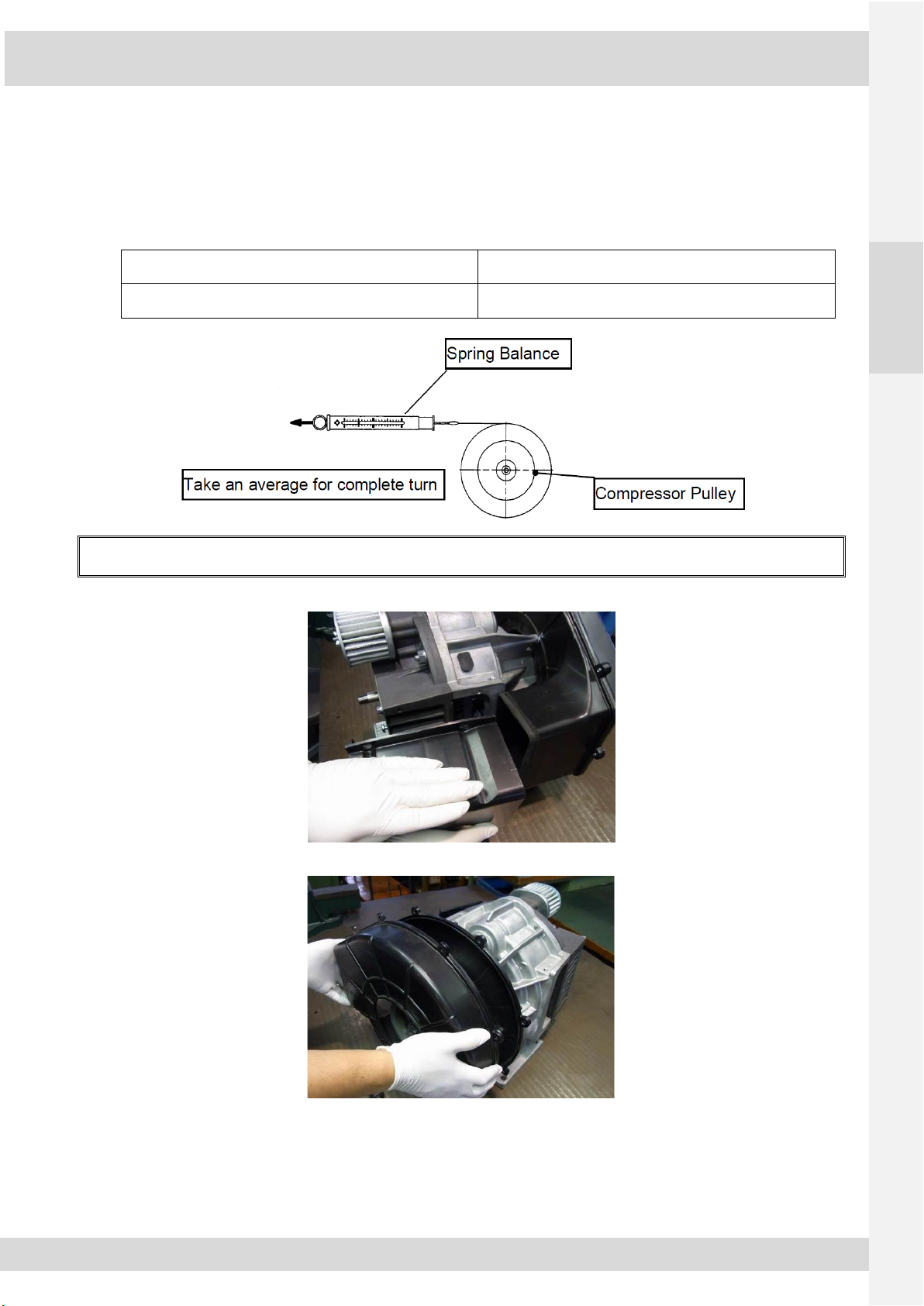

④After assembling the fixed scroll to the casing, turn the shaft by hand to confirm the smooth rotation of the shaft.

⑤Measure the torque of the shaft

After installing the fixed scroll, measure torque of the shaft.

Coil a piece of string around the pulley and then connect a spring balance to the another end of the string and then turn the

pulley more than one complete turn by pulling the spring balance. Take a measurement of the spring balance, and calculate

the average.

Model

Torque of the Shaft [Unit:1Kg]

15SP1CB/ 13SP2CB - 35SP1CB/ 29SP2CB

52SP1CB / 42SP2CB

Less than 2.2 Kg

If the rotation is hard at fixed angle during measuring the torque or rotation by hand, there is a possibility of misalignment.

In this case, the air-end must be replaced.

