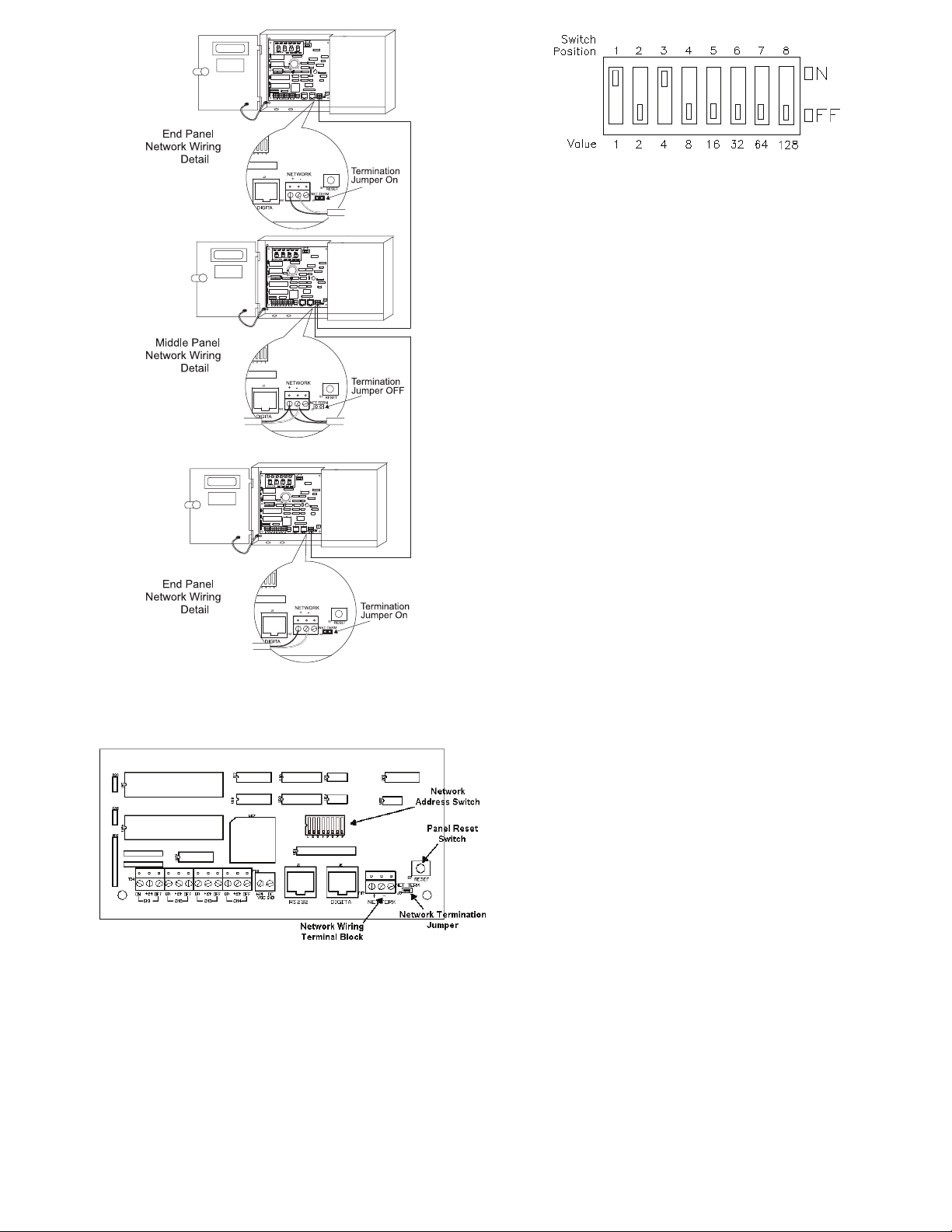

Figure-8 GDS-I Wiring Detail

Applying Power

1. After wiring is complete, make certain to clean panel of all

wire clippings and fragments ensuring that no fragments

get lodged between the circuit board and enclosure.

2. Ensure that there are no loose wires or exposed wires that

could short out.

3. Make certain that the line-voltage section of the enclosure

is closed and secure.

4. Power up the unit. It is recommended that the unit be

cleared of all programming unless the unit has been sent

pre-programmed to you by the factory. To perform this step,

hold down the reset button for about 15 seconds.

5. Please refer to the operation section of this instruction for

information on turning on and off lighting loads. Refer to

the Keeper Enterprise Software manual for information

regarding the programming of the ControlKeeper-4.jumper.

Relay Override Operation

The ControlKeeper-4 has two means of override located on the

logic board: individual relay override buttons and a hardware

override switch. It is possible to control lighting loads and

override programming using these override mechanisms.

Figure-10 ControlKeeper-4 Status LEDs

Individual Relay Override Notes

Each relay on the ControlKeeper-4 may be overridden using

the individual relay override switches located at the top left

of the low voltage section. See Figure 9 for location of these

switches. These override switches will toggle the associated

relay’s state with each push of the button. This type of over

ride is temporary in that the override will last until the next

command that the relay is given.

Hardware Override Switch Notes

In addition to the individual relay override switches, there is a

hardware override switch that allows the override of all relays

on the board. If this switch is moved to the ALL ON or ALL OFF

position, all four relays will remain ON or OFF as long as the

switch is in that ALL ON or ALL OFF position. The ON or OFF

state is maintained regardless of programmed state. In order

for relays to run programmed scheduling the hardware override

switch must be in the AUTO or center position. See Figure 9

for location of the hardware override switch.