3) Assemble the side duct

4) Assemble the fan duct cover

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

12 520606-00

EN

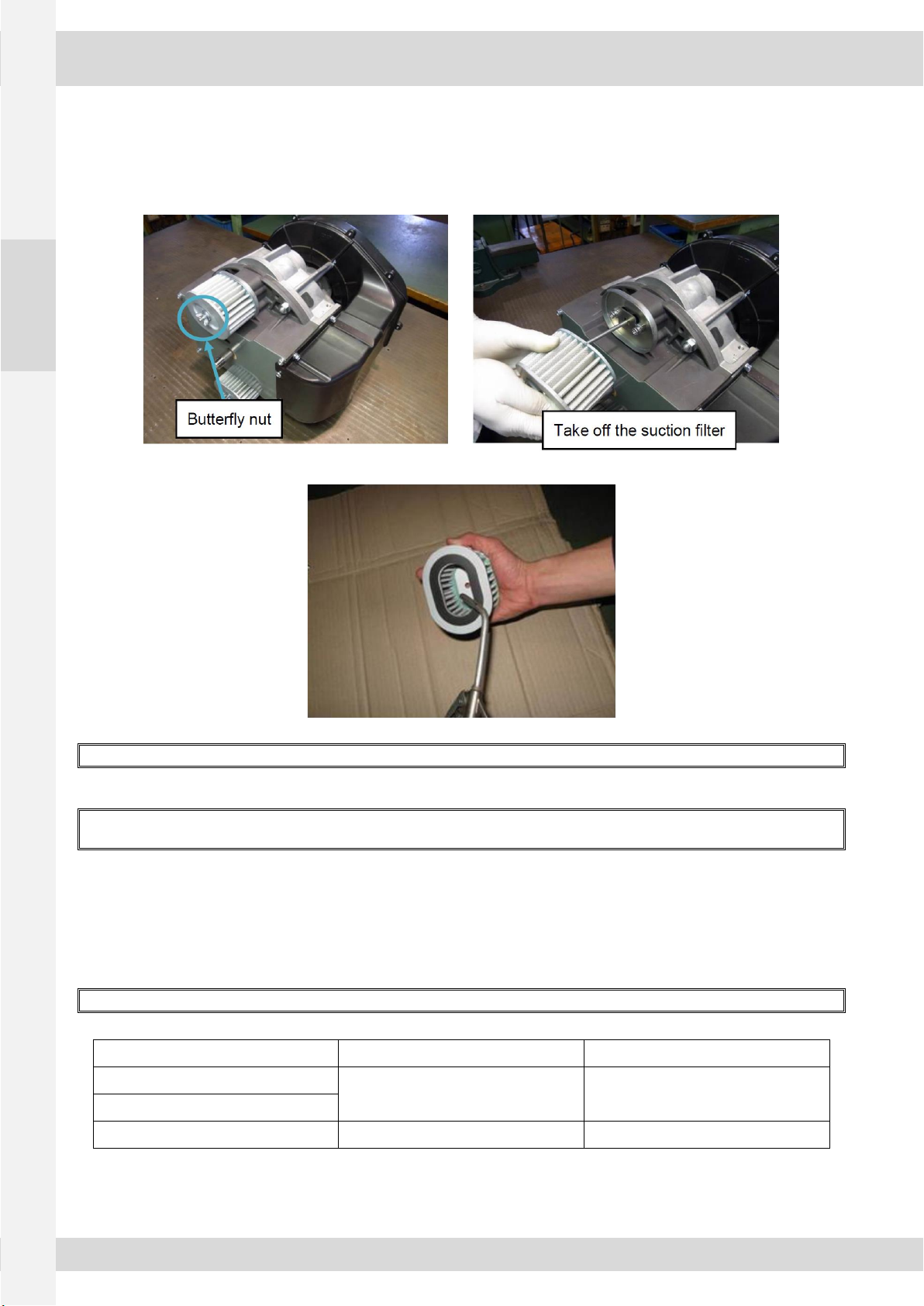

3.6 Cleaning the suction filter or replacement

1) Remove the suction filter

①Remove the butterfly nut, then remove the suction filter

2) Air blow from inside of suction filter

In case that the filter is very and/or damaged, replace to the new one.

3.7 Re-tightening discharge piping

Refer to the following procedure to re-tighten discharge piping after maintenance of air-end in case when removed the

discharge piping tentatively from the air-end during maintenance

Tighten the discharge pipe in the correct procedure as shown below.

1) Finger-tighten the discharge pipe till you cannot

At this stage, do not use the wrench.

2) Put a reference line on the discharge pipe to count turns.

3) Tighten the discharge pipe additional turns shown in table below using wrench.

Over tightening of discharge pipe will cause damage to screw thread of pipe and air-end.

Model

Nominal pipe diameter

Additional turns

15SP1CB / 13SP2CB

3/8B (10A)

4 to 4.5

35SP1CB / 29SP2CB

52SP1CB / 42SP2CB

1/2B (15A)

3 to 3.5

SCROLL 15SP1CB / 13SP2CB –35SP1CB / 29SP2CB –52SP1CB / 42SP2CB

520606-00 13

EN

4OTHERS

Inspection of the air-end

(1) Rotation of bearings

If the main shaft does not rotate smoothly, replace the air-end.

(2) Condition of scroll wrap is contacted each other and scratched, replace the scroll air-end.

www.mils.fr

This manual suits for next models

5

Table of contents

Other MIL'S Air Compressor manuals

Popular Air Compressor manuals by other brands

AirMan

AirMan PDS400S-6C3 Service manual

Mi-T-M

Mi-T-M ACD Series Operator's manual

Jefferson

Jefferson TANDEM JEFC270T10B-230 user manual

Doosan

Doosan 7/72 Operation and maintenance manual

Craftsman

Craftsman 919.16778 Operator's manual

Industrial Air Contractor

Industrial Air Contractor C042I Operator's & parts manual

Craftsman

Craftsman 919.725502 owner's manual

EINHELL

EINHELL EURO8/24 operating instructions

Kobalt

Kobalt 215914 manual

Bauer Compressors

Bauer Compressors Junior II WT Instruction manual and replacement parts list

Grizzly

Grizzly T32336 owner's manual

Schneider Airsystems

Schneider Airsystems CPM 210-8-10 WXOF Original operating manual