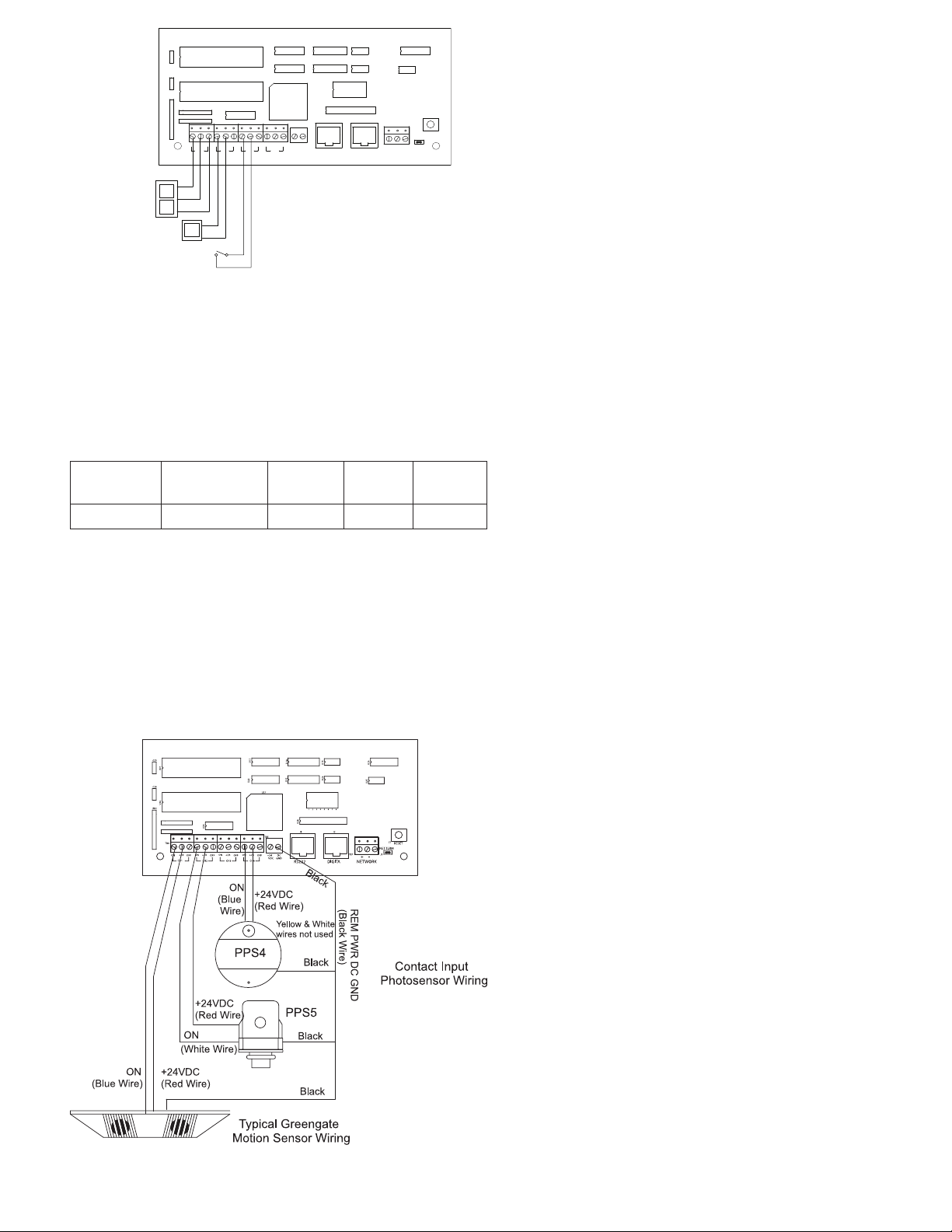

LED Operation

The ControlKeeper-4 has LEDs for status monitoring. They

consist of System Status LEDs and Relay Status LEDs.

Figure-10 ControlKeeper-4 Status LEDs

System Status LEDs

There are six (6) system status LEDs that are located in the

upper left corner of the ControlKeeper-4. Please refer to Fig-

ure 10 for location of these status LEDs. These status LEDs

will indicate proper operation or potential problems with the

ControlKeeper-4. Normal Operation includes the following

LED states.

Status LED: The Status LED will ash ON and OFF con-

tinuously under normal operation. The LED is an indication of

microprocessor health. If the LED is ON or OFF all the time,

please use the soft reset button on the controller. If the LED

does not resume normal ashing state, contact Technical

Support.

Digital Switch LEDs: These LEDs, labeled CAN-TX and

CAN-RX, will ash when Digital Switch information is being

passed back and forth between the Digit Switch Gateway and

the ControlKeeper-4.

Power LEDs: These LEDs, labeled POWER and ISO POWER,

indicate that the ControlKeeper-4 is getting the proper expected

voltage from the transformer. If one or both of these LEDs is not

lit, there is a problem with power to the board. Please contact

Technical Support for further details.

Network LED: The Network LED should ash only when ac-

tivity is present on the network wire. If communications com-

mands are not being transmitted over the network wire from

the Keeper Enterprise Software or broadcast switches and this

LED is ickering, ON constant, or ashing, it is an indication

of noise on the network wire that may interfere with proper

system operation. Please check all network wiring carefully for

shorts to AC Ground if this condition exists. Contact Technical

Support for further troubleshooting help.

-+

NETWORKRS232

VDC

DC

GND

+24

CH4

OFF

ON +24

CH3

OFF

ON +24

CH2

OFF

ON +24

CH1

OFFON +24

RESET

NET TERM

U28

U25

U26

U22

U24 U19

U20

U29

TB7

41235687

J2J1

U18

U27

U23

U21

TB5

TB4

S7

RN1

J3

C26

C20

U17

GDS-I

Page 5